Purification method of acetone oxime

A purification method and technology of acetone oxime, which are applied in the field of organic compound purification, can solve the problems of unsuitability for industrial production, easy decomposition of acetone oxime, complicated process, etc., and achieve the effects of easy separation, reduced decomposition and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

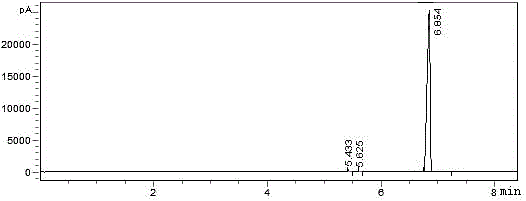

Image

Examples

Embodiment 1

[0020] a. Extraction experiment of acetone oxime

[0021] Acetone oxime reaction solution generated by acetone ammoximation (contact acetone, ammonia gas or ammonia water, hydrogen peroxide, solvent (tert-butanol and water) and catalyst TS-1 titanium silicon molecular sieve, heat, and react under normal pressure to obtain acetone oxime reaction solution) Filtrate, the filtrate is rectified under normal pressure, the reflux ratio is 2:1, the tert-butanol distillate is 70°C~85°C, the aqueous solution in the tower is a water oxime mixture, and the oxime content is 90g / L. Extract three times with ethyl acetate of 0.5 times the volume of the water oxime mixture, the upper layer is the ethyl acetate layer, and the lower layer is the water layer. Ethyl acetate once extracted, the recovery rate of acetone oxime was 58%, the recovery rate of acetone oxime was 80% in the second extraction, and the recovery rate of acetone oxime was 90% in three extractions.

[0022] b. Rectification an...

Embodiment 2

[0025] a. Extraction experiment of acetone oxime

[0026] Acetone oxime reaction solution generated by acetone ammoximation (contact acetone, ammonia gas or ammonia water, hydrogen peroxide, solvent (tert-butanol and water) and catalyst TS-1 titanium silicon molecular sieve, heat, and react under normal pressure to obtain acetone oxime reaction solution) Filtrate, the filtrate is rectified under normal pressure, the reflux ratio is 2:1, the tert-butanol distillate is 70°C~85°C, the aqueous solution in the tower is a water oxime mixture, and the oxime content is 90g / L. Extract three times with ethyl acetate of 1.0 times the volume of the water oxime mixture, the upper layer is the ethyl acetate layer, and the lower layer is the water layer. Ethyl acetate once extracted, the recovery rate of acetone oxime was 68%, the second extraction, the recovery rate of acetone oxime was 90%, and the recovery rate of acetone oxime was 93% after three extractions.

[0027] b. Rectification a...

Embodiment 3

[0030] a. Extraction experiment of acetone oxime

[0031] The reaction of acetone oxime generated by acetone ammoximation (contacting acetone, ammonia gas or ammonia water, hydrogen peroxide, solvent (tert-butanol and water) and catalyst TS-1 titanium silicon molecular sieve, heating, and reacting at normal pressure to obtain acetone oxime reaction liquid) Liquid filtration, the filtrate is rectified under normal pressure, the reflux ratio is 2:1, the tert-butanol distillate is 70°C~85°C, the aqueous solution in the tower is a water oxime mixture, and the oxime content is 90g / L. Extract three times with ethyl acetate of 0.25 times the volume of the water oxime mixture, the upper layer is the ethyl acetate layer, and the lower layer is the water layer. Ethyl acetate once extracted, the acetone oxime recovery rate was 40%, the second extraction, the acetone oxime recovery rate was 65%, and the three extractions, the acetone oxime recovery rate was 80%.

[0032] b. Rectification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com