Preparation method of ketoxime

A technology of ketoxime and oximating agent, applied in oxime preparation, organic chemistry, etc., can solve the problems of unsuitable industrial application, long process time consumption, inconvenient operation, etc., achieve continuous production, short process time, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

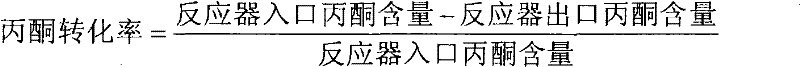

[0025] According to one embodiment of the present invention, the method for preparing ketoxime provided by the present invention may comprise the following steps:

[0026] (1) Mix ketone, oxidant and solvent to form solution A, and send the above solution A and oximating agent or oximating agent solution B into the reactor equipped with catalyst at the same time, at 60-110°C and 0.2MPa-2MPa Continuous reaction under pressure for 30-50 minutes;

[0027] (II) introducing the reaction product into an external membrane tube for solid-liquid separation;

[0028] (III) The solid obtained by the solid-liquid separation is recycled back to the reactor to be used as part or all of the catalyst, and the liquid component containing ketoxime is sent to the product storage tank.

[0029] Described tensio-active agent can exist in solution A, in solution B or in reactor, or exist in above-mentioned three at the same time, as long as guarantee that the contact of ketone and oximating agent ...

Embodiment 1

[0036] This example is used to illustrate the method for preparing ketoxime provided by the present invention.

[0037] 58g acetone (1 mole), 124g hydrogen peroxide (H 2 o 2 Concentration is 27.5% by weight, 1 mole), surfactant and 51g tert-butyl alcohol are made into mixed solution A, and 87g ammoniacal liquor (concentration is 25% by weight, 1.3 mole) and surfactant are made into solution B, solution A and Solution B joins together in the reactor containing HTS titanium silicon molecular sieve catalyst (purchased from Hunan Jianchang Co., Ltd. trademark is HTS-3) and surfactant, wherein the consumption of catalyst is 5.00g catalyst / mol acetone, solution A, The surfactant in the solution B and the reactor is a mixture of sorbitol fatty acid ester and polyoxyethylene sorbitan fatty acid ester with a weight ratio of 0.8: 1, wherein the grade of sorbitol fatty acid value is SP-60, the total The dosage is 0.008g surfactant / mol acetone, the grade of polyoxyethylene sorbitan fatt...

Embodiment 2

[0044] This example is used to illustrate the method for preparing ketoxime provided by the present invention.

[0045] 58g acetone (1 mole), 173g hydrogen peroxide (H 2 o 2 Concentration is 27.5% by weight, 1.4 mole), tensio-active agent and 102g tert-butanol are made into mixed solution A, will contain 115g ammoniacal liquor (concentration is 25% by weight, 1.7 mole) and tensio-active agent are made into solution B, solution A Join together with solution B in the reactor that contains catalyst HTS molecular sieve (purchased from Hunan Jianchang Co., Ltd. trademark is HTS-3), wherein the consumption of catalyst is 25g catalyst / mol acetone, and surfactant is sorbitol fatty acid ester (the brand is SP-60, the total consumption 0.013g surfactant / mol acetone in solution A and solution B) and polyoxyethylene sorbitan fatty acid ester (the brand is TW-80, in solution A and solution B The total amount used in 0.010g surfactant / mol acetone), the reaction temperature is controlled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com