Method for preparing molybdenum powder by molybdenum trioxide

A technology of molybdenum trioxide and molybdenum powder, which is applied in the field of molybdenum trioxide to prepare molybdenum powder, which can solve the problems of poor fluidity, production paralysis, energy consumption and cost increase, and achieve the effect of narrow control range and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

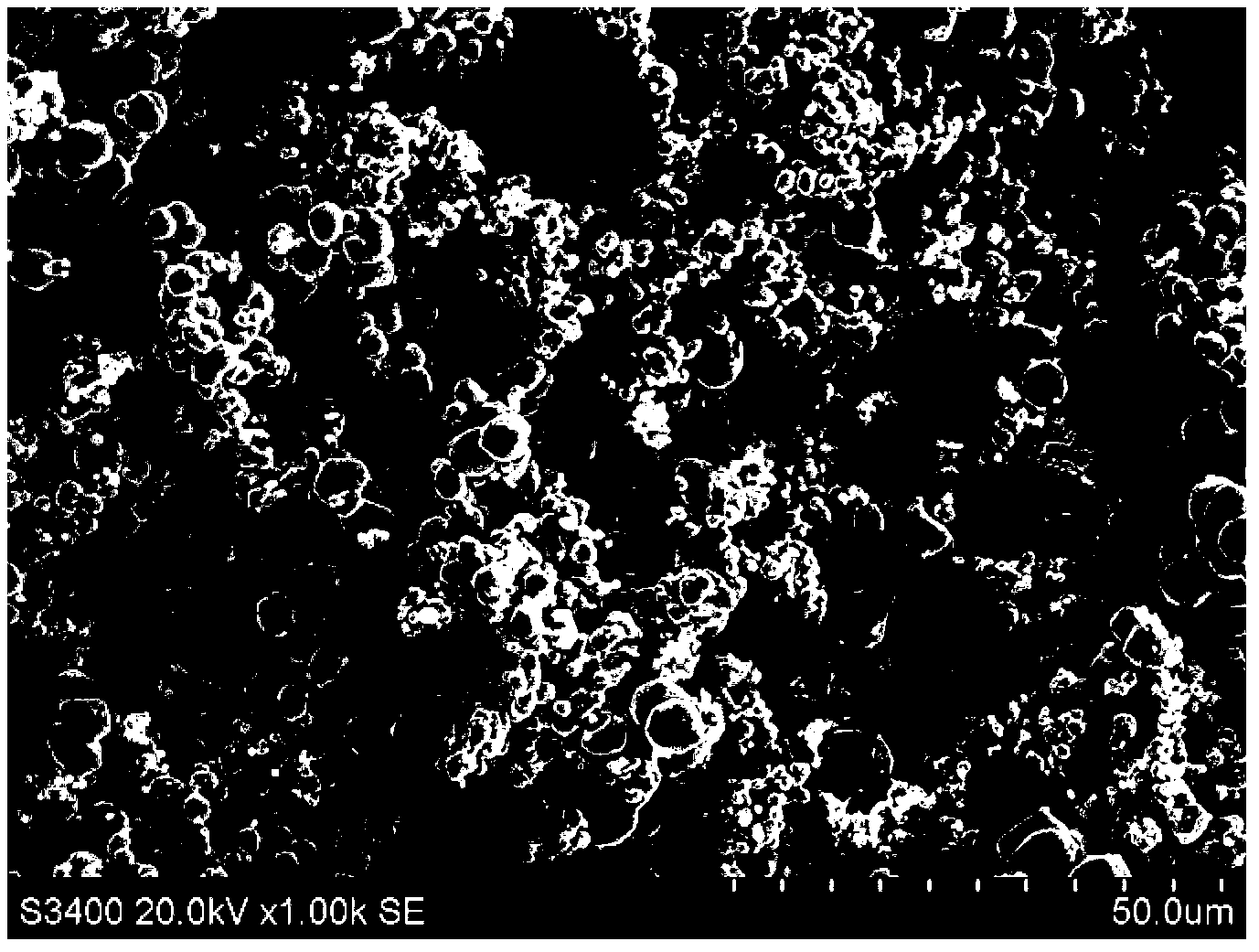

Image

Examples

Embodiment 1

[0032] The method that present embodiment utilizes molybdenum trioxide to prepare molybdenum powder comprises the following steps:

[0033] Step 1. Molybdenum trioxide is passed through a 40-mesh sieve to get the oversize, and then the oversize after sieving is put into a ball mill for ball milling to obtain molybdenum trioxide powder with a molybdenum mass percentage content of 66.62%; in the present embodiment, The ball mill is an ASM type horizontal agitating ball mill, and the ball milling medium in the ASM type horizontal agitating ball mill is a molybdenum ball with a molybdenum mass percentage content of 99.95% and a diameter of 10mm; the Fischer particle size of the molybdenum trioxide powder is 6.0 μm, the bulk density of the molybdenum trioxide powder is 0.95g / cm 3 The moisture content of the molybdenum trioxide powder (the moisture content of the molybdenum trioxide powder refers to the mass percentage of water in the molybdenum trioxide powder) is 1.5%;

[0034] S...

