Patents

Literature

63results about How to "Easy to quantitative control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium anode surface treatment method of lithium metal battery

ActiveCN107093705AEasy to operateEase of production and quantitative controlImpregnation manufacturingLithium dendriteOrganic solvent

The invention discloses a lithium anode surface treatment method of a lithium metal battery and belongs to the technical field of lithium batteries. According to the method, a chemical method is adopted, and the method comprises the steps that 1, salts or esters as additives are dissolved into an organic solvent, and an electrolyte solution is prepared; 2, the electrolyte solution is reacted with a metal lithium sheet, so that a solid electrolyte protection layer is formed on the surface of the lithium sheet. The operation method is simple and convenient for large-scaled production and quantitative control; the solid electrolyte layer formed on the metal lithium surface in place can effectively inhibit generation of lithium dendrites, the loss of a lithium source is reduced, so that the coulombic efficiency of the whole battery is improved obviously under the condition without the additives, the stability and the high efficiency of a metal lithium anode are achieved in the long battery life process, and obvious effects on inhibiting the metal lithium dendrites and improving and keeping the high coulombic efficiency of the whole battery are achieved.

Owner:TSINGHUA UNIV

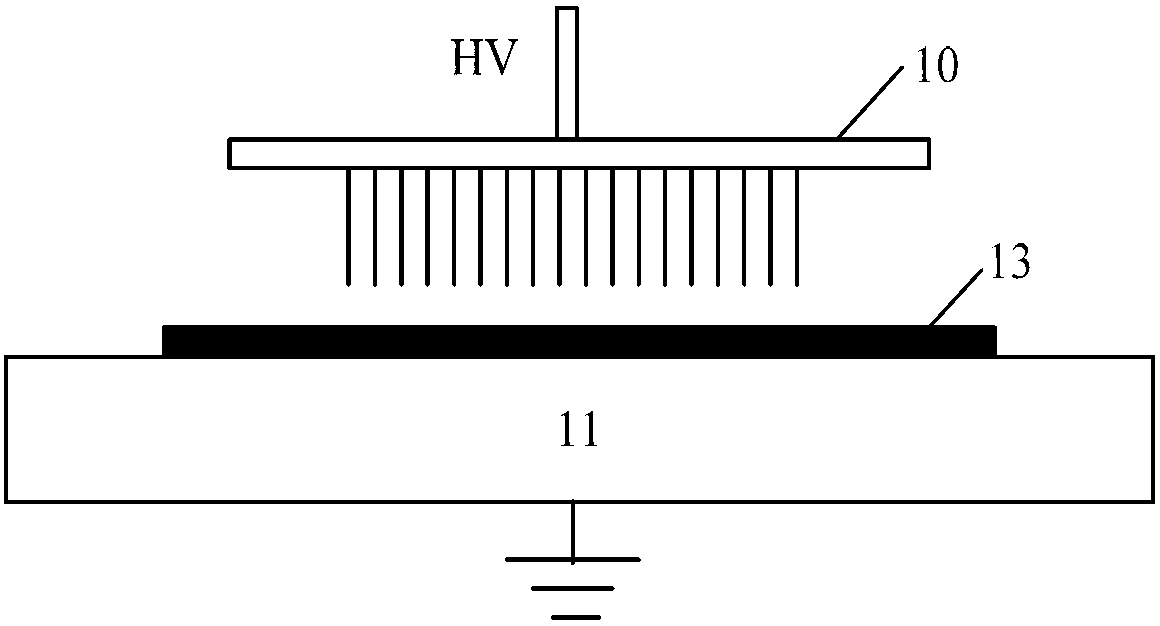

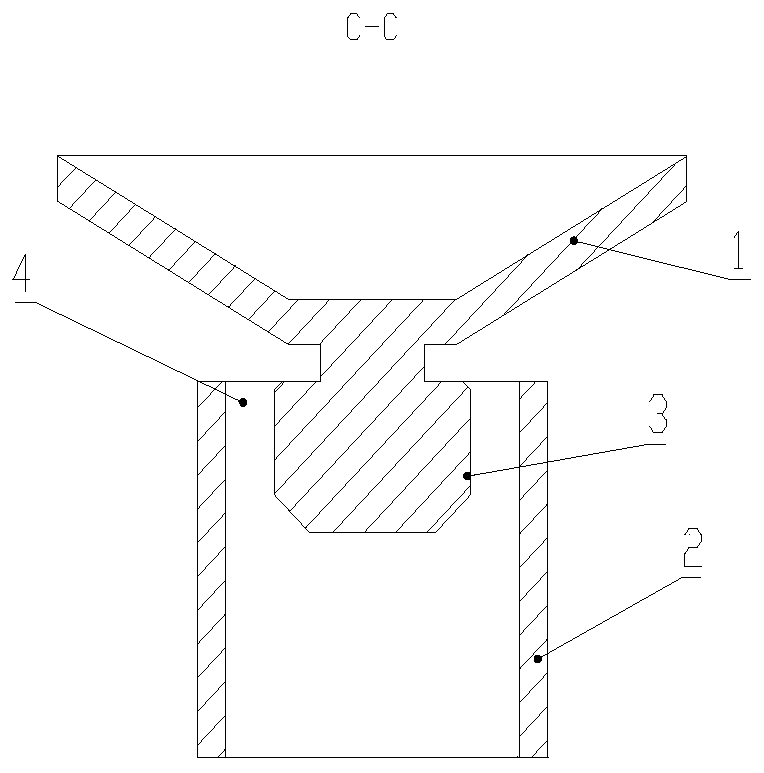

Corona aging acceleration device and method for polymer insulating material

InactiveCN103278752ALow requirements for experimental conditionsEasy to operateTesting dielectric strengthPolymer insulationCorona discharge

The invention discloses a corona aging acceleration device and a corona aging acceleration method for a polymer insulating material. The device comprises a sealed corona aging experimental case in which a pin array electrode and a metal plate electrode are arranged, wherein the pin array electrode is connected with a high voltage generation device; the metal plate electrode is grounded; a pinpoint array is arranged on the pin array electrode; a test sample is arranged on the metal plate electrode, and is opposite to the pinpoint array; and after voltage is applied, uniform corona discharge is generated between the pin array electrode and the metal plate electrode to perform corona aging on the test sample. The device and the method have the advantages of low requirements on experimental conditions, convenience for operation and quantitative control over aging factors in an experiment, and short experimental period, and are applied to researches on the corona aging resistance of insulating materials in a laboratory.

Owner:XI AN JIAOTONG UNIV +1

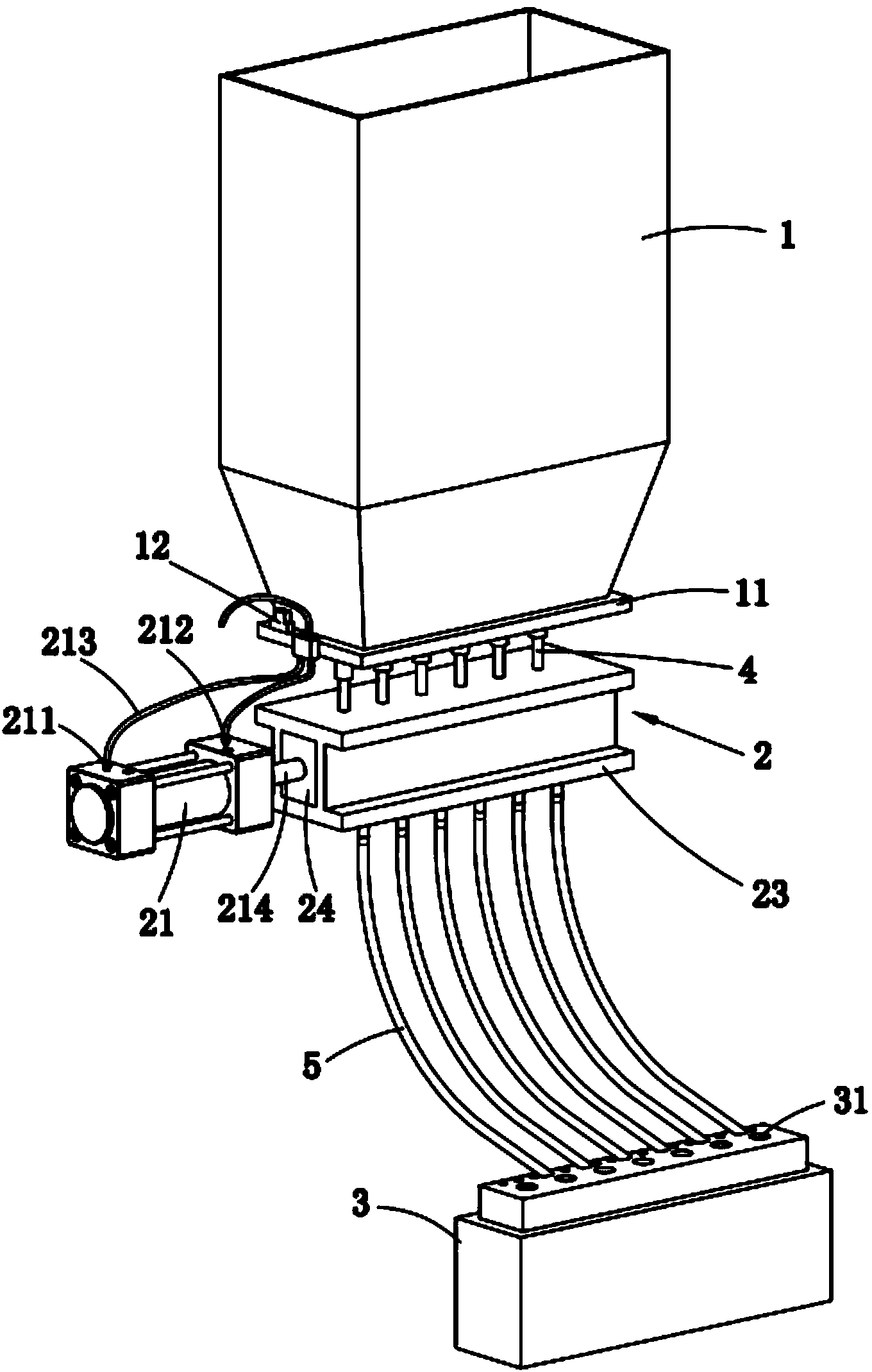

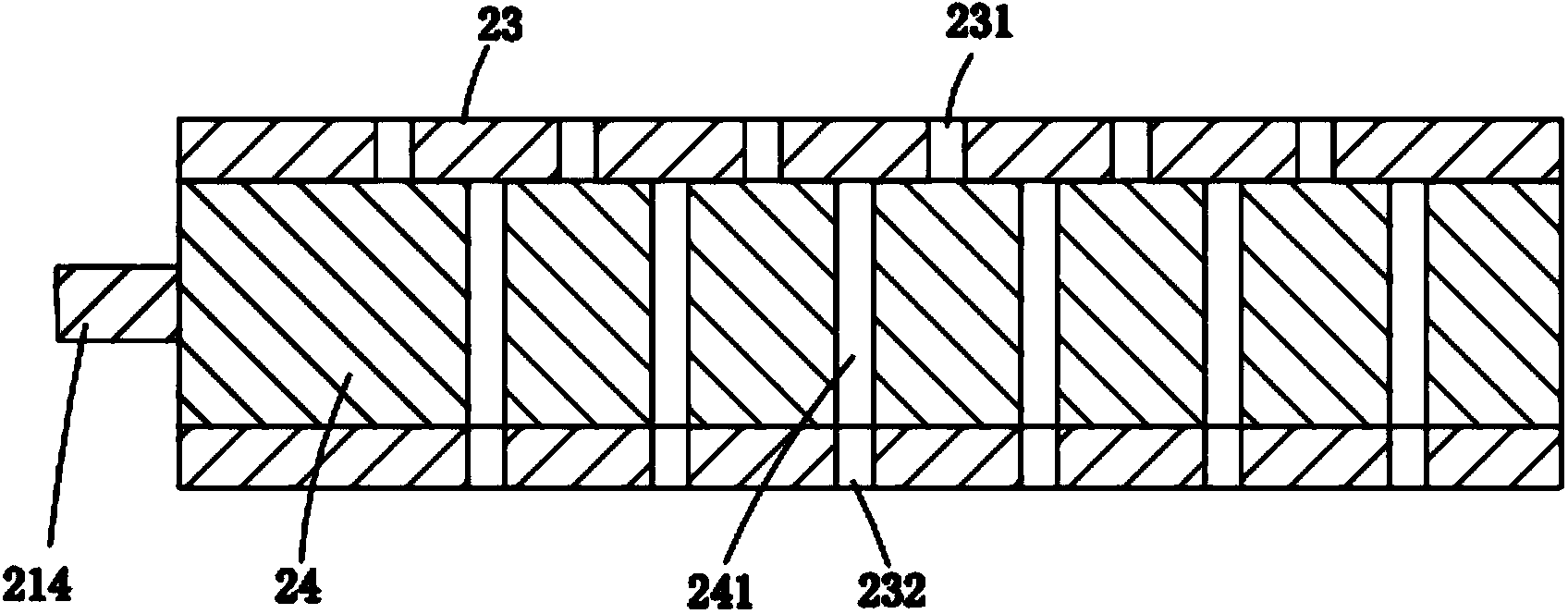

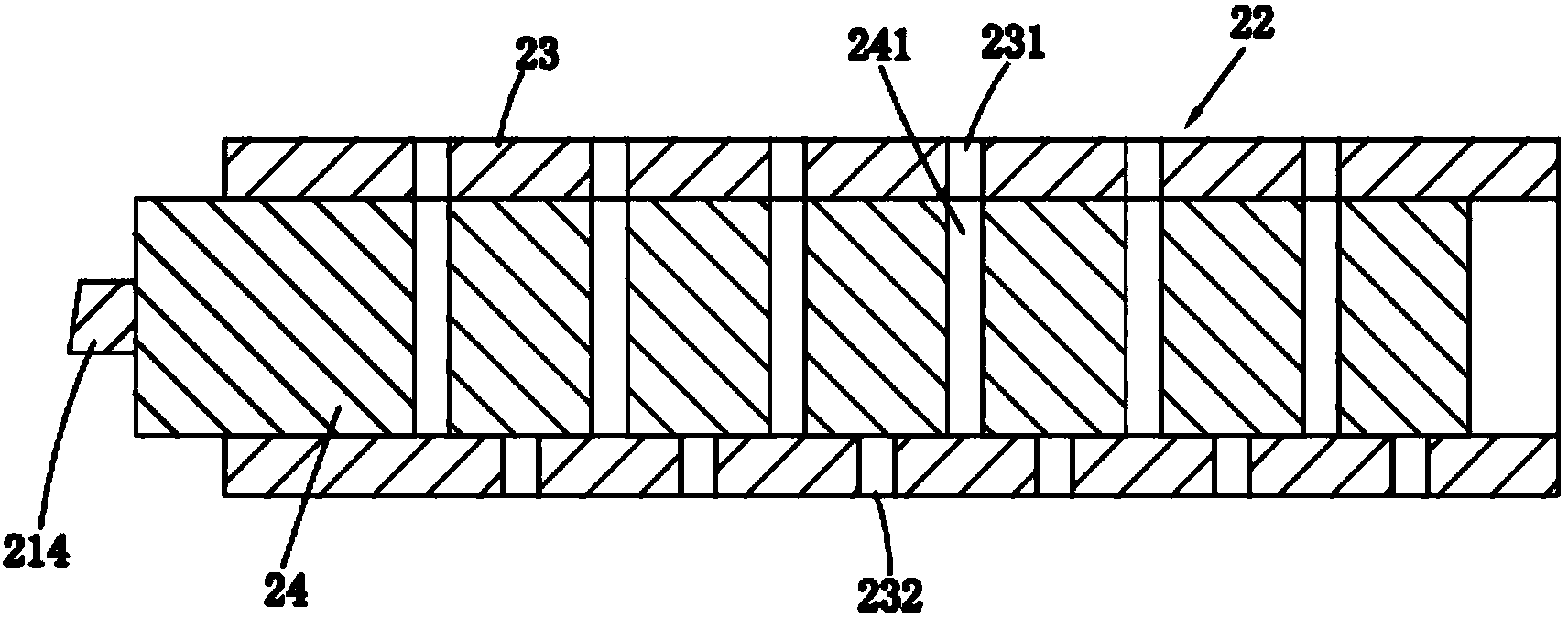

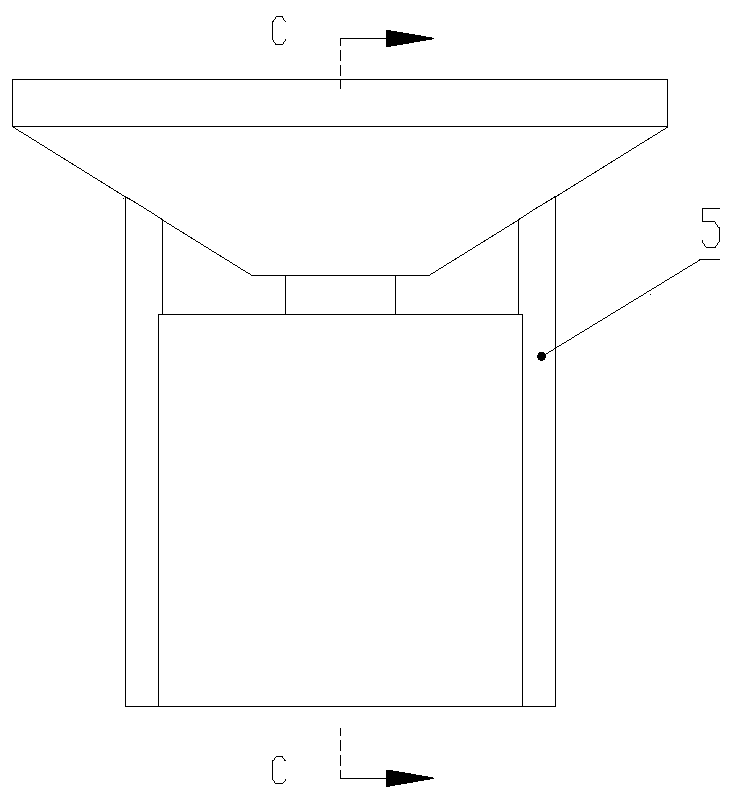

Quantitative material injection device of mould

The invention relates to a quantitative material injection device of a mould. The quantitative material injection device comprises a hopper, a feeding device and a lower mould body, wherein the hopper is further provided with a material level detection sensor connected with a main controller and an opening sealing plate is arranged at the bottom of the hopper; a plurality of outlets are uniformly formed in the opening sealing plate; each outlet is provided with a material guide pipe; the feeding device comprises an air cylinder and a material injection mechanism; a plurality of material injection openings corresponding to the outlets of the opening sealing plate are formed in the upper surface of the material injection mechanism; a plurality of discharging holes are formed in the lower surface of the material injection mechanism; a plurality of cavities are vertically formed in the lower mould body; the front side of each cavity is obliquely provided with a material injection pipe communicated with the cavity; the tops of the material injection pipes are correspondingly connected with the discharging holes respectively. The quantitative material injection device can be used for rapidly feeding back the volume of raw materials in the hopper in time through the material level detection sensor so that a certain pressure value is maintained in the hopper; the feeding device is driven by the air cylinder to automatically and quantitatively feed and discharge the materials at intervals, and furthermore, the feeding amount in the mould is controlled; the quantitative material injection device is reasonable in structure and high in production efficiency and can be used for continuously and smoothly discharging the materials.

