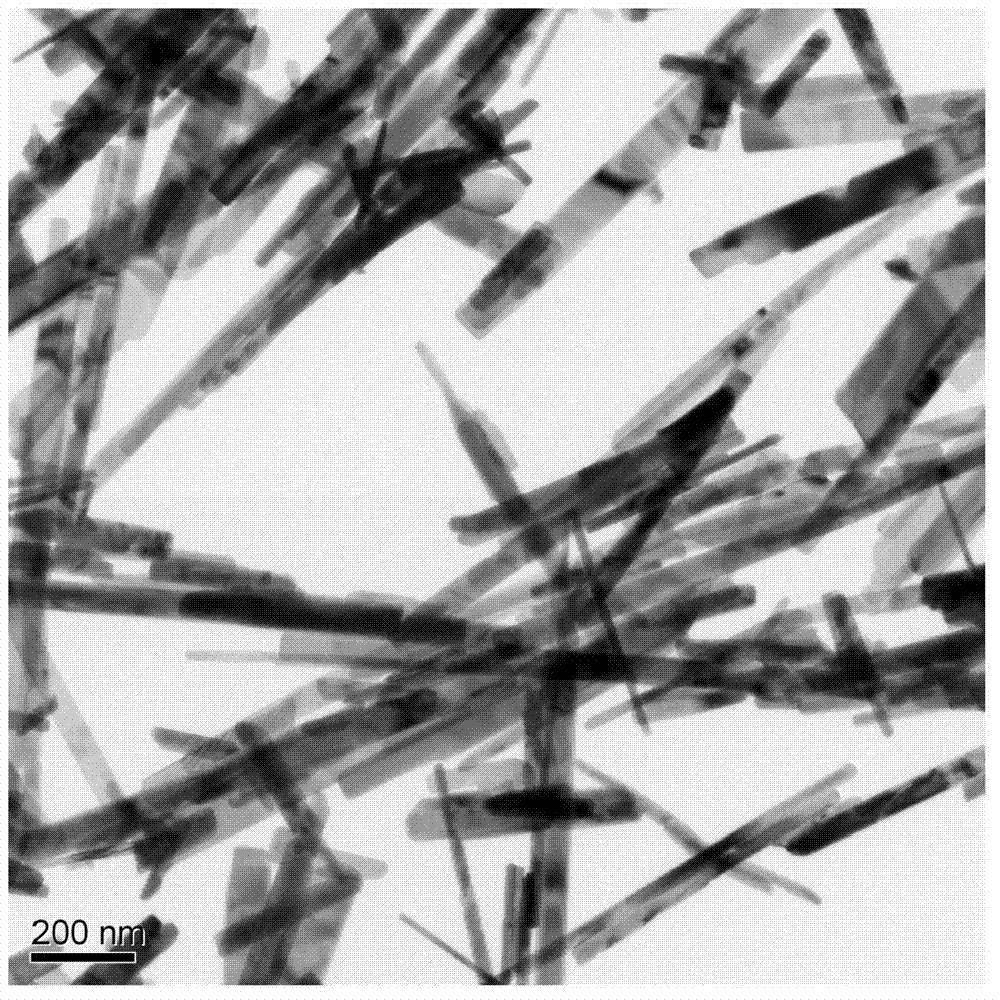

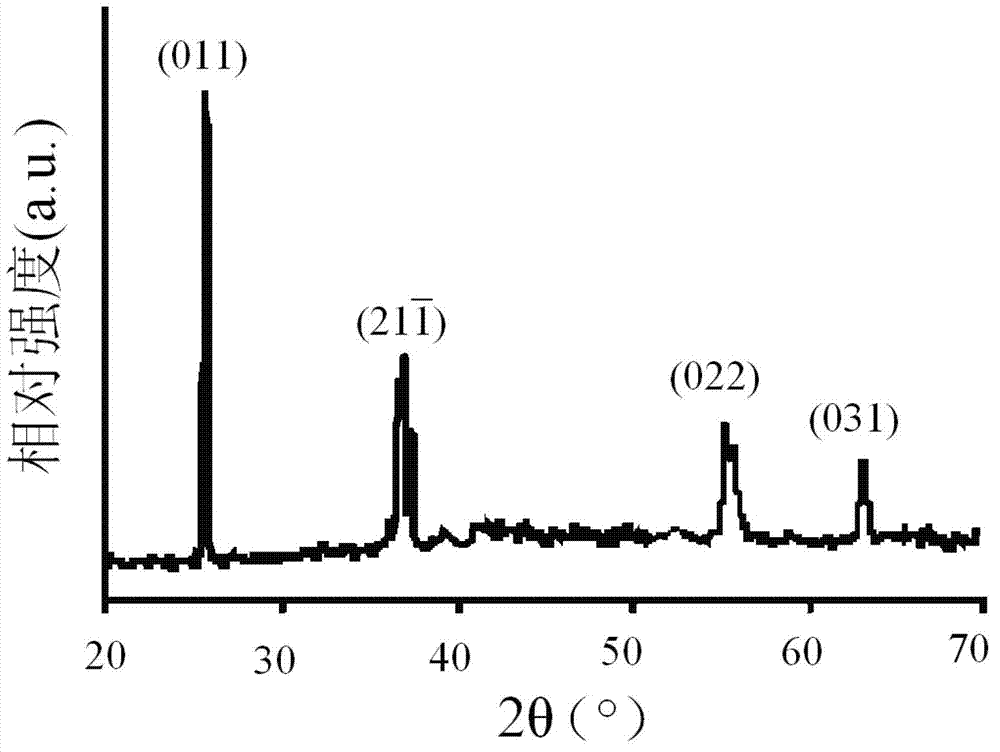

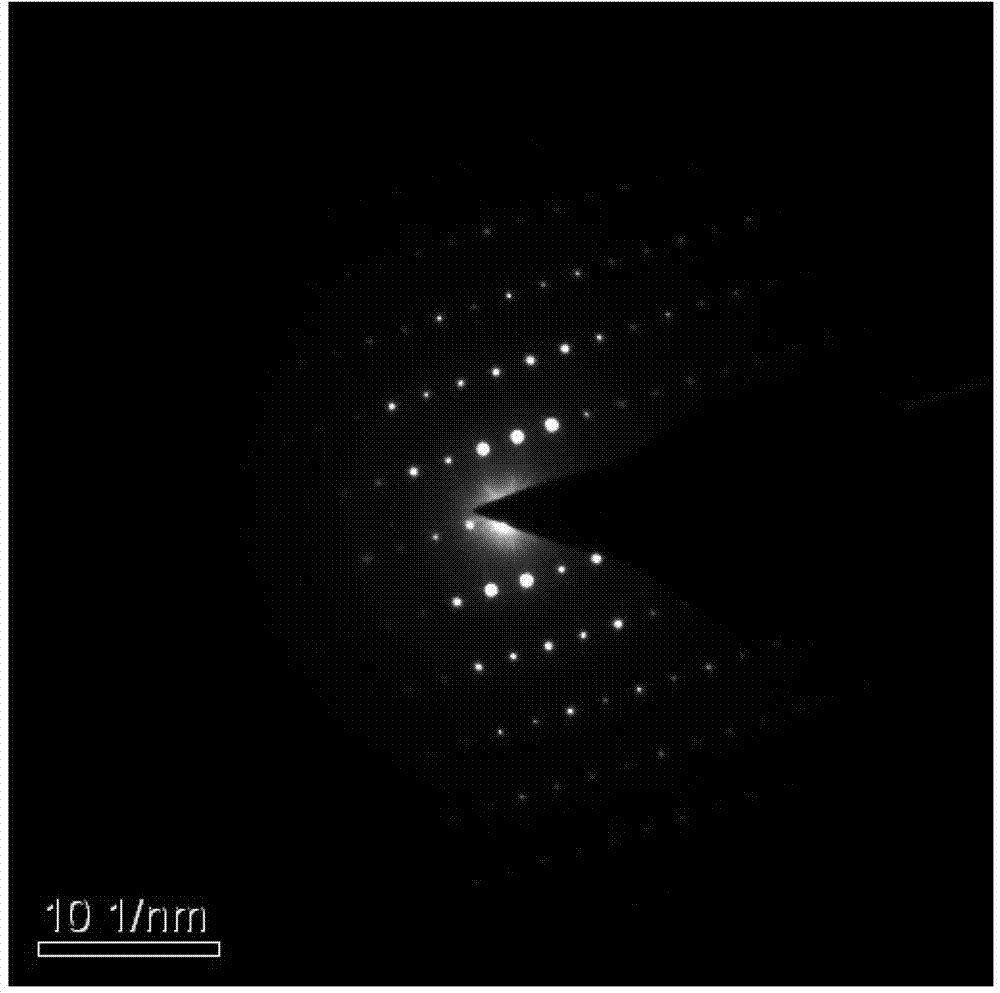

Preparation method of molybdenum dioxide nanorod

A technology of molybdenum dioxide and nanorods, which is applied in the field of nanomaterials, can solve the problems of uneven product morphology, harsh synthesis conditions, and high synthesis temperature, and achieve the effects of low cost, low raw material cost, and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve sodium tungstate in dimethylformamide after grinding, and magnetically stir to obtain a concentration of 0.1mol L -1 The sodium molybdate suspension; in the case of continuing to stir, add 1ml acetic anhydride to the sodium molybdate suspension, after continuing to stir for 10min; slowly add concentrated hydrochloric acid to it to acidify it in the above suspension, concentrated After hydrochloric acid was added, the suspension became a yellow solution containing white precipitates. The amount of concentrated hydrochloric acid added was such that the pH value of the solution after acidification was 1.5, and stirring was continued for 15 minutes; after the stirring was