Anchor-shaped zipper teeth and zipper employing anchor-shaped zipper teeth

An integrated technology of fastener elements, applied in the field of fastener elements and zippers using the fastener elements, can solve the problems of the zipper being hard and not easy to bend, and achieve the effects of increasing softness, reducing production costs, and being highly practicable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

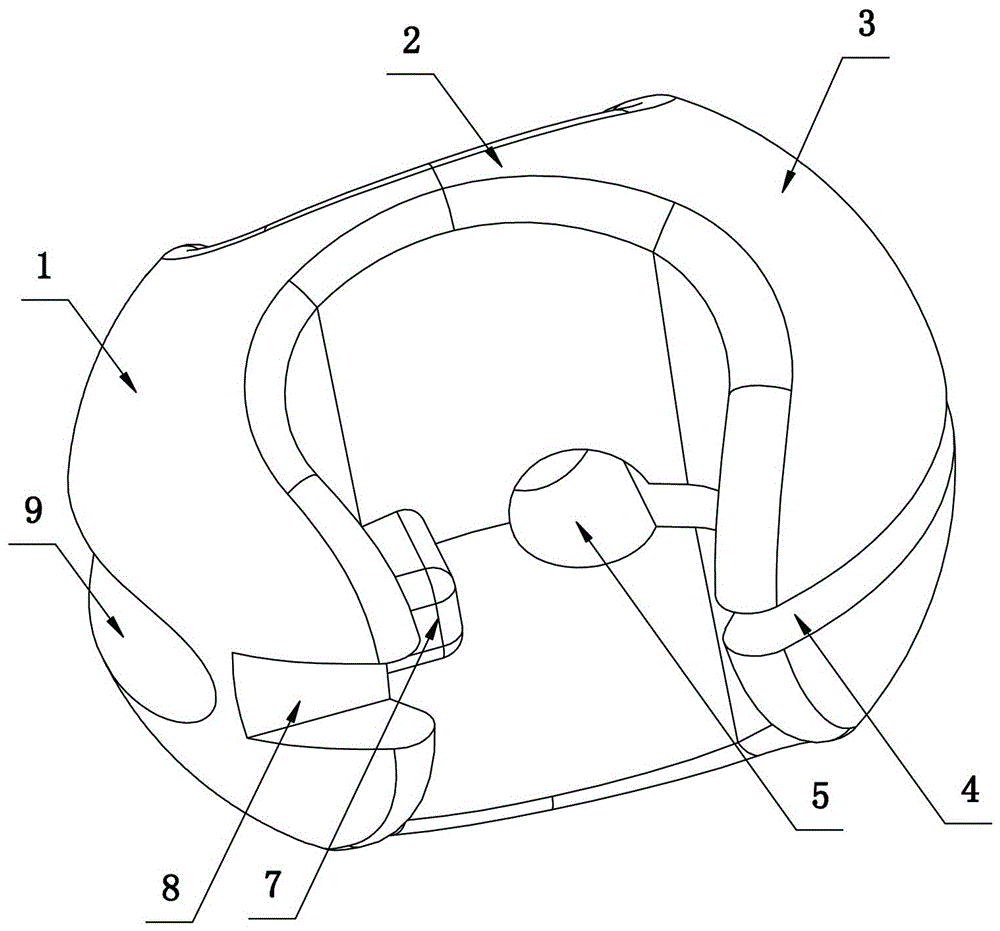

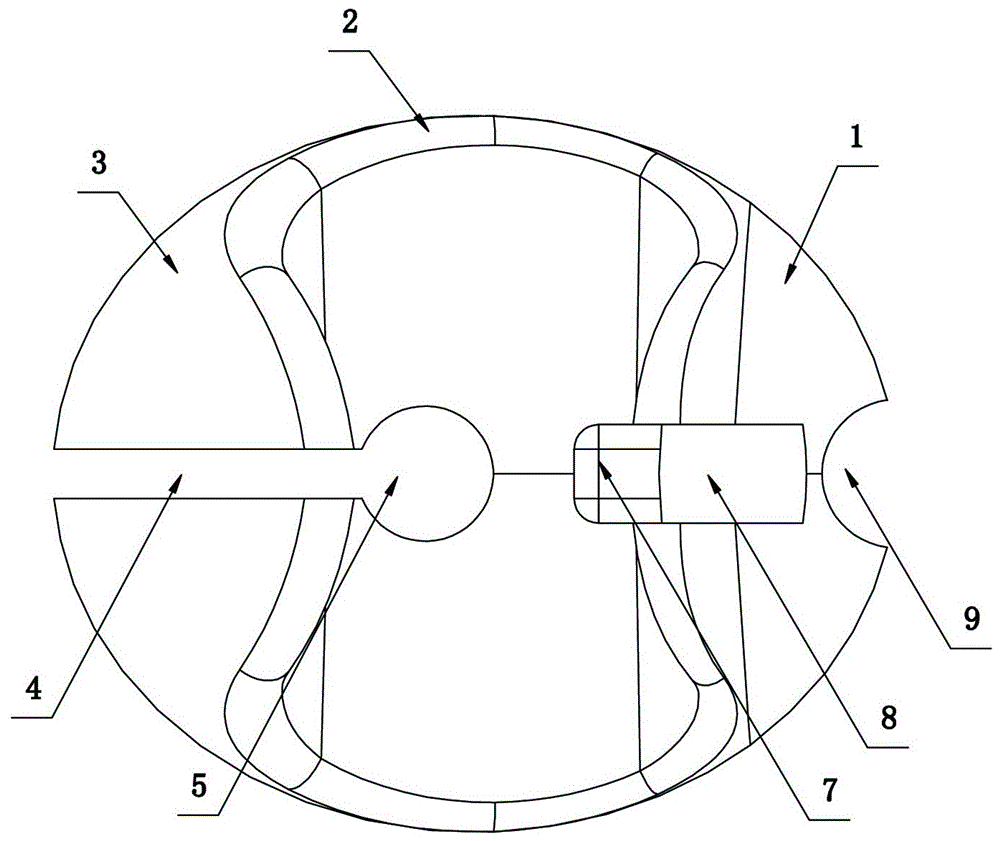

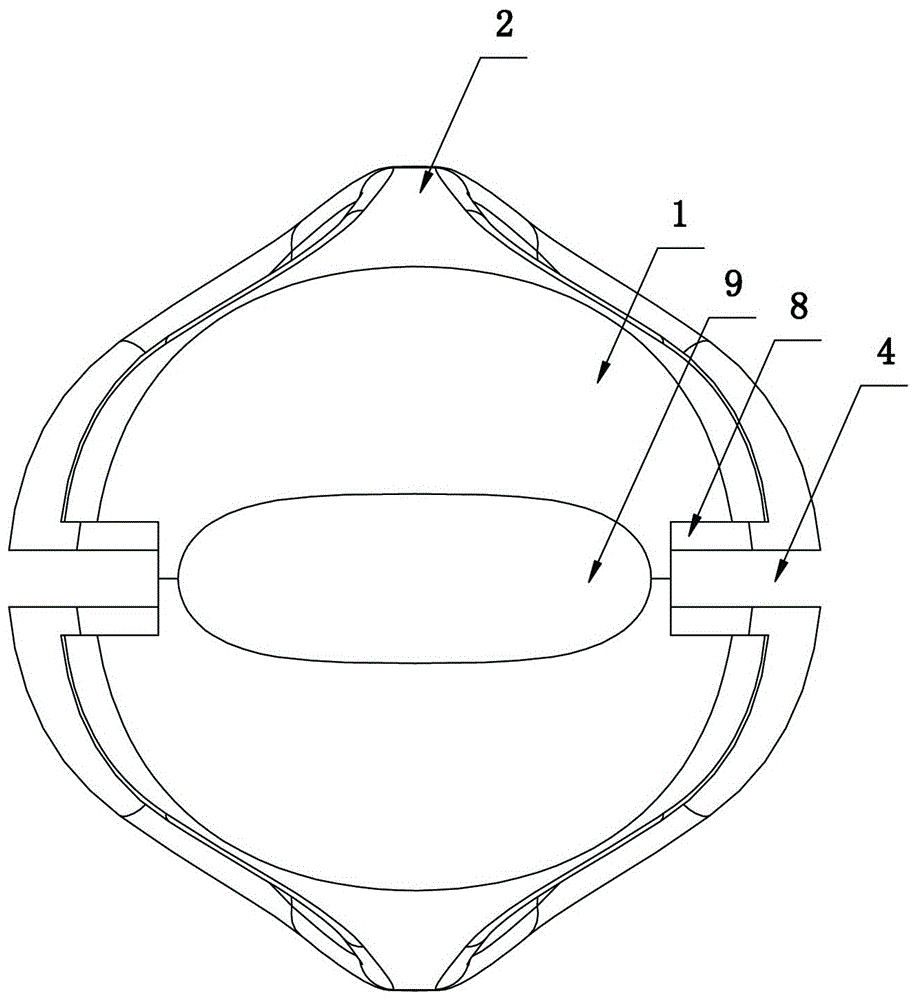

[0025] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0026] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 . An anchor chain element includes an anchor tooth top 1 , a tooth shoulder 2 and an anchor tooth root 3 integrally formed. The tooth shoulder 2 is located between the anchor-shaped tooth top 1 and the anchor-shaped tooth root 3, and the side facing the anchor-shaped tooth top 1 and the anchor-shaped tooth root 3 forms two concave arc-shaped surfaces with the left and right side walls of the tooth shoulder 2 , and the opposite side of the anchor tooth top 1 and the anchor tooth root 3 is a convex arc surface, and the area of the convex arc surface on the anchor tooth top 1 is smaller than the convex arc surface on the anchor tooth root 3 The area of the arc face. The middle part of the anchor tooth root 3 is provided with a cloth tape 6 that can be inserted into the cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com