Owner:东莞市宜曼洲电子科技有限公司

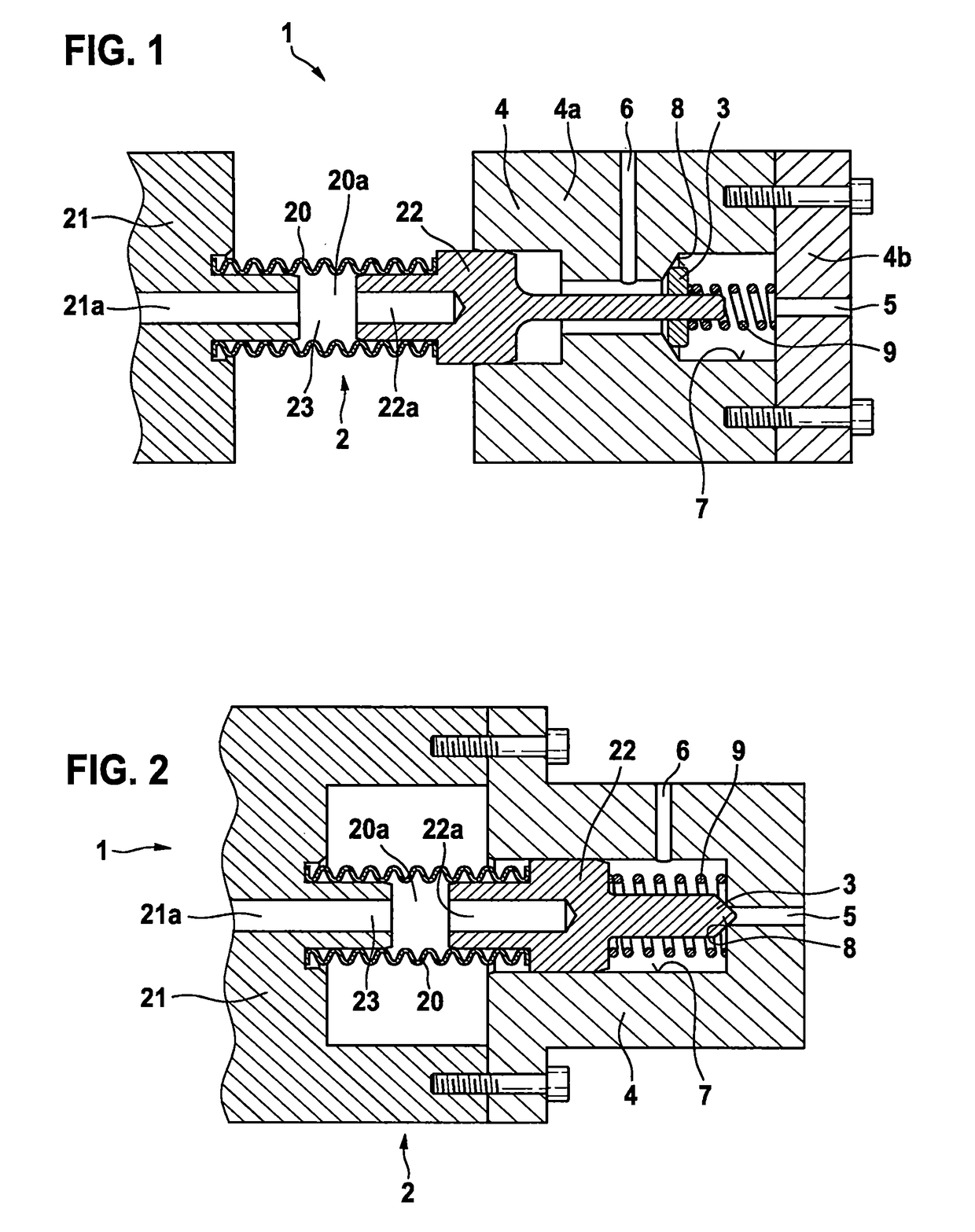

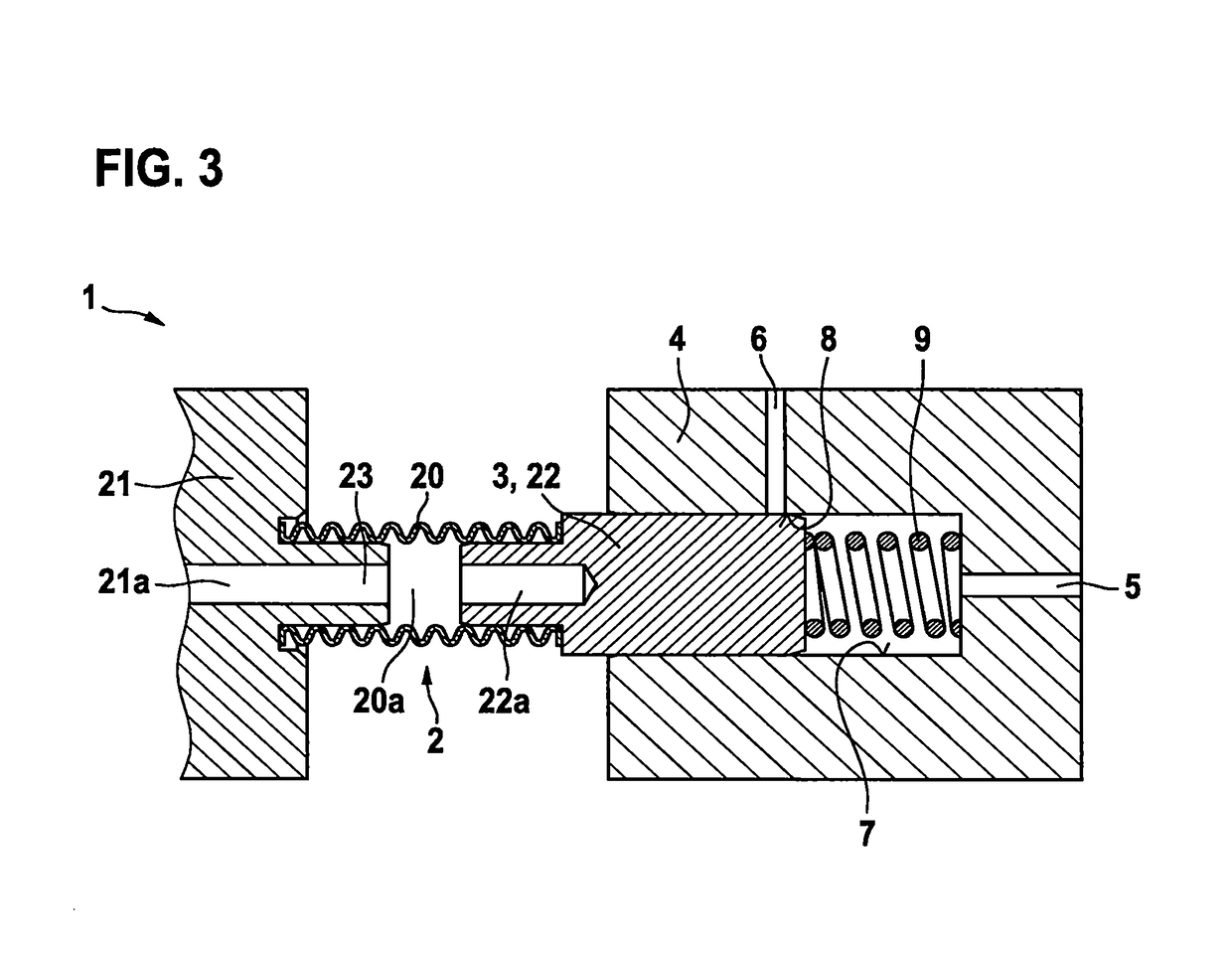

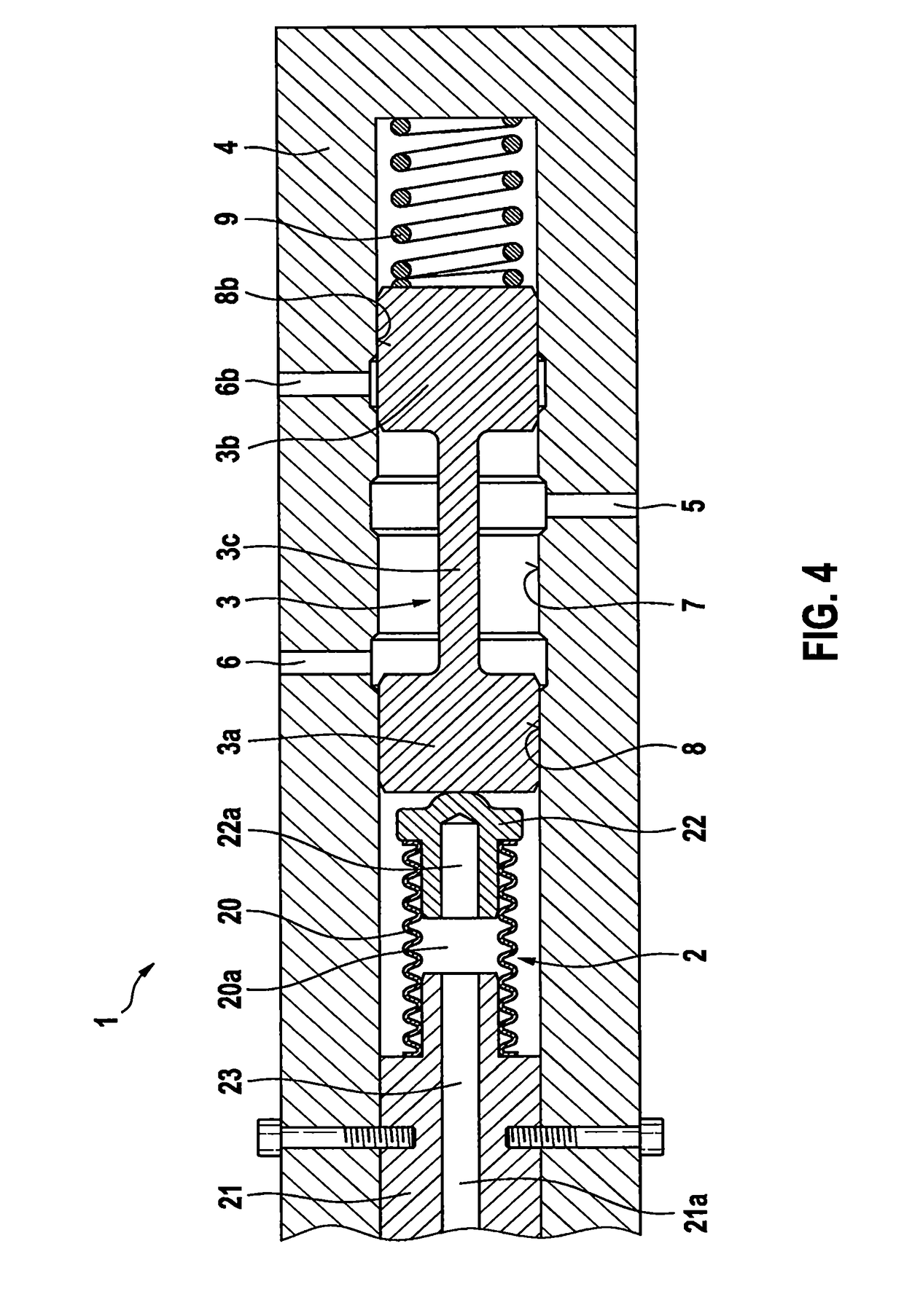

Valve having a metal-bellows/piston unit

InactiveUS20170370481A1Quick activationEasy to quantitative controlOperating means/releasing devices for valvesInternal combustion piston enginesInlet channelEngineering

The invention relates to a valve (1), comprising a valve housing (4) and a closing body (3) arranged in the valve housing (4) in such a way that the closing body can be moved longitudinally, wherein at least one inlet channel (5) and at least one outlet channel (6) are arranged in the valve housing (4). The closing body (3) interacts with a valve seat (8) formed on the valve housing (4) by means of the longitudinal motion of the closing body and thereby opens and closes at least one hydraulic connection between the at least one inlet channel (5) and the at least one outlet channel (6). The closing body (3) can be driven by means of a metal-bellows / piston unit (2), wherein the metal-bellows / piston unit (2) has a variable-length metal bellows (20) and a variable-volume working chamber (23) and wherein the metal bellows (20) bounds the working chamber (23) in a sealing manner.

Owner:ROBERT BOSCH GMBH

Controlled cooling heat treating process and its device for bainite ductile iron

ActiveCN1944691AChange cooling characteristicsImprove hardenabilityFurnace typesHeat treatment furnacesWater flowAlloy

The present invention relates to one kind of controlled cooling heat treatment process and apparatus for bainite ductile iron. The process includes atomizing water as quenching medium in the controlled cooling heat treatment apparatus to spray ductile iron workpiece after austenization at controlled water flow pressure to obtain sufficient cooling speed to avoid pearlite transformation in the high temperature area and to cool to bainite transforming temperature fast; passing through the medium temperature area at lowest cooling speed for bainite transformation; and chilling after bainite transformation to below martensitic transformation point; so as to obtain complex bainite / martensite structure. The present invention has low cost and reduced environmental pollution, and is suitable for large scale production.

Owner:YUNNAN KUNGANG WEAR RESISTANT MATERIAL SCI

Combination of medication for treating obstetrical diseases and preparation method

InactiveCN1660201AEasy to quantitative controlConducive to expanding productionPharmaceutical delivery mechanismUnknown materialsDiseaseMedicine

A Chinese medicine for treating obstetrical diseases is prepared from 5 Chinese-medicinal materials including Chinese angelica root, Chuan-xiong rhizome, peach kernel, liquorice root, etc through slicing, pulverizing, proportionally mixing, preparing nanoparticles, microwave extracting, vacuum concentrating, and spray drying.

Owner:WUHAN UNIV

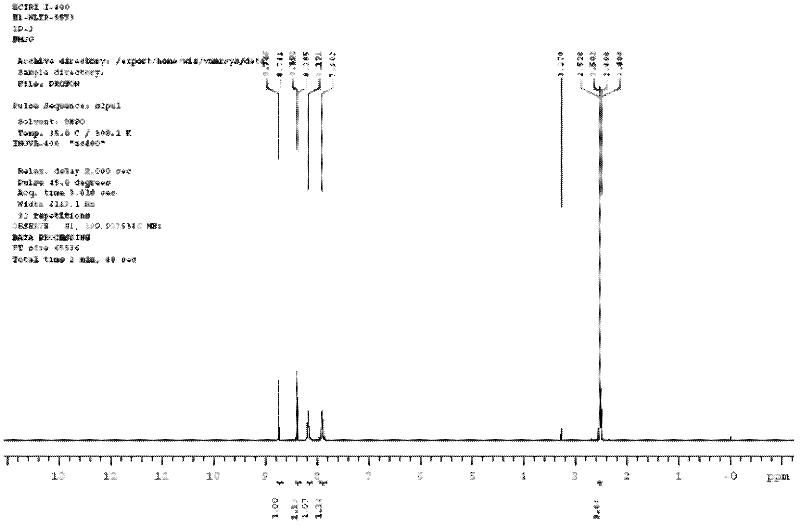

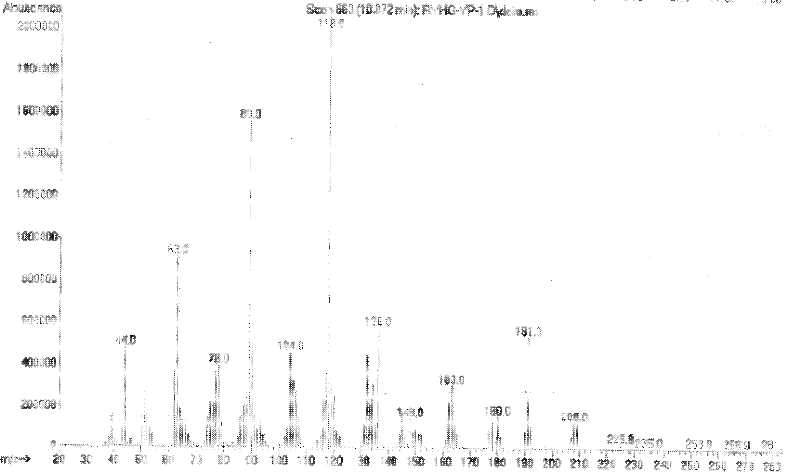

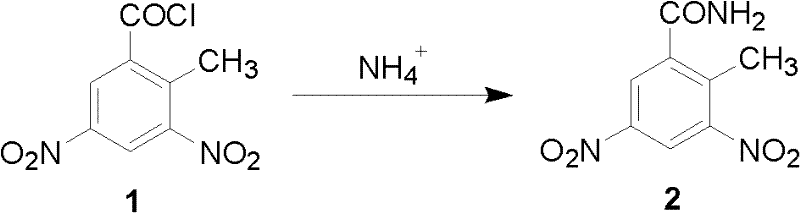

Preparation method of 3, 5-binitro-2-methyl benzamide

InactiveCN102531945AEasy to quantitative controlSolve the problem of volatilityOrganic compound preparationCarboxylic acid amides preparationSynthesis methodsBenzoyl chloride

The invention discloses a preparation method of 3, 5-binitro-2-methyl benzamide, which includes the following steps: 3, 5-binitro-2-methyl benzoyl chloride is slowly and dropwise added to ammonium salt aqueous solution with the mass concentration of 10% to 40%, reaction is conducted for 0.5 hour to 3 hours at the temperature of 10 DEG C to 50 DEG C, after reaction is finished, reaction liquid is filtered, and filter cake is dried to obtain 3, 5-binitro-2-methyl benzamide. The time for dropping 3, 5-binitro-2-methyl benzoyl chloride is 0.5 hour to 3 hours, and the proportion of the amount of 3, 5-binitro-2-methyl benzoyl chloride to the amount of an ammonium salt feeding material is 1:1-6. The preparation method of 3, 5-binitro-2-methyl benzamide uses ammonium salt aqueous solution as an amination reagent, thereby facilitating quantitative control of feeding volume, saving cost, avoiding the problem of ammonia volatilization, and being an environment-friendly, green and efficient synthesis method of Zoalene.

Owner:ZHEJIANG RONGYAO CHEM

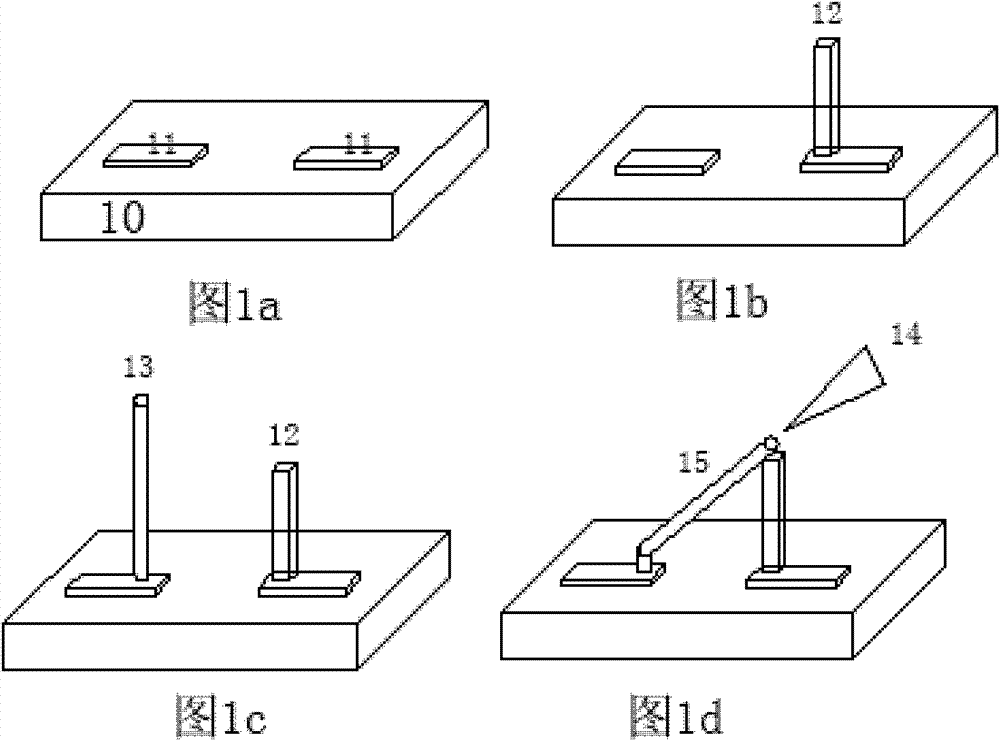

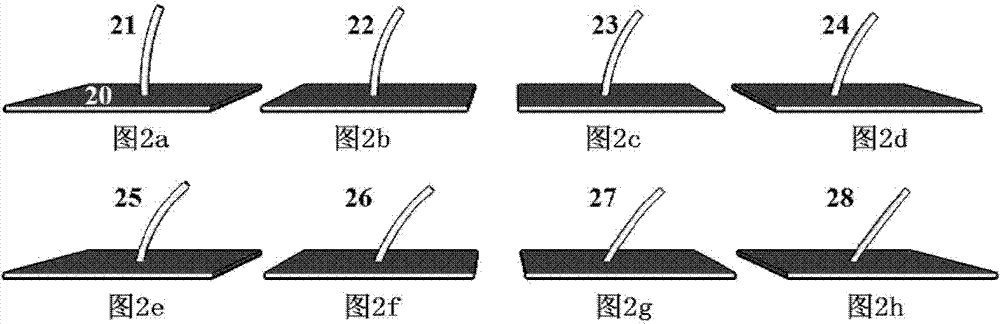

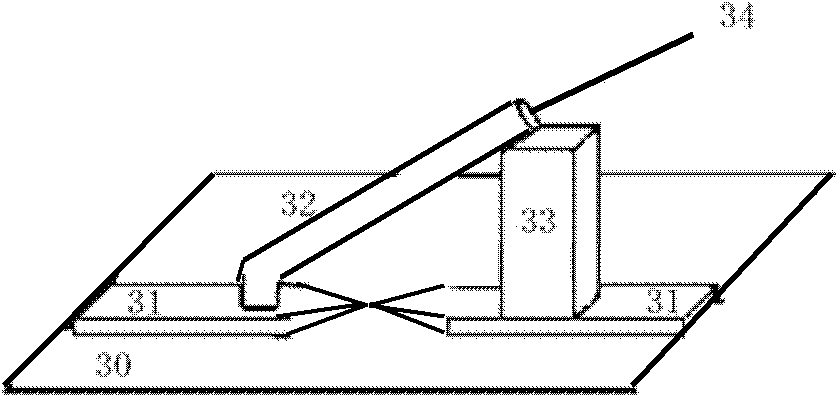

Method for manufacturing three-dimensional superconduction micro-nano device

ActiveCN102765696ARich varietyFunction increaseNanostructure manufactureElectrode ContactVacuum chamber

The invention discloses a method for manufacturing a three-dimensional superconduction micro-nano device, relating to three-dimensional micro-nano device technology. The method provided by the invention comprises the following steps: (1), growing a superconduction electrode contact block or a connecting wire; (2) placing and fixing a processed sample in the step (1); (3), putting the sample fixed on a sample support on a sample stage arranged in a vacuum chamber of an ion beam device; (4) growing a superconduction micro-nano material freely standing on the superconduction electrode contact block or the connecting wire; (4), controlling deformation of the micro-nano material manufactured in (4B); and (6), obtaining a finish product. In the manufacturing method provided by the invention, a superconduction micro-nano structure which is not positioned in a support substrate plane is manufactured based on the control for the deformation of the freely-standing nano material by ion beam irradiation, so as to form the three-dimensional superconduction micro-nano device which is in a certain included angle with the support substrate plane; and the method provided by the invention is flexible in process, high in efficiency and good in control.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

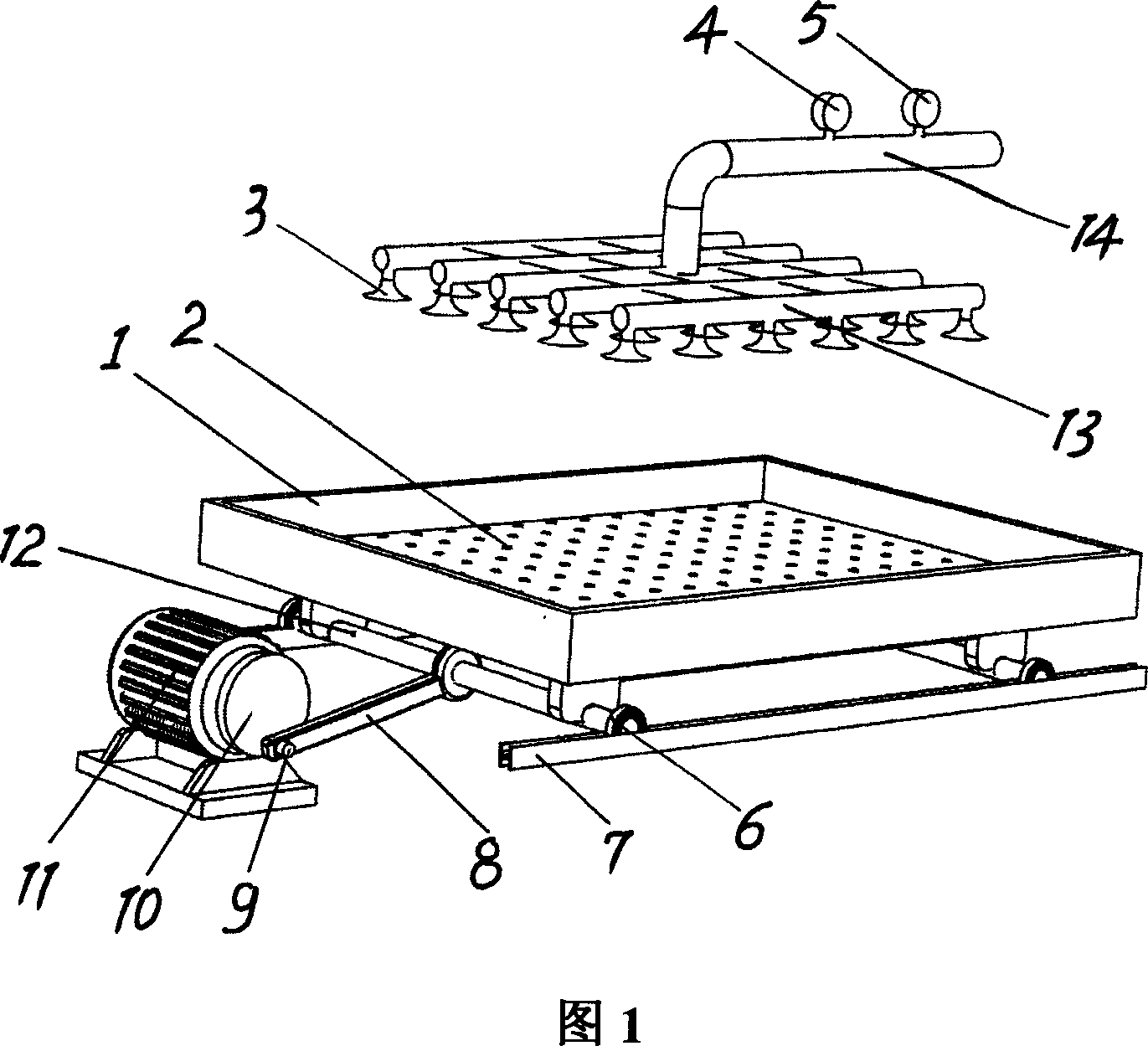

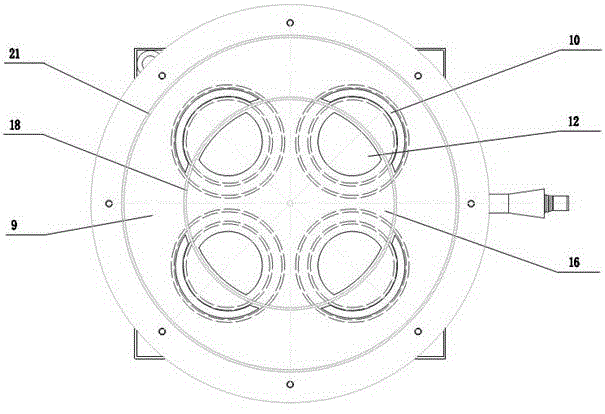

Device and method for multi-component atomizing and mixing

The invention belongs to the technical field of liquid component mixing and particularly relates to a multi-component atomizing and mixing technology. According to the technical scheme, a multi-component atomizing and mixing device comprises a plurality of atomizing devices atomizing liquid components, and a mixing device for mixing fog drops after the various liquid components are atomized. A multi-component atomizing and mixing method includes the steps that A, the various liquid components are atomized and dispersed into the fine and small fog drops; and B, the fine and small fog drops formed by atomizing and dispersing the various components are mixed in one space. According to the multi-component atomizing and mixing technology, the structure is simple, and atomizing and mixing of the liquid components under the controllable condition of factor variables can be achieved.

