Quantitative material injection device of mould

A technology of feeding device and mold, applied in the direction of feeding device, manufacturing tool, etc., can solve the problems of uneven injection, high labor intensity, hidden safety hazards, etc., and achieve reasonable structure design, convenient feeding flow, and stable equipment operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

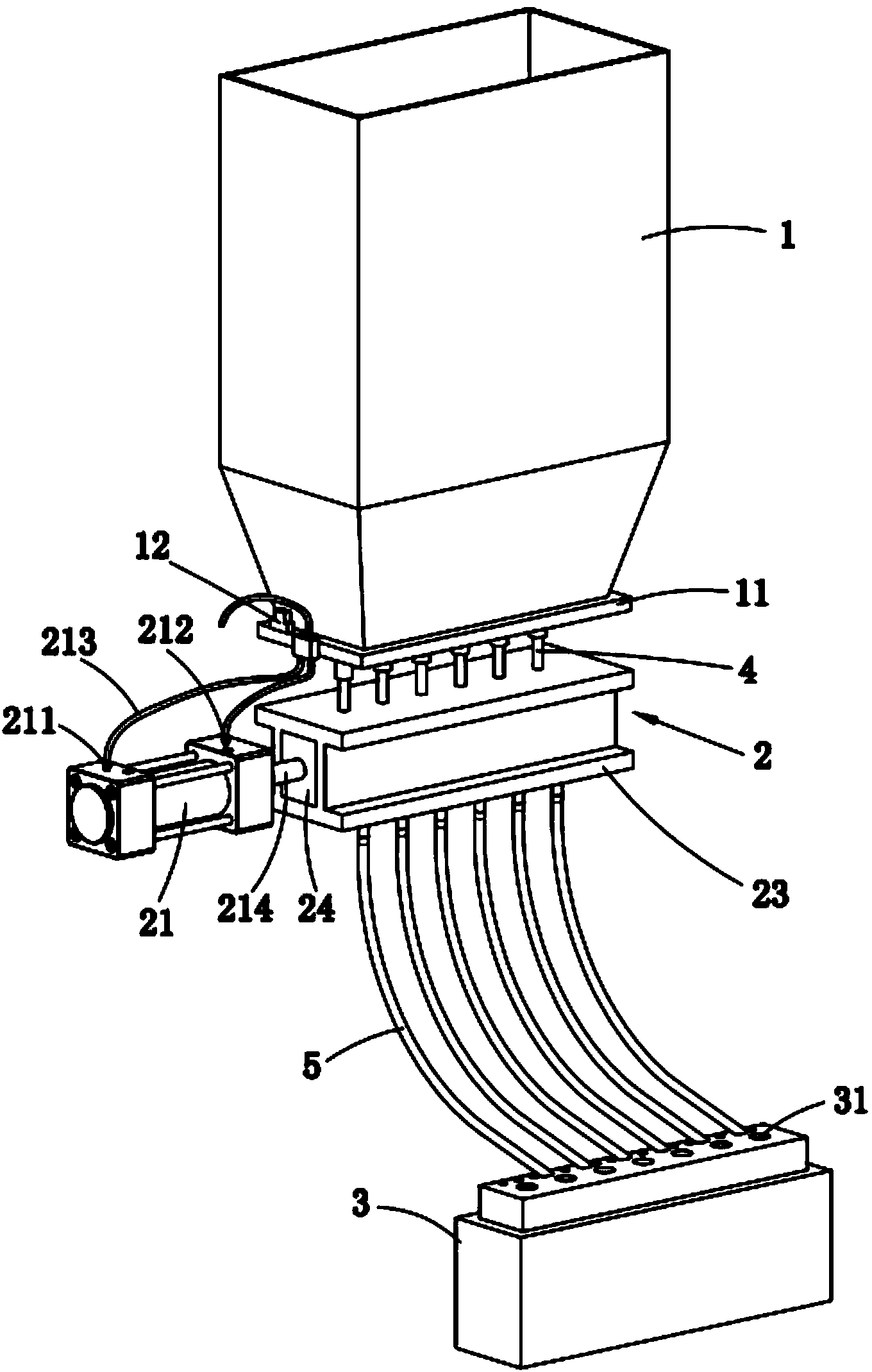

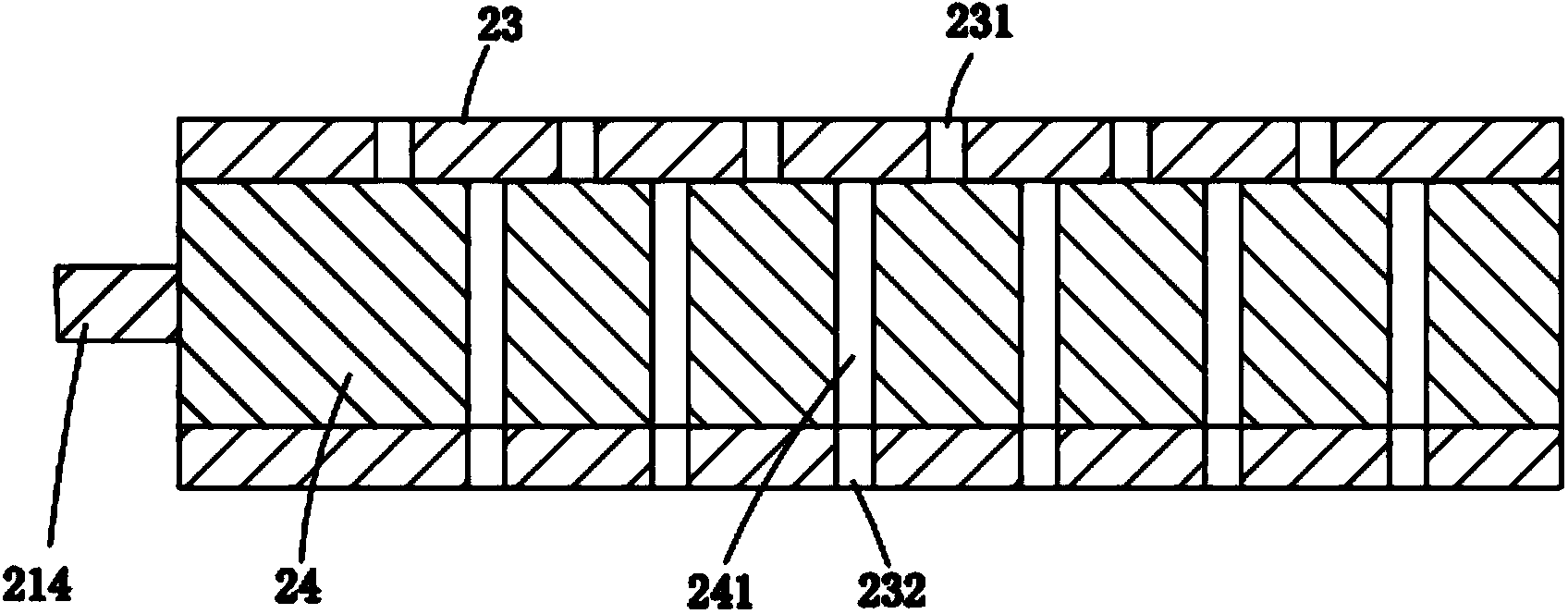

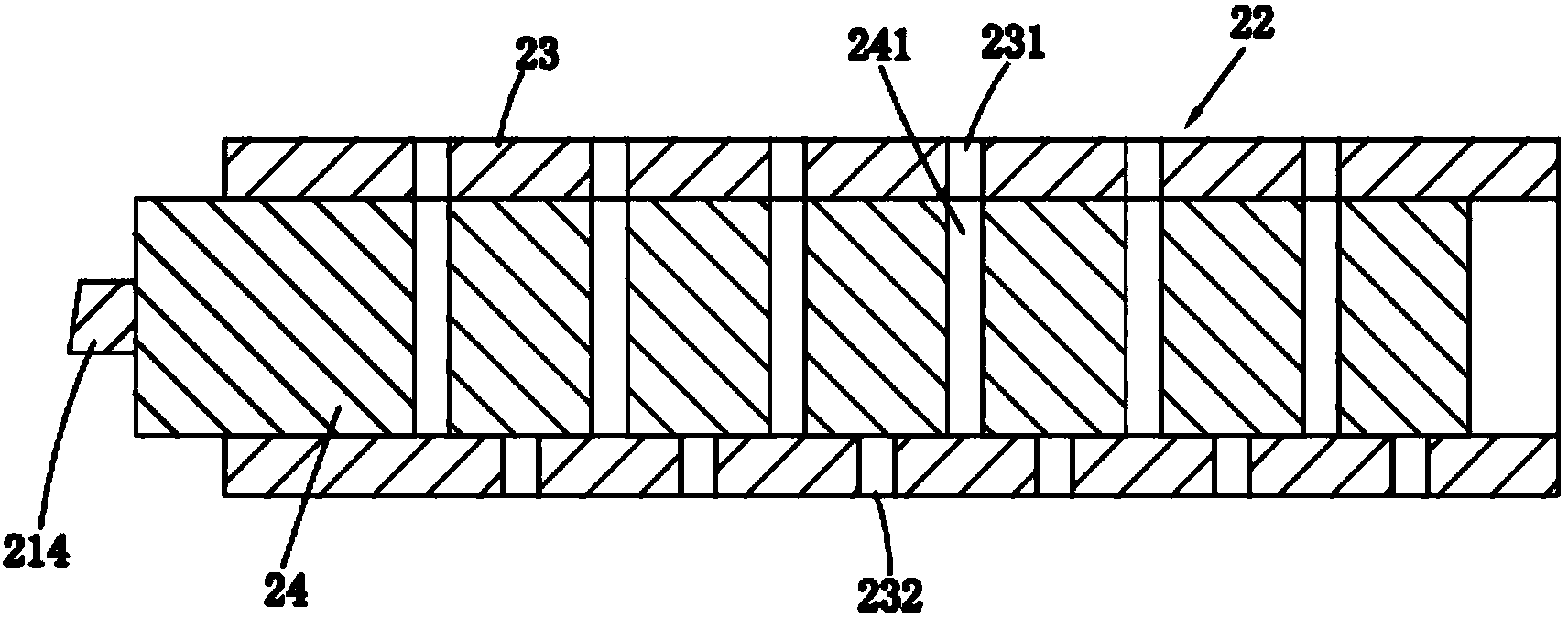

[0020] Such as figure 1 As shown, a mold quantitative injection device includes a hopper 1 with an open upper end, a feeding device 2 and a lower mold body 3, the bottom of the hopper 1 is provided with a sealing plate 11, and several outlets are evenly distributed on the sealing plate 11. Each outlet is provided with a feed pipe 4; the feeding device 2 includes a cylinder 21 and a material injection mechanism 22, and an air inlet 211 and an air outlet 212 are also provided above the cylinder 21, and the air inlet 211 and the air outlet 212 Connected to the external air source through the connecting pipe 213; the injection mechanism 22 is driven by the cylinder 21 and placed directly below the hopper 1; as figure 2 with image 3 As shown, the injection mechanism 22 includes a housing 23 and a slider 24 that is slidable in the housing 23. The length of the slider 24 is equal to the inner cavity of the housing 23, and its upper and lower surfaces are respectively connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com