Liquid-containing hazardous chemical substance treatment method

A treatment method and technology for hazardous chemicals, applied in garbage collection, household appliances, applications, etc., can solve the problems of inability to collect gas hazardous chemicals, increase the difficulty of handling hazardous chemicals, and troublesome collection of sand and soil, etc., to achieve Reduce the probability of sand and soil bonding, improve the treatment range, and reduce the effect of secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

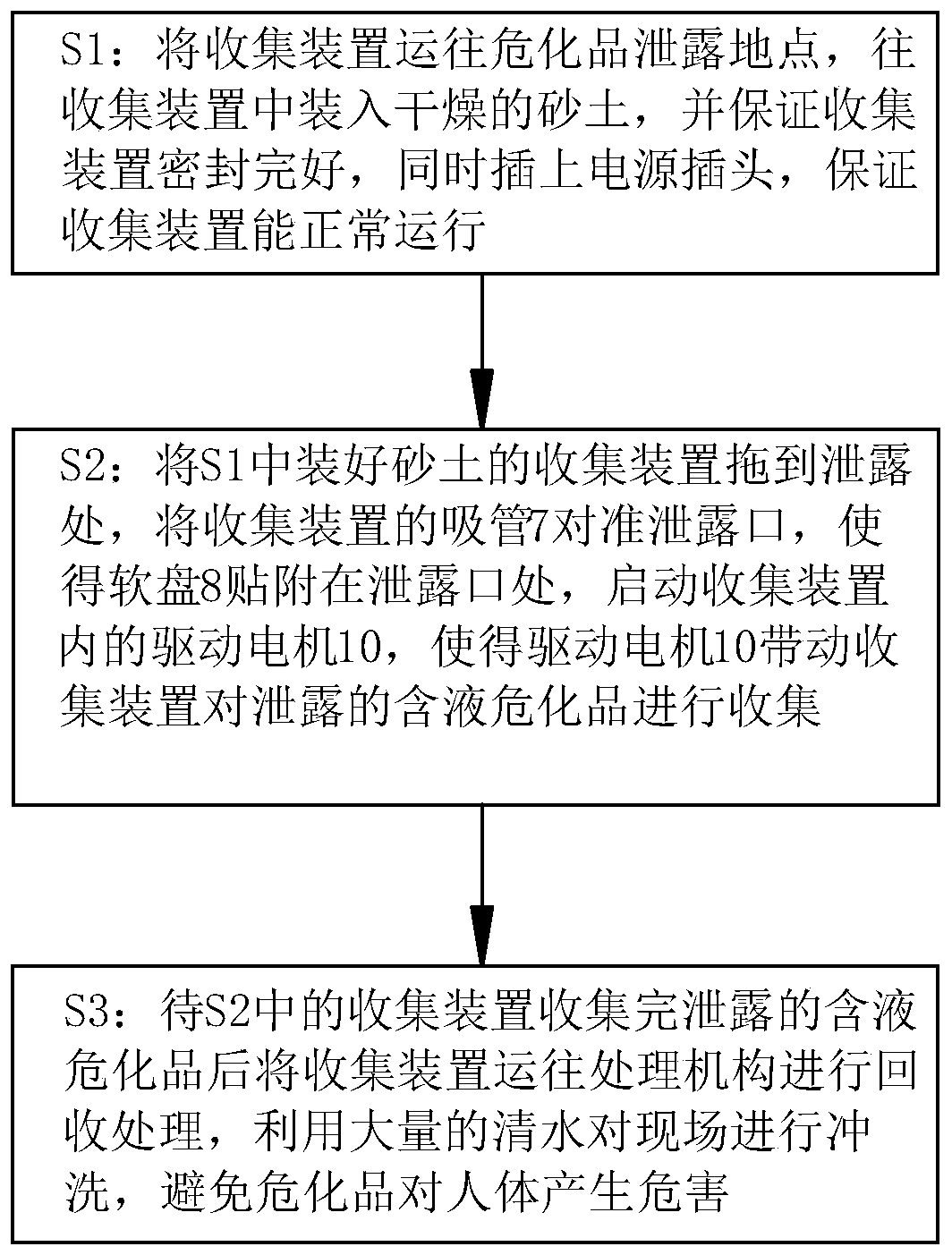

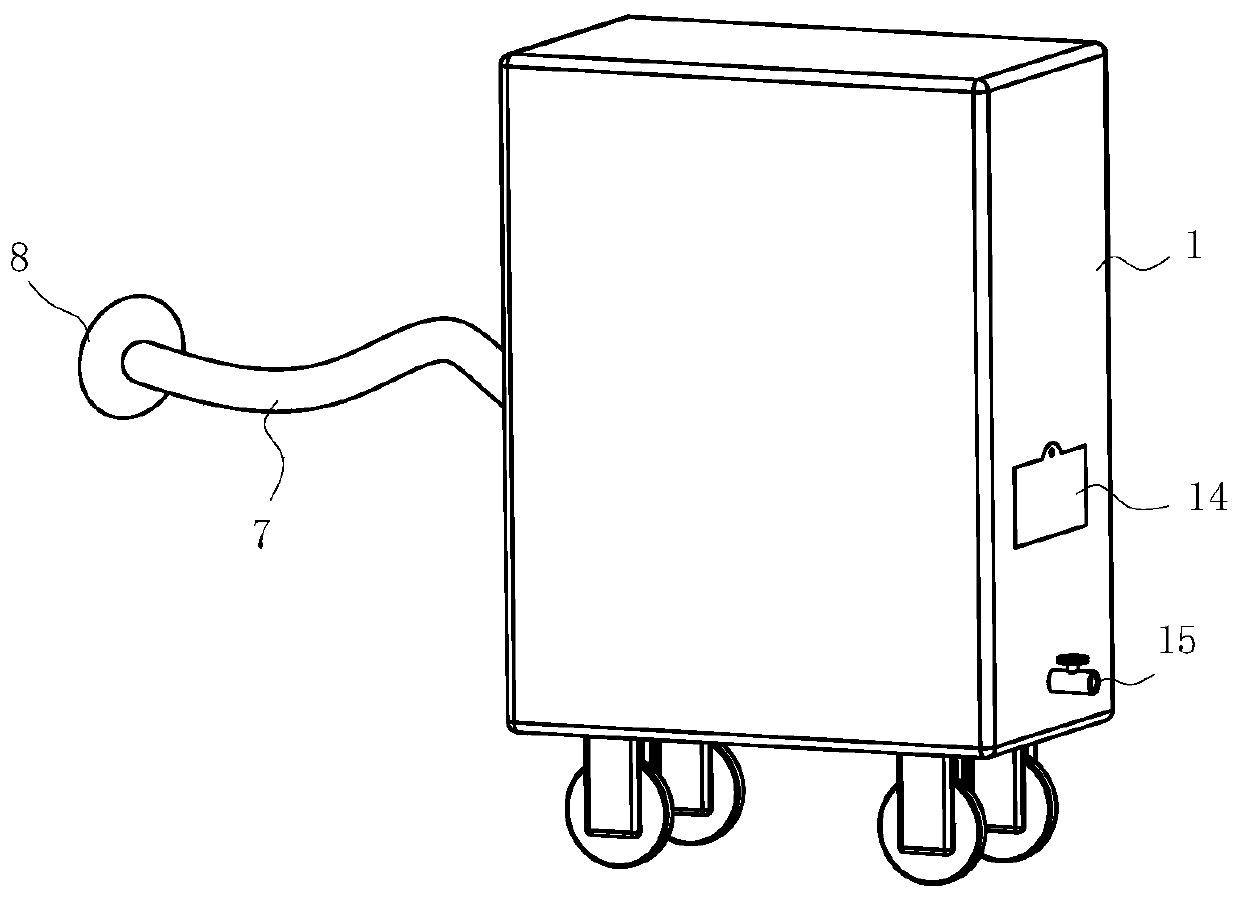

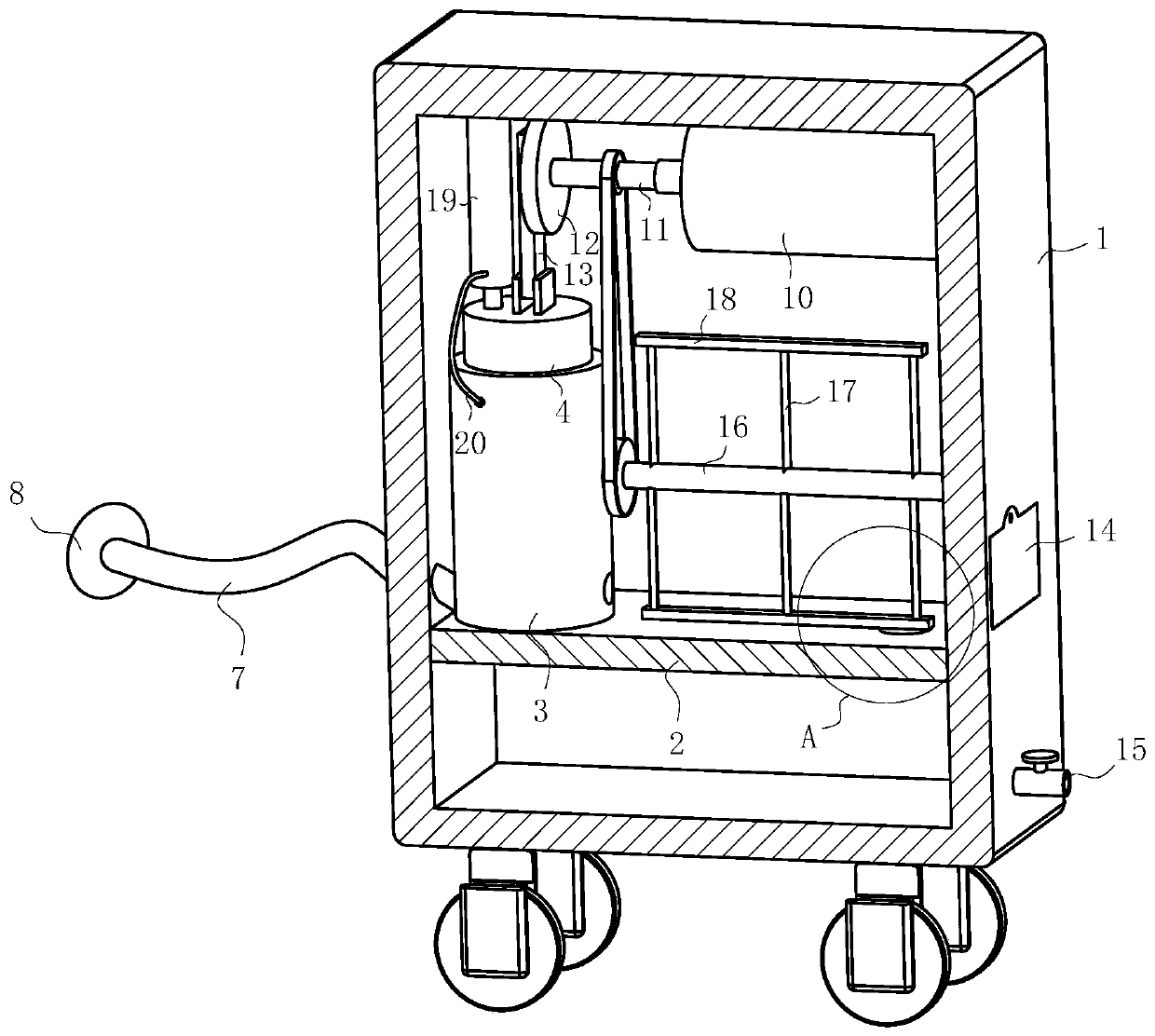

[0027] Such as Figure 1 to Figure 6 As shown, a method for treating liquid-containing hazardous chemicals according to the present invention comprises the following steps:

[0028]S1: Transport the collection device to the leaking site of hazardous chemicals, and fill the collection device with dry sand. When the collection device absorbs liquid hazardous chemicals and is absorbed by the sand, the collection capacity of the collection device can be improved and the collection can be ensured. The device is well sealed, so that the collection device will not leak when processing hazardous chemicals, ensuring the normal operation of the collection device, and plugging in the power plug at the same time to ensure the normal operation of the collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com