A method for preparing medium-low alkalinity all-vanadium-titanium self-fluxing pellets by using calcium oxide

A calcium oxide and self-fluxing technology, which is applied in the field of iron and steel metallurgy and ironmaking, can solve the problems of low ball-forming efficiency, low compressive strength, and easy bonding of the cue ball, and achieves improved green ball strength and compressive strength. , the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

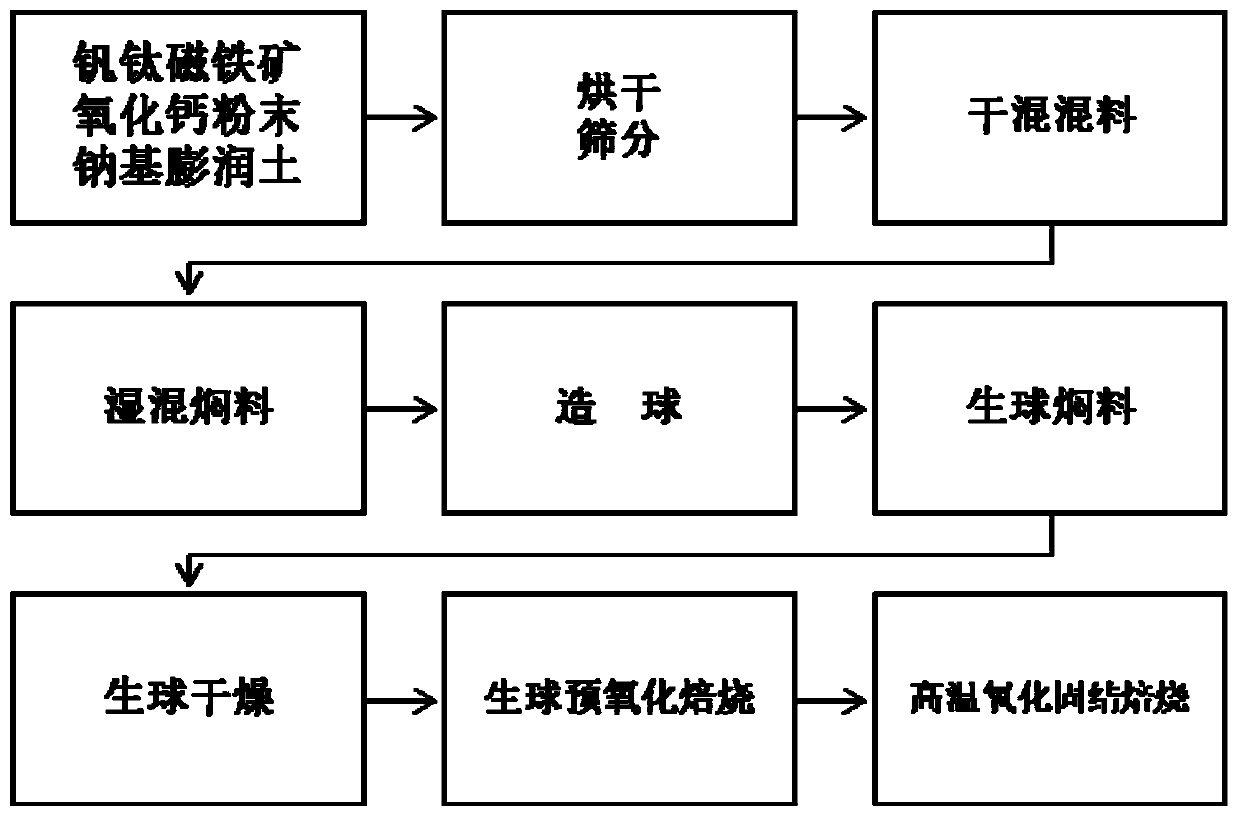

Method used

Image

Examples

Embodiment 1

[0043] 1. Take 5Kg of low-chromium vanadium-titanium magnetite in Hongge area as raw material, prepare 90.81g of pure calcium oxide powder for analysis, and 50g of sodium-based bentonite as additives, and obtain an alkalinity of 0.8; calcium oxide powder accounts for 1.8 of the total amount of raw materials %.

[0044] 2. Put the raw materials and additives in an enamel tray and dry them in a drying oven at a temperature of 105°C. Since the CaO and bentonite added later will affect the dry mixing effect due to water absorption, it is necessary to Carry out sufficient drying to eliminate free water, and the drying time is 6 hours, so that the moisture content of the mineral powder is less than 1%;

[0045] 3. Sieve the dried vanadium-titanium ore powder with a -0.5mm sieve, finely grind and re-sieve those that do not meet the particle size requirements, so that the ore powder below 200 mesh reaches 70%;

[0046] 4. Dry-mix the vanadium-titanium ore powder, analytically pure ca...

Embodiment 2

[0055] 1 Take 5Kg of low-chromium vanadium-titanium magnetite in Hongge area as raw materials, prepare 102.2g of pure calcium oxide powder for analysis, and 50g of sodium bentonite as additives, and the alkalinity obtained is 0.9; calcium oxide powder accounts for 2.02% of the total mass of raw materials .

[0056] 2. Put the raw materials and additives in an enamel tray and dry them in a drying oven at a temperature of 104°C. Since the CaO and bentonite added later will affect the dry mixing effect due to water absorption, the mineral powder should be properly mixed. Carry out sufficient drying to eliminate free water, and the drying time is 6 hours, so that the moisture content of the mineral powder is less than 1%;

[0057] 3. Use a -0.5mm sieve to sieve the dried vanadium-titanium ore powder, and finely grind and re-sieve those that do not meet the particle size requirements, so that the ore powder below 200 mesh reaches 75%;

[0058] 4. Dry-mix the vanadium-titanium ore ...

Embodiment 3

[0067] 1. Take 5Kg of low-chromium vanadium-titanium magnetite in the Hongge area as raw materials, prepare 113.5g of pure calcium oxide powder for analysis, and 50g of sodium bentonite as additives, and the alkalinity obtained is 1.0; calcium oxide accounts for 2.25% of the total mass of raw materials .

[0068] 2. Put the raw materials and additives in an enamel tray and dry them in a drying oven at a temperature of 105°C. Since the CaO and bentonite added later will affect the dry mixing effect due to water absorption, it is necessary to Carry out sufficient drying to eliminate free water, and the drying time is 6 hours, so that the moisture content of the mineral powder is less than 1%;

[0069] 3. Sieve the dried vanadium-titanium ore powder with a -0.5mm sieve, finely grind and re-sieve those that do not meet the particle size requirements, so that the ore powder below 200 mesh reaches 70%;

[0070] 4. Dry-mix the vanadium-titanium ore powder, analytically pure calcium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com