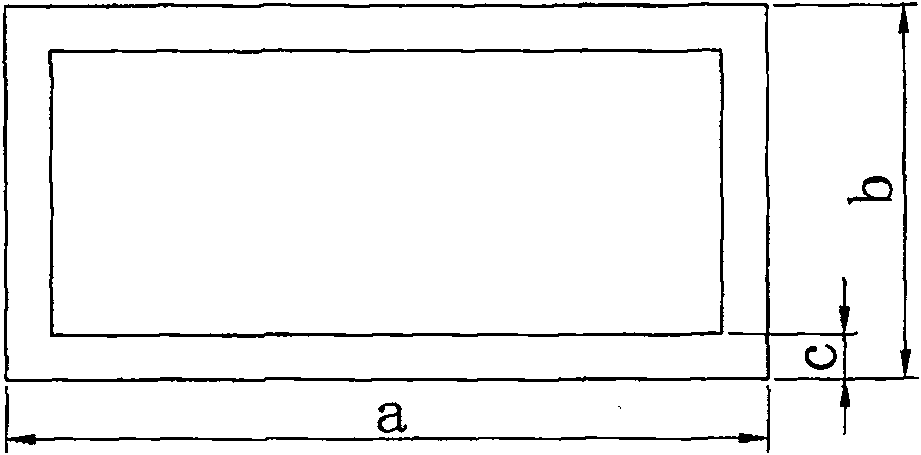

Method for processing austenite seamless stainless steel rectangular water pipe used for turbine generator

A turbogenerator and processing method technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of unqualified intergranular corrosion, poor surface quality, large size deviation, etc., to eliminate lattice defects, reduce Effect of intermediate annealing and reduction of drawing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022]The mass percentage content is carbon 0.010%, silicon 0.09%, manganese 0.2%, sulfur 0.001%, phosphorus 0.001%, chromium 18.10%, nickel 9.10%, rare earth element Re 0.003%, silver 0.002%, and the balance is iron and Austenitic stainless steel with impurities is hot-rolled into Φ13mm round steel at 1180°C; the round steel is stripped and passed through a continuous extruder at an extrusion speed of 50 m / h at a temperature of 890°C on the extruder instrument. Extruded into a bright round tube of Φ10.5mm and wall thickness of 0.82mm, and cut to length according to the process requirements; the outer surface of the cut-to-length round tube is evenly coated with 3.1% tallow, 32% molybdenum disulfide, 6.9% of PS6040 drawing oil and the rest of slaked lime are composed of compound lubricants according to mass percentage, and then the fixed-length round tube is drawn into an elliptical tube with a minor axis of 7mm and a major axis of 12mm by using a mandrelless rod, and then on t...

Embodiment 2

[0024] The mass percentage content is carbon 0.012%, silicon 0.19%, Mn0.37%, sulfur 0.002%, phosphorus 0.004%, chromium 18.50%, nickel 9.80%, rare earth element Re0.002%, silver 0.003%, and the balance is iron Austenitic stainless steel with impurities is hot rolled into Φ14.5mm round steel at a temperature of 1200°C; after the round steel is peeled, it is extruded at a rate of 45 m / h through a continuous extrusion machine at a temperature of 890°C displayed on the instrument of the extrusion machine The speed is continuously extruded into a bright round tube of Φ12mm and wall thickness 0.93mm, and cut to length according to the process requirements; the outer surface of the cut-to-length round tube is evenly coated with 3.5% tallow, 38% molybdenum disulfide, 5.5% of PS6040 drawing oil and the rest of slaked lime are composed of compound lubricants according to mass percentage, and then the fixed-length round tube is drawn into an elliptical tube with a minor axis of 7.8mm and ...

Embodiment 3

[0026] The mass percentage content is carbon 0.015%, silicon 0.24%, manganese 0.50%, sulfur 0.0012%, phosphorus 0.0014%, chromium 18.70%, nickel 10.10%, rare earth element Re 0.005%, silver 0.001%, and the balance is iron and Austenitic stainless steel with impurities is hot-rolled at a temperature of 1200°C into a Φ15.8mm round steel; after the round steel is peeled, it is extruded at a rate of 40 m / h through a continuous extrusion machine at a temperature of 900°C displayed on the instrument of the extrusion machine The speed is continuously extruded into a bright round tube of Φ13.4mm and wall thickness of 0.92mm, and cut to length according to the process requirements; the outer surface of the cut-to-length round tube is evenly coated with 3.8% tallow and 36% disulfide Molybdenum, 5.4% PS6040 drawing oil and the composite lubricant composed of the balance of slaked lime according to the mass percentage, then the fixed-length round tube is drawn into an elliptical tube with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com