Preparation method for high-capacity molybdenum dioxide anode material and application of high-capacity molybdenum dioxide anode material

A molybdenum dioxide and negative electrode material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of limited capacity of negative electrode materials and inability to adapt to industrial production, achieve high specific capacity, suitable for large-scale production, improve electronic Effects of Conductivity and Ion Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First, 1 gram of ammonium molybdate, 4 milliliters of deionized water, 4 milliliters of absolute alcohol and 40 milliliters of 10% polyvinyl alcohol solution were mixed to obtain a precursor solution.

[0026] Secondly, the precursor solution is subjected to an electrostatic high voltage of 8 kV to form composite nanofibers of ammonium molybdate and polyvinyl alcohol.

[0027] Then, the obtained nanofibers were first stabilized in the air. The stabilization process was to raise the temperature to 180° C. at a rate of 1° C. per minute, keep the temperature for 30 minutes, and then raise the temperature to 300° C. at the same rate, and keep the temperature for 30 minutes.

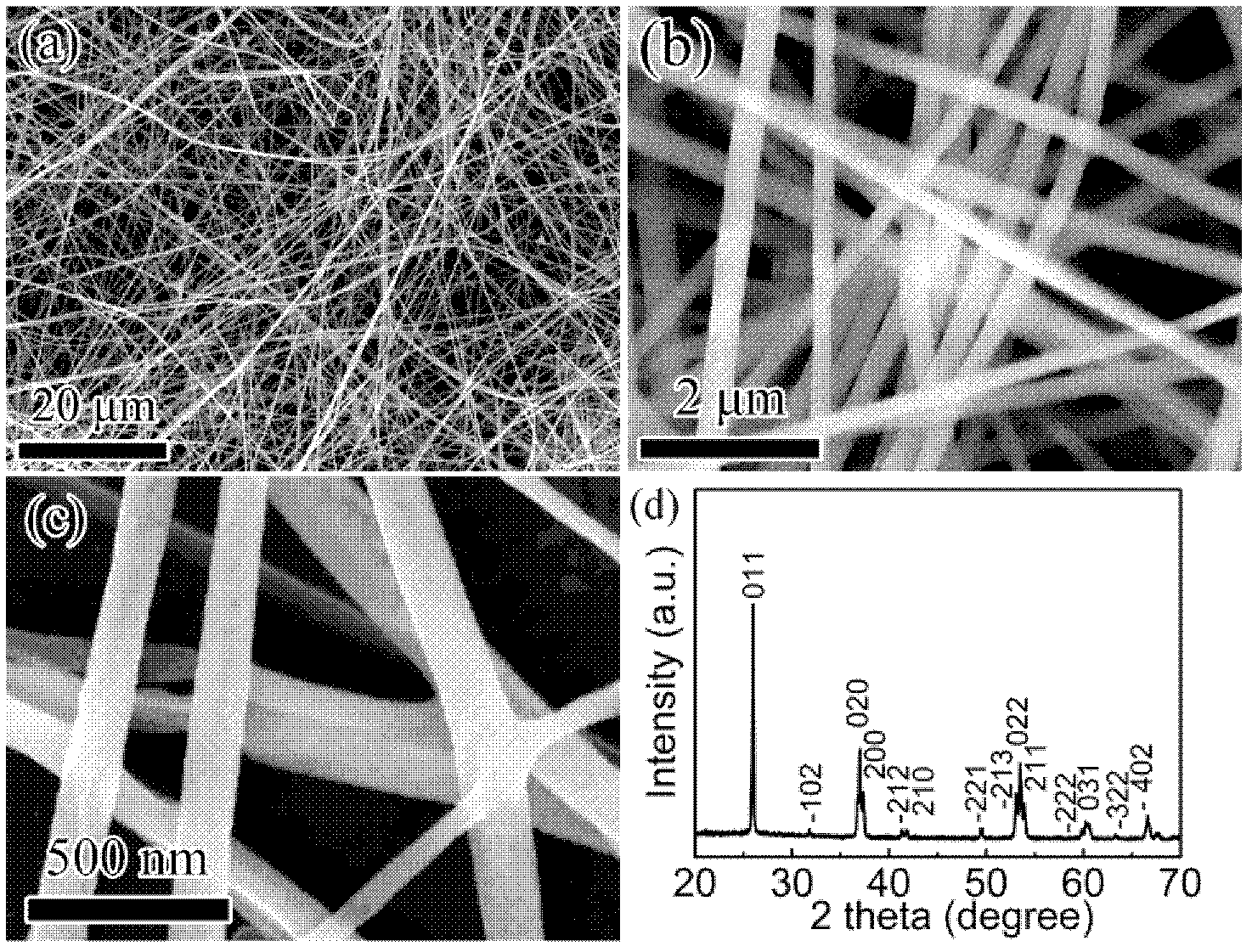

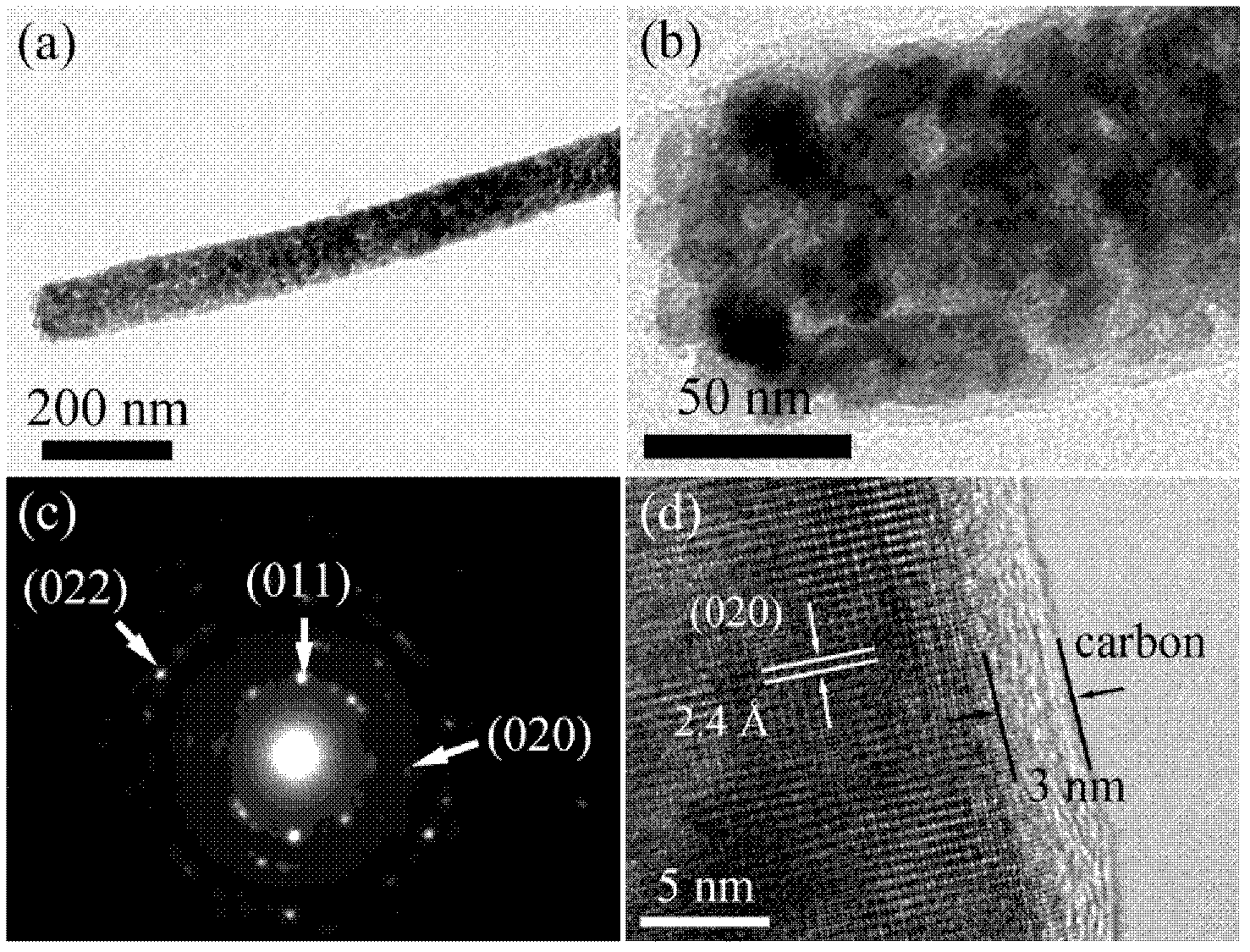

[0028] figure 1 (a) and (b) are different magnification FESEM images of ammonium molybdate and polyvinyl alcohol composite nanofibers. It can be seen that the carbon-coated molybdenum dioxide composite nanofibers obtained after stabilization in air and reduction in a reducing atmosphere maintain a ver...

