Parallel flow condenser and air conditioner with same

A condenser and parallel flow technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems that affect the heat exchange efficiency, and the tube wall is easy to form liquid film or oil film, etc., so as to improve the heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

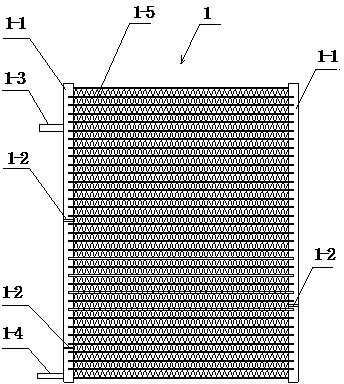

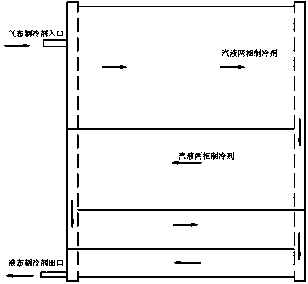

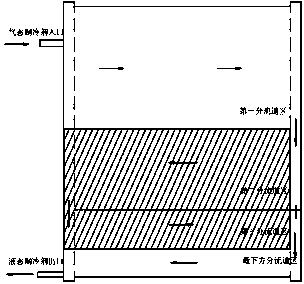

[0022] Embodiment 1, this embodiment proposes a parallel flow condenser 1, including a left header 1-1, a right header 1-1, and several refrigerants connecting the left header and the right header The branch pipe 1-5, the refrigerant branch pipe 1-5 is a flat pipe with a plurality of flow channel holes axially penetrating the flat pipe, and the gaseous refrigerant inlet pipe 1-3 and the gaseous refrigerant The outlet pipe 1-4, the left side header and the right side header 1-1 are respectively provided with spacers 1-2, which divide the internal flow channel of each header into a plurality of sub-flow channel areas, and each sub-flow channel The zone is connected with the corresponding refrigerant branch pipe to change the flow direction of the refrigerant, thereby adjusting the flow of the refrigerant inside the parallel flow condenser.

[0023] The number and arrangement of partitions in each header depends on the refrigerant in different states, preferably 1 to 4, and the i...

Embodiment 2

[0031] Embodiment 2. This embodiment proposes an air conditioner, on which the parallel flow condenser described in Embodiment 1 is installed. Part of the liquid refrigerant and compressor oil are introduced into the second half of the condenser by installing the above condenser, thereby greatly improving the heat exchange efficiency in the middle of the parallel flow condenser.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com