Owner:SHANGHAI NORMAL UNIVERSITY

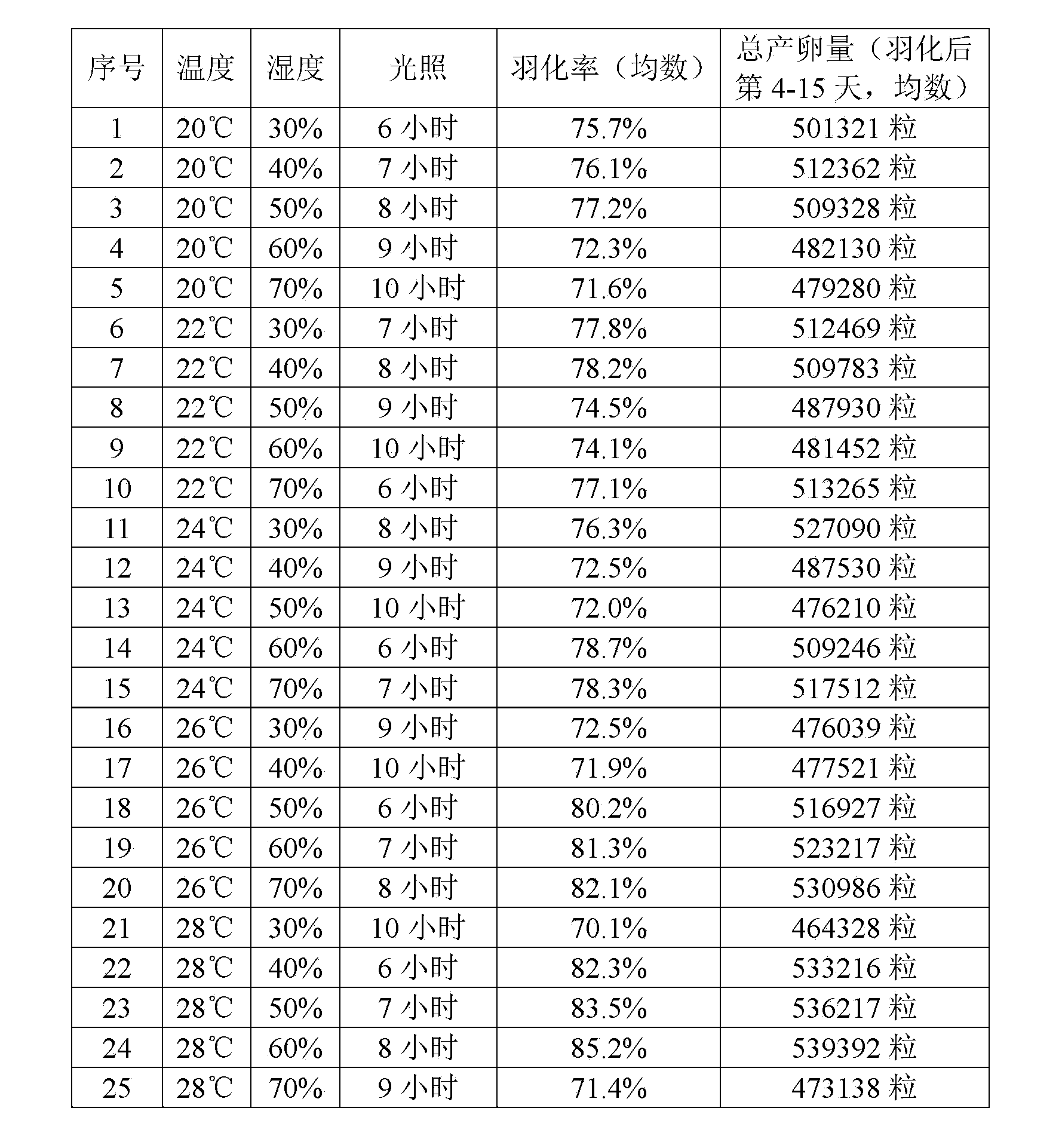

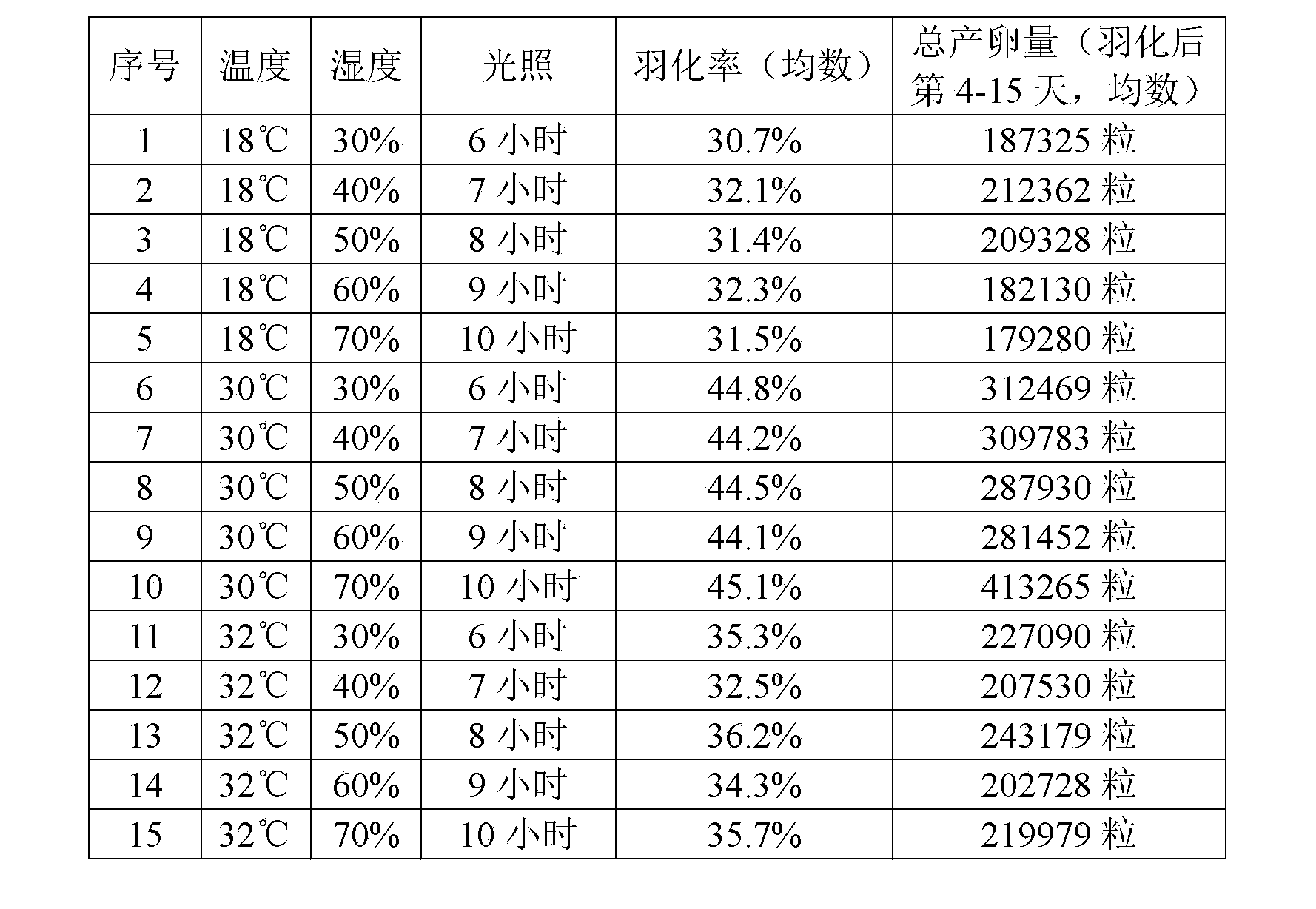

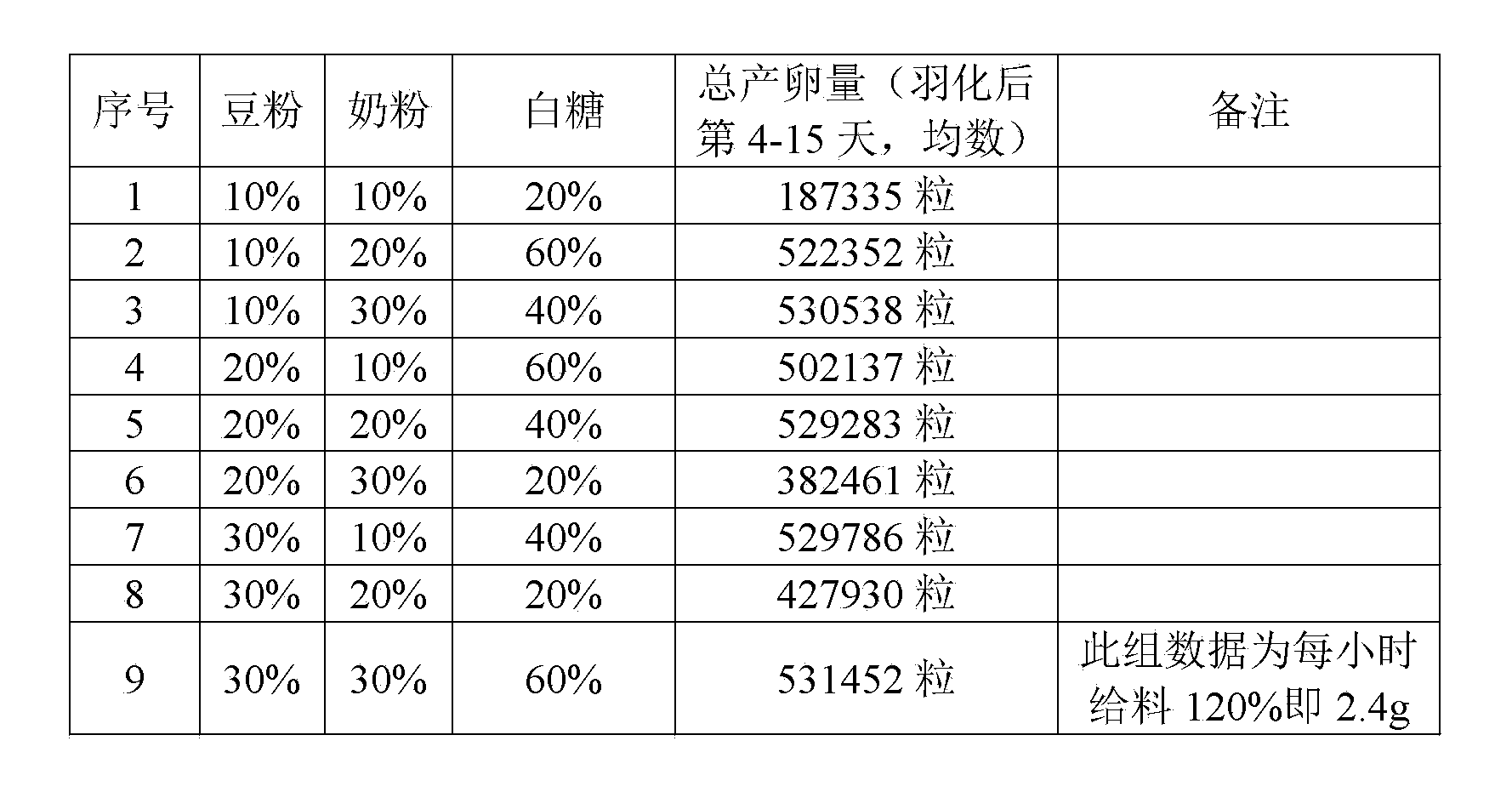

Method for promoting intensive spawning of houseflies and used breeding feed and egg receiving material

ActiveCN103371272APromote intensive spawningIncrease egg productionAnimal feeding stuffHouseflyWheat Brans

The invention discloses a method for promoting intensive spawning of houseflies and a used breeding feed and an egg receiving material, wherein the breeding feed for adult flies is prepared from 10%-30% of soybean meal, 5%-15% of dry maggot powder, 10%-30% of milk powder, 20%-60% of white sugar, 1%-10% of plant medicine residue and 1%-5% of balloon flower; and the egg receiving material for houseflies is prepared by mixing 25%-30% of wheat bran, 5%-10% of balloon flower and 60%-70% of water, and further adding 1-10mg of oviposition pheromone for the houseflies into per kilogram of mixture. By adopting the technical scheme disclosed by the invention, the fecundity of the houseflies during the period of reproductive peak can be improved, and the hatchability of fly eggs and the survival rate of larvae of the houseflies after inoculation are further improved.

Owner:GUIZHOU BOKANG BIOENG

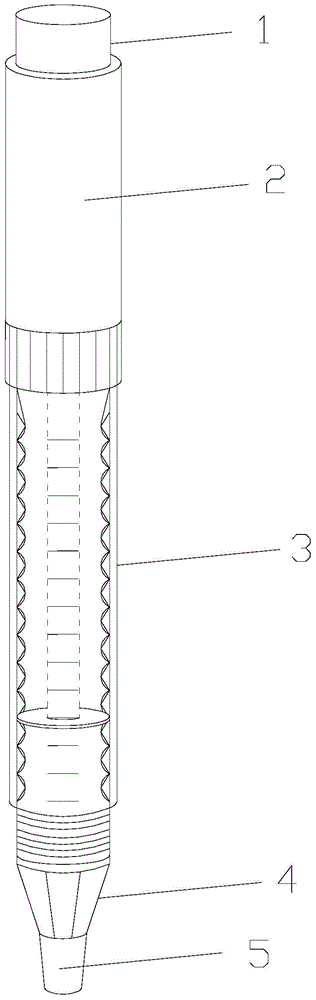

Laparoscopic varicocele ligation puncture device

InactiveCN107468292AInhibit sheddingMeet the needs of safe use functionsSurgical needlesDiagnostic recording/measuringVeress needlePERITONEOSCOPE

The invention discloses a laparoscopic varicocele ligation puncture device. Such structure design that a fixing mechanism and an anti-disengagement mechanism is adopted, the expansion stretch-out and draw-back principle of an elastic air bag and the adsorption principle of a carbon nano tube array are made use of, a conical head can be effectively prevented from being disengaged from a puncture part, a main sheath tube thus does not move in the human body or outside the human body in the operation process, the operability is largely improved, meanwhile an air guide hole is formed in the conical head, the air inflation effect of a veress needle can be achieved, and the safe use function requirements of puncture and pneumoperitoneum are met.

Owner:重庆爱德华医院有限公司

Compression device for wood chip recovery

ActiveCN108972760AEasy to useAchieve consumptionBark-zones/chip/dust/waste removalCompression deviceEnergy conservation

The invention discloses a compression device for wood chip recovery. The compression device for wood chip recovery comprises a feeding mechanism, a pressing mechanism and a receiving mechanism, wherein the pressing mechanism is arranged below the feeding mechanism; the receiving mechanism is arranged below the pressing mechanism; and the feeding mechanism is composed of a storage box, a conveyingpipe, a central shaft, a first rotary blade, a conveying motor, an unloading pipe, an unloading box, a transmission shaft, a second rotary blade, an unloading motor, a support block, a feeding cylinder and a transport box. The compression device for wood chip recovery is compact in structure, and facilitates recovery and use for wood chips; through the arrangement for the feeding mechanism and control over rotation time of the unloading motor and the second rotary blade, quantitative control over unloading is facilitated, and manual operation control is not required, so that the labor intensity of workers is lowered; through the arrangement for a compression mechanism, one-process forming for the wood chips is facilitated, and the wood chips are directly conveyed out after being formed, the operation is convenient and rapid, and the working procedures are reduced, so that the working time is saved, consumption and waste for electric energy are reduced, and energy conservation and environment protection are realized; and the compression device for wood chip recovery is more flexible in structure and high in practicability.

Owner:曾金玉

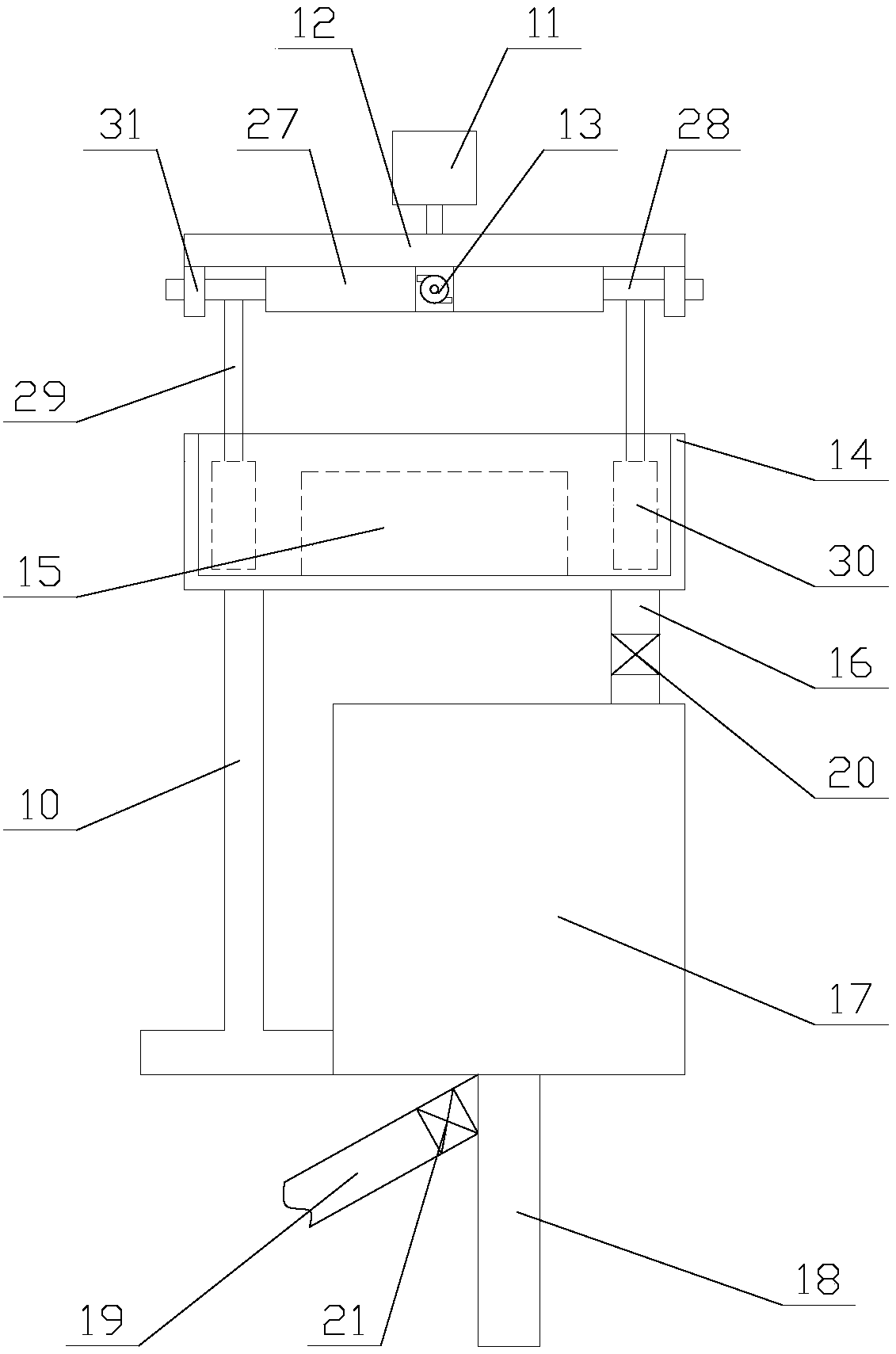

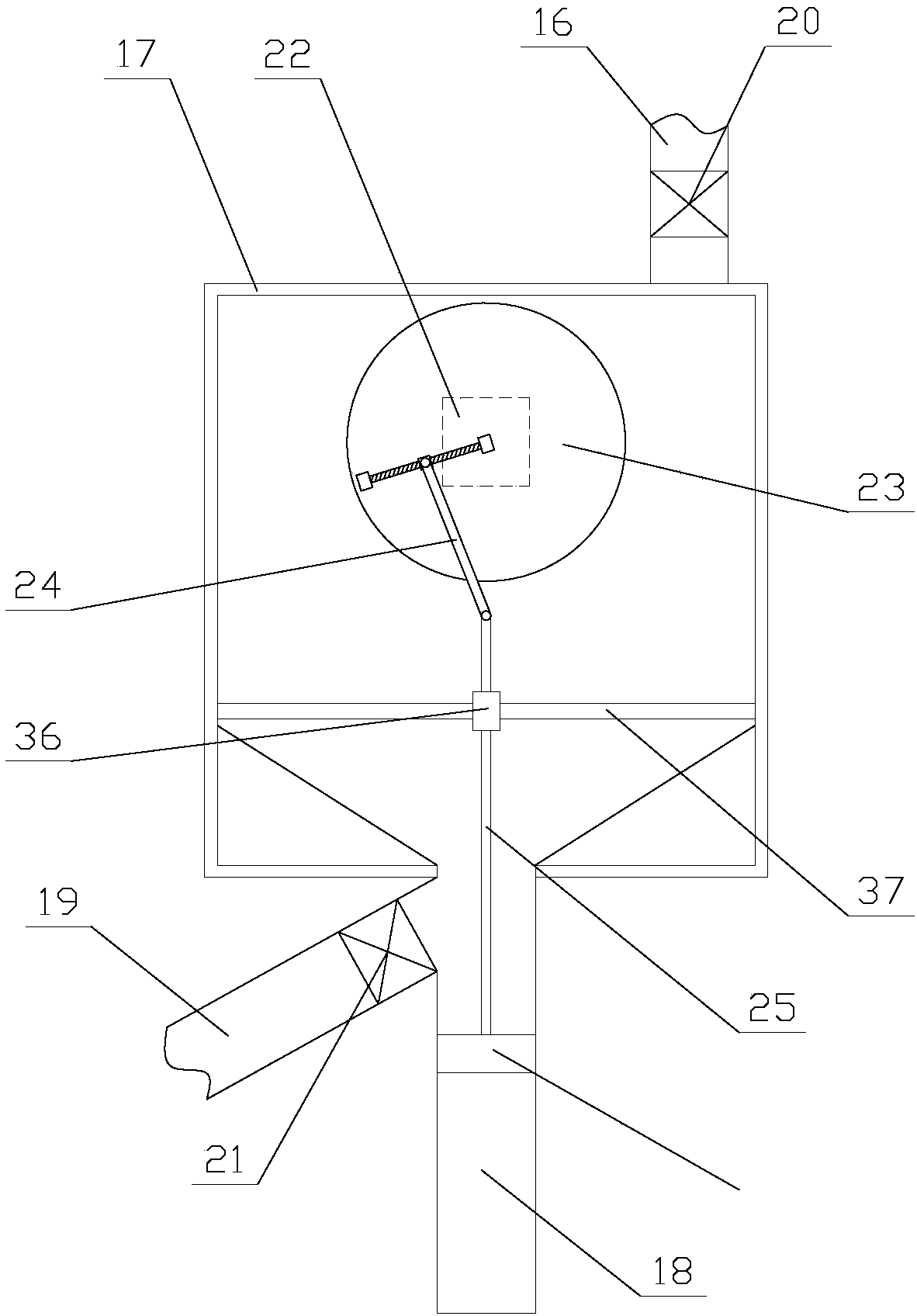

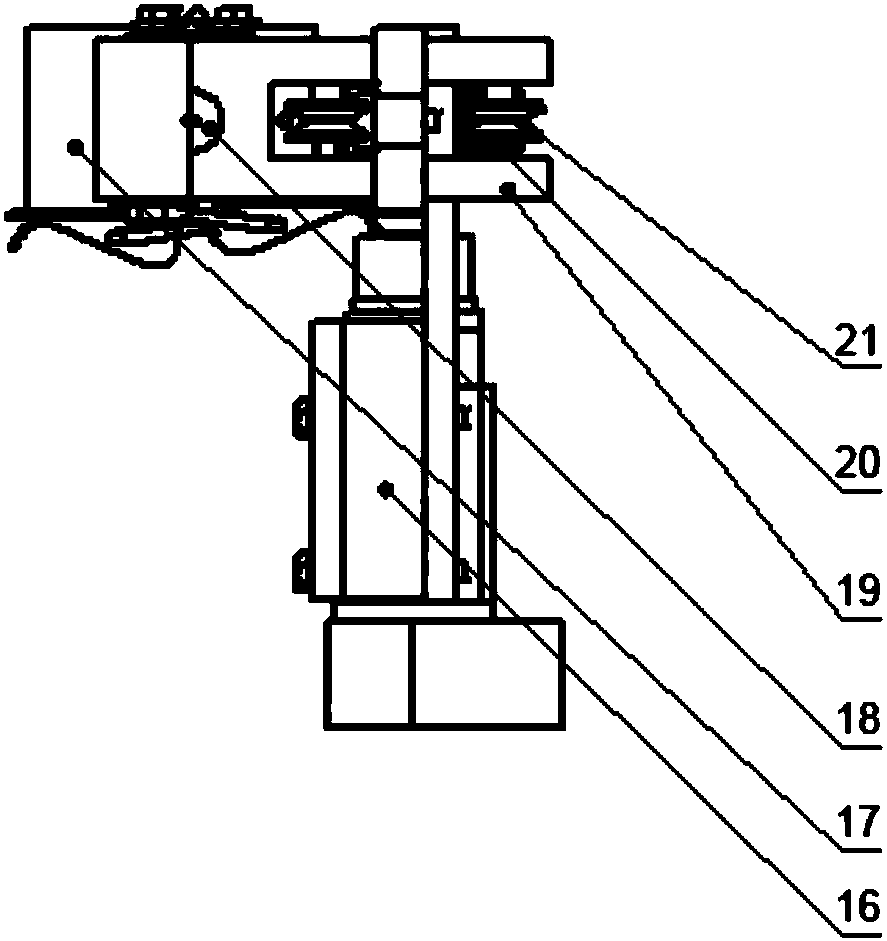

Spine puncture needle inserting mechanism

PendingCN107789041AEasy to disassembleHigh control precisionSurgical needlesTrocarSpinal columnApparatus instruments

Owner:嘉兴复尔机器人有限公司

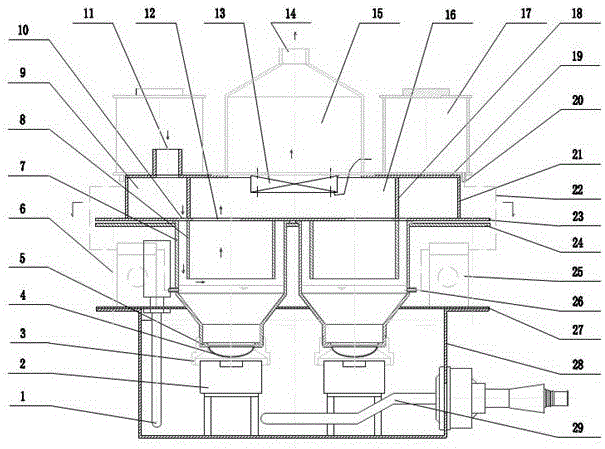

Novel dehumidifying device applied to baking room

InactiveCN102305531AIncrease temperatureEnergy savingDispersed particle separationDrying solid materialsEngineeringEnergy conservation

The invention discloses a novel dehumidifying device applied to a baking room. The dehumidifying device comprises a shell and a dehumidifying mechanism, wherein the shell is provided with an air inlet, an air outlet and a drain pipe; and the dehumidifying mechanism is arranged in the shell, and the drain pipe is connected with the dehumidifying mechanism. Compared with the prior art, the novel dehumidifying device applied to the baking room can be capable of dehumidifying the baking room and dose not redundantly take away the heat of the baking room, thereby avoiding waste of heat and saving energy.