Embodiment 2

[0034] Mix 1 gram of ammonium molybdate, 4 milliliters of deionized water, 4 milliliters of absolute alcohol and 40 milliliters of 10% polyvinyl alcohol solution to obtain a precursor solution. The precursor solution becomes a composite nanofiber of ammonium molybdate and polyvinyl alcohol under the action of an electrostatic high voltage of 8 kV. The obtained nanofibers are first stabilized in the air. The stabilization process is to raise the temperature to 180° C. at a rate of 1° C. per minute, keep the temperature for 30 minutes, and then raise the temperature to 300° C. at the same rate, and keep the temperature for 30 minutes. The stabilized nanofibers were then carbonized at 500°C for 12 hours in a nitrogen atmosphere to obtain molybdenum dioxide composite fibers with a carbon coating.

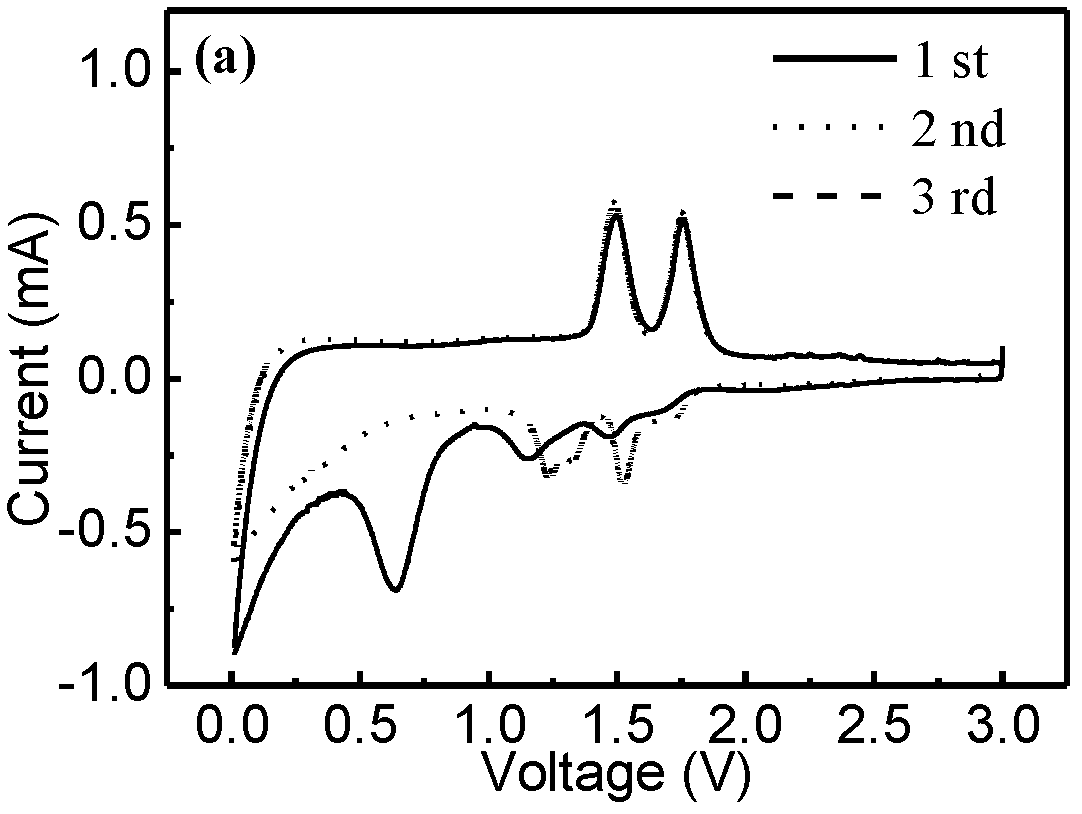

[0035] The carbon-coated molybdenum dioxide nanofibers obtained above were assembled into a button battery in the same manner as in Example 1, and the performance of the point was teste...

Embodiment 3

[0037] Mix 2 grams of ammonium molybdate, 8 milliliters of deionized water, 8 milliliters of absolute alcohol and 80 milliliters of 10% polyvinyl alcohol solution to obtain a precursor solution. The precursor solution becomes a composite nanofiber of ammonium molybdate and polyvinyl alcohol under the action of an electrostatic high voltage of 8 kV. The obtained nanofibers are first stabilized in the air. The stabilization process is to raise the temperature to 180° C. at a rate of 1° C. per minute, keep the temperature for 30 minutes, and then raise the temperature to 300° C. at the same rate, and keep the temperature for 30 minutes. The stabilized nanofibers were then carbonized at 700°C for 4 hours in a nitrogen atmosphere to obtain molybdenum dioxide composite fibers with a carbon coating.

[0038] The carbon-coated molybdenum dioxide nanofibers obtained above were assembled into a button battery in the same manner as in Example 1, and the performance of the point was teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com