Breathable ultraviolet-resistant anti-static polyurethane resin coating adhesive and preparation method thereof

A polyurethane resin, anti-ultraviolet technology, applied in textiles, papermaking, fiber treatment, etc., to achieve the effects of excellent water resistance, excellent anti-ultraviolet performance, and excellent antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

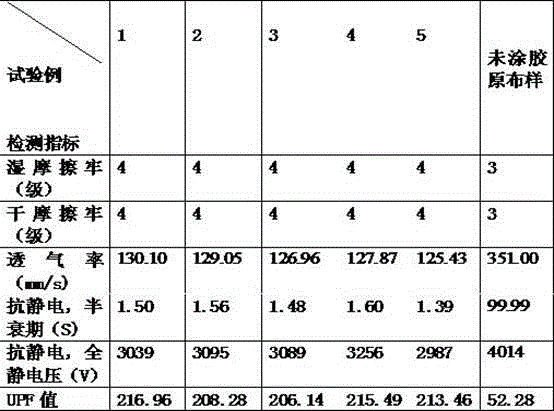

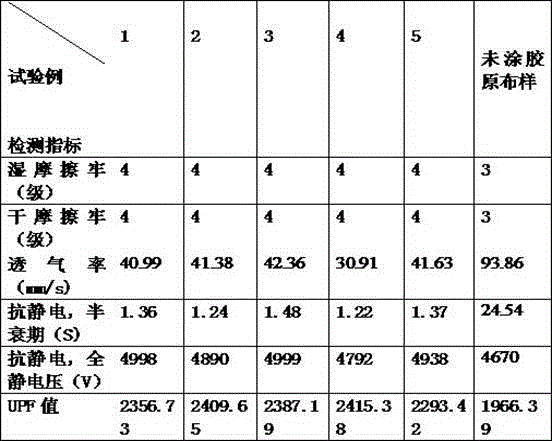

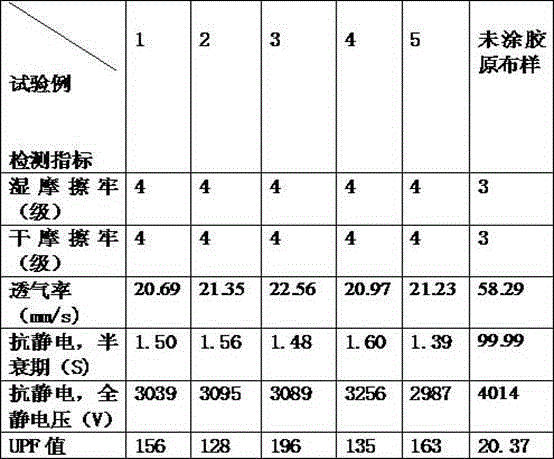

Examples

Embodiment 1

[0062] A1 component preparation:

[0063] (1) 60 parts of polyoxypropylene ether diol (number average molecular weight 2000), 120 parts of polyoxyethylene ether diol (number average molecular weight 2000), 3 parts of trimethylolpropane, toluene diisocyanate (TDI) Add 46 parts, 0.03 parts of dibutyltin dilaurate, and 30 parts of acetone to the reaction kettle in turn, stir and heat up, and react at 76±2°C for 2.5 hours to prepare a polyurethane prepolymer;

[0064] (2) Add 4.5 parts of chain extender 1,4-butanediol and react at 76±2°C for 5 hours to obtain chain extended polyurethane prepolymer;

[0065] (3) Put the above chain-extended polyurethane prepolymer into an emulsification kettle, cool down to 25±2°C, add a solution of 8 parts of sodium bisulfite and 12.5 parts of deionized water, and react at 25±2°C for 35 minutes to prepare Obtain sodium bisulfite end-capped polyurethane prepolymer;

[0066] (4) Add 6 parts of sodium bicarbonate to 525 parts of deionized w...

Embodiment 2

[0068] A2 component preparation:

[0069] (1) 80 parts of polyoxypropylene ether diol (number average molecular weight 1600), 180 parts of polyoxyethylene ether diol (number average molecular weight 1500), 3 parts of trimethylolpropane, toluene diisocyanate (TDI) 30 parts, 34.3 parts of 1.6-hexamethylene diisocyanate (HDI), 36 parts of dimethylformamide, and 0.04 parts of dibutyltin diacetate were added to the reaction kettle in sequence, stirred and heated up, and reacted at 75±2°C for 2 hours to prepare Obtain polyurethane prepolymer;

[0070] (2) Add 5 parts of neopentyl glycol, a chain extender, and react for 4.5 hours at 75±2°C to obtain a chain-extended polyurethane prepolymer;

[0071] (3) Put the above chain-extended polyurethane prepolymer into an emulsification kettle, cool down to 23±2°C, add a solution of 8 parts of sodium bisulfite and 13.8 parts of deionized water, and react at 23±2°C for 30 minutes to prepare Obtain sodium bisulfite end-capped polyurethan...

Embodiment 3

[0074] A3 component preparation;

[0075] (1) 90 parts of polyoxypropylene ether diol (number average molecular weight 2500), 160 parts of polyoxyethylene ether diol (number average molecular weight 1000), 3.5 parts of trimethylolpropane, isophorone diisocyanate 95.5 parts of (IPDI), 0.04 parts of dibutyltin dilaurate, 20 parts of N-methylpyrrolidone, and 20 parts of acetone were added to the reaction kettle in turn, stirred and heated, and reacted at 77±2°C for 2.5 hours to obtain polyurethane prepolymerization body;

[0076] (2) Add 2.5 parts of chain extender 1,4-butanediol and 2.5 parts of neopentyl glycol, and react at 77±2°C for 4.5 hours to obtain a chain-extended polyurethane prepolymer;

[0077] (3) Put the above-mentioned chain-extended polyurethane prepolymer into the emulsification kettle, then lower the temperature to 26±2°C, add a solution of 9 parts of sodium bisulfite and 15.8 parts of deionized water, and react at 26±2°C for 30 minutes, Obtain sodium bisul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com