Owner:CHINA TOBACCO GUANGDONG IND

Method for producing compound Geqing capsule or granule

InactiveCN1562273AConducive to the control of finished product quantityGood for absorptionUnknown materialsGranular deliveryGinkgo GenusAdemetionine

A compound Haqing capsule (or particle) is prepared through decocting 9 Chinese-medicinal materials including dried toad, astragalus root, ginkgo seed, etc three times, vacuum filter, vacuum concentrating, mixing with fine powder of astragalus root, granulating, drying, mixing with starch, and loading in capsules.

Owner:王永清

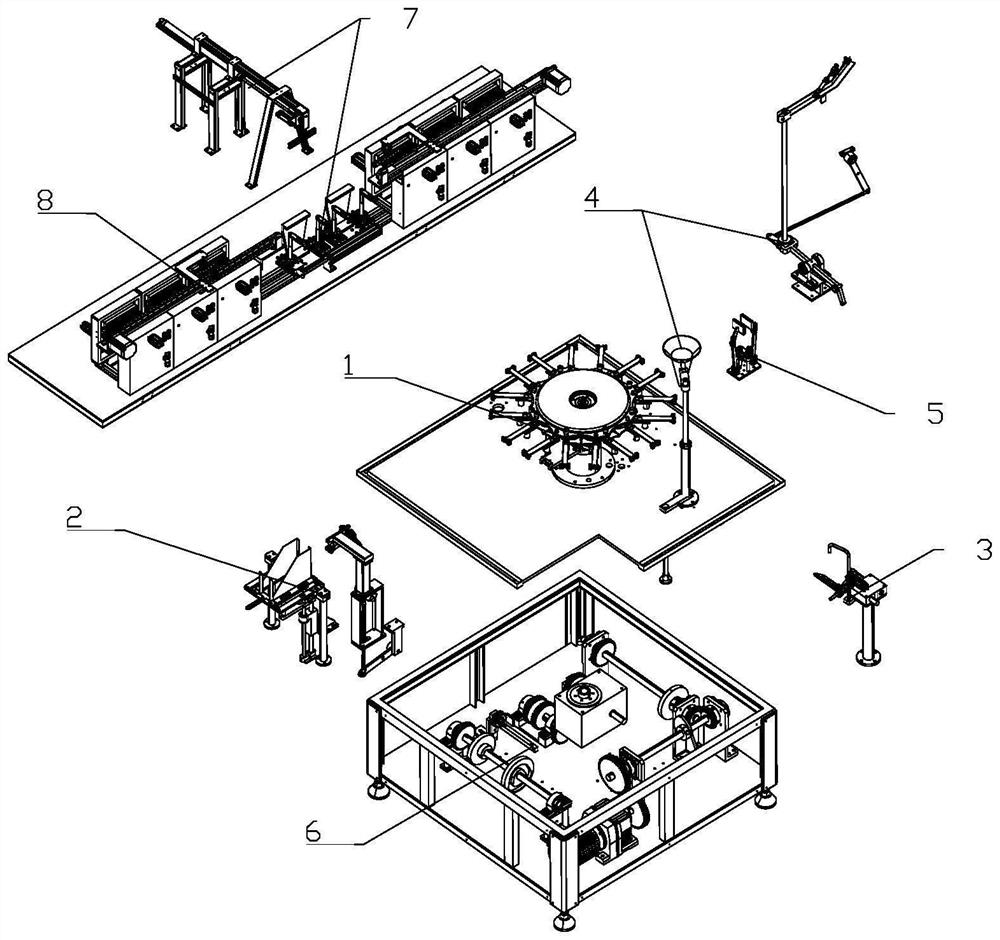

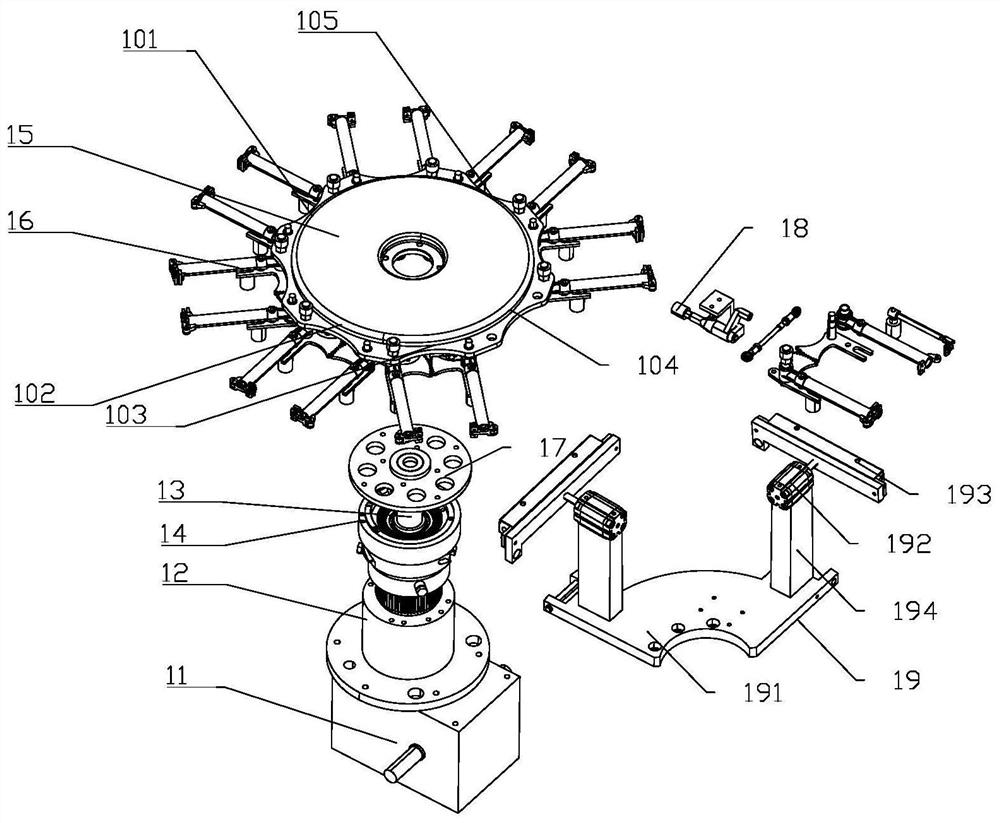

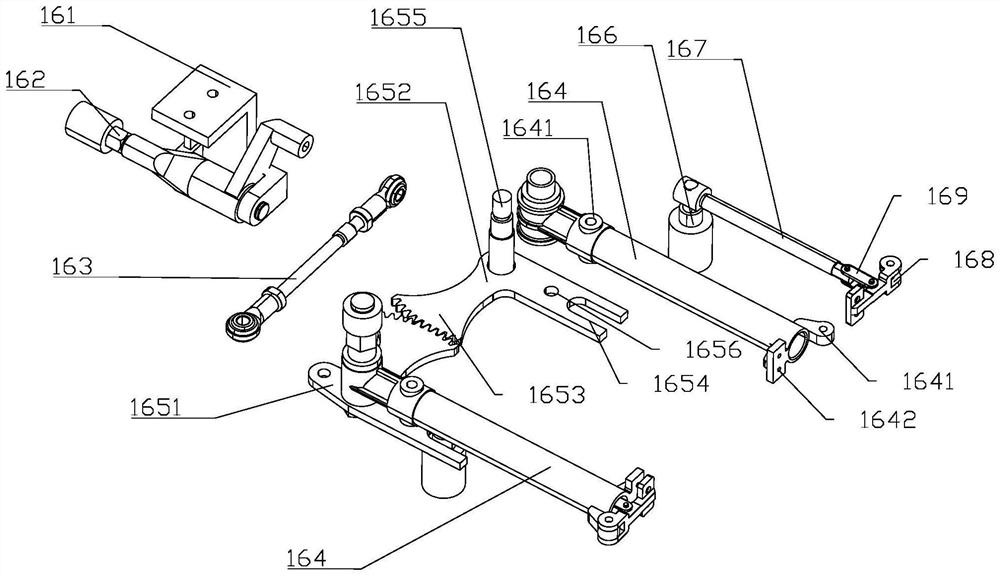

Automatic food bagging machine and working method thereof

InactiveCN113800048AImprove work efficiencySimple structurePackaging by pressurising/gasifyingWrapper twisting/gatheringProcess engineeringPower apparatus

The invention relates to an automatic food bagging machine. The automatic food bagging machine comprises a rack, a rotary bag clamping device, a bag feeding device, a bag opening device, a discharging device, a bag clamping device, a power device, a moving and taking device and heat sealing devices, wherein the rotary bag clamping device, the bag feeding device, the bag opening device, the discharging device, the bag clamping device, the power device, the moving and taking device and the heat sealing devices are mounted on the rack; and the power device is arranged below the rack, the moving and taking device is connected with the rotary bag clamping device and the heat sealing devices, and the heat sealing devices are arranged on the two sides of the moving and taking device respectively. The automatic food bagging machine has the advantages that packaging bag clamping is reliable and efficient; a connecting rod mechanism carries a packaging bag, and the carrying efficiency is high; the packaging bag is opened reliably and fully; food discharging is accurate and controllable; driving components are few, and transmission is compact and efficient; the packaging bags are moved and taken in order, and the moving and transporting efficiency is high; and the packaging quality is high, and the sealing performance is good.

Owner:伍福庆

Process for smelting and processing Mg-alloy particles used for thixotropic injection moulding

A process for smelting and processing the granular Mg alloy used for thixotropic injection formation includes such steps as double refining with the solid flux containing MgCl2, KCl BaCl2 and CaF2 and the argon gas controlling chemical components of Mg alloy by adding Al, Zn and itermediate alloy according to the mark of the smelting Mg alloy, low-pressure semi-conticast under protection of argongas to obtain Mg-alloy rod, granulating by cutting, sieving and magnetic separation to obtain the product. Its advantages are low content of Fe, Ni and Cl impurities, uniform granularity and flowability.

Owner:戴建林

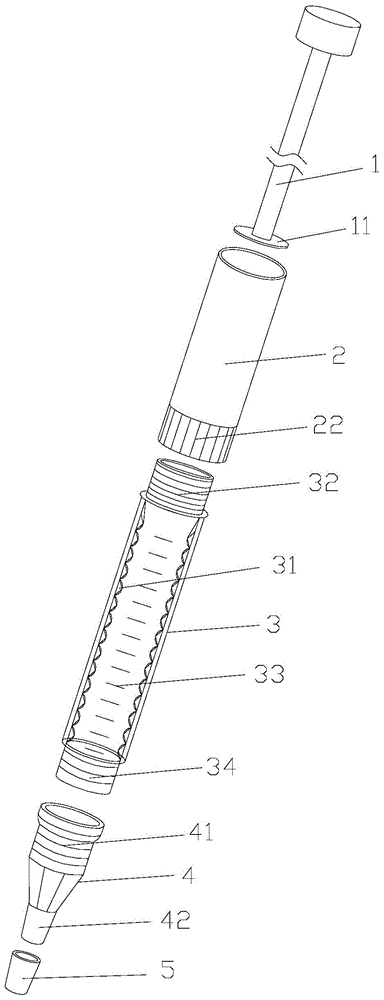

Handheld capsule filling device for pharmacy department

The invention discloses a handheld capsule filling device for a pharmacy department. The handheld capsule filling device comprises a pressing rod, an extending tube, a pharmaceutical storage tube, a pharmaceutical injection head and a sealing sleeve; the extending tube, the pharmaceutical storage tube and the pharmaceutical injection head are sequentially connected in a screwed mode through threads, the pharmaceutical storage tube is made of a transparent material, the inner wall of the pharmaceutical storage tube is provided with a rack, the outer diameter of a pharmaceutical injection opening formed in the pharmaceutical injection head is smaller than the inner diameter of an opening of a capsule body, the pharmaceutical injection opening is matched with the sealing sleeve, the pressing rod is contained in the extending tube and the pharmaceutical storage tube and matched with the extending tube and the pharmaceutical storage tube, the end of the pressing rod is provided with a piston body made of rubber, and the piston body is matched with the rack in a contacting mode. The handheld capsule filling device has the advantages of being small in size, low in manufacture cost, portable, easy to hold, capable of avoiding pharmaceutical waste and controllable in filling dosage.

Owner:张天英

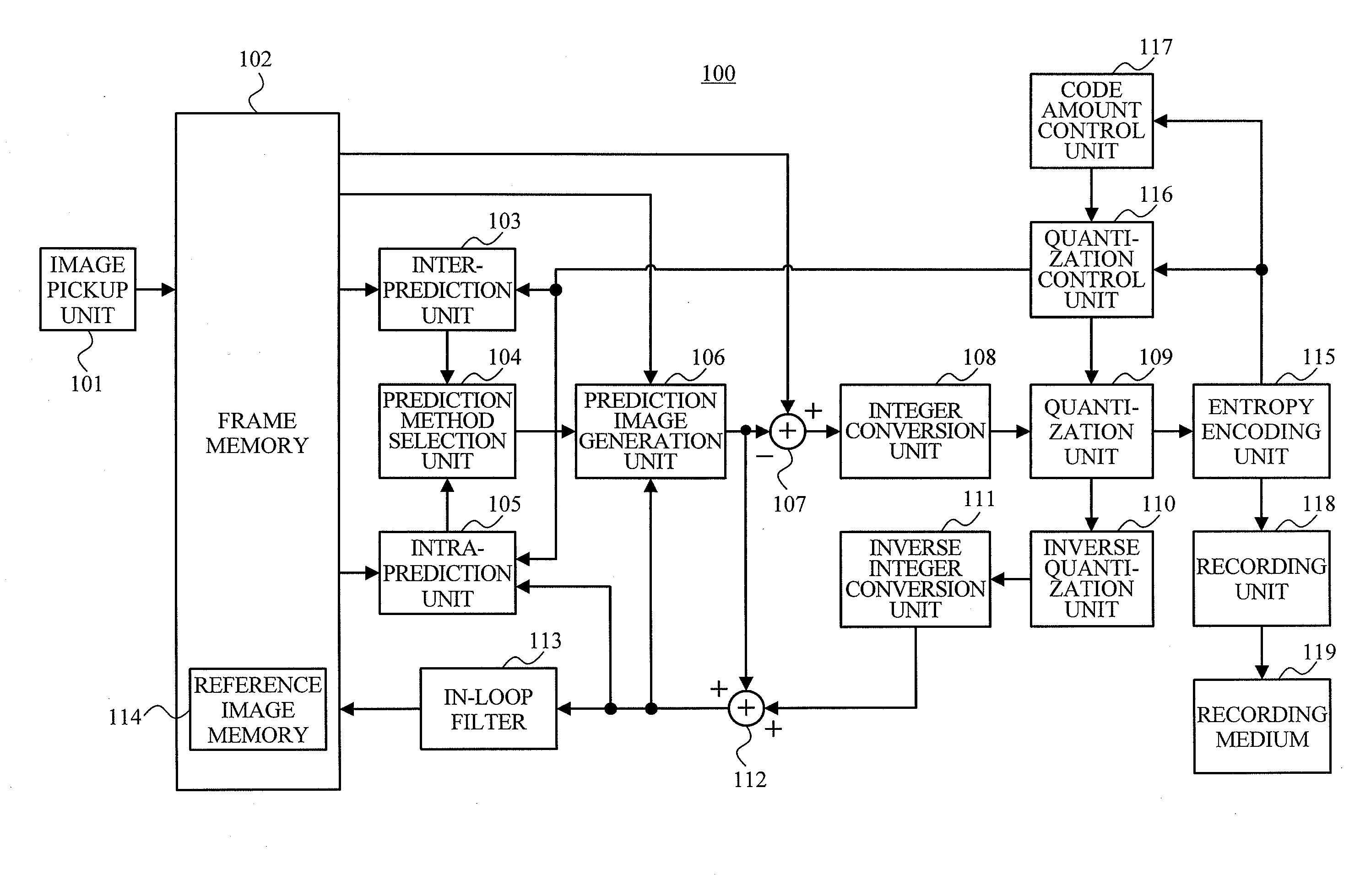

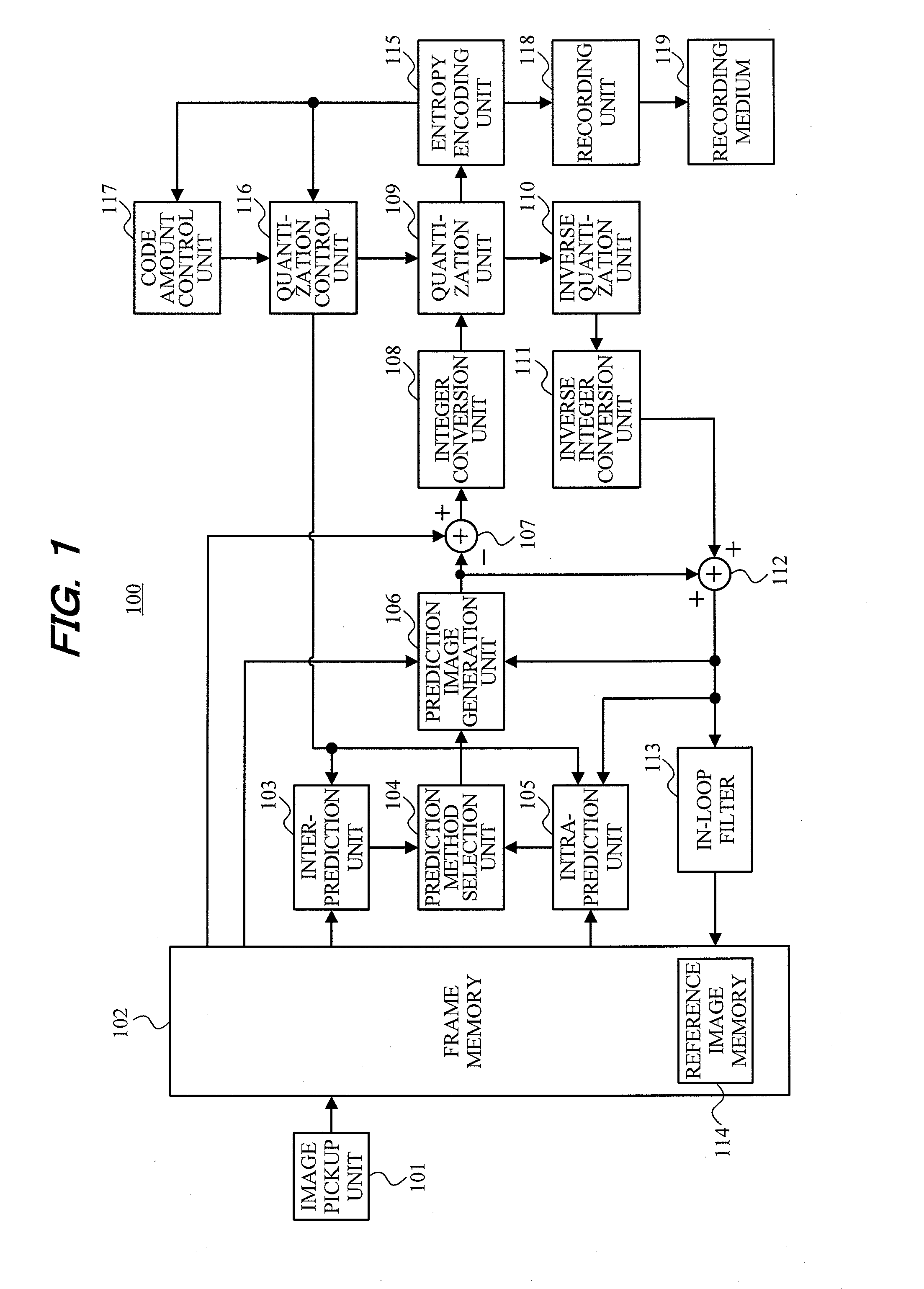

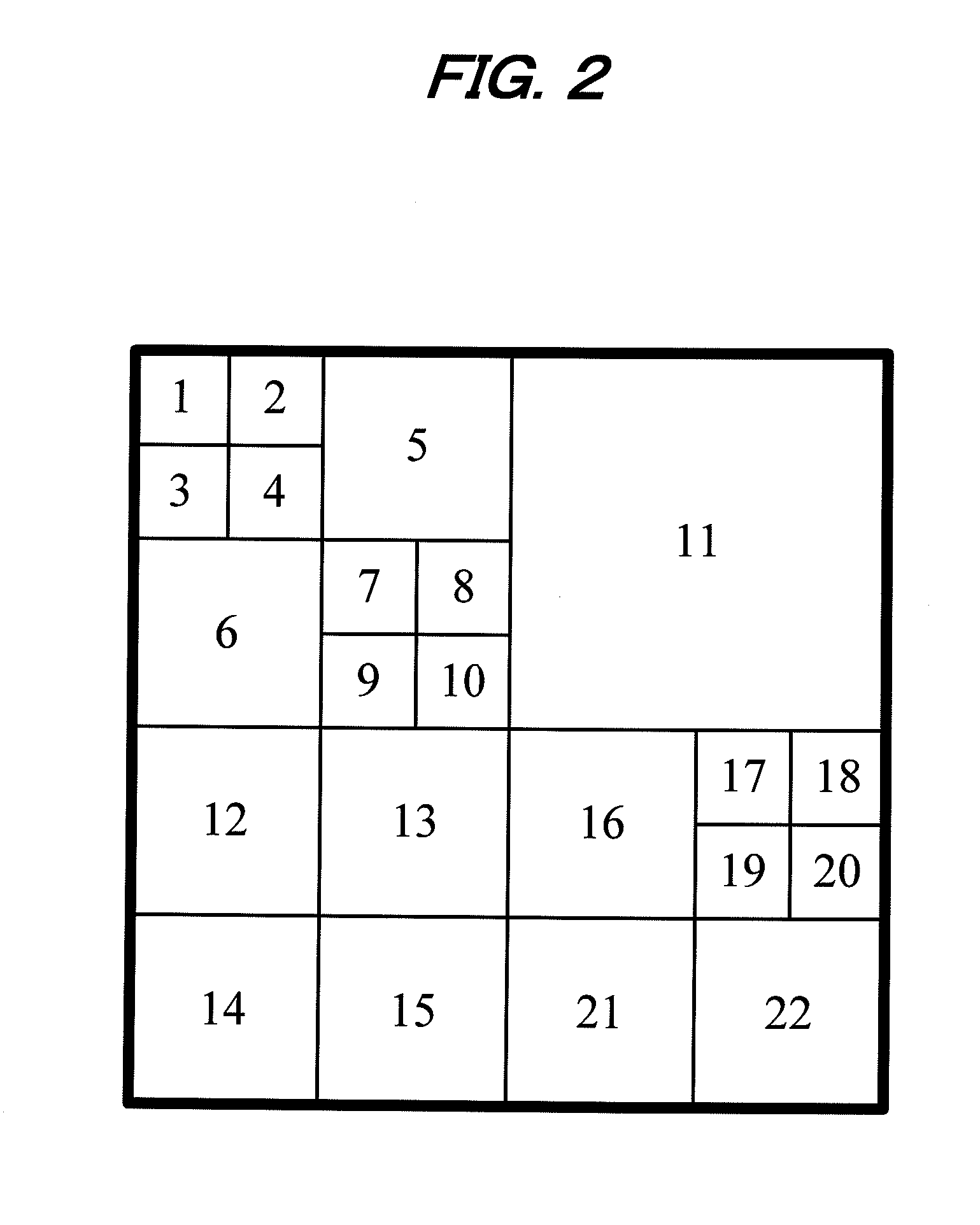

Image encoding apparatus and its control method

ActiveUS20130343449A1Enhance the imageEasy to quantitative controlColor television with pulse code modulationColor television with bandwidth reductionFrame basedImaging data

An image encoding apparatus for encoding image data including a plurality of frames, determines an encoding block size of an encoding subject frame of the image data based on the obtained image data, encodes the obtained image data on an encoding block unit basis in accordance with the determined encoding block size, controls a code amount of the size-decided encoding block based on encoding information regarding the current size-decided encoding block and the encoding block encoded before the current encoding block, operates predetermined encoding information of the encoding subject frame based on the encoding information, and restricts the encoding block size to be determined, in accordance with the operated predetermined encoding information.

