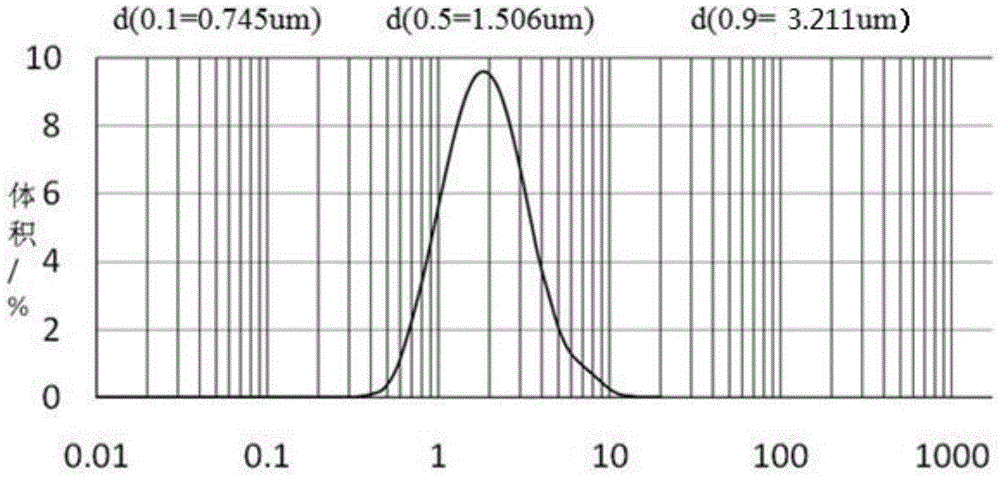

Preparation method for highly-dispersed ultrafine molybdenum powder with narrow particle size distribution

A technology of ultra-fine molybdenum powder with narrow particle size distribution, applied in the preparation of ultra-fine molybdenum powder with narrow particle size distribution, in the field of high dispersion, can solve the problems of high cost and serious agglomeration of molybdenum powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

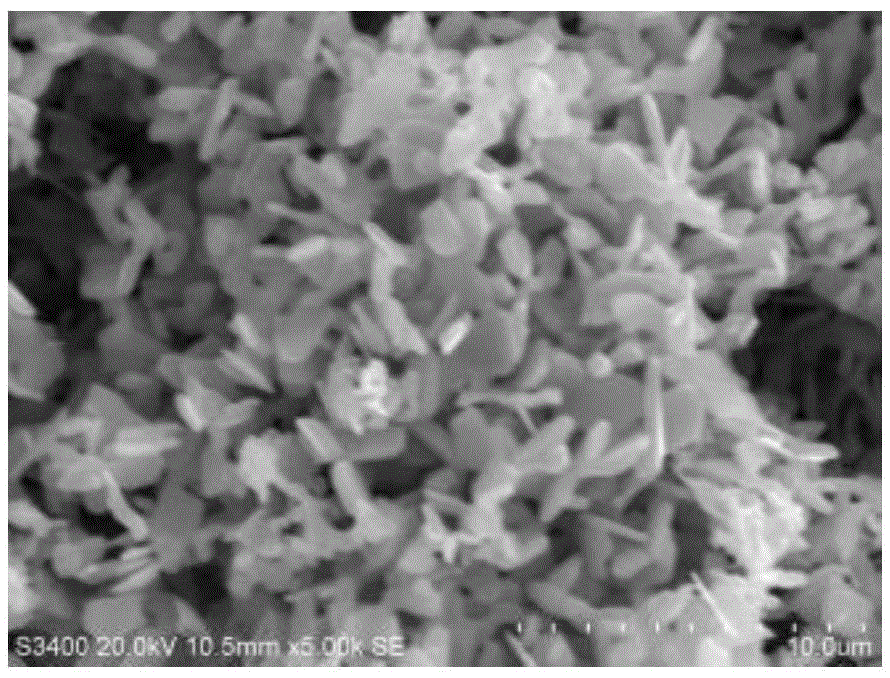

Embodiment 1

[0021] Put the molybdenum trioxide powder produced by the sublimation method into a molybdenum boat, and perform a one-stage reduction. The reduction temperature is 450°C, using dry hydrogen, the hydrogen dew point is -60°C, and the hydrogen flow rate is 2m 3 / h, add molybdenum trioxide 100g / boat to the material boat, and push the boat at a speed of 30min / boat to complete the first-stage reduction of molybdenum oxide. After the completion, put the material boat in the furnace to cool to room temperature, and then sieve it. The product of one-stage reduction is molybdenum dioxide with regular and uniform flakes. Then carry out the second-stage reduction, the process reduction temperature is 700°C, the boat loading capacity is 200g / boat, and the hydrogen flow rate is 2m 3 / h, hydrogen dew point -30°C, boat pushing speed 30min / boat to achieve two-stage reduction, after the completion of the material boat placed in the cooling zone nitrogen cooling, screening, testing, packaging. ...

