Coating material for restraining excessive bonding during smelting reduction of iron ore pellets and preparation method of coating material

A coating material and iron ore ball technology, applied in the field of smelting reduction ironmaking, can solve the problem of excessive bonding of iron ore pellets, and achieve the effects of inhibiting excessive bonding, reducing the probability of bonding, and preventing large-scale cracking or falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

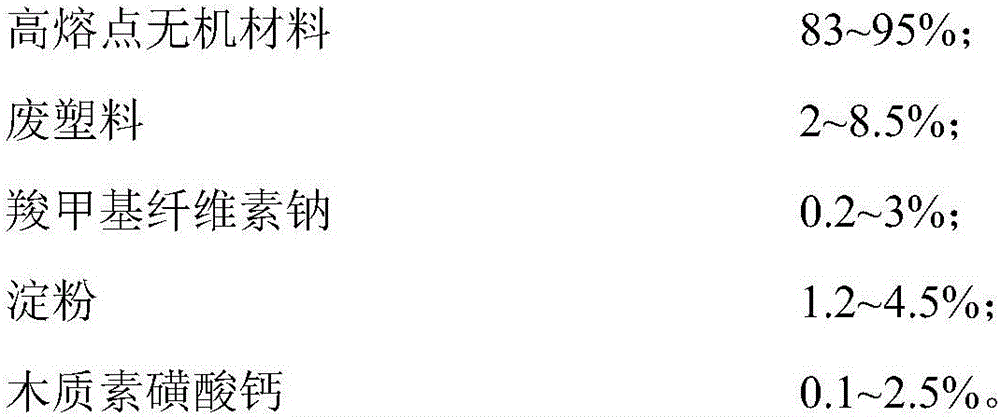

[0037] A coating material for inhibiting excessive bonding of iron ore pellets in smelting reduction of the present embodiment is composed of the following components in weight percentage: 84.5% of high melting point inorganic materials, 7.5% of waste plastics, 1.0% of sodium carboxymethyl cellulose, Starch 4.5%, calcium lignosulfonate 2.5%. Among them, the high melting point inorganic material is composed of α-alumina, aluminum hydroxide and magnesium aluminum spinel, and the above-mentioned components are composed as follows in parts by mass: 45 parts of α-alumina, 24 parts of aluminum hydroxide, 20 servings. In the high-melting-point inorganic material of this embodiment, the mass with a particle size of less than 200 mesh accounts for ≥95% of the total mass of the high-melting-point inorganic material, and the Al in α-alumina 2 o 3 The mass percentage content is not less than 95%, in magnesium aluminum spinel (MgO+Al 2 o 3 ) The mass percent content is not less than 98...

Embodiment 2

[0056] A coating material for inhibiting excessive bonding of iron ore pellets in smelting reduction of the present embodiment is composed of the following components in weight percentage: 94.2% of high melting point inorganic materials, 2.5% of waste plastics, 0.2% of sodium carboxymethylcellulose, Starch 1.2%, calcium lignosulfonate 1.9%. Among them, the high melting point inorganic material is composed of α-alumina, aluminum hydroxide and magnesium aluminum spinel, and the above-mentioned components are composed as follows in parts by mass: Stone 6 parts. In the high-melting-point inorganic material of this embodiment, the mass with a particle size of less than 200 mesh accounts for ≥95% of the total mass of the high-melting-point inorganic material, and the Al in α-alumina 2 o 3 The mass percentage content is not less than 95%, in magnesium aluminum spinel (MgO+Al 2 o 3 ) The mass percent content is not less than 98%. The waste plastics of this embodiment is a mixture...

Embodiment 3

[0066] A coating material for inhibiting excessive bonding of iron ore pellets in smelting reduction of the present embodiment is composed of the following components in weight percentage: 89.5% of high melting point inorganic materials, 5.0% of waste plastics, 2.8% of sodium carboxymethyl cellulose, Starch 2.5%, calcium lignosulfonate 0.2%. Among them, the high melting point inorganic material is composed of α-alumina, aluminum hydroxide and magnesium aluminum spinel, and the above-mentioned components are composed as follows in parts by mass: 57 parts of Stone 15 parts. Described waste plastics is the mixture that is made up of polypropylene (PP), polystyrene (PS) and polyethylene terephthalate (PET), and each component of this mixture is made up as follows by weight percentage: Polypropylene (PP) 20%, polystyrene (PS) 10%, polyethylene terephthalate (PET) 70%.

[0067] The preparation method of the above-mentioned coating material for inhibiting the excessive bonding of i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com