Owner:CANON KK

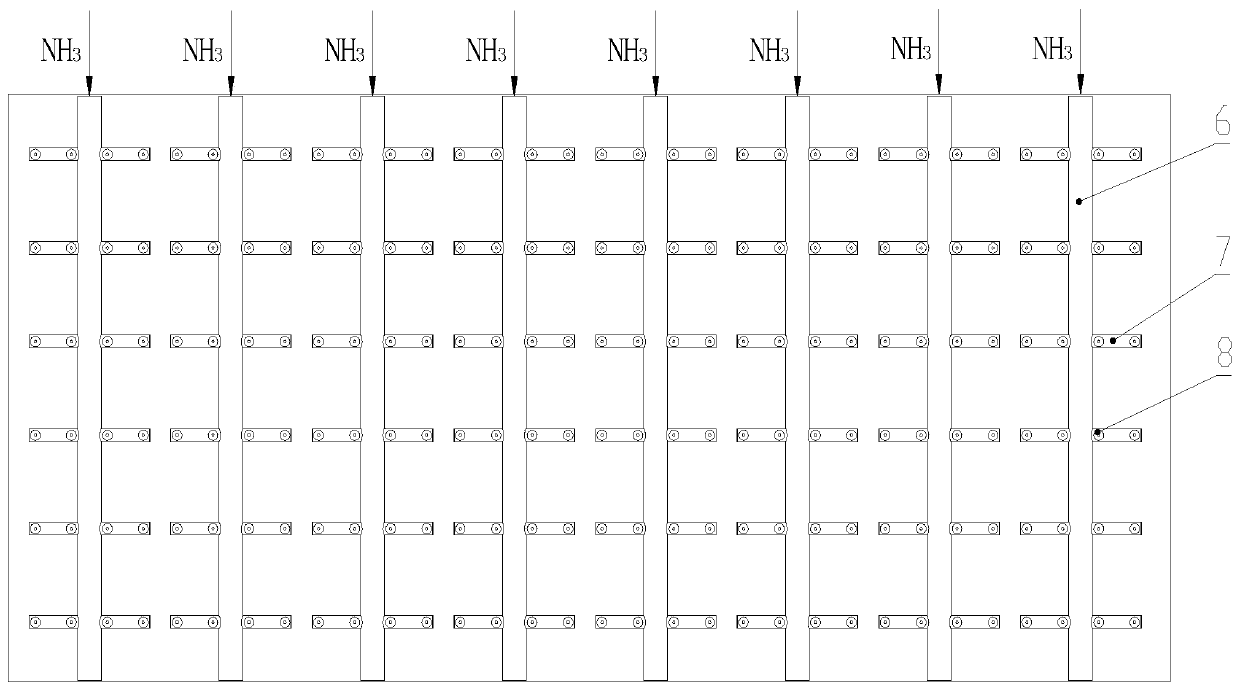

Ammonia spraying device used for improving uniformity of ammonia gas distribution

ActiveCN109821379AShorten the mixing distanceImprove uniformityFlow mixersDispersed particle separationFlueChemistry

The invention discloses an ammonia spraying device used for improving uniformity of ammonia gas distribution. The device is installed on the section of the portion, in front of a denitrification reactor, of a mixing flue to fully mix sprayed ammonia gas with flue gas and meet the requirement of the ammonia and nitrogen molar ratio to the greatest extent. An ammonia gas spraying grate of the deviceis composed of an ammonia gas spraying pipeline and comprises a mother ammonia gas spraying pipe, a first-level ammonia gas spraying branch pipe and a second-level ammonia gas spraying branch pipe; aspraying head is provided with an annular spraying port and a flow guiding piece in a circular cone shape, and the annular spraying port is formed in the direction consistent with the flowing direction of the flue gas. The annular spraying port and the flow guiding piece in the circular cone shape are beneficial for diffusion and guiding of ammonia gas. By arranging the ammonia gas spraying gratedevice, the mixing distance of the ammonia gas and the flue gas can be effectively shortened, and the uniformity of ammonia gas distribution is improved.

Owner:NANJING GUODIAN ENVIRONMENTAL PROTECTION TECH

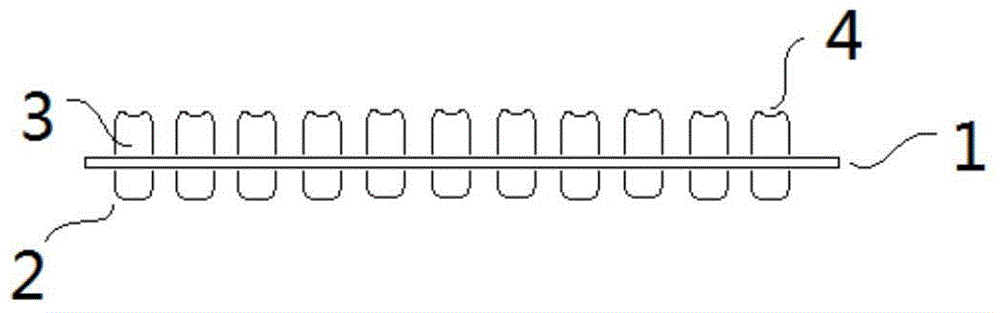

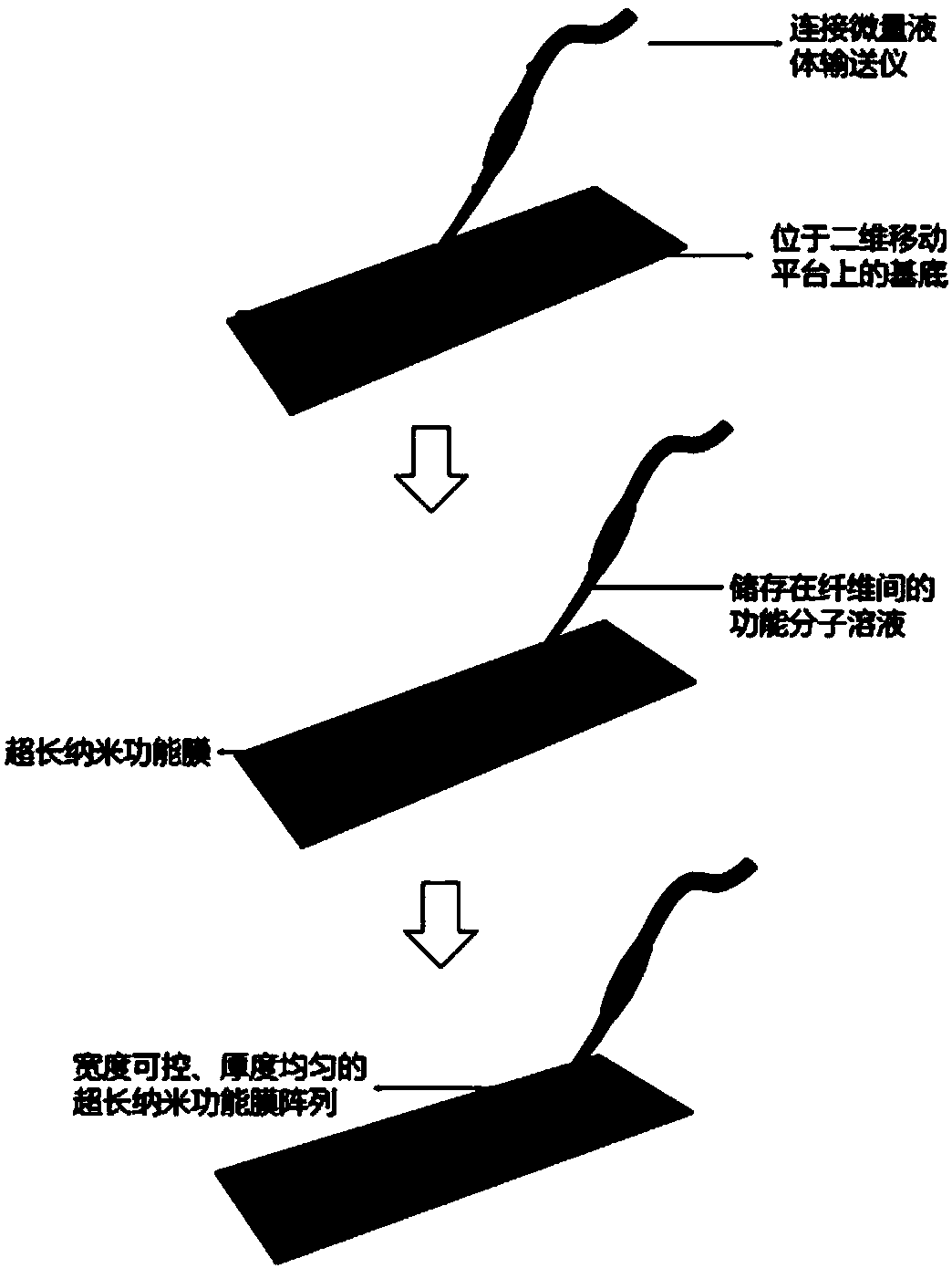

Brush printing film making device and nano film printing method based on the same

ActiveCN109693329AGuaranteed uniformityImprove adaptabilityNanostructure manufactureFlat articlesBrush deviceEngineering

The invention discloses a brush printing film making device and a nano film printing method based on the same. The brush printing film making device includes a brush device. The brush device includesan outer liquid supply pipe (1), a fastening pipe (2) and an inner liquid supply pipe (3). Several protruding pen hair (5) is fixedly arranged on the inner wall of the inner liquid supply pipe (3). The several protruding pen hair (5) is divided into two parts. Each part is arranged on each of the opposite inner walls of the inner liquid supply pipe (3), and the tip ends of the two protruding pen hair parts intersect and converge. A loop of liquid storage hair (4) is fixedly arranged on the outer wall of the inner liquid supply pipe (3) and around the inner liquid supply pipe. The outer liquidsupply pipe (1) sleeves the liquid storage hair (4). The fastening pipe (2) sleeves the outer liquid supply pipe (1). The outer liquid supply pipe and the inner liquid supply pipe fixed with the liquid storage hair and protruding pen hair are fixed by the fastening pipe, and so the protruding pen hair and the liquid storage hair are combined to be a conical fiber brush head. An ultra-long functional nano film prepared by the invention has good repeatability.

Owner:BEIJING SCITECH NANOTECH CO LTD

Aircraft structure test piece bending preventing and measuring device and measuring method thereof

ActiveCN106021776AEasy to quantitative controlAnti-bending effectiveGeometric CADMachine part testingMeasurement deviceEngineering

The invention relates to an aircraft structure test piece bending preventing and measuring device which comprises multiple bending preventing and measuring mechanisms. A test piece is clamped through the multiple bending preventing and measuring mechanisms. Each bending preventing and measuring mechanism comprises a spherical roller, a pulley support, a first lead screw, a second lead screw and a sensor, wherein the spherical roller is arranged in the spherical surface of the pulley support and presses the surface of the test piece to be in contact with the test part, the pulley support is connected with one end of the sensor through the first lead screw, and the other end of the sensor is fixed to a bearing wall through the second lead screw. The aircraft structure test piece bending preventing and measuring device achieves the purposes of effectively preventing bending and conducting quantitative control on bending prevention by arranging the spherical rollers and arranging the load sensors at the connecting positions of the spherical rollers.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

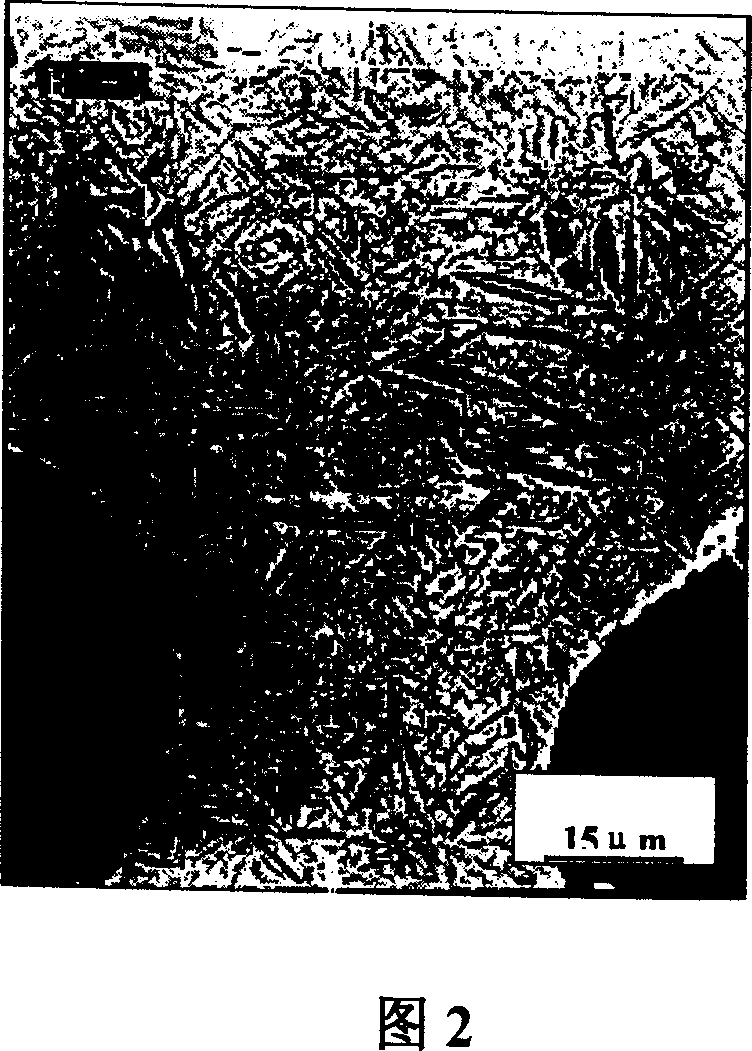

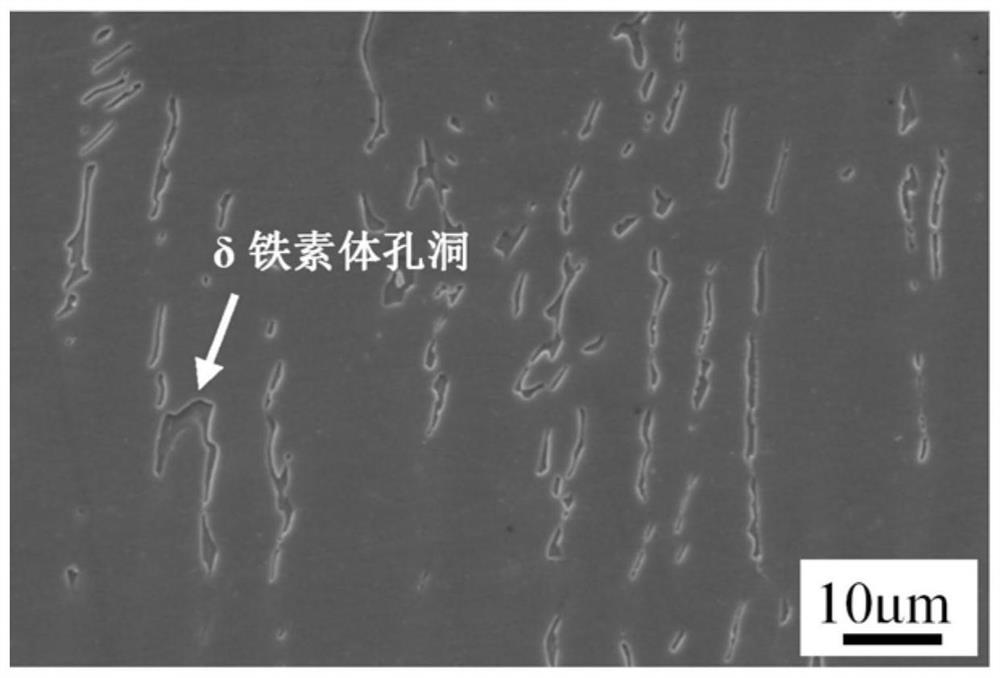

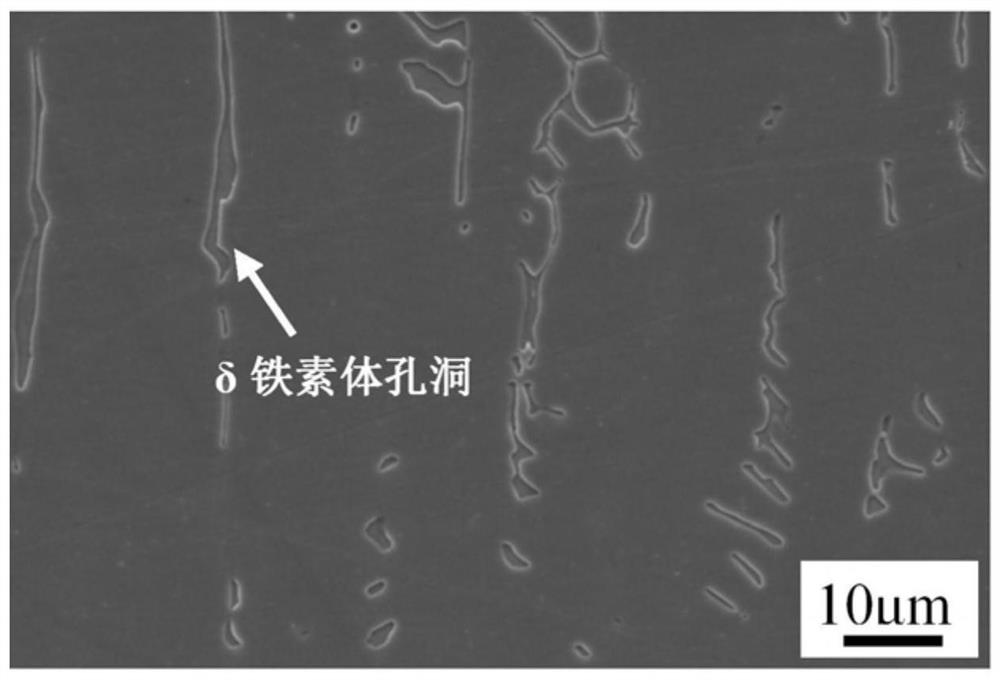

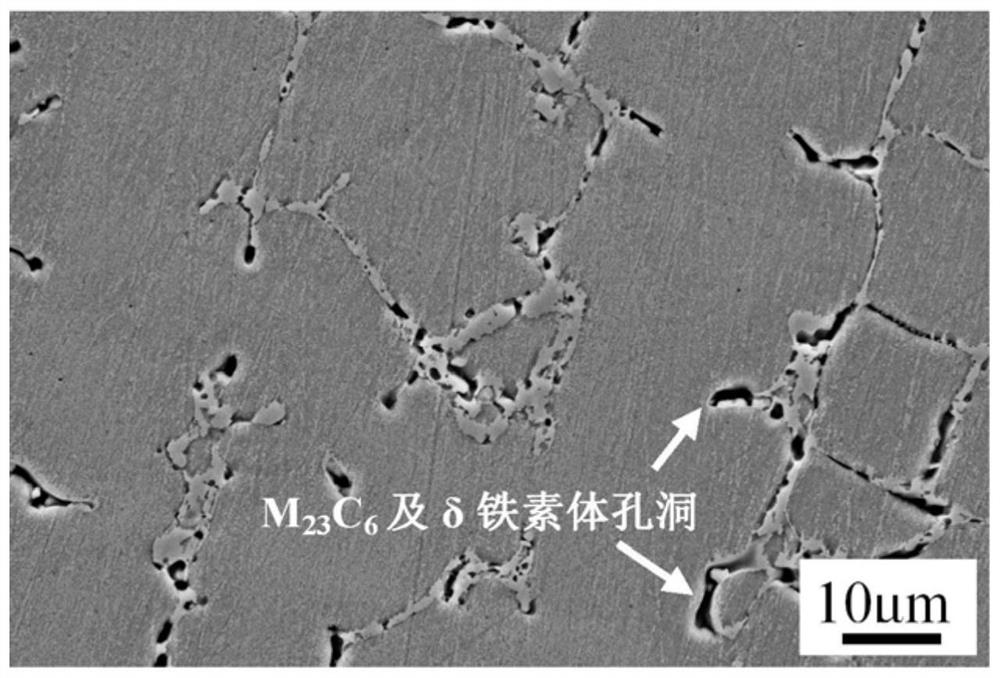

Metallographic corrosion method for multiphase austenitic stainless steel weld metal

ActiveCN112665954ACorrosion conditions and simple operationEasy to quantitative controlPreparing sample for investigationAustenitic stainless steelAqueous solution

The invention discloses a metallographic corrosion method for multi-phase austenitic stainless steel weld metal, and belongs to the technical field of metallographic corrosion. The method comprises the following operation processes: firstly, preparing a mixed aqueous solution of ferric trichloride, hydrochloric acid and nitric acid, then soaking a test sample into the solution for 25-60 seconds, taking out the test sample, sequentially washing the test sample with water and alcohol, and drying the test sample with hot air. By adopting the metallographic corrosion method disclosed by the invention, delta ferrite in an austenitic stainless steel weld joint in a welded state and delta ferrite decomposition products after long-term high-temperature aging can be clearly displayed, the delta ferrite and the decomposition products thereof are prevented from falling off in a large amount in corrosion, and support is provided for subsequent analysis of the types of the delta ferrite decomposition products. Corrosion conditions and operation are simple, quantitative control is easy, reproducibility is good, and the method is suitable for metallographic structure corrosion of multi-phase austenitic stainless steel weld metal containing a small amount of delta ferrite and decomposition products of delta ferrite.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