Embodiment 2

[0023] Put the molybdenum trioxide powder produced by the sublimation method into a molybdenum boat, and perform a one-stage reduction. The first-stage reduction temperature is 500°C, using dry hydrogen, the hydrogen dew point is -60°C, and the hydrogen flow rate is 1.8m 3 / h, add molybdenum trioxide 120g / boat to the material boat, and push the boat at a speed of 35min / boat to complete the first-stage reduction of molybdenum oxide. After the completion, put the material boat in the furnace to cool to room temperature, and then sieve it. The product of one-stage reduction is molybdenum dioxide with regular and uniform flakes. Then carry out the second-stage reduction, the process reduction temperature is 750°C, the loading capacity of the boat is 150g / boat, and the hydrogen flow rate is 1.5m 3 / h, hydrogen dew point 0°C, boat pushing speed 30min / boat to achieve two-stage reduction, after the completion of the material boat placed in the cooling zone nitrogen cooling, screening,...

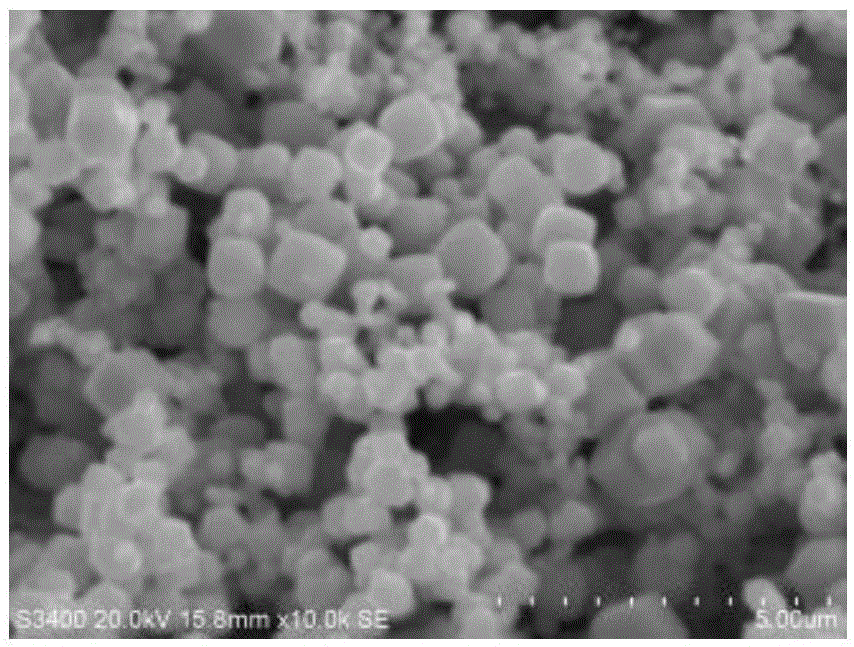

Embodiment 3

[0025] Put the molybdenum trioxide powder produced by the sublimation method into a molybdenum boat, and carry out one-stage reduction. The first-stage reduction temperature is 500°C, using dry hydrogen, the hydrogen dew point is -60°C, and the hydrogen flow rate is 1.5m 3 / h, add molybdenum trioxide 100g / boat to the material boat, and complete the one-stage reduction of molybdenum oxide at a speed of 25min / boat. After the completion, put the material boat in the furnace and cool it to room temperature. Molybdenum dioxide, sieve the molybdenum dioxide. Then carry out the second-stage reduction, the process reduction temperature is 800°C, the loading capacity of the boat is 180g / boat, and the hydrogen flow rate is 1.0m 3 / h, hydrogen dew point 8 ℃, boat pushing speed 25min / boat to achieve two-stage reduction, after the completion of the material boat placed in the cooling zone nitrogen cooling, screening, testing, packaging. The tested molybdenum powder Fisher particle size is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fisherman's particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com