Direct reduced iron production method and device

A direct, iron ore technology, applied in furnace types, furnaces, shaft furnaces, etc., can solve the problems of low emissions, high production energy consumption, easy furnace ring formation, etc., to achieve enhanced activity, high utilization value, and improved air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

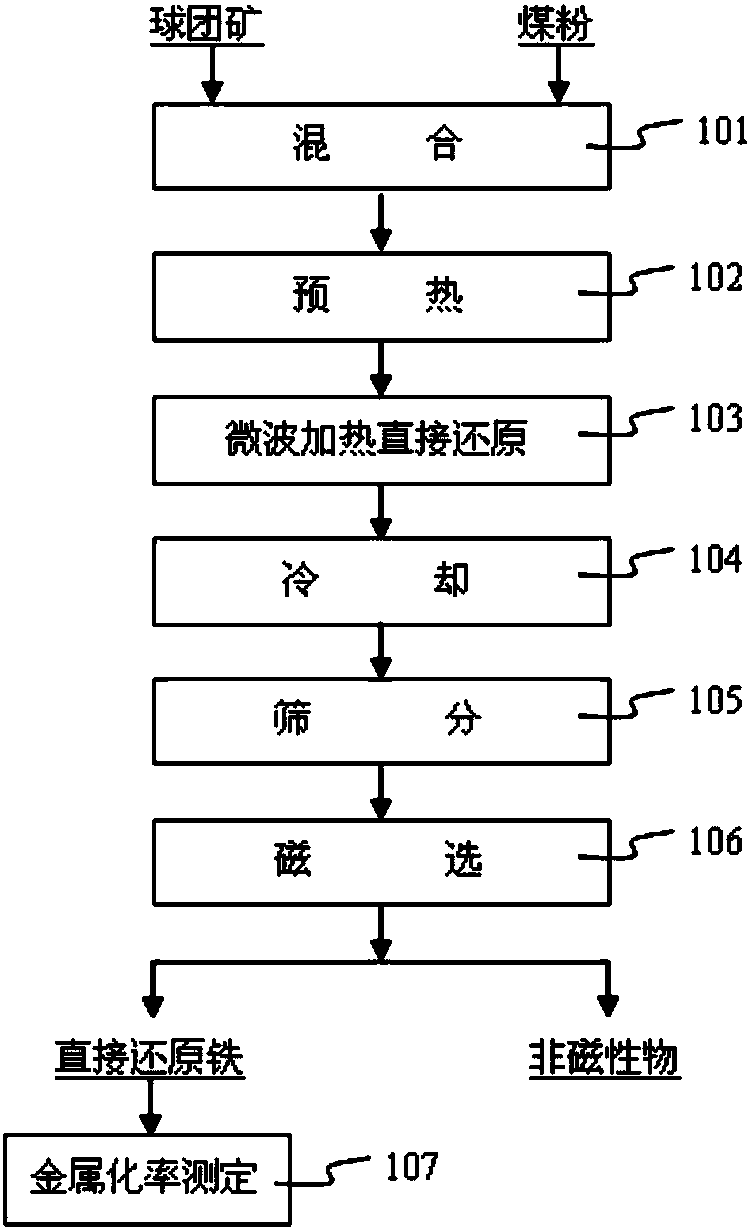

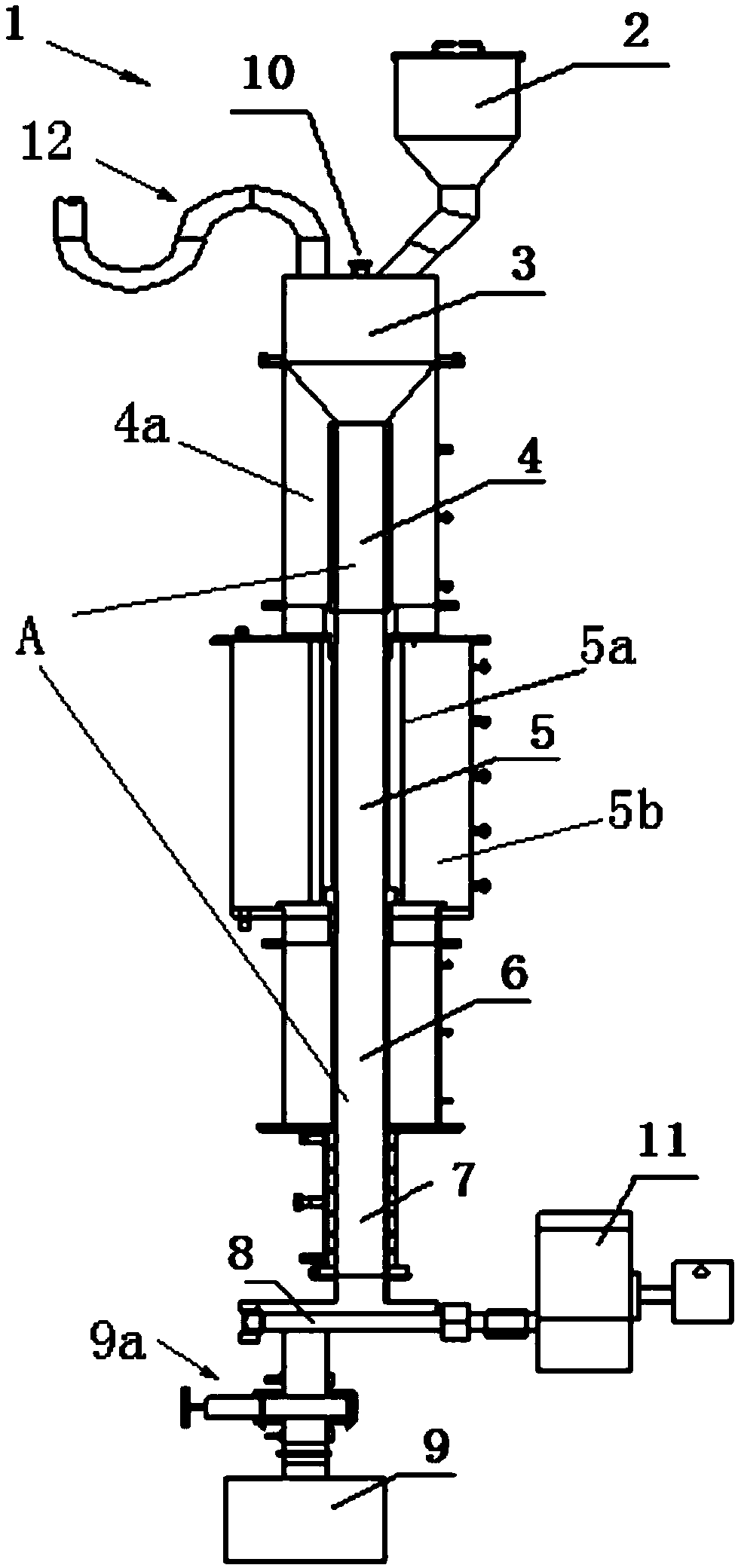

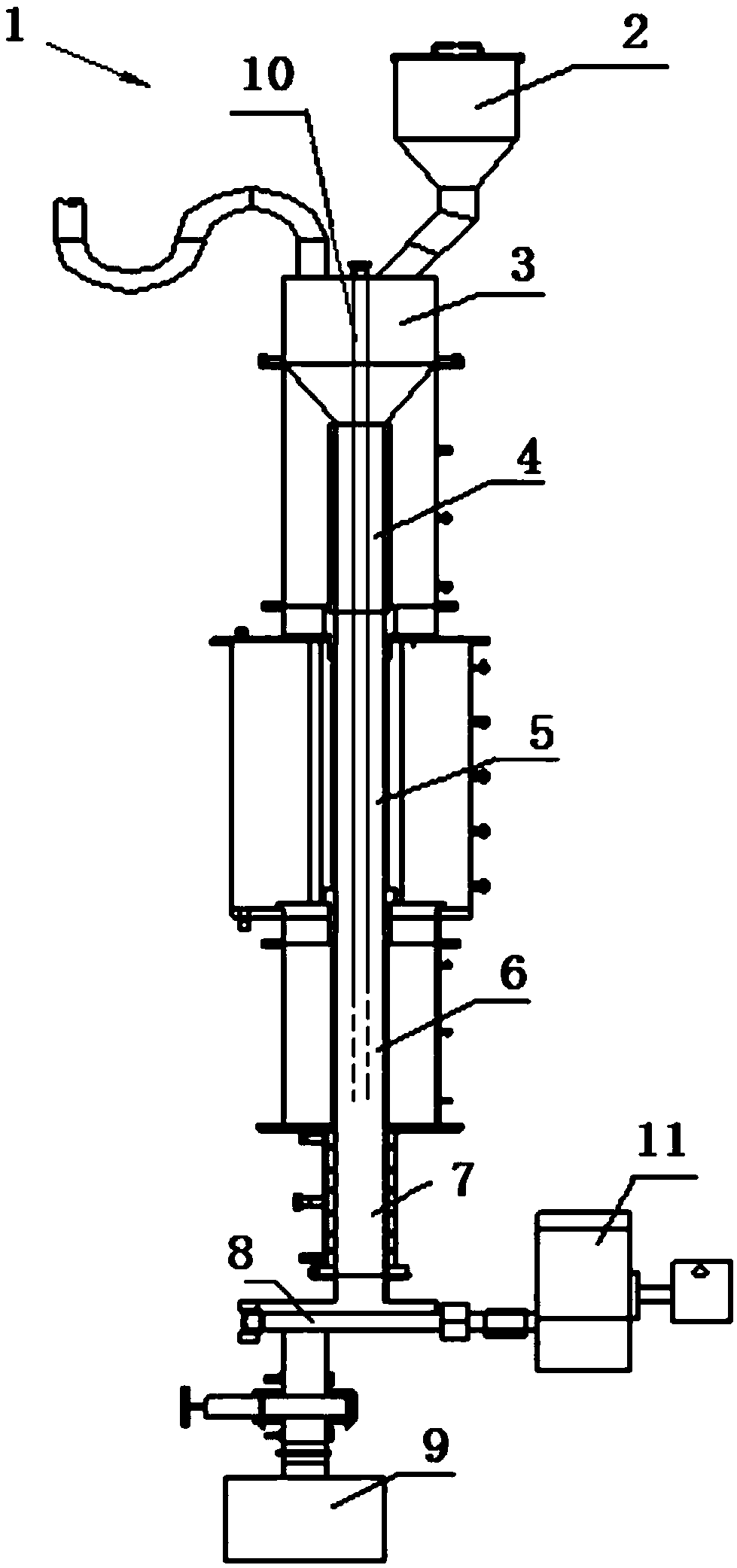

[0113] The preheated pellets are mixed with coal powder to carry out direct reduction in the microwave shaft furnace. The preheated pellets are TFe66.32%, and the compressive strength is 850N. The coal powder is added according to the ratio of 1:1. In the furnace, after preheating, microwave heating, reducing roasting, and cooling, the metallization rate and carbon