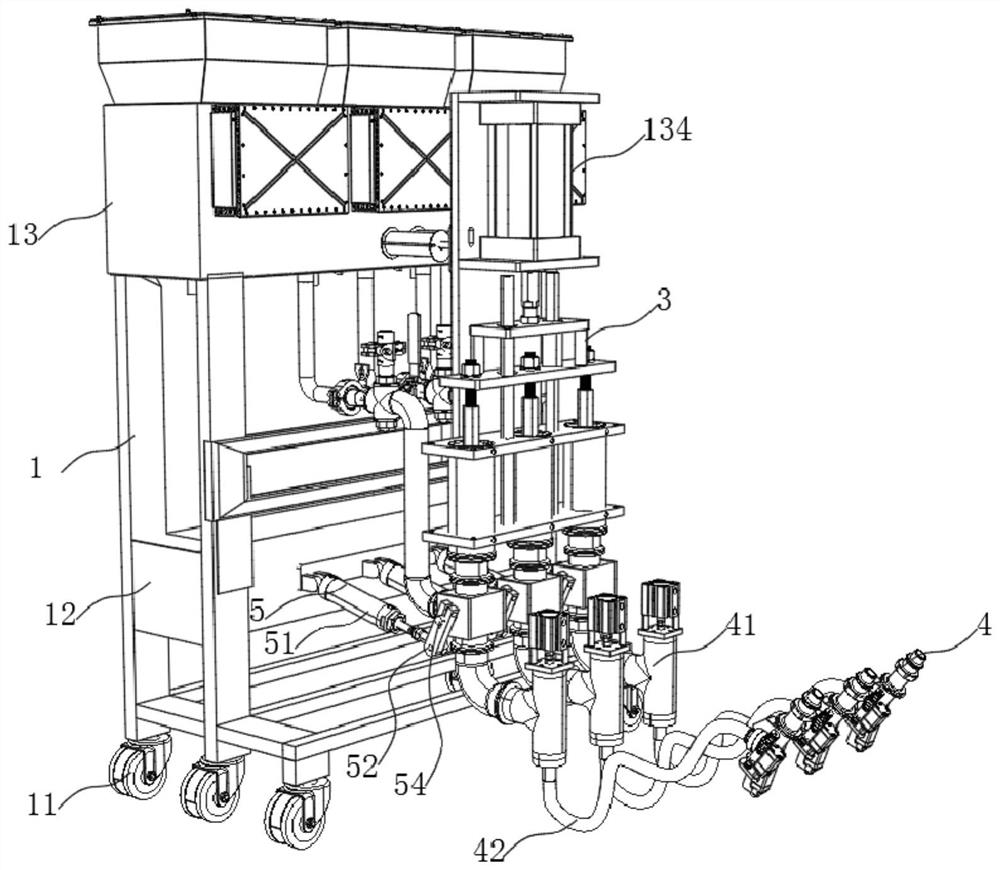

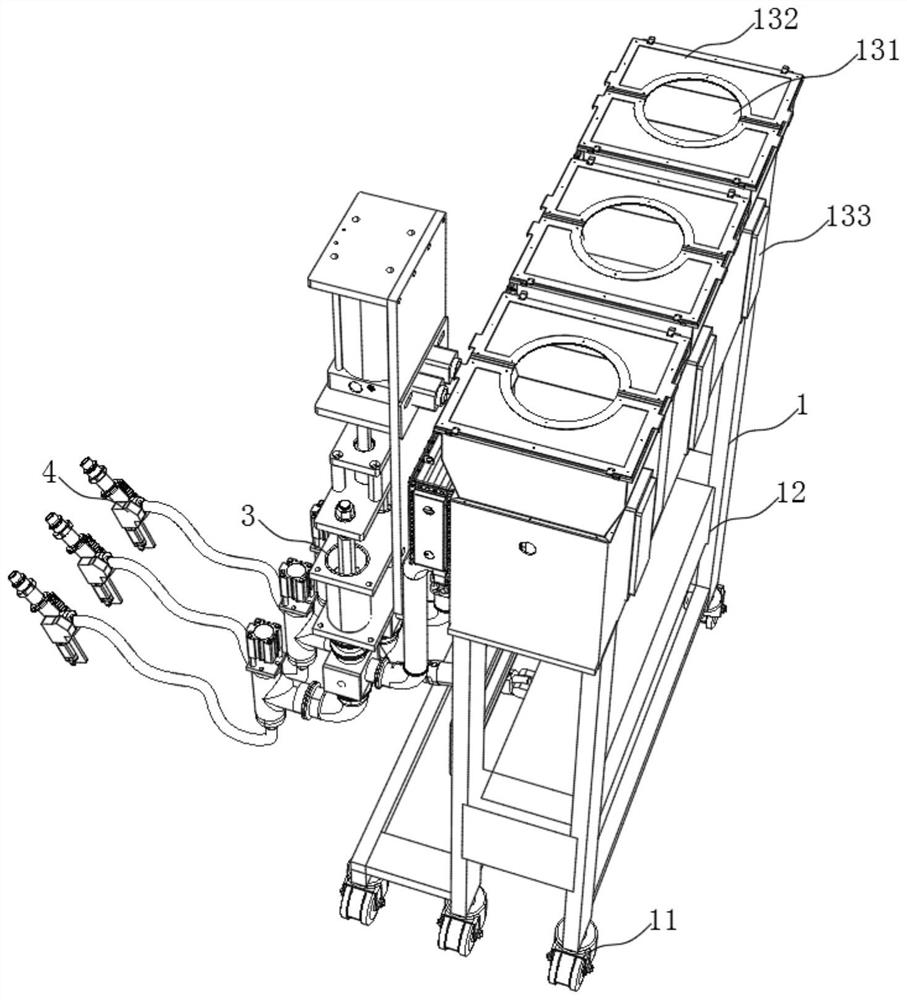

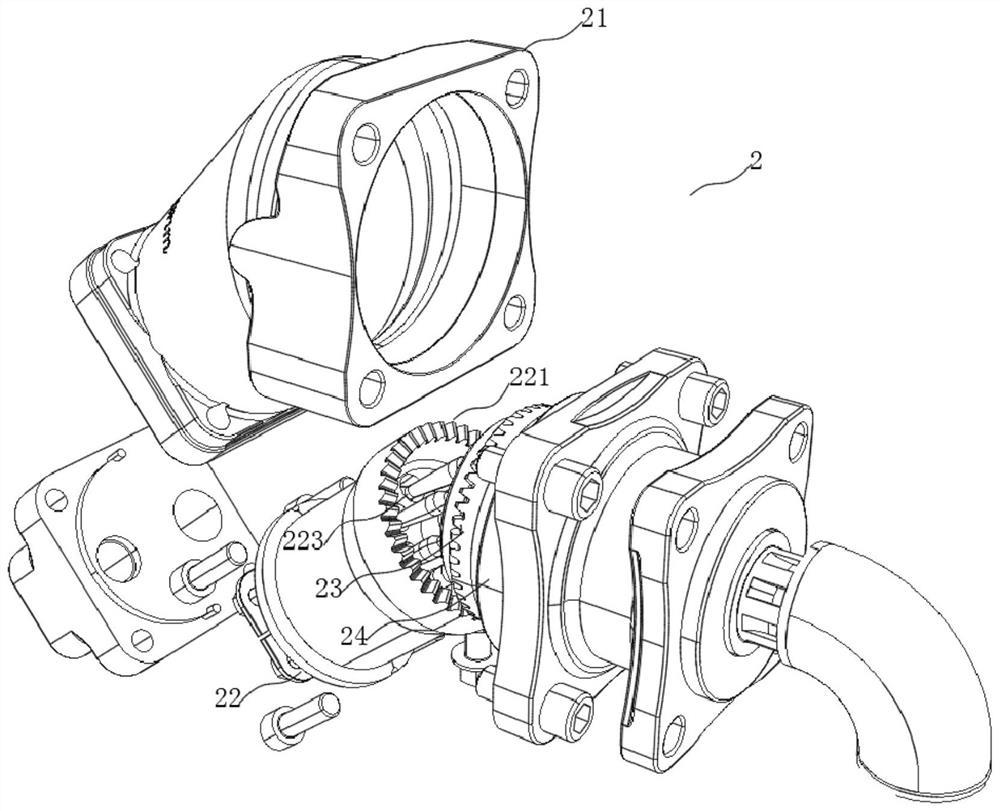

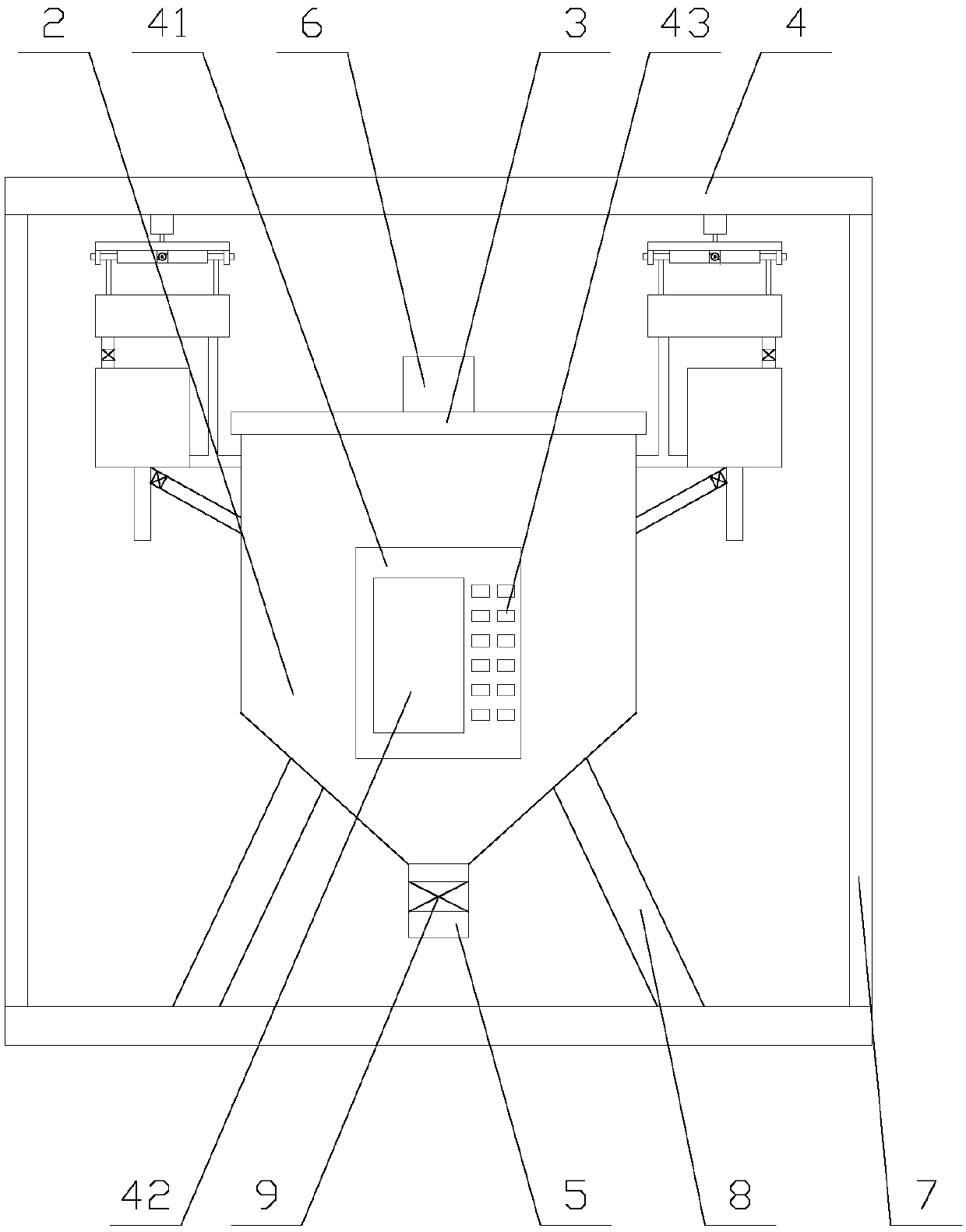

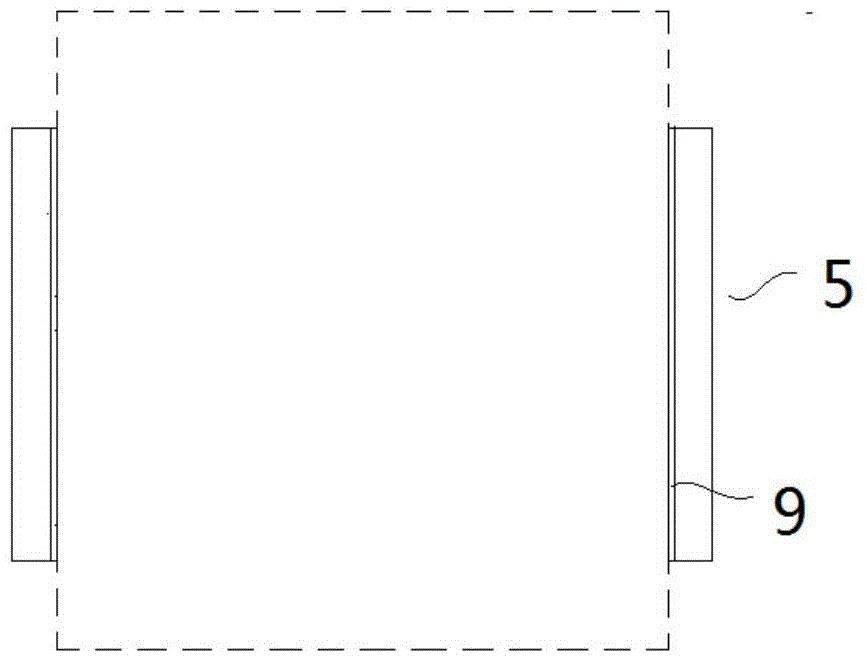

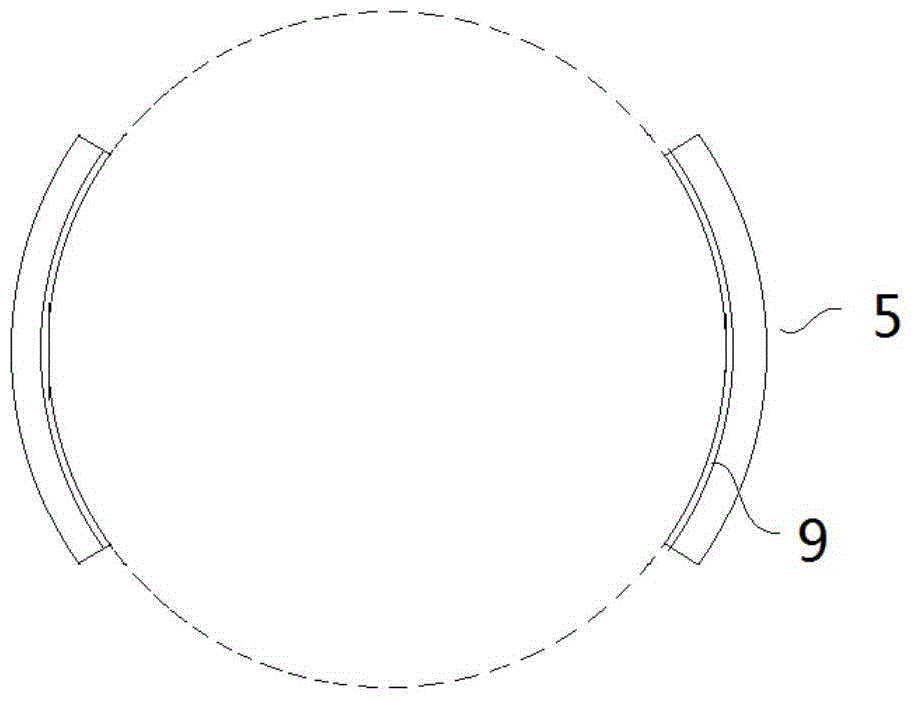

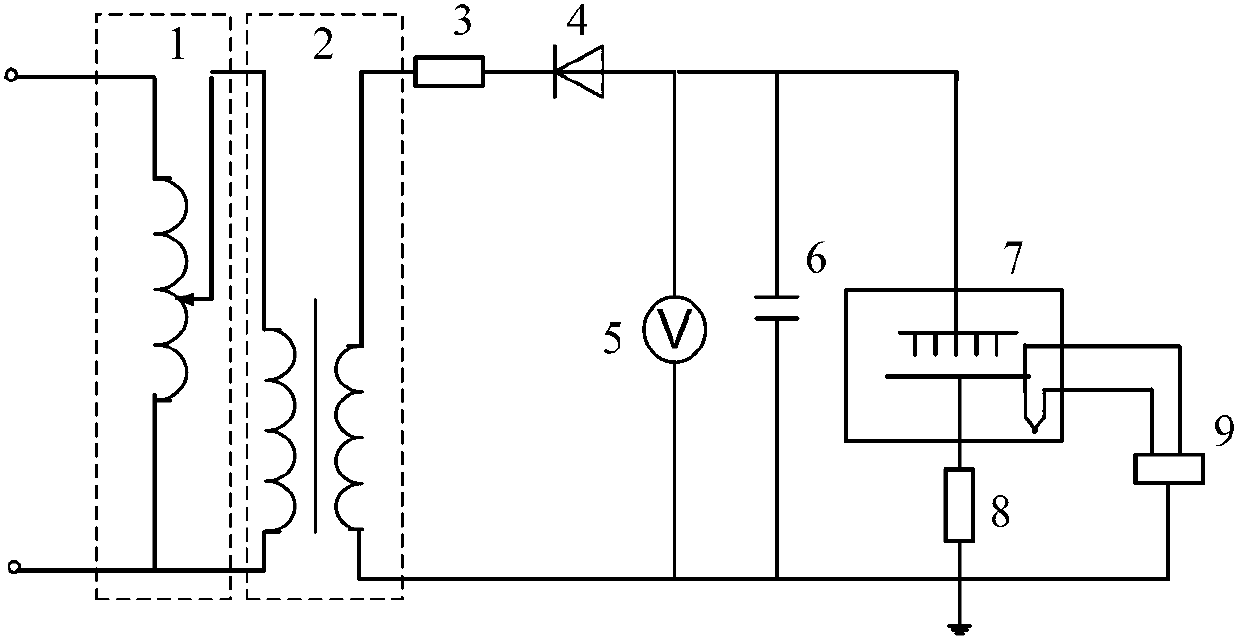

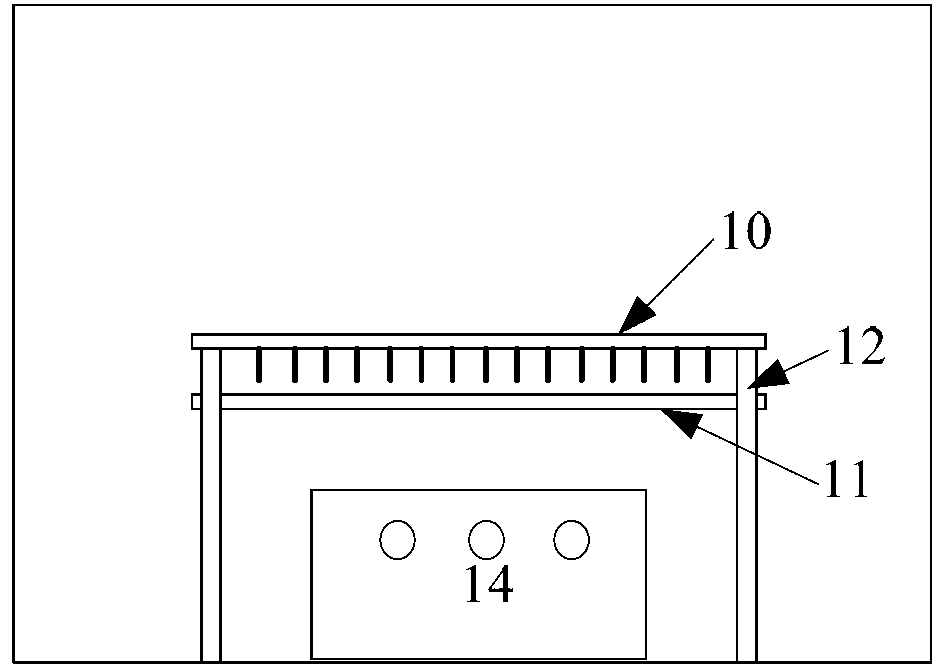

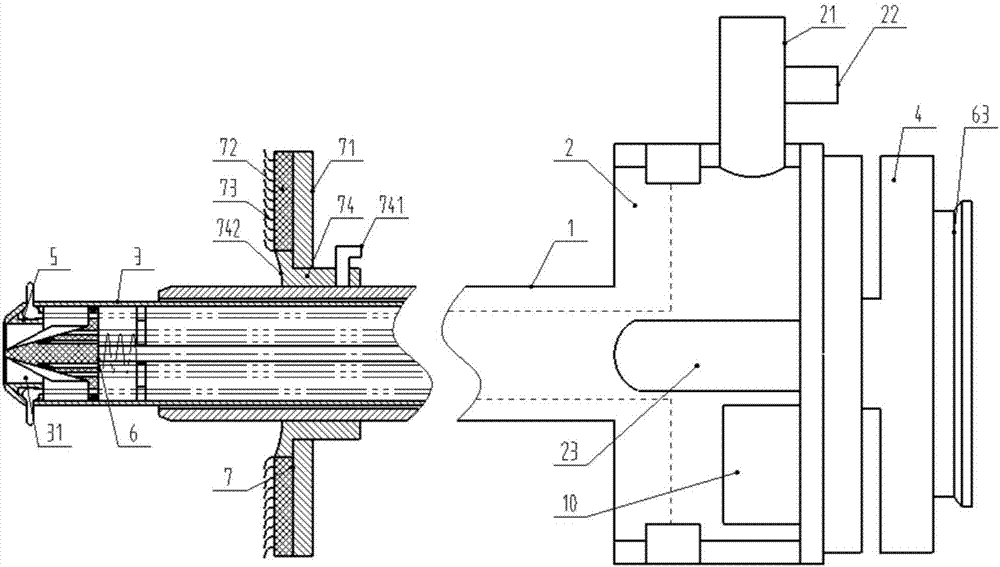

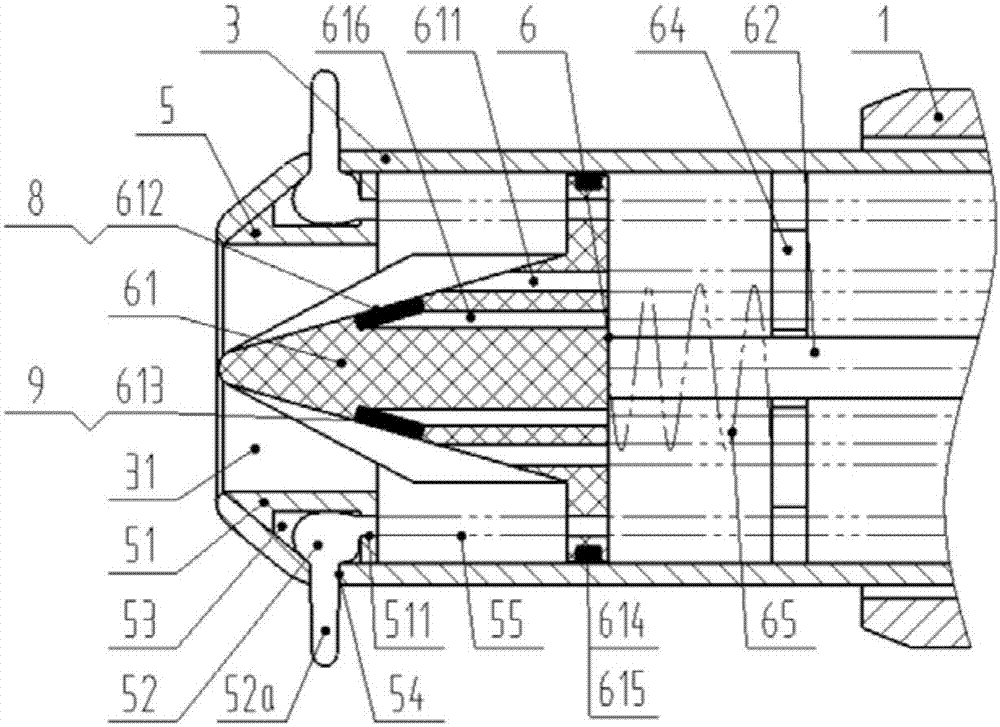

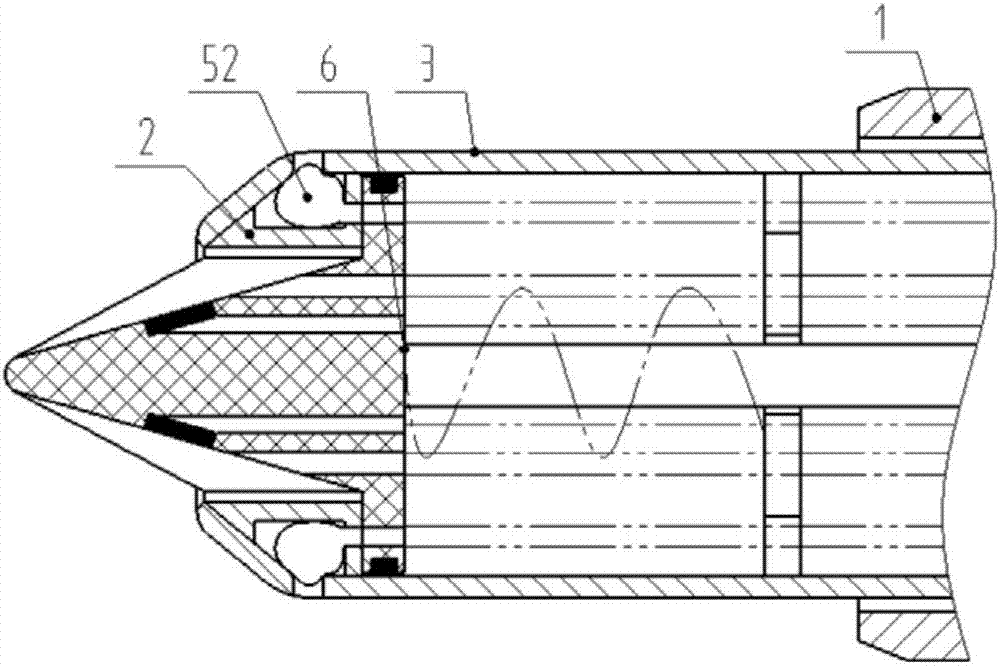

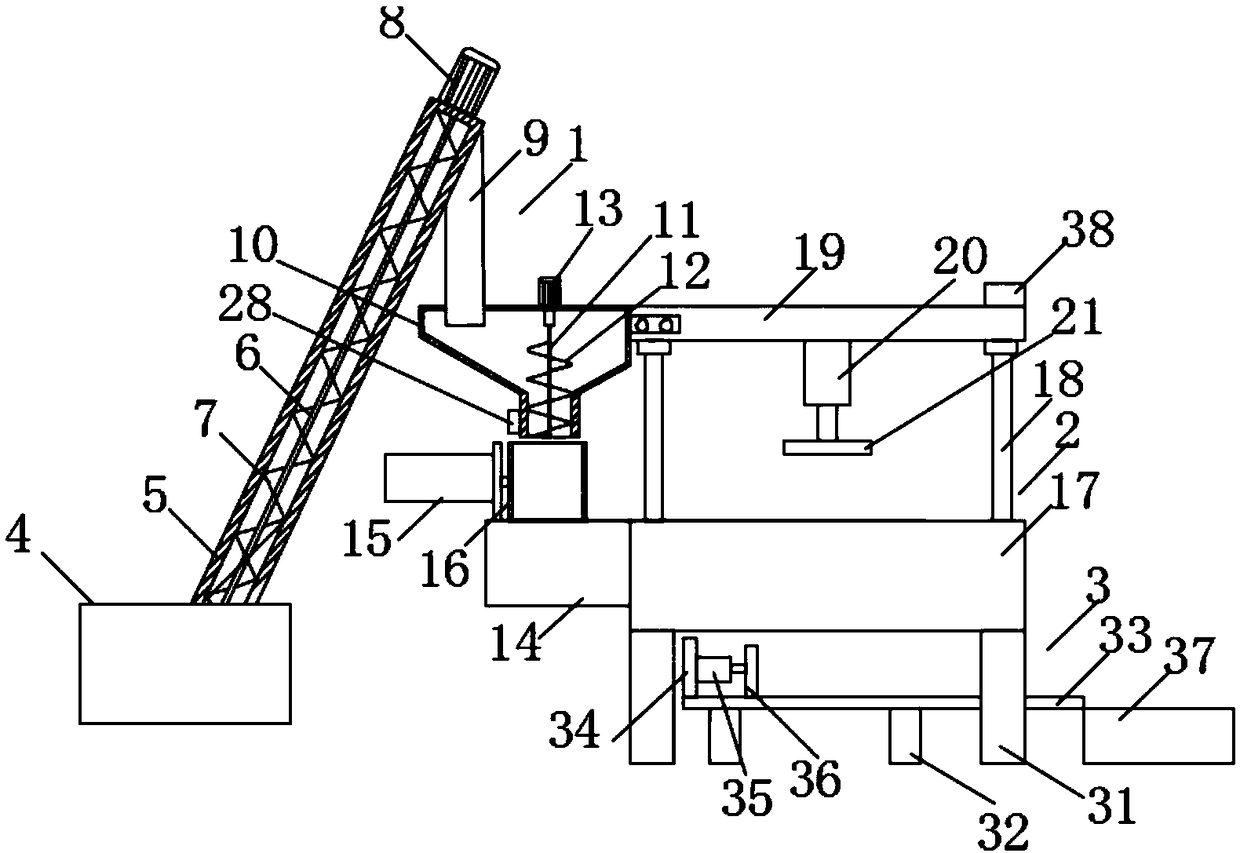

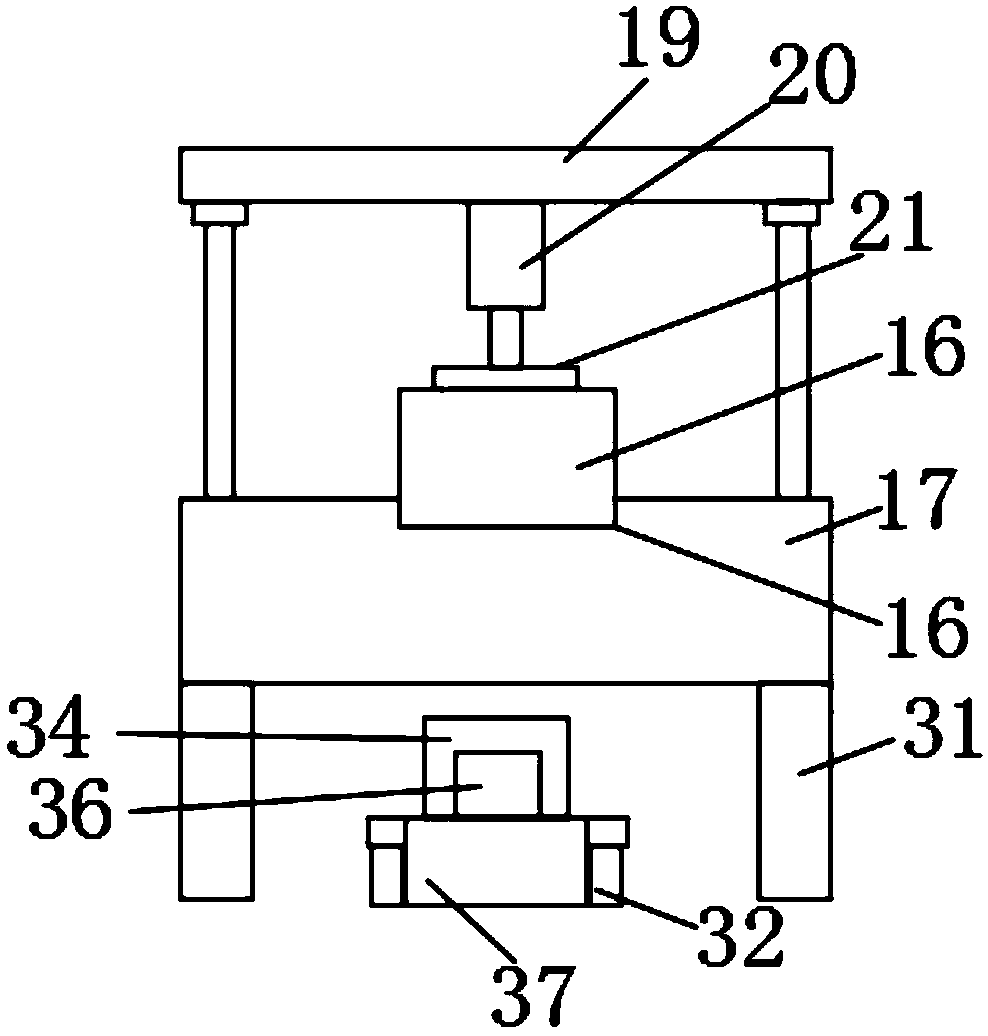

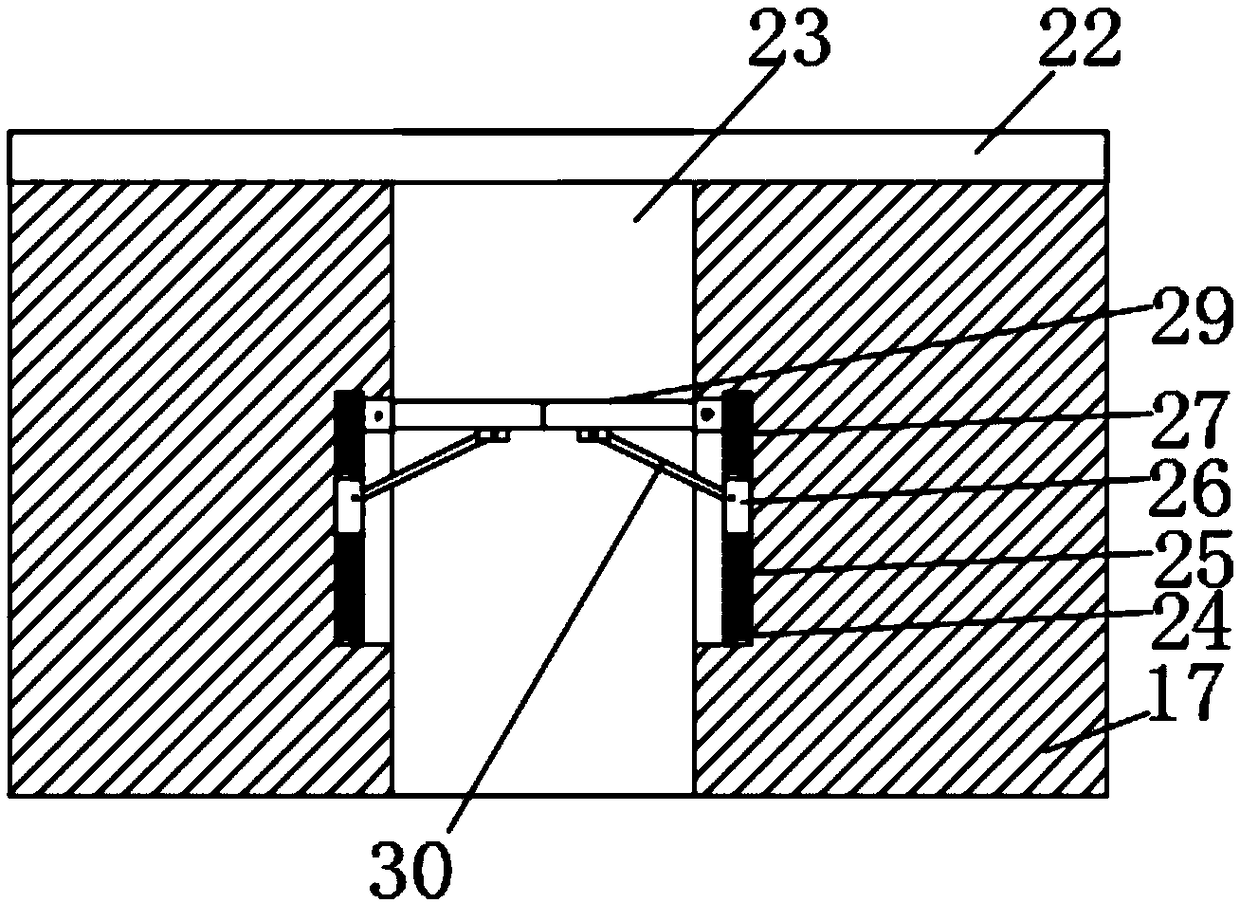

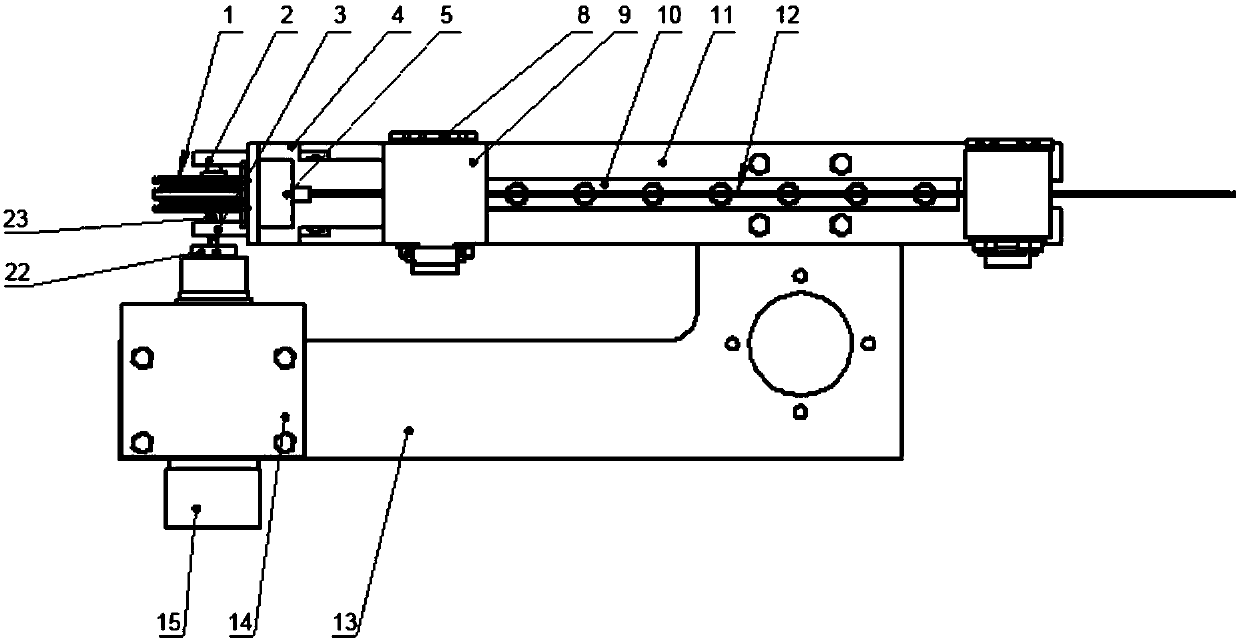

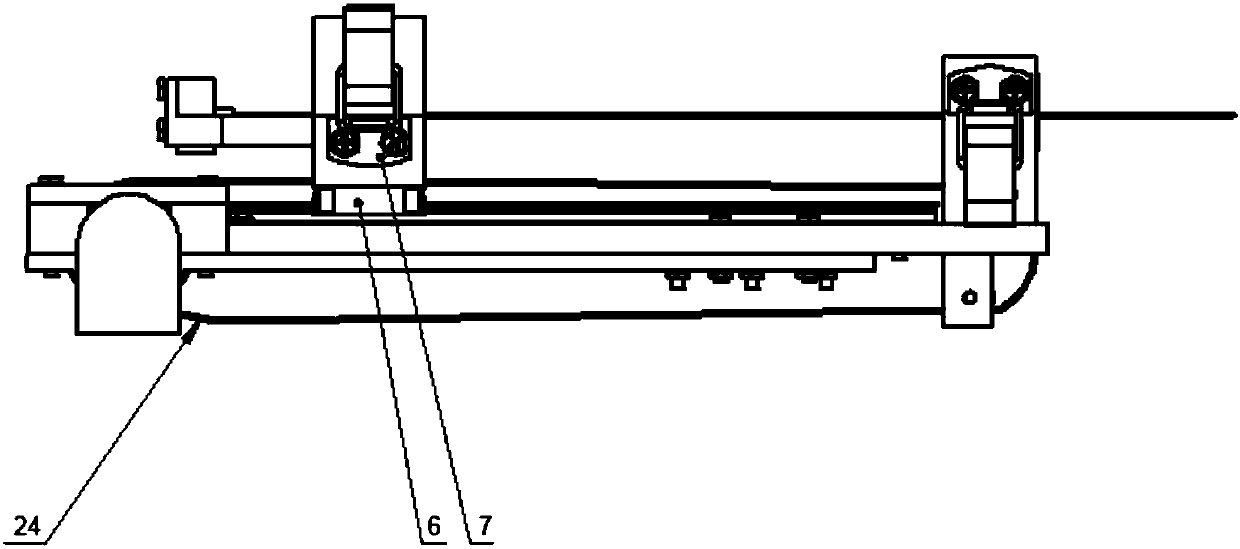

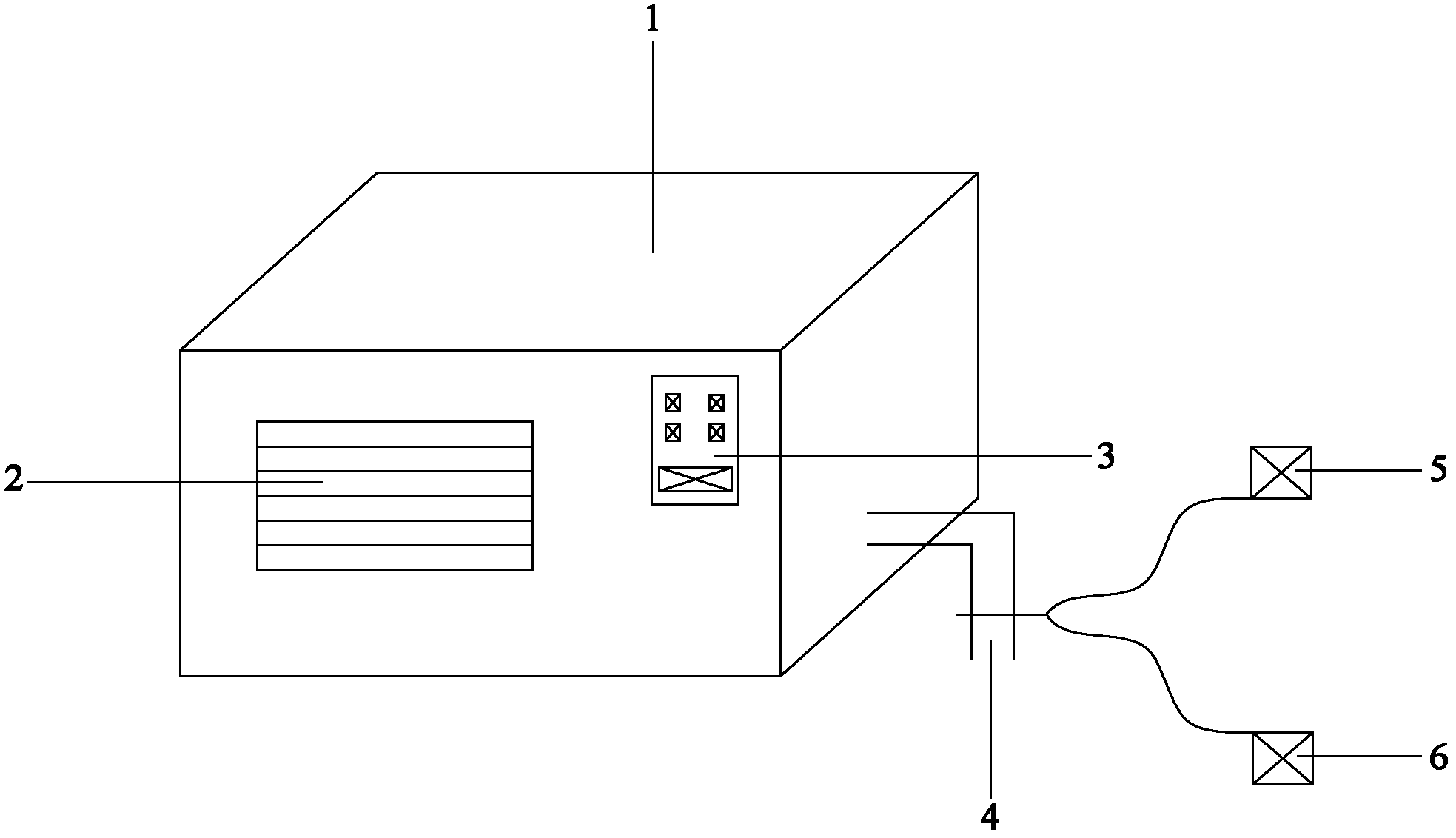

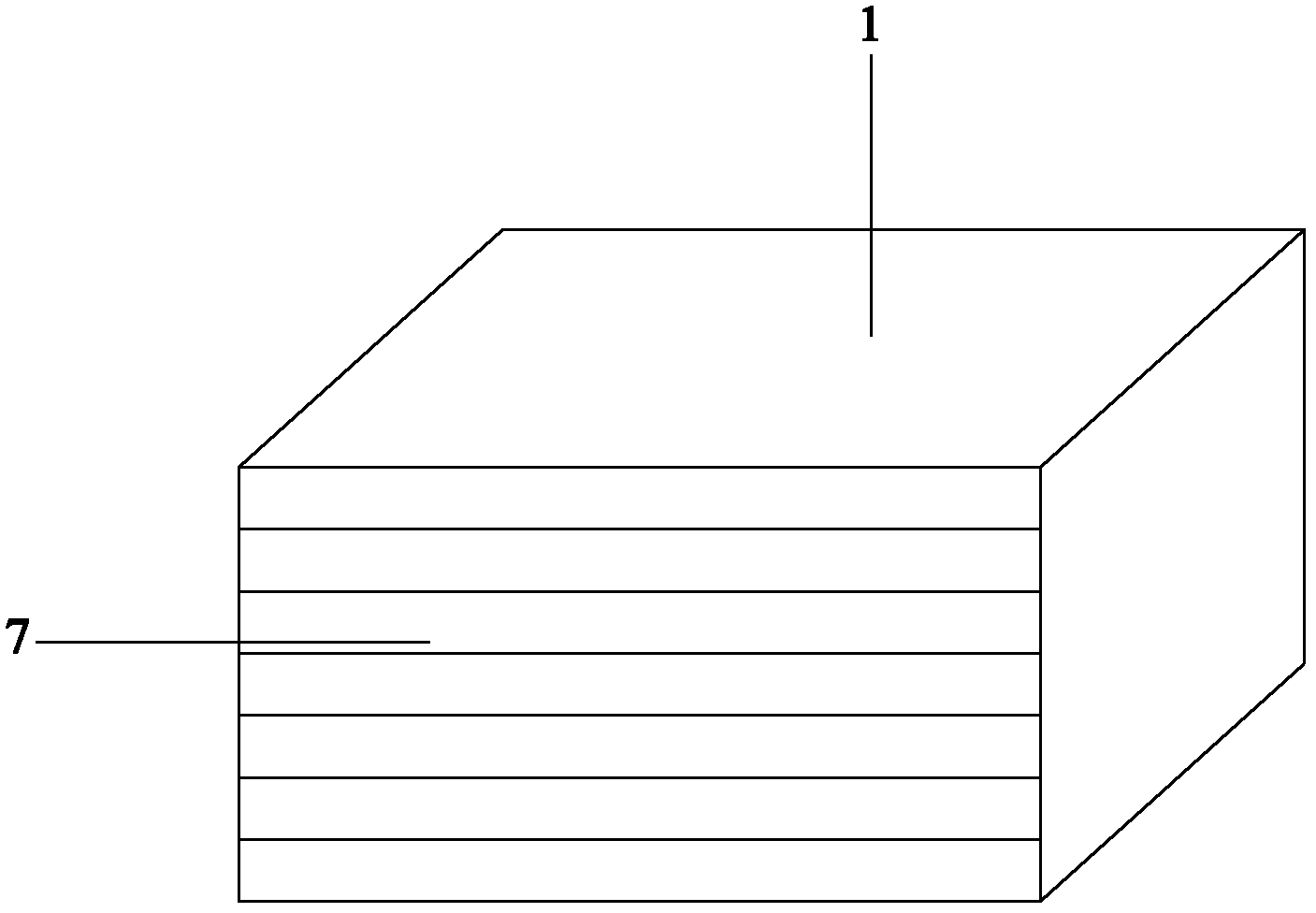

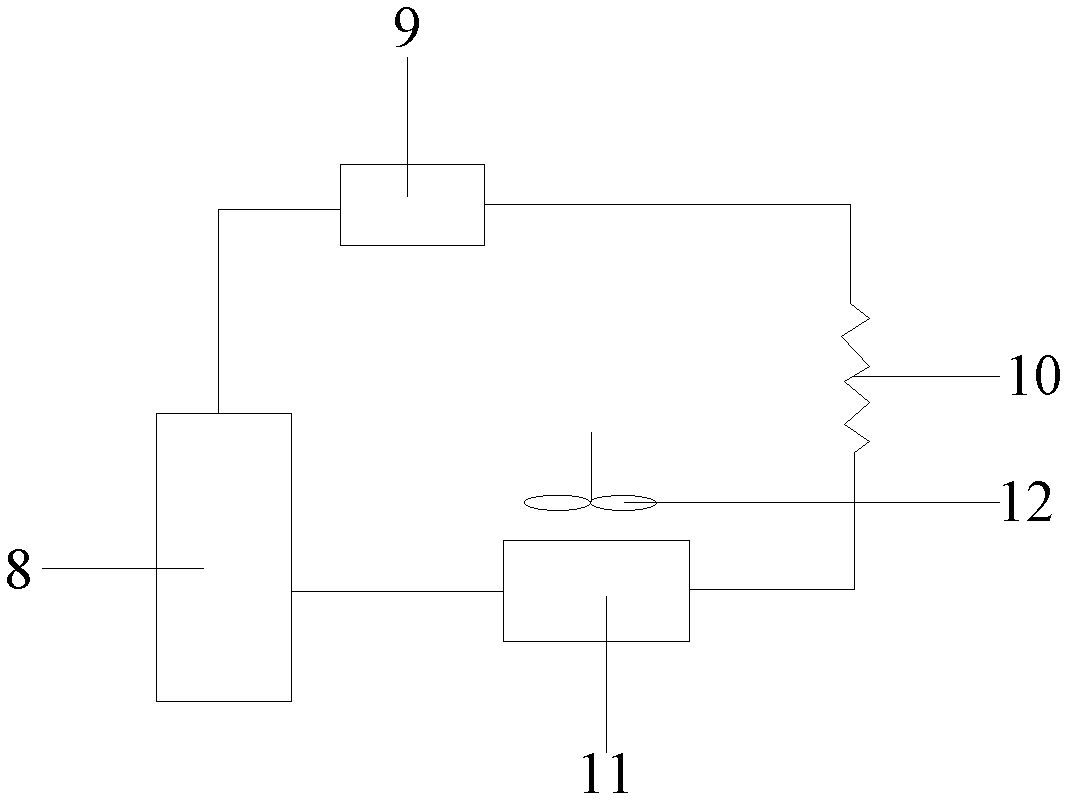

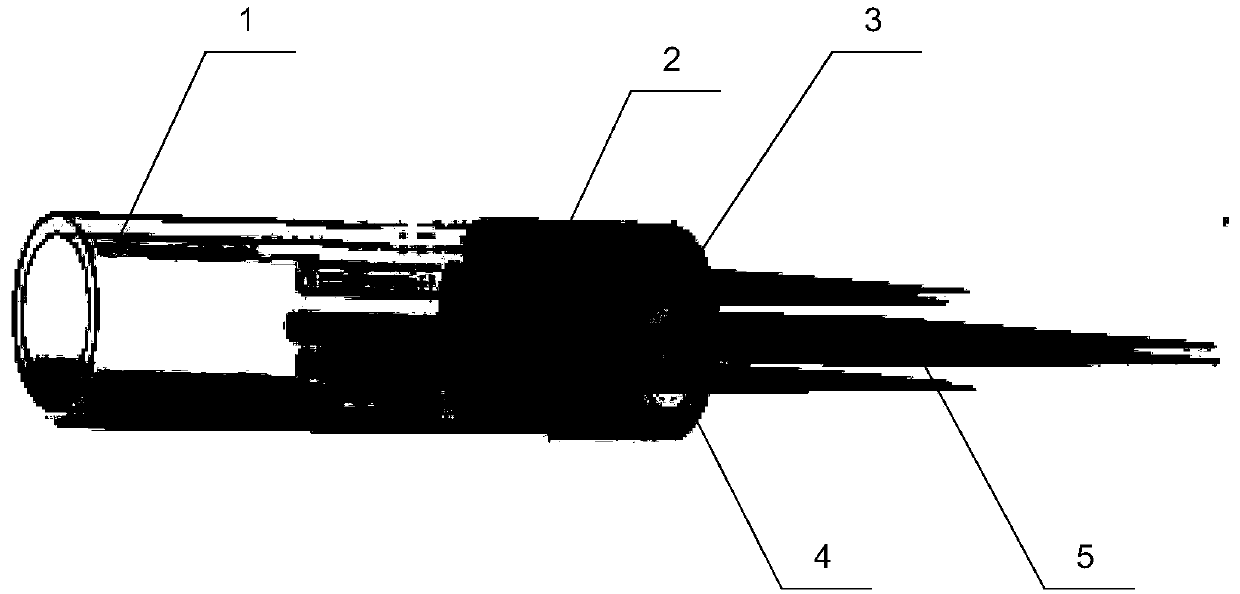

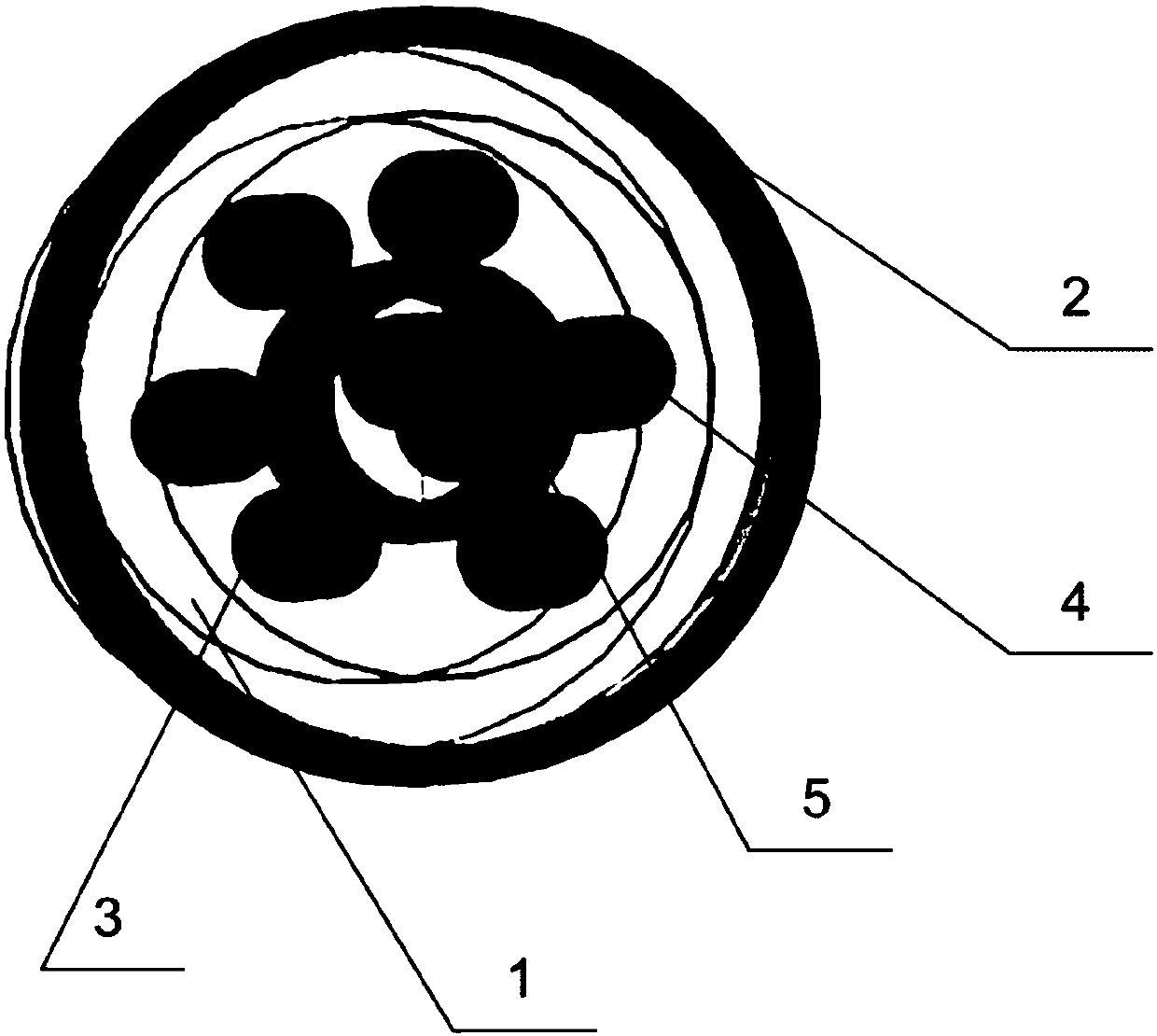

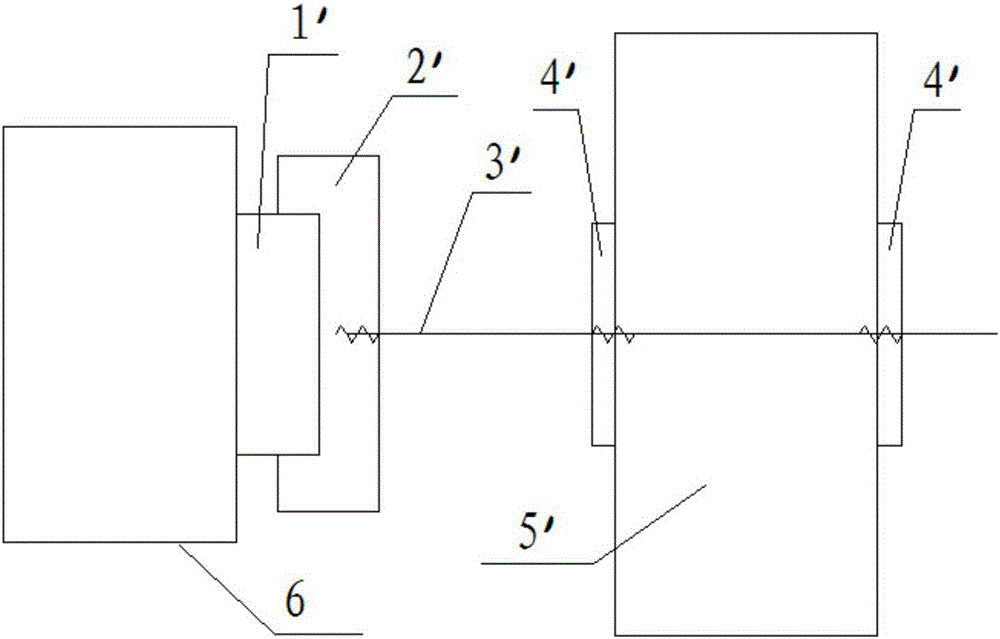

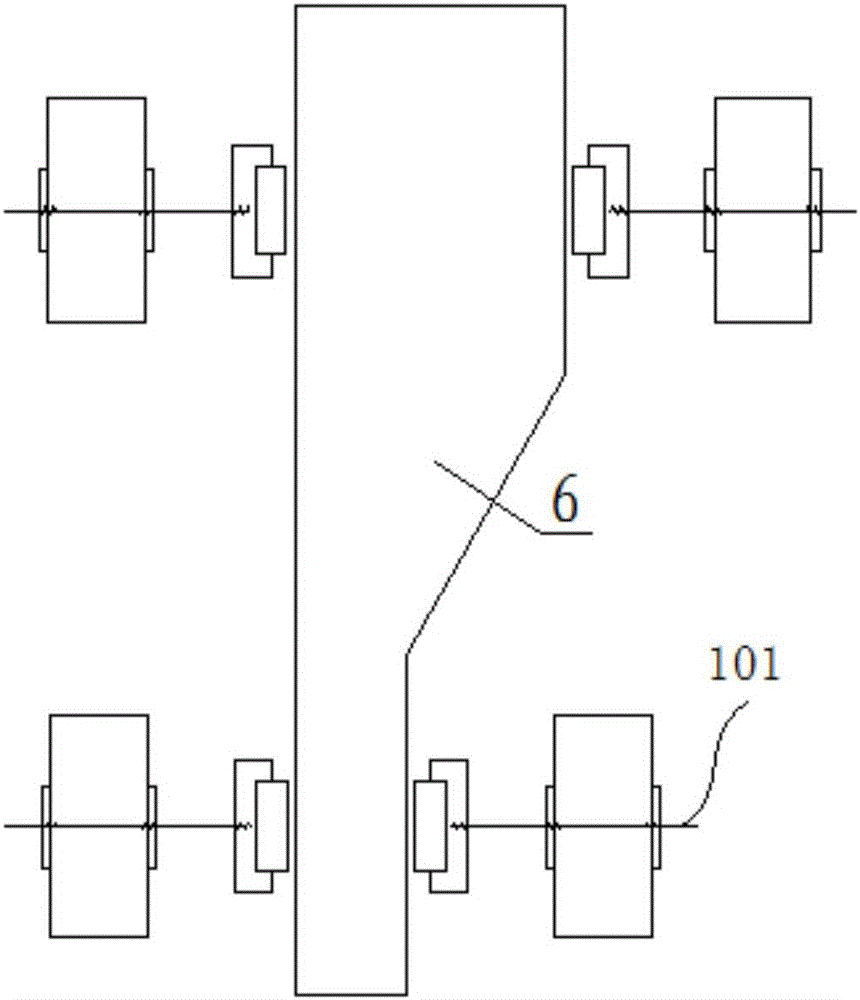

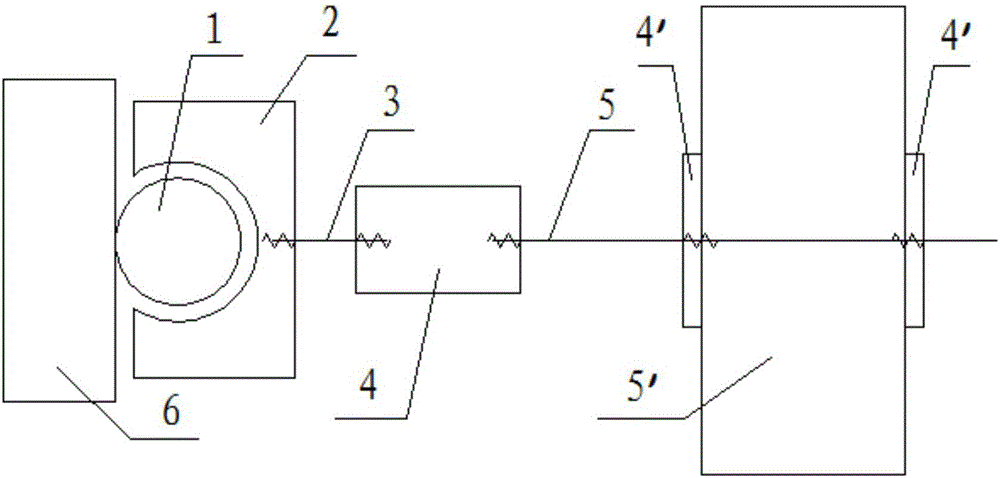

Automatic synthesis device and method of sodium fluoride [< 18 > F] injection

PendingCN113332142ASimple and fast operationImprove efficiencyPharmaceutical product form changeSodium Chloride InjectionHigh doses

The invention discloses an automatic synthesis device and method of a sodium fluoride [< 18 > F] injection. The synthesis device comprises an < 18 > F <-> supply device, a sodium chloride injection supply device, a sterilization injection water supply device, a first three-way valve group, a QMA column, a second three-way valve group, a sodium fluoride [< 18 > F] injection receiving device and a waste liquid recovery bottle group, the <18>F <-> supply device, the sodium chloride injection supply device and the sterilization injection water supply device are respectively connected with the first three-way valve group, the QMA column, the second three-way valve group and the waste liquid recovery bottle group in series, and are selectively communicated under the control of the first three-way valve group and the second three-way valve group. Compared with a traditional manual mode, the automatic synthesis device of the sodium fluoride [< 18 > F] injection has the advantages that the efficiency is high, the operation is simple and convenient, the clinical use requirement of sterility and no pyrogen can be ensured through a clamping sleeve type structural design, and operators can be prevented from receiving high-dose radioactive radiation.

Owner:HTA CO LTD

Anti-infection quantitative medicine applying device and method for dermatological department

InactiveCN112156351AEasy to controlAvoid discomfortMedical devicesMedical applicatorsDermatology departmentElectric machinery

The invention provides an anti-infection quantitative medicine applying device and method for the dermatological department. The anti-infection quantitative medicine applying device comprises a fixingframe, a plurality of sliding wheels are fixedly mounted on the two sides of the bottom end of the fixing frame, a mounting base is fixedly mounted on one side of the middle of the fixing frame, three quantitative medicine boxes are fixedly mounted at the top of the fixing frame, and feeding ports are formed in the tops of the three quantitative medicine boxes; and box covers are hinged to the two edges of the inner sides of the quantitative medicine boxes through hinges, and quantitative medicine distributing mechanisms are mounted in the quantitative medicine boxes. According to the anti-infection quantitative medicine applying device and method, a driving motor rotates to drive a driving gear and a driven gear to be in engaged connection, so that in the process of the driven gear, a conical cylinder in a groove is driven to mechanically stretch out and draw back along with rotation of a column body, thus medicine in a medicine dispensing shell is quantitative conveyed, liquid medicine is absorbed and conveyed through centrifugal force generated in the rotating process of the driving motor, the quantitative liquid medicine can be conveniently subjected to quantity control, and the medicine applying effect is improved.

Owner:陈荣举

Intelligent raw material grinding and mixing device for car brake pad production

