Device and method for multi-component atomizing and mixing

A technology of atomization device and mixing device, which is applied in the direction of spray device, liquid spray device, etc., to avoid the influence of purity, facilitate start-stop adjustment, and optimize the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

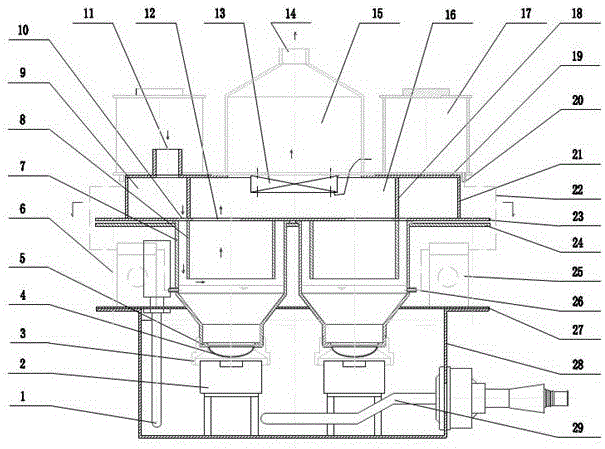

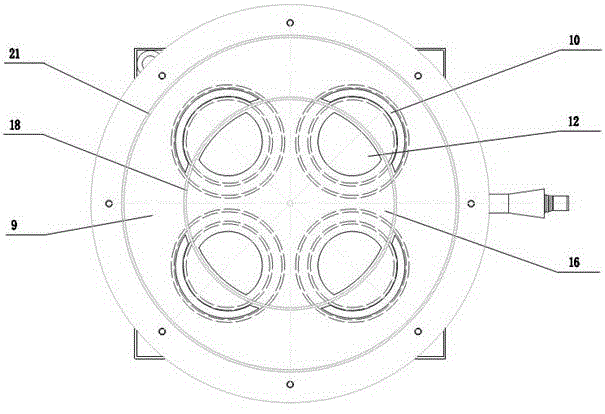

[0043] Example 1: if figure 1 , figure 2 As shown, a multi-component atomization and mixing device is characterized in that it includes: multiple atomization devices and mixing devices;

[0044] The atomizing device is used to atomize the liquid components, and is provided with a spray port (12);

[0045] The mixing device is a cavity, which communicates with a plurality of atomizing devices through the spray port (12), and is used for mixing the atomized droplets of various liquid components;

[0046] The atomizing device and the mixing device are provided with an air channel for air flow between the atomizing device and the mixing device.

[0047] The atomization device is an ultrasonic atomization device.

[0048] The atomization device includes an ultrasonic device (2), a solution cup (7), and an elastic film (4);

[0049] The solution cup (7) is a device with openings at both ends, and its side wall is provided with a liquid filling port (26);

[0050] The elastic f...

example 2

[0055] Example 2: if figure 1 , figure 2 As shown, a multi-component atomization and mixing device as shown in Embodiment 1 also includes a seat plate (27), a middle plate (23), a bottom plate (24), and a top plate (19);

[0056] The seat plate (27), the middle plate (23) and the bottom plate (24) are fixedly connected by a screw (6);

[0057] The bottom plate (24) is placed on the water tank (28), and is provided with an opening for passing the solution cup (7);

[0058] The seat plate (27) is arranged above the bottom plate (24) at a certain distance, and is provided with holes (preferably 2-8, uniformly arranged) for passing the solution cup (7), and the The solution cup (7) is fixed;

[0059] The middle plate (23) is arranged above the seat plate (27) at a certain distance, and is used to fix the guide ring (8), and its center overlaps with the center of the corresponding solution cup 7; the middle plate (23) A plurality of said mist exhaling ports (12) are provided; ...

example 3

[0070] Example 3: if figure 1 , figure 2 Shown, a kind of method of multi-component atomization mixing is characterized in that comprising the steps:

[0071] A. A variety of liquid components are atomized and dispersed into fine droplets;

[0072] B. The fine mist droplets formed by the atomization and dispersion of each component are mixed in one space.

[0073] The atomization in step A is ultrasonic atomization, the mixing in step B includes preliminary mixing and re-mixing, and the ultrasonic atomization is carried out in a water bath.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com