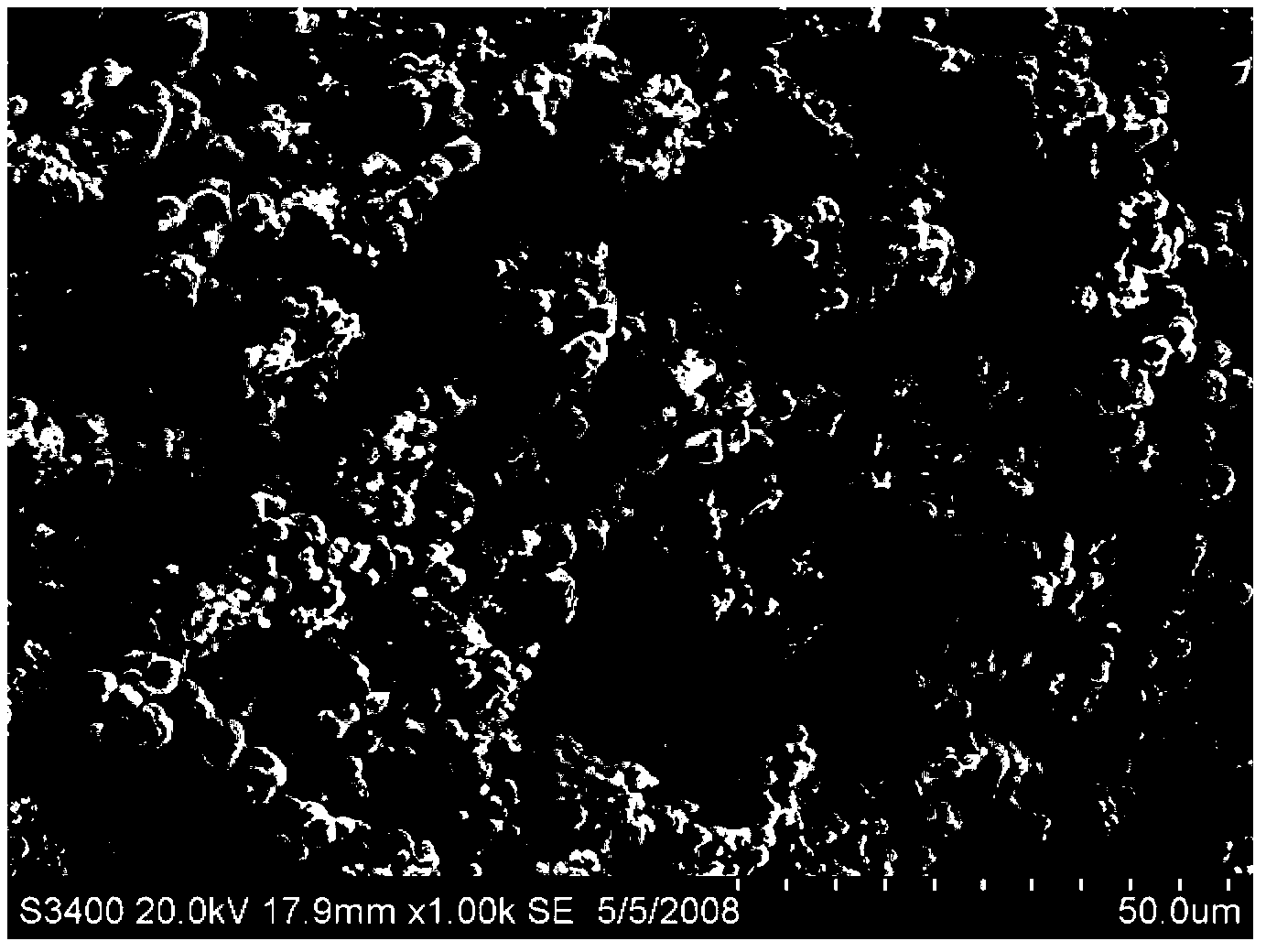

Embodiment 2

[0039] The method that present embodiment utilizes molybdenum trioxide to prepare molybdenum powder comprises the following steps:

[0040] Step 1, passing molybdenum trioxide through a 40-mesh sieve to get the oversize, and then putting the sieved oversize into a ball mill for ball milling to obtain molybdenum trioxide powder with a molybdenum mass percentage of 66.63%; in this embodiment, The ball mill is an ASM type horizontal agitating ball mill, and the ball milling medium in the ASM type horizontal agitating ball mill is a molybdenum ball with a molybdenum mass percentage content of 99.97% and a diameter of 12mm; the Fischer particle size of the molybdenum trioxide powder is 4 μm, the bulk density of the molybdenum trioxide powder is 0.9g / cm 3 The moisture content of the molybdenum trioxide powder (the moisture content of the molybdenum trioxide powder refers to the mass percentage of water in the molybdenum trioxide powder) is 1.7%;

[0041] Step 2. Under a hydrogen at...

