Environment-friendly oil drainage tool for oil pipe

An environmentally friendly and oil-draining technology, applied in drilling pipes, casings, cleaning appliances, etc., can solve problems such as increasing the cost of crude oil production, difficulty in wellhead operations, affecting construction progress, and inability to discharge oil, and improving wellhead operating conditions. , The effect of reducing operating costs and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

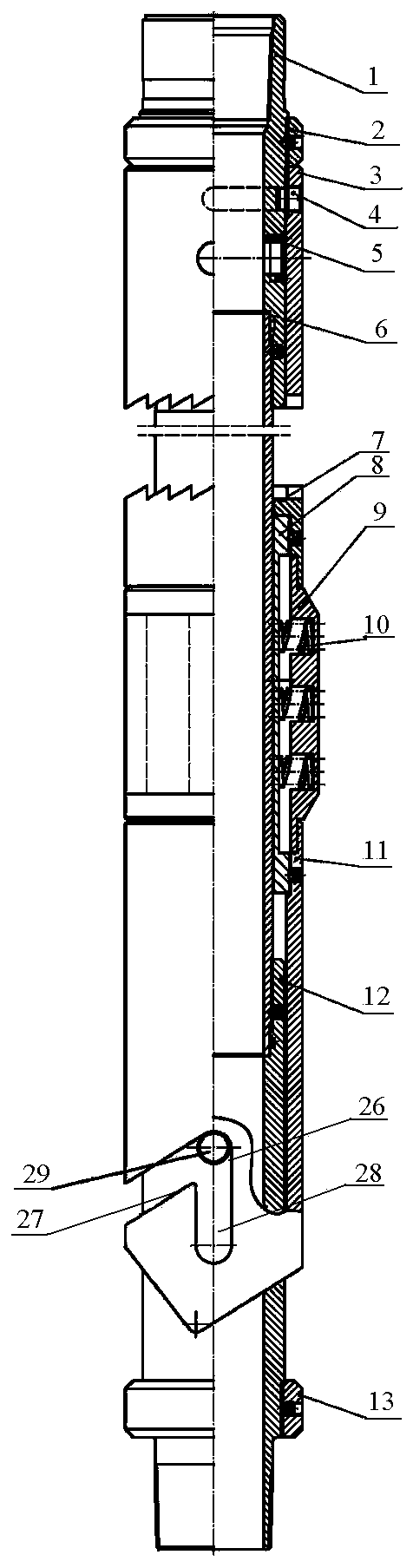

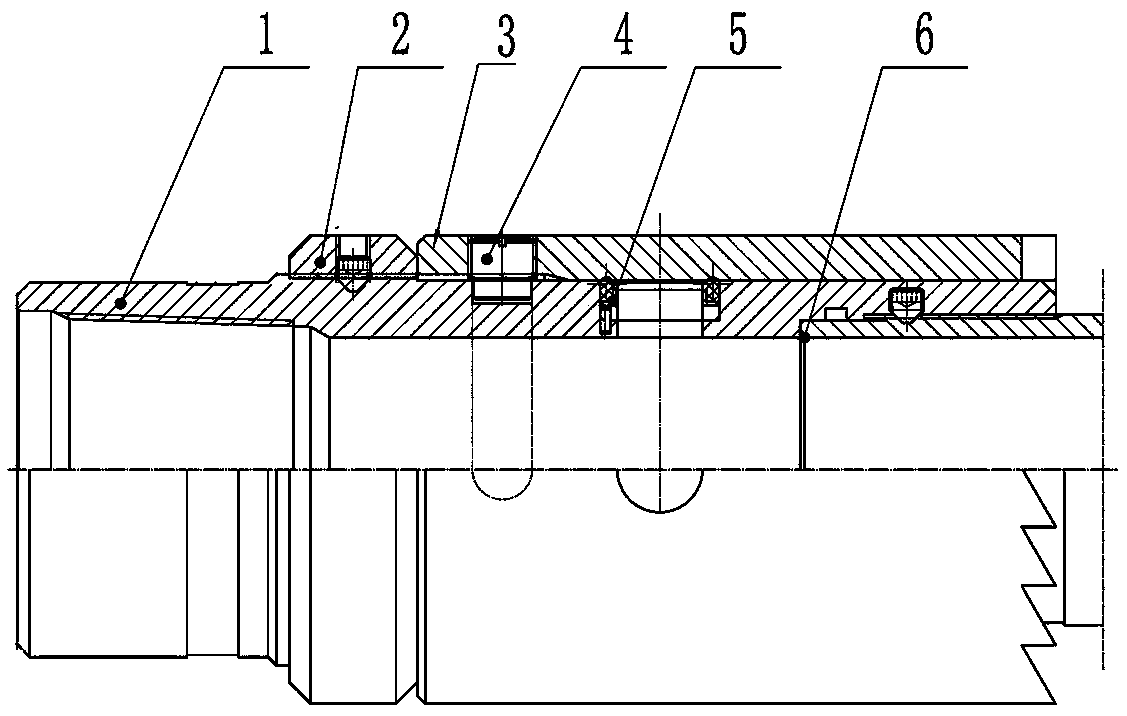

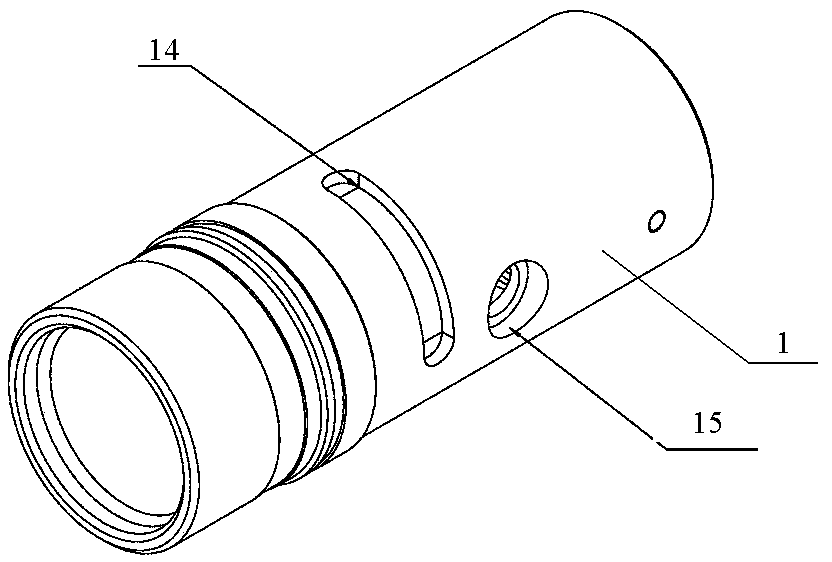

[0018] see Figure 1-Figure 7 The specific structure of this embodiment is: an oil pipe drain device, including a central pipe 6, the upper end of the central pipe 6 is threadedly connected to the upper joint 1, the lower end of the central pipe 6 is threadedly connected to the lower joint 12, the upper joint 1 There is a circumferential strip hole groove 14 and an oil drain hole I15. The oil drain hole I15 is provided with a sealing ring 5; the upper joint 1 is threaded with a protective ring 2, and the upper joint 1 is sleeved with a seal The sealing sleeve 3 is located behind the protective ring 2, the sealing sleeve 3 is provided with a toothed rear end 16, the sealing sleeve 3 is provided with a pin hole 17 and an oil drain hole Ⅱ 18, and the pin hole 17 is A positioning pin 4 is provided, and the positioning pin 4 is threaded into the sealing sleeve 3, and the cylindrical shaft part of the lower part of the positioning pin 4 enters the strip hole 14 of the upper joint 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com