Method for rapidly replacing online tundish of ultra-wide thin slab continuous casting machine

A thin slab continuous casting and tundish technology, which is applied to the field of quick replacement of online tundish for ultra-wide thin slab continuous casting machines, can solve the problems of effective operating rate limitation, crystallizer sticking to cold steel, and unable to pull, etc., to reduce sticking Probability of bonding, avoiding steel infiltration, and good connection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

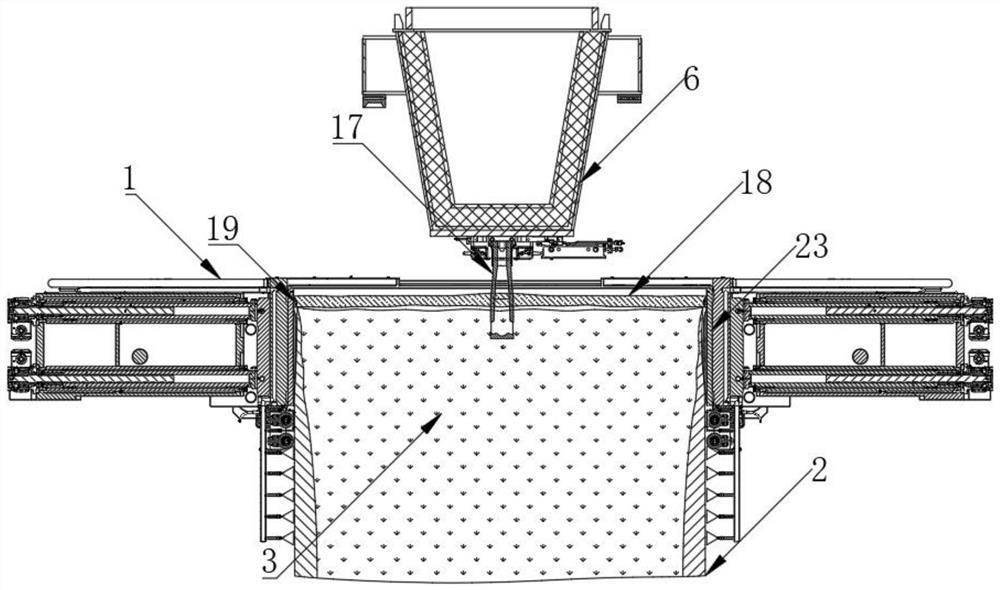

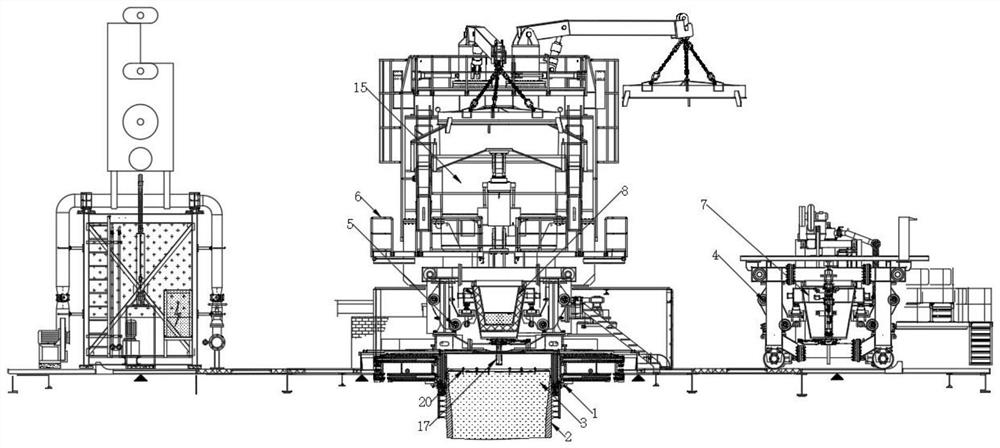

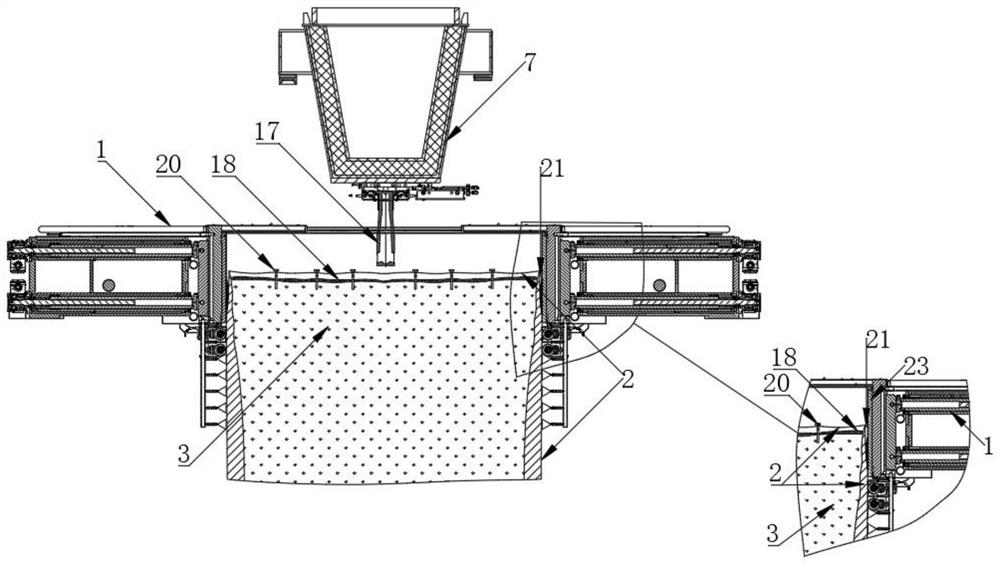

[0041] This embodiment provides a method for rapidly replacing the online tundish for an ultra-wide thin slab continuous casting machine, such as Figure 1-4 shown, the specific steps are as follows:

[0042] (S1), 30 minutes before the rapid replacement of the tundish, control the thickness of the mold slag layer 18 in the mold 1, speed up the regeneration of mold slag near the immersion nozzle 17, and clean the sintered slag in the mold slag layer 18, while the mold The mold slag strips 19 attached to the wall 23 are cleaned up to prevent the slag strips from being involved in the billet shell after the replacement of the tundish and causing a steel breakout accident;

[0043] (S2), before replacing the tundish, after the ladle 15 is closed, as the molten steel in the old tundish 8 continues to drop, the pulling speed is Figure 4 The control curve is reduced from the normal 1.20m / min to 0.4m / min, and the secondary cold water weak cooling control is carried out in the proce...

Embodiment 2

[0047] This embodiment provides a method for rapidly replacing the online tundish for an ultra-wide thin slab continuous casting machine, such as Figure 1-4 shown, the specific steps are as follows:

