Method for producing flyash brick

A production method, the technology of fly ash bricks, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of easy shrinkage cracks, high production costs, difficult mechanical production, etc., and achieve light weight , low cost, high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] A production method of fly ash bricks, comprising the steps of material selection, crushing, batching, mixing, injection of cross-linking agent, compression molding, health care treatment and the like. in:

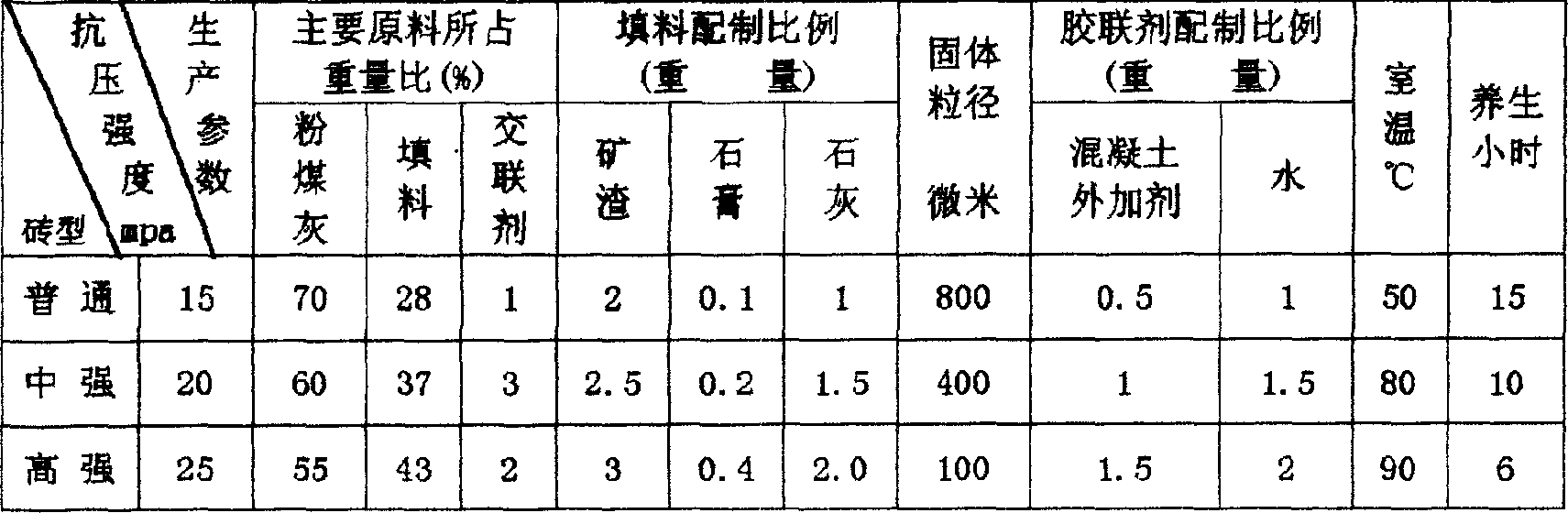

[0008] Fly ash is selected as the base material; slag, gypsum, and lime are used as fillers; the mixture of concrete admixture and water is used as a crosslinking agent, and the weight ratio of each material in the unit weight is 55-70% for the base material and 28% for the filler. -43%, the crosslinker is 1-3%. The weight ratio of slag, gypsum and lime in the filler is: 2-3:0.1-0.4:1.0-2.0. The weight preparation ratio of concrete admixture and water in the crosslinking agent is: 0.5-1.5: 1-2. Fly ash, slag, gypsum, and lime are crushed into particles with a diameter of 100-800 microns. Mix well according to the amount prepared by the above parameters, inject the glue until uniform, send it to the mold for compression molding, and cure it in a kiln at 50°C-90°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com