Modified PET copolyester and preparation method and application thereof

A copolyester and modification technology, applied in the field of polyester preparation, can solve the problems of high price of diacylbiscaprolactam, unfavorable industrial production, difficulty in diffusion of small molecules, etc., so as to reduce thermal degradation reaction, shorten production cycle, and reduce polycondensation. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] Preparation of oxazoline compound masterbatch: (taking 2,2-bis-2-oxazoline as an example)

[0062] After mixing 3Kg of 2,2-bis-2-oxazoline and 7Kg of polyethylene terephthalate-co-polyethylene adipate in a high-speed mixer, put it into a twin-screw extruder , the temperature of the extruder is 140-160°C. After extrusion, strand drawing, water cooling, and pelletizing, the masterbatch of oxazoline compounds is obtained.

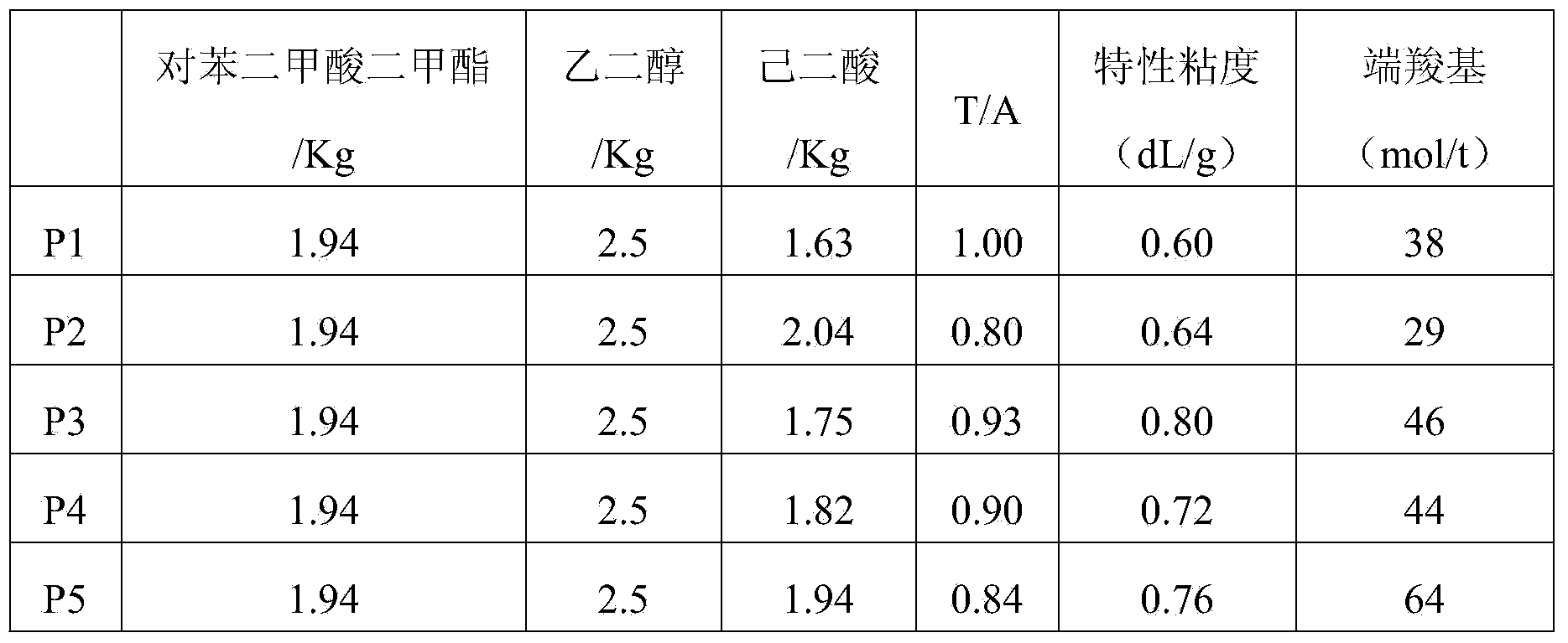

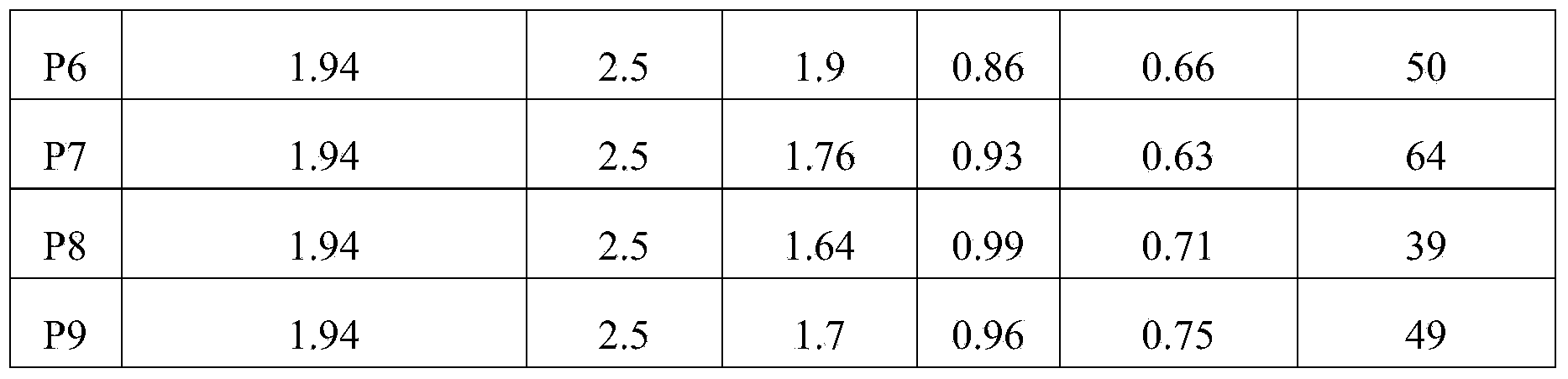

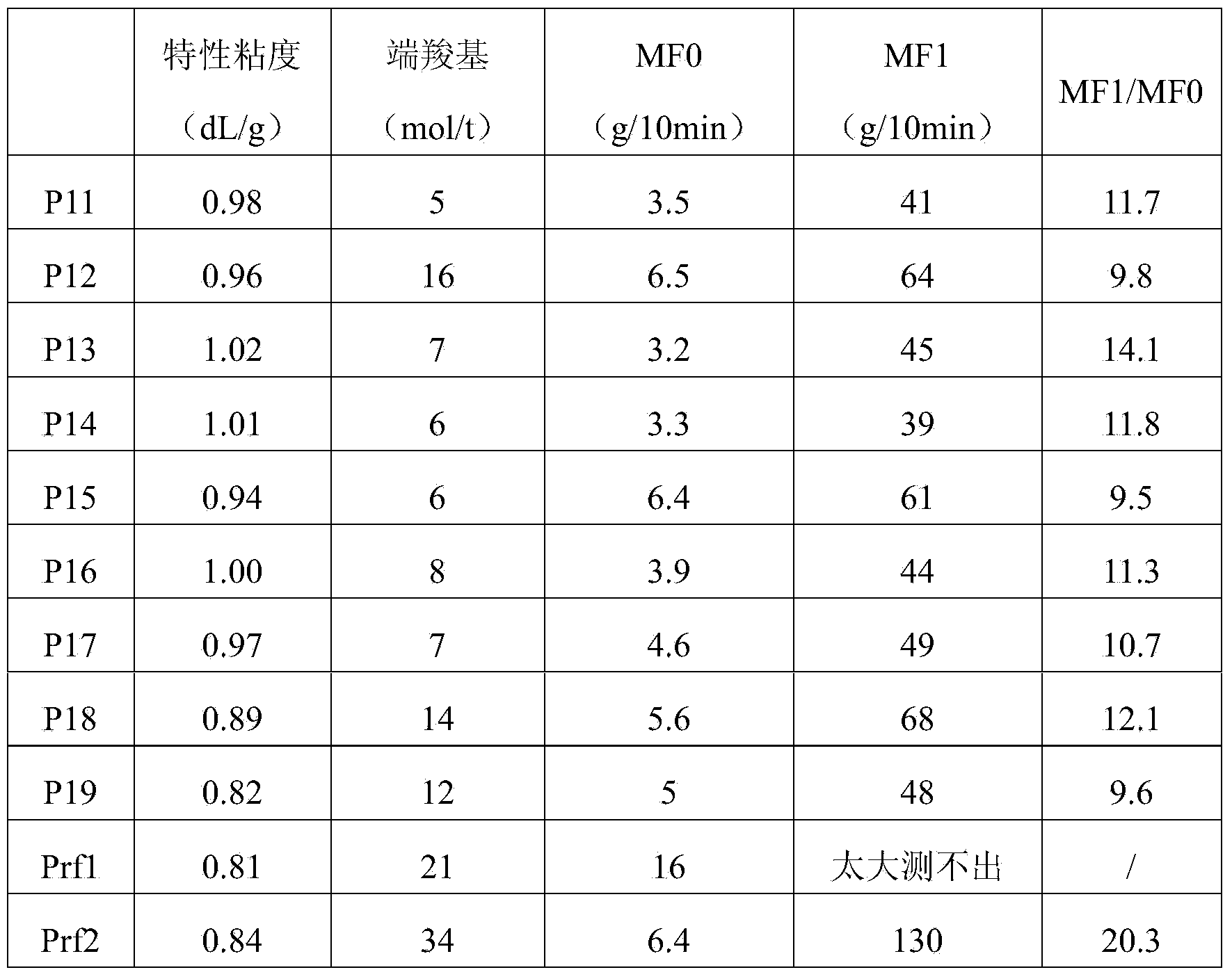

Embodiment 1

[0063] Example 1: Preparation of modified PET copolyester with high viscosity, low carboxyl content, and good hot water resistance

[0064] Mix 1Kg P1, 20g 2-oxazolinylbenzene, and 6g hexamethylene diisocyanate in a high mixer, and then put them into a twin-screw extruder. The temperature of the extruder is 200-240°C. After extruding, drawing, water cooling and pelletizing, the modified PET copolyester P11 with high viscosity, low carboxyl content and good hot water resistance is obtained.

Embodiment 2

[0065] Example 2: Preparation of modified PET copolyester with high viscosity, low carboxyl content, and good hot water resistance

[0066] Mix 1Kg of P2, 8g of 1,3-bis(2-oxazolinyl)benzene, and 9g of ADR-4370S in a high-speed mixer, and then put them into a twin-screw extruder. The temperature of the extruder is 200-240°C. After extruding, drawing, water cooling and pelletizing, the modified PET copolyester P12 with high viscosity, low carboxyl content and good hot water resistance is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com