A method for automatic control of argon blowing in continuous casting crystallizer

A continuous casting mold and continuous casting technology are applied in the field of automatic control of argon blowing in continuous casting molds, which can solve problems such as inability to meet actual needs, and achieve the effects of improving automatic control capability, control accuracy, and control capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The pouring station is ready for pouring, and the argon blowing control execution unit starts.

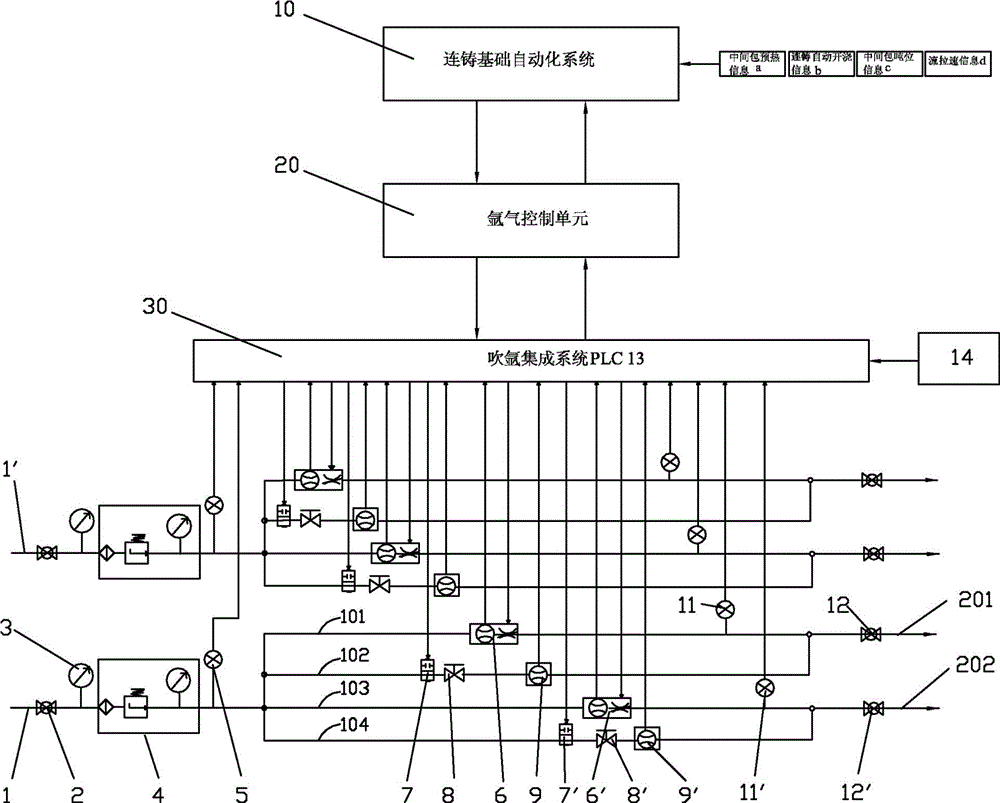

[0037] The pouring station executes automatic pouring, the continuous casting basic automation system sends instructions to the argon control unit PLC, and the argon control unit PLC sends instructions to the pouring station argon blowing integrated system PLC, calls the argon formula one, and the steel worker confirms the crystallization Whether the steel flow and liquid level are normal, if there is any abnormality, it can be directly adjusted manually.

[0038] During the pouring process, if the crystallizer is found to be abnormal or biased, the argon formula can be adjusted through the HMI screen of the central control room or the knob on the field argon blowing flow control panel or the touch screen 14 screen by switching the operating place.

[0039] When the casting flow rate corresponding to the pouring station rises and is greater than a specific value, the continuous cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com