Method and tool for installing large electric vertical-type rectangular cabinet products

A rectangular, vertical technology, applied in the direction of electrical components, electrical components, substation/power distribution equipment shells, etc., can solve the problem of no tooling guarantee, etc., and achieve the effect of improving the image of the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

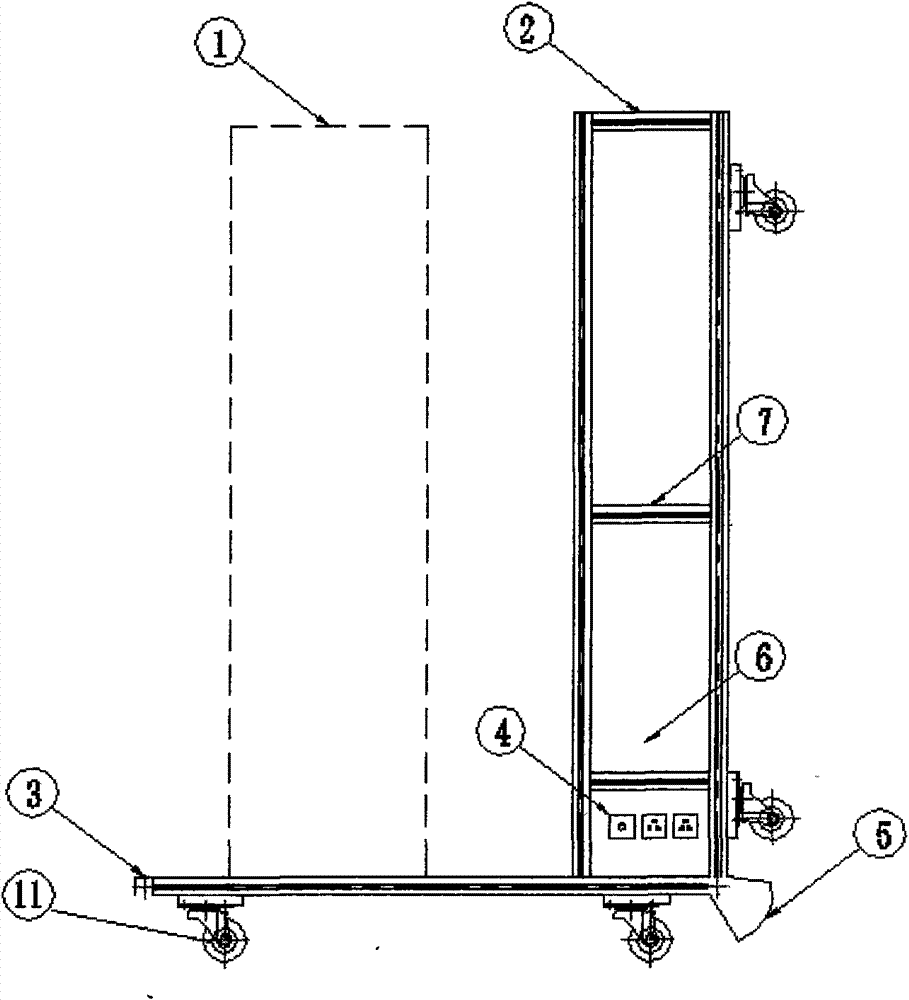

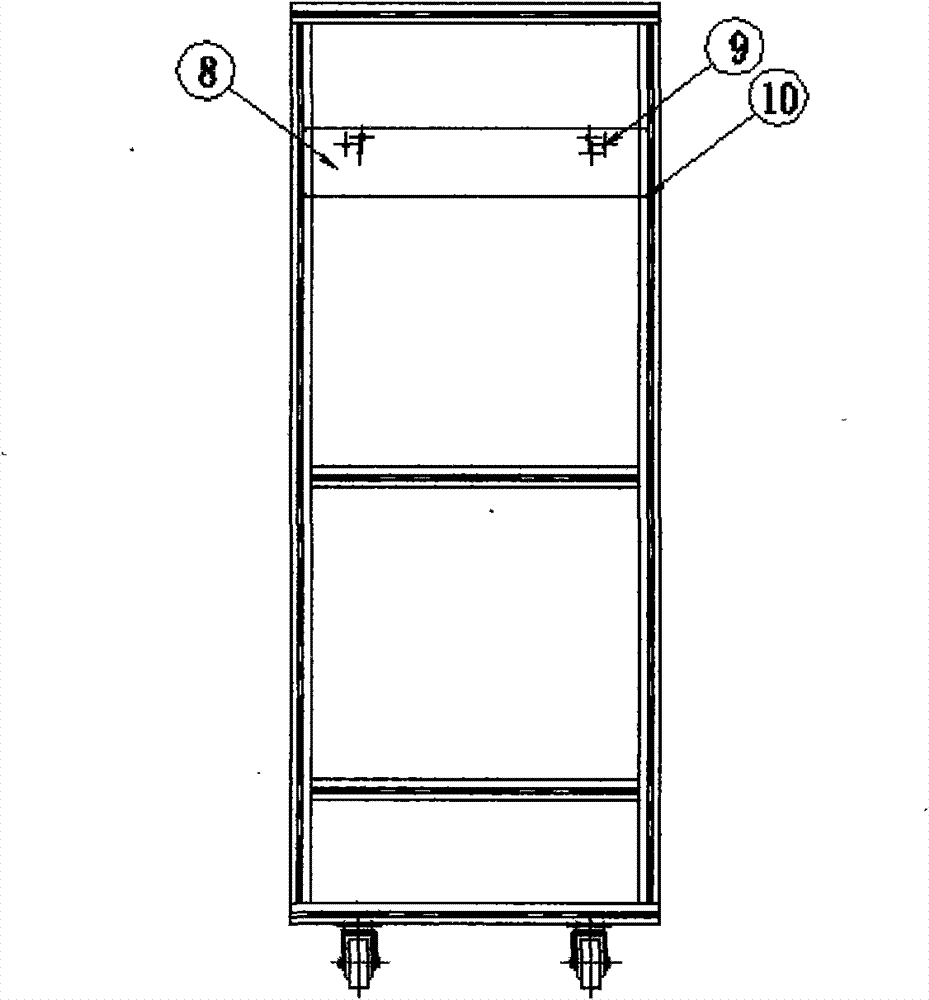

[0027] attached figure 1 Provided is a large-scale electric vertical rectangular cabinet product operation tooling, it can be seen from the accompanying drawings that the large-scale electric vertical rectangular cabinet product operation tooling of the present invention is a tool that can be turned over by 90°, and the described The tooling that can be turned over by 90° is two working platforms that are 90° to each other, and a right-angled combined tooling is formed by combination, one of which is a horizontal working platform 3, and the other is a vertical working platform 2, and the horizontal working platform 3 and The vertical work platforms 2 are cross-connected at 90° through the end of one end; a transitional labor-saving device 5 for turning over the platform is provided at the joint between the horizontal work platform 3 and the vertical work platform 2, when working on a platform After completion, the tooling that can be turned over by 90° can be turned over by 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com