A rotary joint capable of filtering impurities

A technology for rotary joints and impurities, which is applied in the direction of filtration and separation, pipes/pipe joints/fittings, adjustable connections, etc. It can solve the problems of reducing the service life of sealing rings, aggravating sealing rings, oil leakage, etc., and increasing flow resistance , reduce wear and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

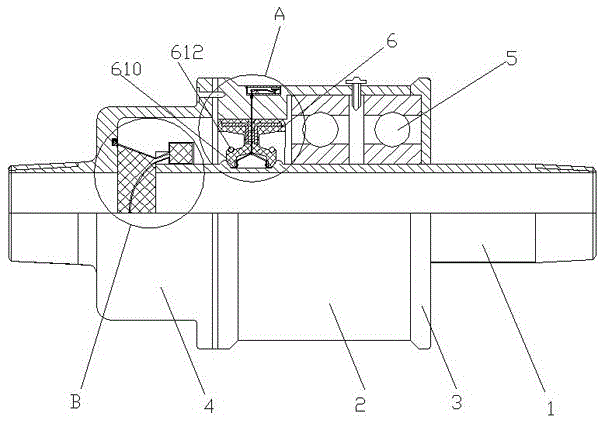

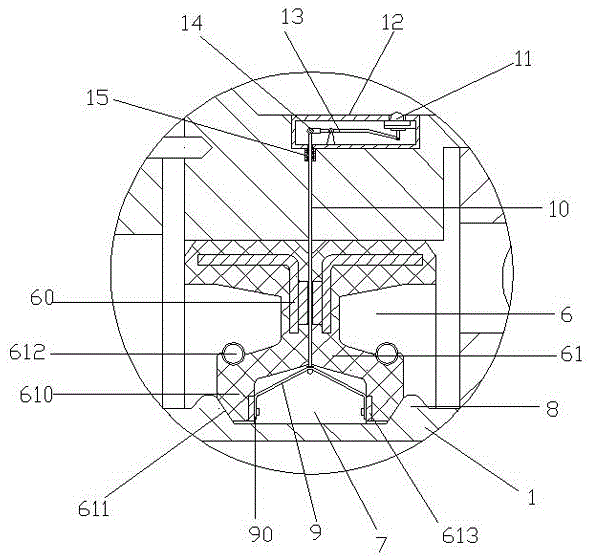

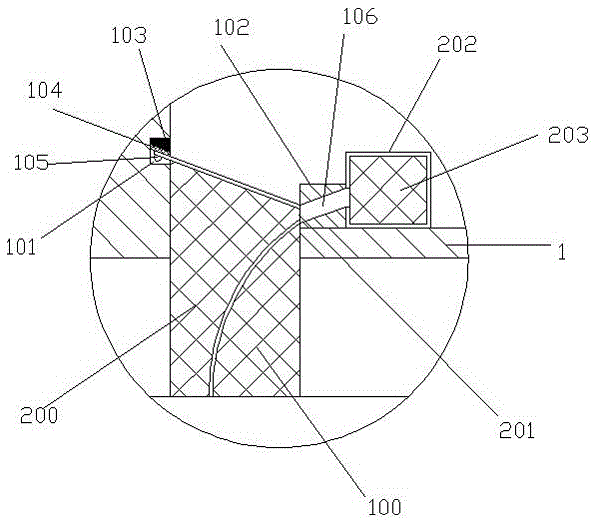

[0024] Such as figure 1 A rotary joint capable of filtering impurities is shown, including a hollow shaft 1, a shaft sleeve 2, one end of the shaft sleeve is provided with an end cover 3, and the other end of the shaft sleeve is provided with a connector 4, and the connector is connected to the shaft sleeve by bolts. A sealing gasket is provided on the connection surface between the connector head and the shaft sleeve, a bearing 5 is provided between the hollow shaft and the shaft sleeve, and a skeleton sealing ring 6 is provided between the hollow shaft 1 and the shaft sleeve 2, and the skeleton sealing ring includes a skeleton 60, The sealing ring body 61, the inner ring of the sealing ring body 61 is extended to form two parallel sealing lips 610, the outer side and inner ring of the two sealing lips are provided with a sealing tapered surface 611...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com