residue were measured. Among them, the reduction temperature is 1050°C, and the reduction time is 68 minutes. The metallization rate of the obtained direct reduced iron product is 94.26%, and the carbon residue is 0.17%. 2 3.5%.

Embodiment 2

[0115] Use oxidized pellets to add coal powder to the microwave shaft furnace for direct reduction, in which the oxidized pellets have TFe64.24%, compressive strength 2973N, add coal powder according to the ratio of 1:1, mix them and send them into the microwave shaft furnace , After preheating, microwave heating, reducing roasting, and cooling, the metallization rate and carbon residue were measured. Among them, the reduction temperature is 1050°C, the reduction time is 65 minutes, the metallization rate of the obtained direct reduced iron product is 95.25%, and the carbon residue is 0.12%. In addition, the CO in the exhaust gas collected from the air duct during the reduction process accounts for 96.5%, and the CO 2 Accounted for 2.7%.

Embodiment 3

[0117] Pre-reduced pellets are mixed with coal powder to carry out direct reduction in a microwave shaft furnace. The pre-reduced pellets have a TFe77.17% and a compressive strength of 1060N. Coal powder is added according to the carbon excess coefficient of 2.0, and then sent into the microwave shaft furnace after mixing. In the furnace, after preheating, microwave heating, reducing roasting, and cooling, the metallization rate and carbon residue were measured. Among them, the reduction temperature is 950°C, and the reduction time is 56 minutes. The metallization rate of the obtained direct reduced iron product is 95.47%, and the carbon residue is 0.11%. 2 Accounted for 1.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com