InactiveCN107715999AImprove grinding efficiencyGuaranteed grinding accuracyRotary stirring mixersTransportation and packagingPre treatmentEngineering

The invention relates to an intelligent raw material grinding and mixing device for car brake pad production. The intelligent raw material grinding and mixing device comprises a stirring cylinder, a top plate, a discharging pipe, a first motor, a stirring mechanism and at least two pretreatment mechanisms. Each pretreatment mechanism comprises a grinding mechanism and a material control mechanism,each grinding mechanism comprises a second motor, a rotary disc, a grinding box and at least two grinding assemblies, and each material control mechanism comprises a material control chamber. Each material control chamber is internally provided with a material control assembly, and each material control assembly comprises a third motor, an eccentric wheel, an adjusting unit, a first connecting rod, a second connecting rod and a plug plate. According to the intelligent raw material grinding and mixing device for car brake pad production, materials are ground through the grinding mechanisms toenable the materials to be refined and powdered, so that quantitative control and material mixing are facilitated, and the grinding accuracy is ensured; and not only that, accurate control over the material use quantity is achieved through the material control mechanisms, and the material control mechanisms are simple in structure and easy to operate and execute, so that the production cost of thedevice is reduced, and the practicability of the device is improved.

Owner:泉州德化宇胜技术咨询有限公司

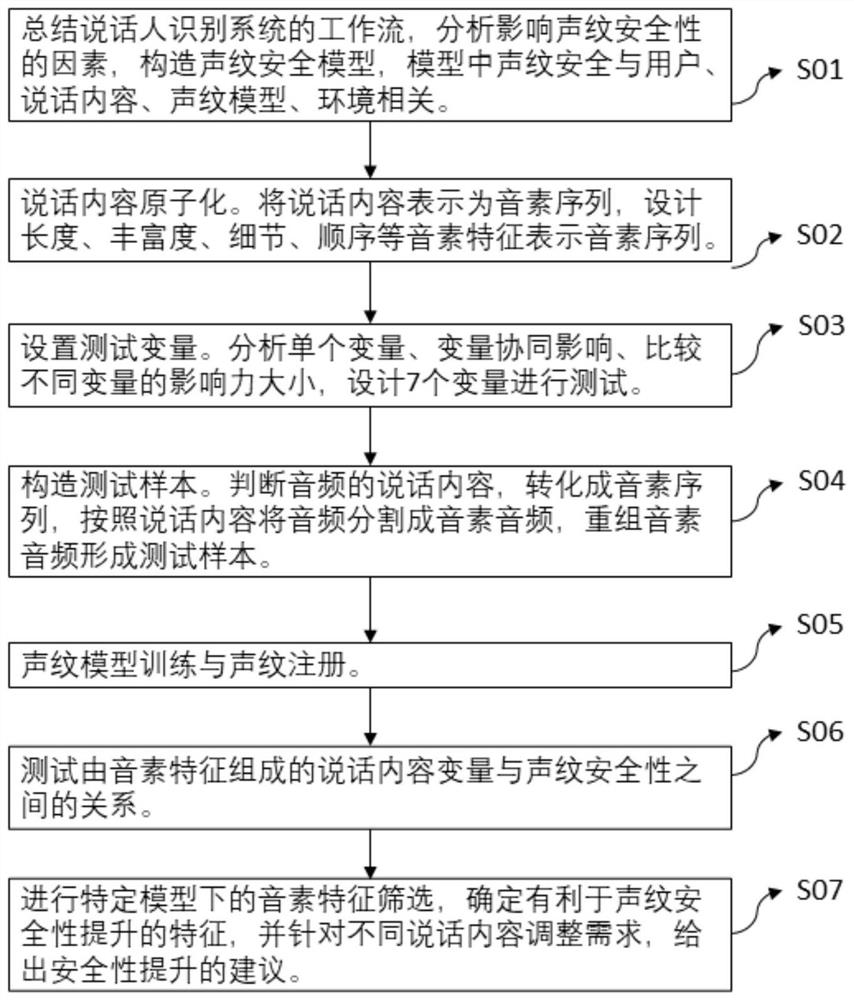

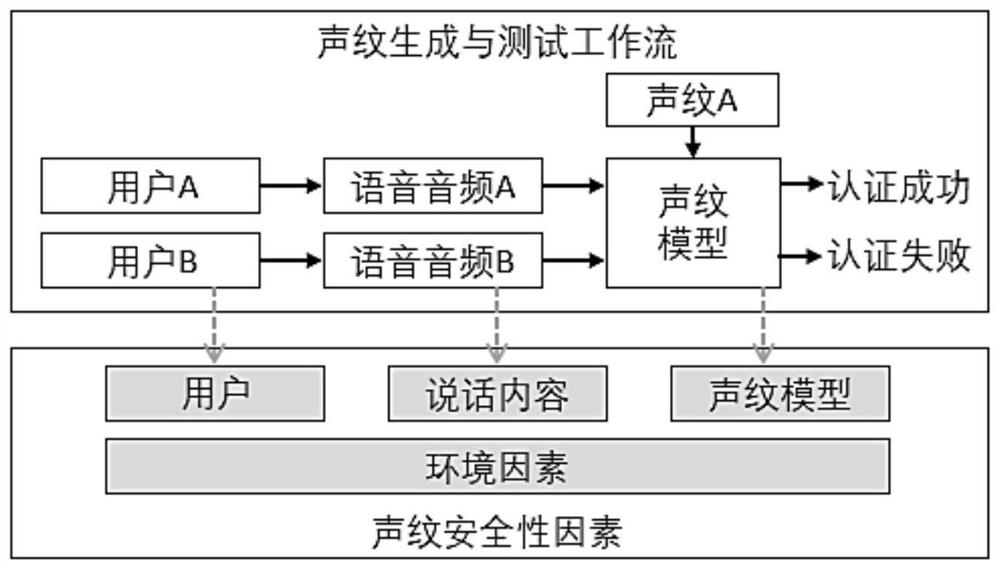

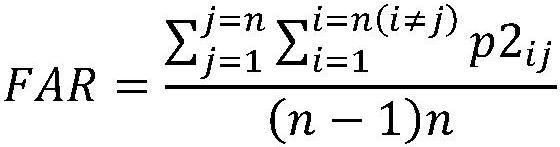

Method for improving voiceprint security

ActiveCN114360553AImprove audio characteristicsEasy to quantitative controlSpeech recognitionNatural language processingTest sample

The invention discloses a method for improving voiceprint security, and belongs to the technical field of speaker recognition security in an intelligent voice system. Comprising the steps of constructing a voiceprint security model; atomizing the speaking content; setting a test variable; constructing a test sample; voiceprint security model training and voiceprint registration are carried out; calculating the misrecognition rate change under the single-step change of the three feature variables of richness, length and details to obtain the weight relationship of the feature variables; for the original authentication word to be authenticated, extracting phoneme features of the original authentication word, and obtaining a misrecognition rate of the original authentication word; and comparing the misrecognition rate with a threshold value, if the misrecognition rate is less than or equal to the threshold value, indicating that the voiceprint is safe, and if the misrecognition rate is greater than the threshold value, optimizing the original authentication word according to the weight relationship of the feature variables. Different from the research trend of improving a voiceprint model and audio characteristics in the existing method, the method provided by the invention aims at improving the voiceprint safety by optimizing the speaking content, and any existing or improved voiceprint model can be compounded.

Owner:ZHEJIANG UNIV

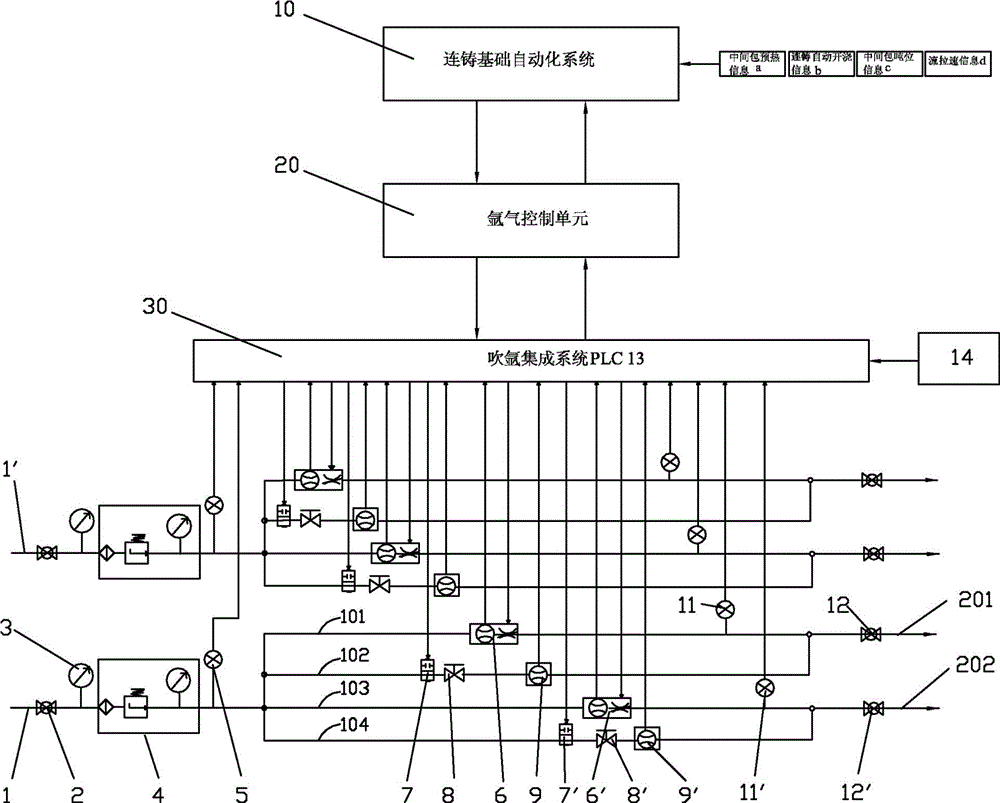

A method for automatic control of argon blowing in continuous casting crystallizer

ActiveCN104249138BEasy to quantitative controlImprove the effect of automatic controlAutomatic controlProgrammable logic controller

