Bent axle box ventilation labyrinth

A crankcase ventilation and labyrinth technology, which is used in crankcase ventilation, engine components, machines/engines, etc., can solve the problems of long distance, high cost and complex structure of oil baffles, and increase the contact area and the number of collisions. , the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

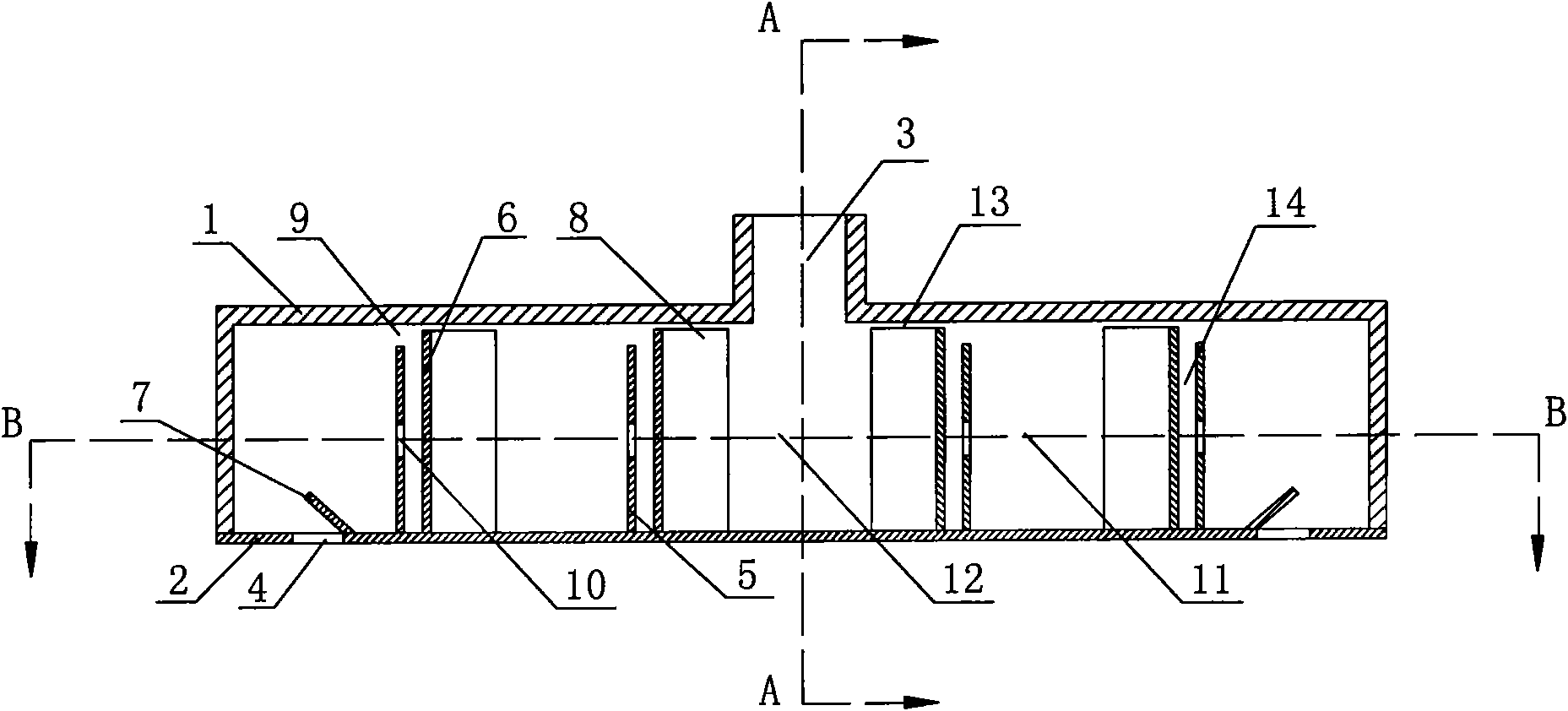

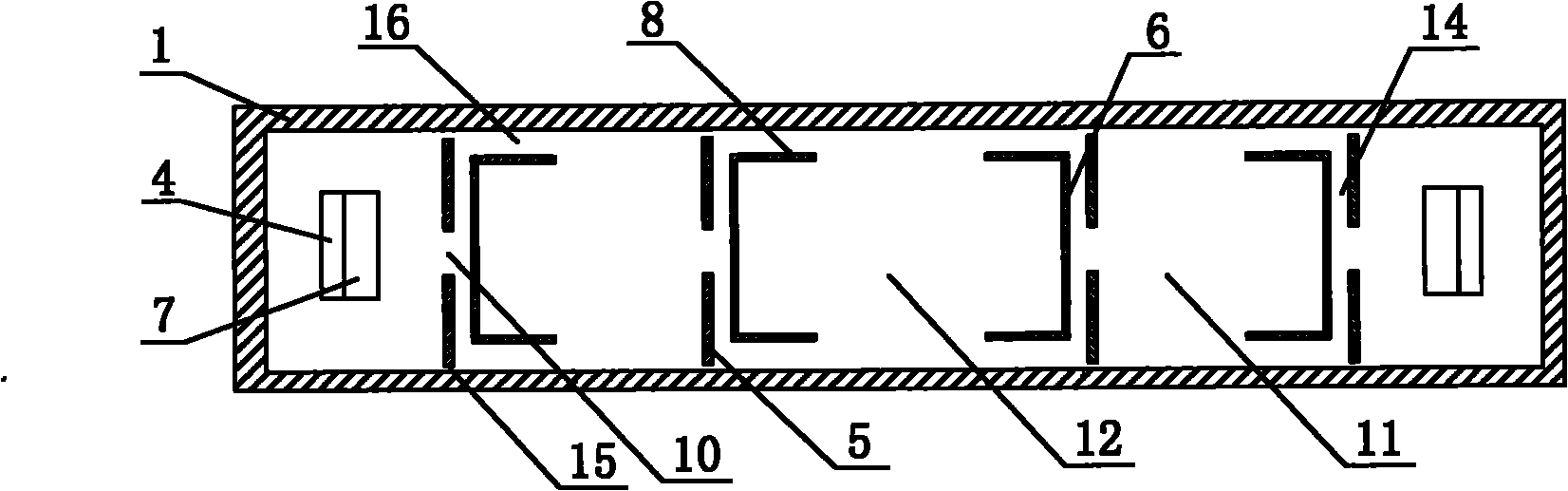

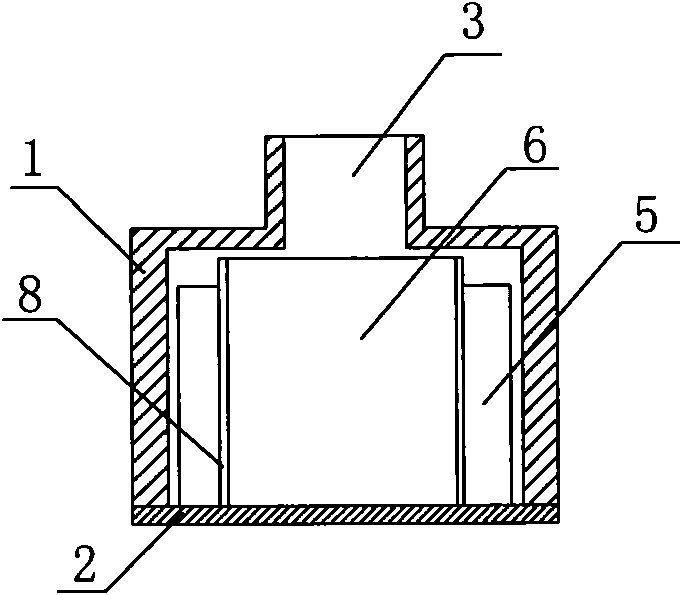

[0014] Such as figure 1 , 2 , 3, the main body of the crankcase ventilation labyrinth of the present embodiment is a cuboid cavity surrounded by the valve chamber cover 1 and the coaming plate 2, the top center of the main body has an air outlet 3, and the bottom two sides have Air inlet 4; two groups of partitions are arranged at intervals between the air outlet 3 and each air inlet 4, and each group of partitions consists of a first partition 5 near the direction of the air inlet 4 and a second partition near the direction of the air outlet 3. Composed of plates 6, the distance between the first partition 5 and the second partition 6 is 2-10 mm; there is a first air gap 9 of 1-10 mm between the top of the first partition 5 and the cover plate of the valve chamber cover 1, A through hole 10 with a diameter of 1-15mm is opened in the center of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com