Ammonia spraying device used for improving uniformity of ammonia gas distribution

A technology with uniform distribution and ammonia gas, applied in the field of denitrification system engineering, can solve the problems of uneven mixing of ammonia and flue gas, and achieve the effect of avoiding excessive nitrogen oxide emissions, improving uniformity, and facilitating mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

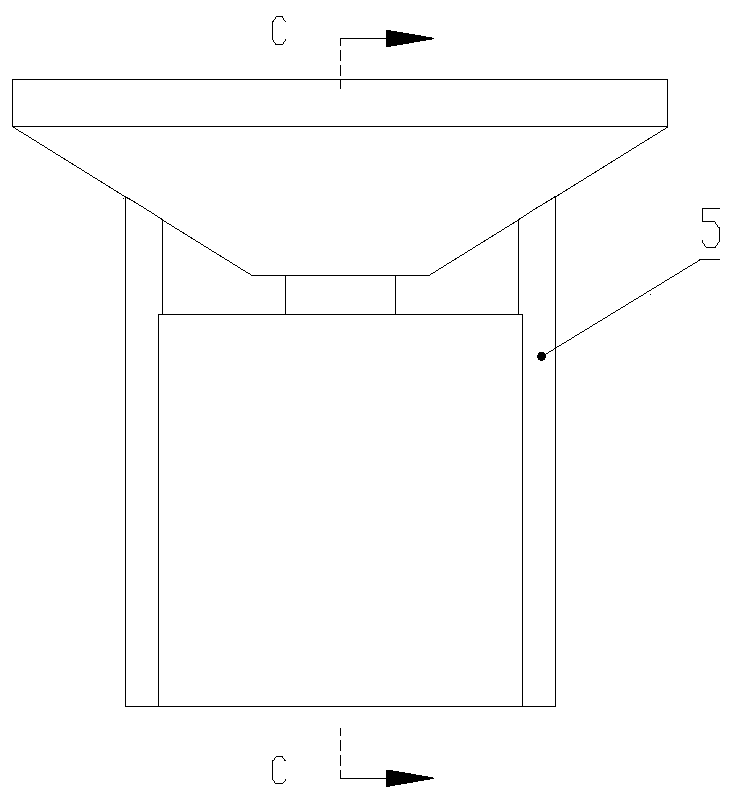

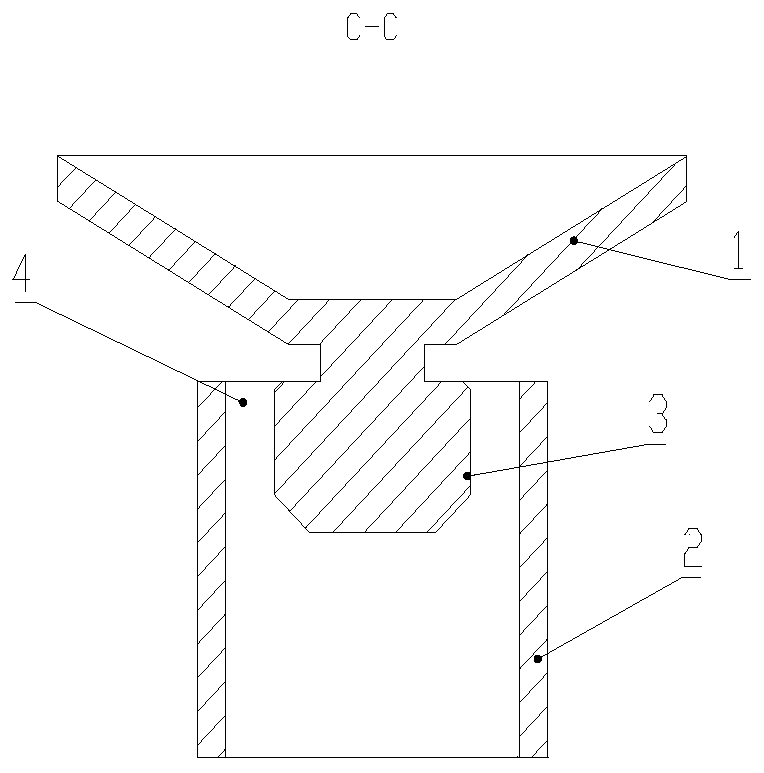

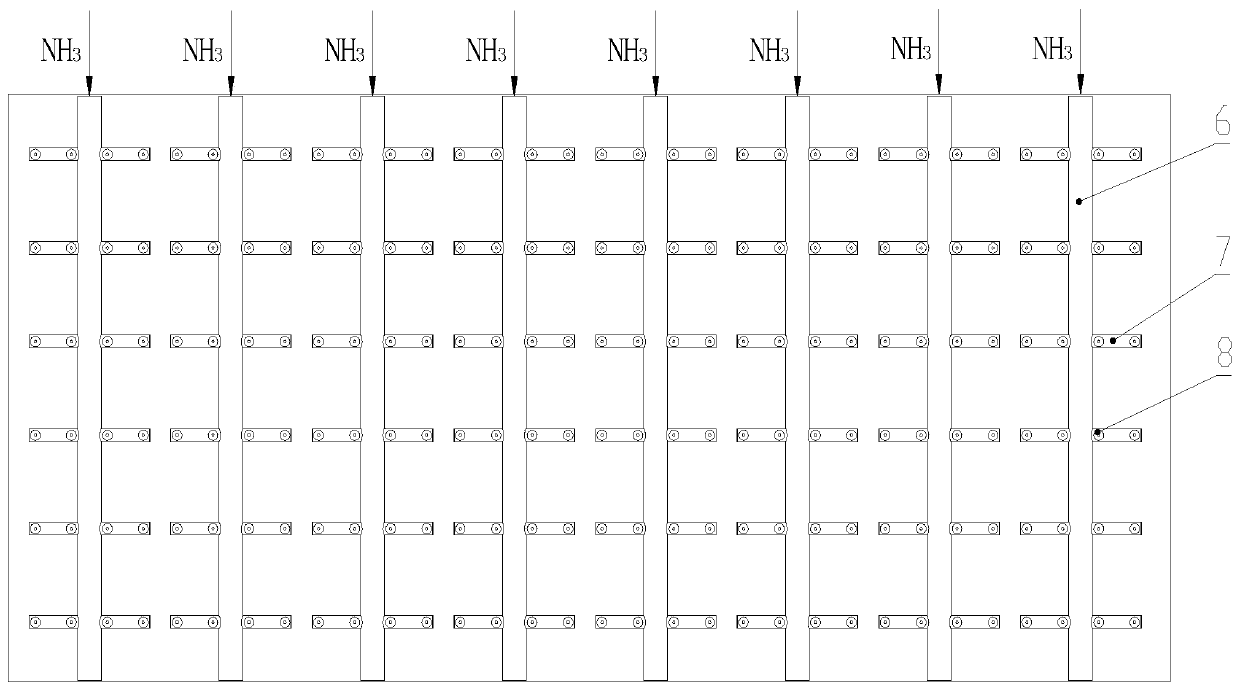

[0039] The present invention is used to improve the ammonia injection device of ammonia distribution uniformity, and the effective mixing embodiment of flue gas and ammonia in the application of this device is as follows:

[0040] Ammonia gas enters several first-stage ammonia injection branch pipes 6 from the ammonia injection main pipe outside the flue. Divided into several partitions. Multiple rows of secondary ammonia injection branch pipes 7 are evenly installed on both sides of each primary ammonia injection branch pipe 6, and the secondary ammonia injection branch pipes 7 evenly divide the flue section into several partitions in the vertical direction, and the interval between the secondary ammonia injection branch pipes is 500mm~700mm. Multiple nozzles 8 are installed on each secondary ammonia injection branch pipe 7, and the spacing density of the nozzles can be adjusted according to the actual flow field distribution of the flue gas.

[0041]The upper end of the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com