[0048] (S1), 30 minutes before the rapid replacement of the tundish, control the thickness of the mold slag layer 18 in the mold 1, speed up the regeneration of mold slag near the immersion nozzle 17, and clean the sintered slag in the mold slag layer 18, while the mold The mold slag strips 19 attached to the wall 23 are cleaned up to prevent the slag strips from being involved in the billet shell after the replacement of the tundish and causing a steel breakout accident;

[0049] (S2), before replacing the tundish, after the ladle 15 is closed, as the molten steel in the old tundish 8 continues to drop, the pulling speed is Figure 4 The control curve is reduced from the normal 1.20m / min to 0.4m / min, and the secondary cold water weak cooling control is carried out in the proce...

Embodiment 3

[0057] This embodiment provides a method for rapidly replacing the online tundish for an ultra-wide thin slab continuous casting machine, such as Figure 1-4 shown, the specific steps are as follows:

[0058] (S1), 30 minutes before the rapid replacement of the tundish, control the thickness of the mold slag layer 18 in the mold 1, speed up the regeneration of mold slag near the immersion nozzle 17, and clean the sintered slag in the mold slag layer 18, while the mold The mold slag strips 19 attached to the wall 23 are cleaned up to prevent the slag strips from being involved in the billet shell after the replacement of the tundish and causing a steel breakout accident;

[0059] (S2), before replacing the tundish, after the ladle 15 is closed, as the molten steel in the old tundish 8 continues to drop, the pulling speed is Figure 4 The control curve is reduced from the normal 1.20m / min to 0.4m / min, and the secondary cold water weak cooling control is carried out in the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com