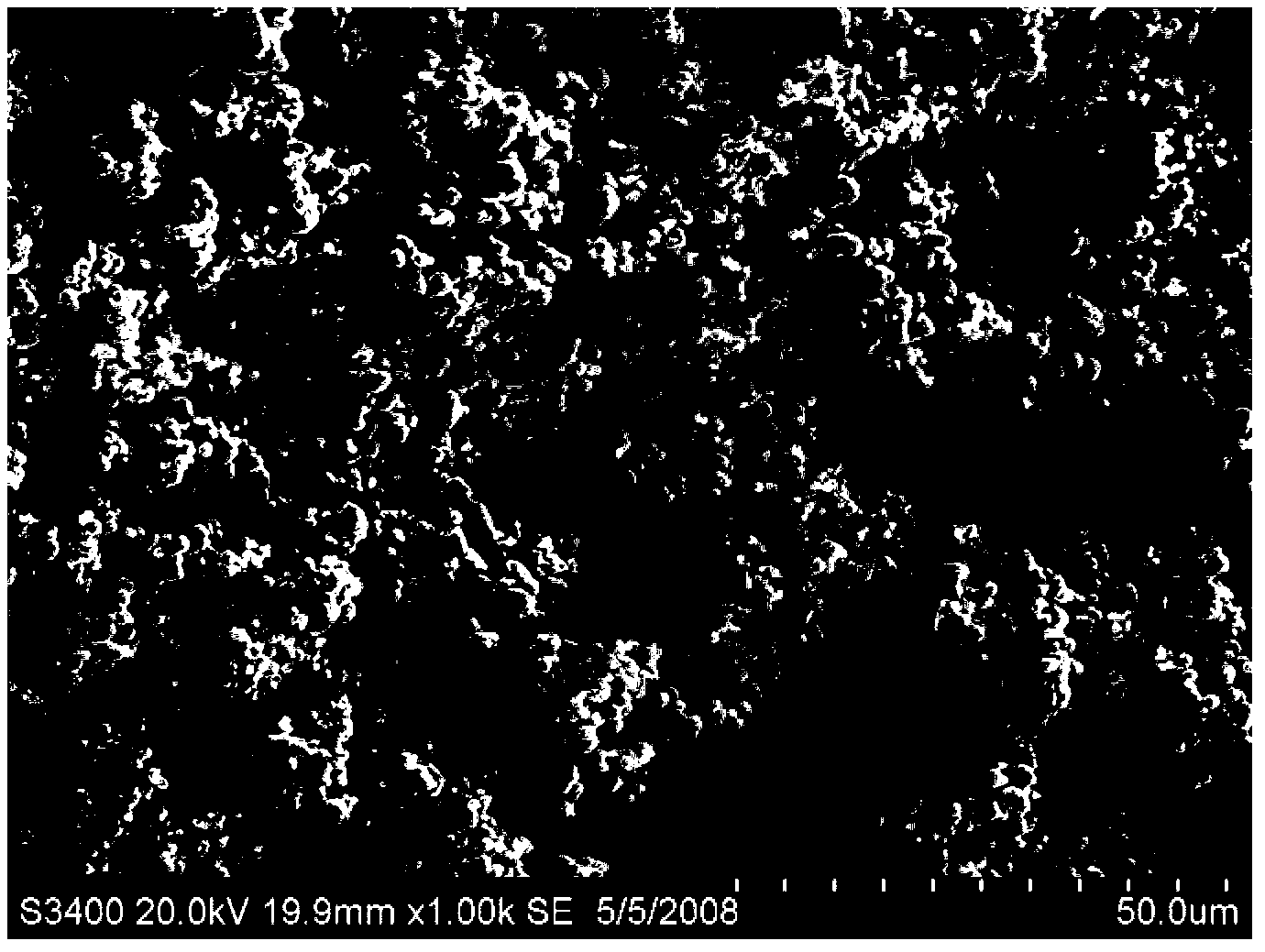

Embodiment 3

[0046] The method that present embodiment utilizes molybdenum trioxide to prepare molybdenum powder comprises the following steps:

[0047] Step 1. Molybdenum trioxide is passed through a 40-mesh sieve to get the oversize, and then the oversize after sieving is put into a ball mill for ball milling to obtain molybdenum trioxide powder with a molybdenum mass percentage content of 66.62%; in the present embodiment, The ball mill is an ASM type horizontal agitating ball mill, and the ball milling medium in the ASM type horizontal agitating ball mill is a molybdenum ball with a molybdenum mass percentage content of 99.97% and a diameter of 8 mm; the Fischer particle size of the molybdenum trioxide powder is 8 μm, the bulk density of the molybdenum trioxide powder is 1.0g / cm 3 The moisture content of the molybdenum trioxide powder (the moisture content of the molybdenum trioxide powder refers to the mass percentage of water in the molybdenum trioxide powder) is 1.6%;

[0048] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fisherman's particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com