The invention relates to an argon blowing automatic control method of a continuous casting crystallizer. A continuous casting argon blowing system comprises an argon control unit and an argon blowing integration system of the continuous casting crystallizer, wherein the argon control unit comprises a PLC (programmable logic controller) and a communication port, the argon blowing integration system is used for receiving a sending instruction from a continuous casting basic automatic system, the continuous casting basic automatic system is used for sending the information including tundish preheating, continuous casting automatic casting, tundish tonnage, flowing speed, drawing speed and the like, and each argon blowing integration unit is used for uploading the detected actual argon flow rate value, pressure value and back pressure value to the continuous casting basic automatic system through the argon control unit. The method has the advantages that according to the production characteristics of continuous casting, by utilizing the called correlation information of automatic control, argon blowing actual performance and slab production actual performance during the interlocking of argon blowing and continuous casting production links, the particular argon prescription can be automatically called in various continuous casting production links and especially under the non-stable casting state, so the liquid level control stability of the crystallizer is improved, the flowing rate of meniscus of the crystallizer is controlled, the inclusion defect of casting blanks is reduced, and the abnormal expansion is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD +1

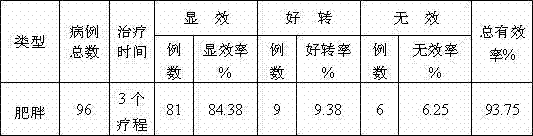

Drug for reducing weight and beautifying facial appearance and preparation method thereof

ActiveCN102805826AEffective treatmentNot easy to dissolveMetabolism disorderAluminium/calcium/magnesium active ingredientsPharmacologyMedicine

The invention discloses a drug for reducing weight and beautifying facial appearance and a preparation method thereof. The drug is mainly prepared by adopting drugs of siberian cocklour fruit, iris ensata thunb, uniflower swisscentaury roots, poisonous buttercup herbs, evening primrose, cassia seeds, and the like according to a certain weight ratio. The drug performs the functions of clearing away heat and toxic materials, inducing diuresis and purging heat, is used for reducing weight and beautifying the facial appearance and has the advantages of quick effectiveness, good curative effect and high cure rate.

Owner:ANHUI HUIEN BIOTECH

Hermertia illucens ovum collector

InactiveCN104585136ARealize batch transferMaintain biological activityAnimal husbandryEngineeringFeeding techniques

The invention belongs to the technical field of insect artificial feeding, and particularly relates to a hermertia illucens ovum collector. The hermertia illucens ovum collector comprises multiple layers of ovum collecting frames in stacked arrangement, each ovum collecting frame comprises a frame body, a sieve plate and ovum collecting units, wherein the adjacent ovum collecting frames are in stacked arrangement through the frame bodies, each sieve plate is horizontally arranged in the corresponding frame body, the ovum collecting units are uniformly embedded in the corresponding sieve plate one by one in a way capable of being pulled away, an ovum collecting cavity is formed inside each ovum collecting unit, the upper end of each ovum collecting unit is provided with a spawning hole, and each spawning hole is communicated with the corresponding ovum collecting cavity. The hermertia illucens ovum collector has the advantages that multiple layers of stacked ovum collecting frames are adopted, so ova can be transported in batch in a concentrated way, meanwhile, the ovum collecting units are adopted for collecting the ova, and the ova collected in each batch can be counted.

Owner:西安洁姆环保科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Automatic synthesis device and method of sodium fluoride [< 18 > F] injection Automatic synthesis device and method of sodium fluoride [< 18 > F] injection](https://images-eureka.patsnap.com/patent_img/824c29d6-5a5c-44a6-bbb3-11ecaa864f83/HDA0003108529710000011.png)

![Automatic synthesis device and method of sodium fluoride [< 18 > F] injection Automatic synthesis device and method of sodium fluoride [< 18 > F] injection](https://images-eureka.patsnap.com/patent_img/824c29d6-5a5c-44a6-bbb3-11ecaa864f83/HDA0003108529710000012.png)

![Automatic synthesis device and method of sodium fluoride [< 18 > F] injection Automatic synthesis device and method of sodium fluoride [< 18 > F] injection](https://images-eureka.patsnap.com/patent_img/824c29d6-5a5c-44a6-bbb3-11ecaa864f83/HDA0003108529710000021.png)