Preparation method of high water absorption composite body

A superabsorbent and composite technology, applied in fiber types, textiles and papermaking, ultrasonic/sonic fiber treatment, etc., can solve the problems affecting the softness and water absorption of superabsorbent composites, particle size and uneven distribution, and reaction conditions Difficult to control and other problems, to achieve the effect of controllable particle size, small specific surface area and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

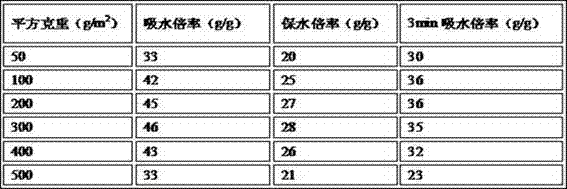

Examples

Embodiment

[0022] 1. Add 18g / m 2 The ES fiber air-through non-woven fabric is subjected to plasma etching treatment to generate defective active catalytic sites;

[0023] 2. For the polymerization solution (sodium hydroxide is used to neutralize acrylic acid, the neutralization degree is 75%, the monomer concentration is 50% (weight), 0.05% N, N`-methylenebisacrylamide crosslinking agent, 0.2 % potassium persulfate initiator) ultrasonic spray to make it adhere to the surface of the fiber, the diameter of the mist particle is 0.4-0.6mm, control the spray volume to achieve the target requirement of the square gram weight of the superabsorbent complex;

[0024] 3. Using microwave heating, the reaction temperature is 85 o C, the reaction time is 15s, and the superabsorbent resin gel attached to the surface of the fiber is prepared by polymerization and crosslinking reaction, and the drying temperature is 110 oC , the drying time is 120s, and the superabsorbent resin particles attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com