Gas-based reduction method and system for granular iron ore and application

An iron ore and granular technology, applied in chemical instruments and methods, waste gas treatment, climate sustainability, etc., can solve problems such as long residence time of reducing gas, affecting fluidization, and unstable operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

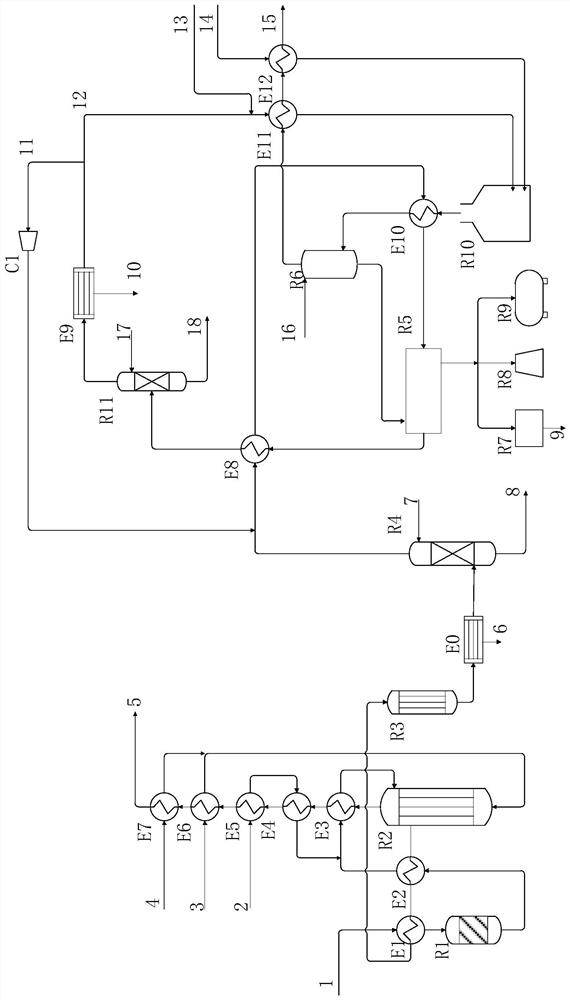

[0097] As a preferred embodiment of the present invention, at least part of the purified tail gas is mixed with the shift gas after the first dehydration treatment for reuse; or, at least part of the purified tail gas is mixed with the first deCO2 2 The treated hydrogen-rich gas is blended for reuse.

[0098] As a preferred embodiment of the present invention, the purified tail gas is mixed with fuel gas and oxygen-containing gas and used as fuel, and the heat generated by combustion can be used to preheat granular iron ore.

[0099] The gas-based reduction method of granular iron ore provided by the present invention can not only realize the preparation of granular direct reduced iron with a higher metallization rate, but also realize the efficient utilization of reducing gas, greatly reduce energy consumption in the process, heat and material It is also fully recycled and has a good application prospect in the field of industrial preparation of granular direct reduced iron. ...

Embodiment 1

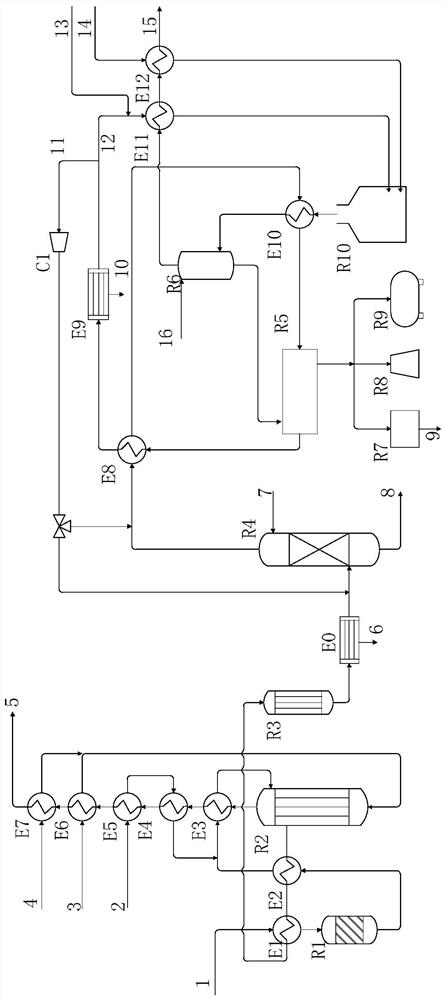

[0142] The present embodiment provides a gas-based reduction method of granular iron ore, comprising the following steps:

[0143] (a) Desulfurize the gasified liquefied natural gas with a pressure of 2.8MPa and mix it with water vapor at a volume ratio of (3.5-3.6): 1 to carry out a reforming reaction. The temperature of the reforming reaction is 870°C to obtain Crude synthesis gas; wherein, the mass fraction of sulfur in the natural gas after desulfurization is less than 1ppm; the dry gas composition in the crude synthesis gas includes: H 2 68-70%, CO 12-13%, CO 2 16-18% and CH 4 1-1.5%;

[0144] The crude synthesis gas is subjected to a shift reaction, and the temperature of the shift reaction is 360-380° C. to obtain the shift gas;

[0145] The shift gas is subjected to the first dehydration treatment and the first deCO 2 Process to obtain hydrogen-rich gas; wherein, the dry gas composition of hydrogen-rich gas includes: H 2 93-96%, CO 3-5%, CO 2 0-0.2%, CH 4 1.2-1....

Embodiment 2

[0153] The present embodiment provides a gas-based reduction method of granular iron ore, comprising the following steps:

[0154] (a) Desulfurize compressed natural gas with a pressure of 2 MPa and mix it with water vapor at a volume ratio of (3.2-3.3): 1 to carry out a reforming reaction. The temperature of the reforming reaction is 850° C. to obtain crude synthesis gas; wherein , the mass fraction of sulfur in natural gas after desulfurization is less than 1ppm; the composition of dry gas in crude synthesis gas includes: H 2 63-65%, CO 15-16%, CO 2 13-15% and CH 4 3-3.5%, N 2 2-3%;

[0155] The crude synthesis gas is subjected to a shift reaction, and the temperature of the shift reaction is 230-250° C. to obtain the shift gas;

[0156] The shift gas is subjected to the first dehydration treatment and the first deCO 2 Process to obtain hydrogen-rich gas; wherein, the dry gas composition of hydrogen-rich gas includes: H 2 92-94%, CO 0.3-0.5%, CO 2 0-0.1%, CH 4 3.5-4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com