Compression device for wood chip recovery

A technology of wood chips and support blocks, which is applied in wood processing appliances, bark area/debris/dust/waste removal, manufacturing tools, etc., can solve the problem of increasing power consumption and waste, inconvenience of one-time molding of wood chips, and inability to achieve energy saving and environmental protection and other problems, to achieve the effect of reducing the working process, saving working time and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

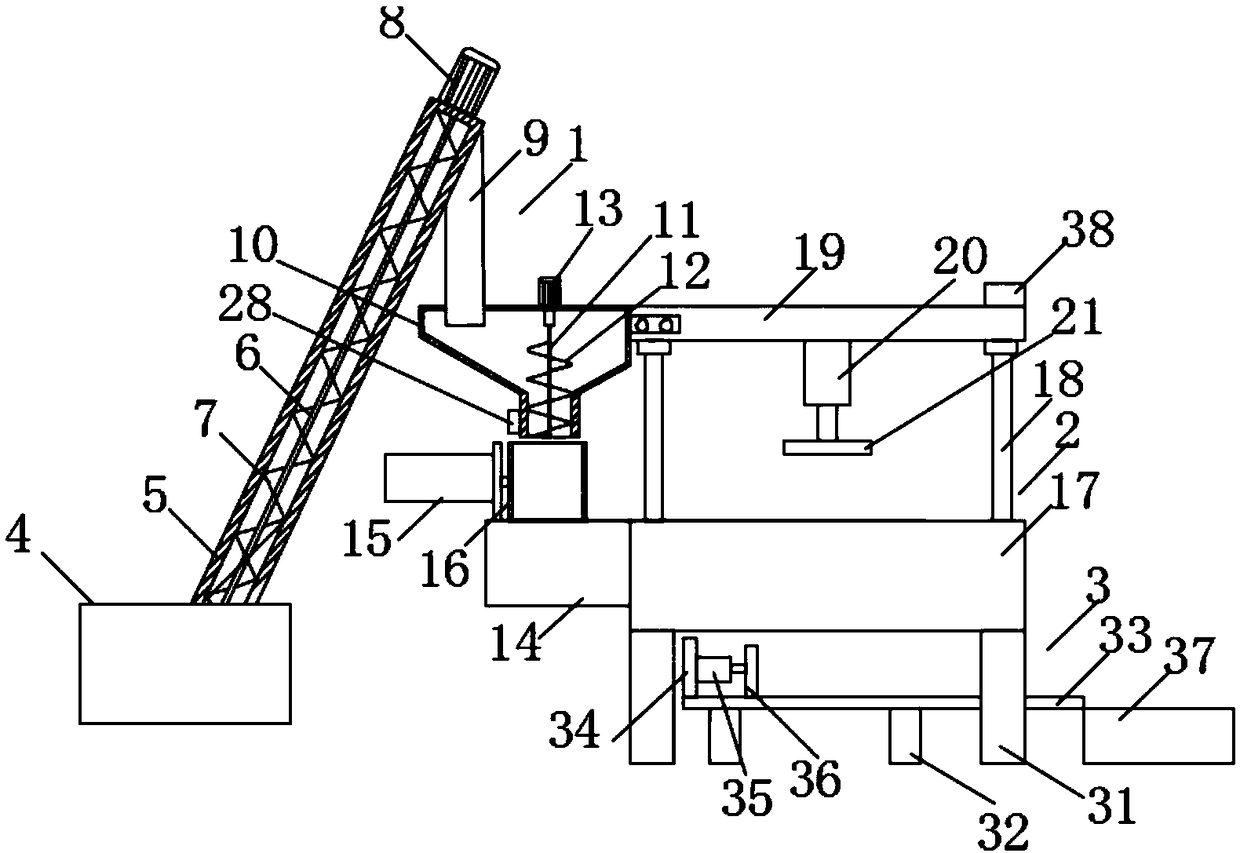

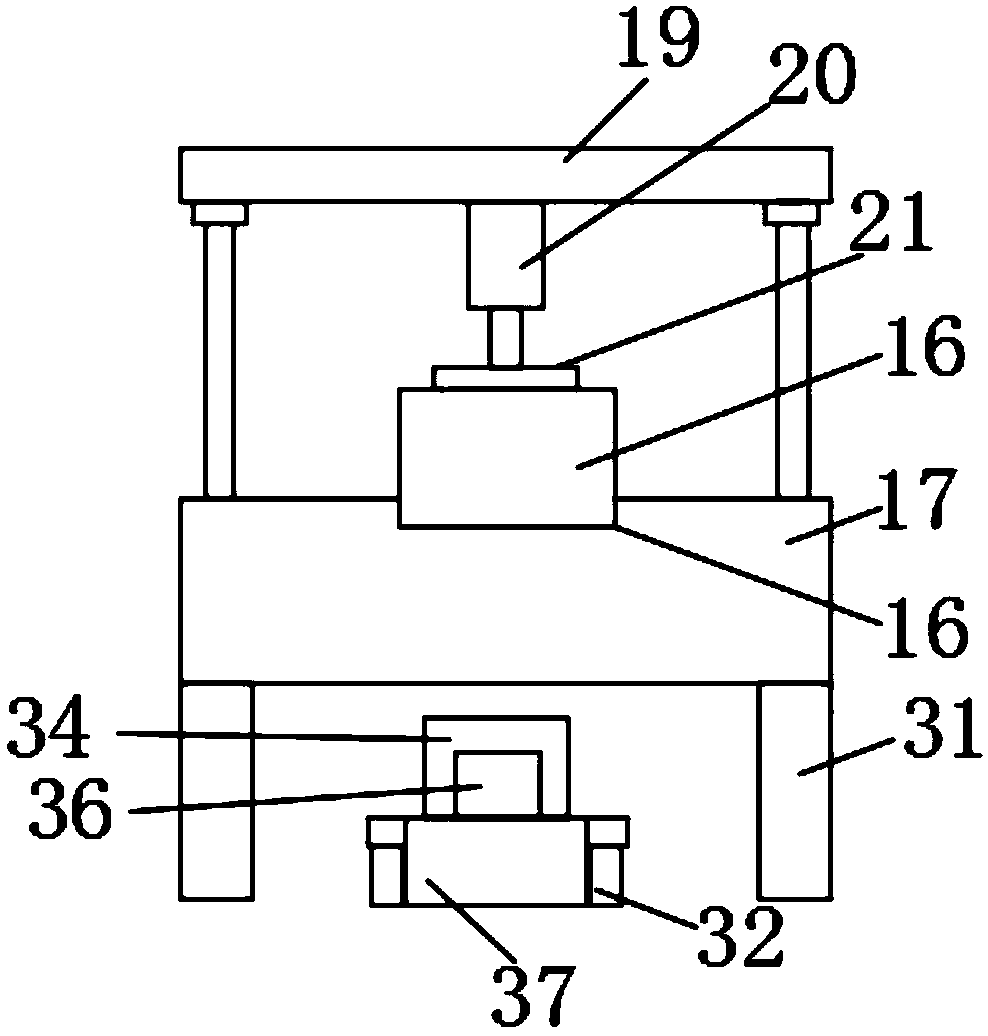

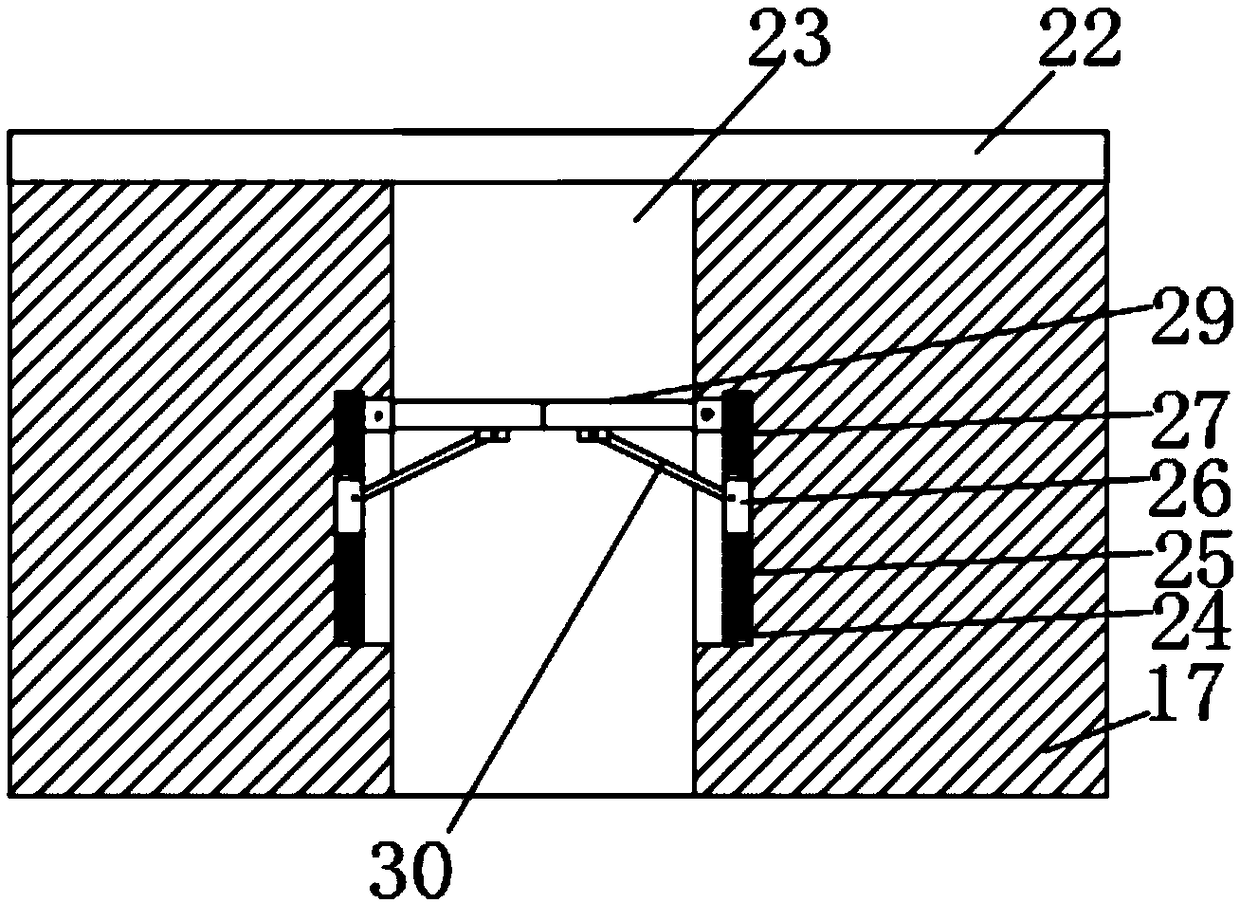

[0019] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a briquetting device for sawdust recycling, including a feeding mechanism 1, a pressing mechanism 2 and a receiving mechanism 3, and a pressing mechanism 2 is provided below the feeding mechanism 1, The bottom of the pressing mechanism 2 is provided with a receiving mechanism 3, and the feeding mechanism 1 is composed of a storage box 4, a feeding pipe 5, a central shaft 6, a first rotating blade 7, a feeding motor 8, and a feeding pipe 9. , feeding box 10, transmission shaft 11, second rotating blade 12, feeding motor 13, support block 14, feeding cylinder 15 and feeding box 16, the fixed connection ring at the top of the storage box 4 has a feeding pipe 5. A central shaft 6 is rotatably connected between the top and the bottom of the inner wall of the feeding pipe 5, and the outer side of the central shaft 6 is fixedly connected with a first rotating blade 7, and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com