completed, the yellow solution containing white precipitates after acidification was Filter to remove the white precipitate to obtain a yellow transparent filtrate; under the condition of magnetic stirring, the concentration is 0.3mol L -1 The dimethylformamide solution of tetrabutylammonium bromi...

Embodiment 2

[0028] Dissolve sodium tungstate in dimethylformamide after grinding, and magnetically stir to obtain a concentration of 0.4mol L -1 The sodium molybdate suspension; in the situation of continuing to stir, add 3ml acetic anhydride to the sodium molybdate suspension, after continuing to stir for 10min; slowly add concentrated hydrochloric acid to it to acidify it in the above suspension, concentrated After hydrochloric acid was added, the suspension became a yellow solution containing white precipitates. The amount of concentrated hydrochloric acid added was such that the pH value of the solution after acidification was 0.5, and stirring was continued for 15 minutes; after the stirring was completed, the yellow solution containing white precipitates after acidification was Filter to remove the white precipitate to obtain a yellow transparent filtrate; under the condition of magnetic stirring, the concentration is 0.5mol L -1 The dimethylformamide solution of tetrabutylammonium ...

Embodiment 3

[0030] Dissolve sodium tungstate in dimethylformamide after grinding, and magnetically stir to obtain a concentration of 0.3mol L -1 The sodium molybdate suspension; in the case of continuing to stir, add 2ml acetic anhydride to the sodium molybdate suspension, after continuing to stir for 10min; slowly add concentrated hydrochloric acid to it to acidify it in the above suspension, concentrated After hydrochloric acid was added, the suspension became a yellow solution containing white precipitates. The added amount of concentrated hydrochloric acid finally made the pH value of the acidified solution 1.0, and continued to stir for 15 minutes; after the stirring was completed, the acidified yellow solution containing white precipitates Filter to remove the white precipitate to obtain a yellow transparent filtrate; under the condition of magnetic stirring, the concentration is 0.4mol L -1 The dimethylformamide solution of tetrabutylammonium bromide was added to the obtained yello...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com