Preparation method for acetoxime

A technology of acetone oxime and ketoxime, which is applied in the field of preparation of acetone oxime, can solve the problems of low selectivity and increased cost, and achieve the effects of high reaction conversion rate, reduced pollution, and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

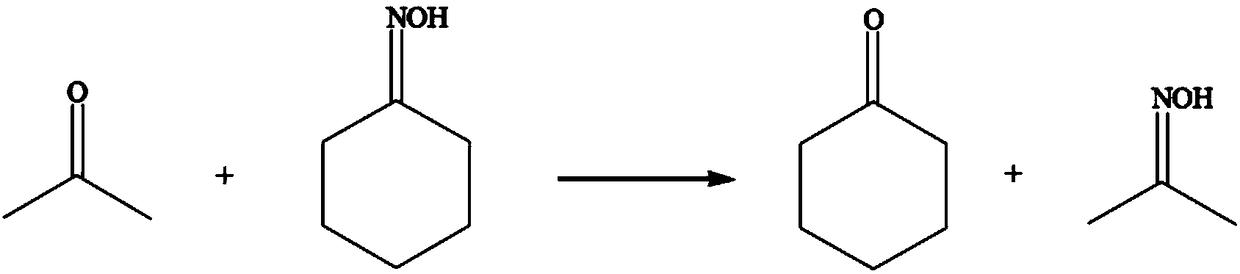

Method used

Image

Examples

Embodiment 1

[0021] a, the synthetic reaction of acetone oxime

[0022] Add cyclohexanone oxime (Sinopharm Chemical Reagent Co., Ltd.), acetone (Sinopharm Chemical Reagent Co., Ltd.) and hydrochloric acid into the reactor according to the molar ratio of 1.0:30.0:0.3, and add water so that the pH value of the solution is 1, and the above The reaction system was heated, the reaction temperature was 30° C., the reaction time was 9 hours, and the pressure of the reaction system was normal pressure.

[0023] b, the purification of acetone oxime

[0024] After the above reaction is finished, the product obtained by rectification and purification is acetone oxime. The detection and analysis results show that the conversion rate of cyclohexanone oxime is 97.1%, and the selectivity of acetone oxime is 99.3%.

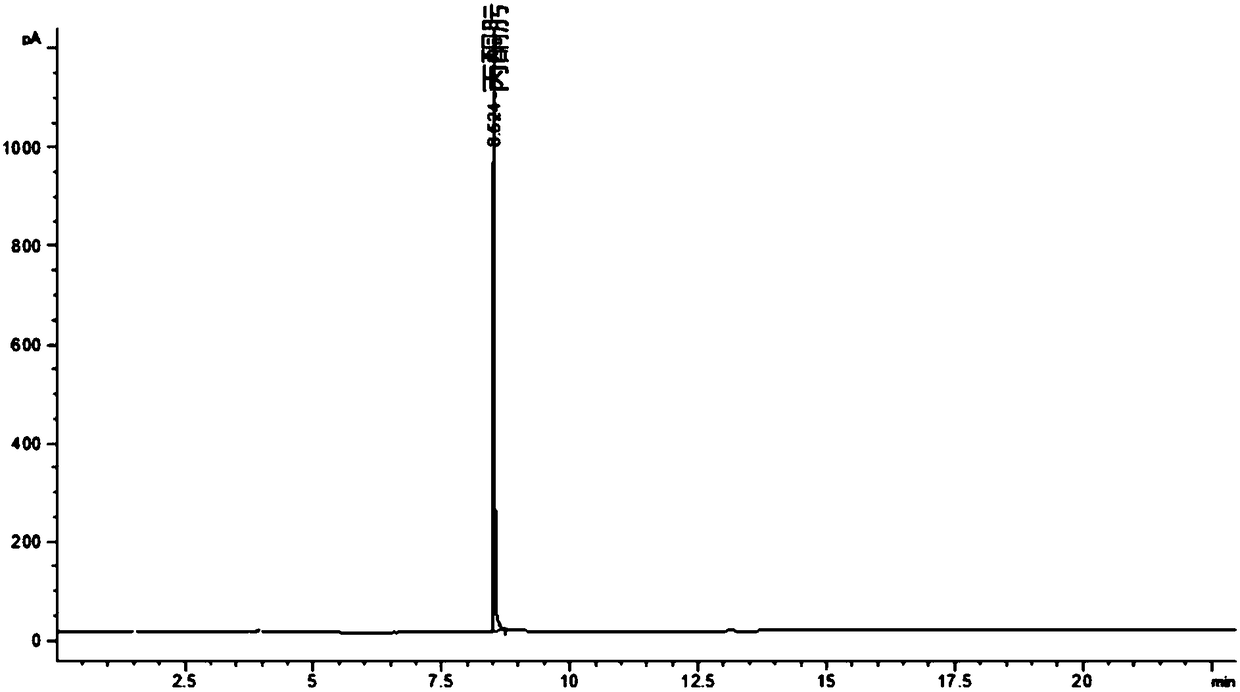

[0025] The gas chromatogram of the product is as follows figure 1 Shown: the product obtained is acetone oxime through gas chromatographic comparison with the standard product.

Embodiment 2

[0027] a, the synthetic reaction of acetone oxime

[0028] Add cyclohexanone oxime (Sinopharm Chemical Reagent Co., Ltd.), acetone (Sinopharm Chemical Reagent Co., Ltd.) and sulfuric acid into the reactor according to the molar ratio of 1.0:35:0.3, and add water so that the pH value of the solution is 2, and the above The reaction system is heated, the reaction temperature is 80° C., the reaction time is 5 hours, and the pressure of the reaction system is normal pressure.

[0029] b, the purification of acetone oxime

[0030] After the above reaction is finished, the product obtained by rectification and purification is acetone oxime. The detection and analysis results show that the conversion rate of cyclohexanone oxime is 98.2%, and the selectivity of acetone oxime is 99.2%. It was confirmed by gas chromatography that the product was acetone oxime.

Embodiment 3

[0032] a, the synthetic reaction of acetone oxime

[0033] Add cyclohexanone oxime (Sinopharm Chemical Reagent Co., Ltd.), acetone (Sinopharm Chemical Reagent Co., Ltd.) and nitric acid into the reactor according to a molar ratio of 1.0:10:0.6, and add water so that the pH value of the solution is 1, and the above The reaction system is heated, the reaction temperature is 70° C., the reaction time is 8 hours, and the pressure of the reaction system is normal pressure.

[0034] b, the purification of acetone oxime

[0035] After the above reaction is finished, the product obtained by rectification and purification is acetone oxime. The detection and analysis results show that the conversion rate of cyclohexanone oxime is 91.6%, and the selectivity of acetone oxime is 99.3%. It was confirmed by gas chromatography that the product was acetone oxime.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com