Patents

Literature

38results about How to "Short polycondensation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

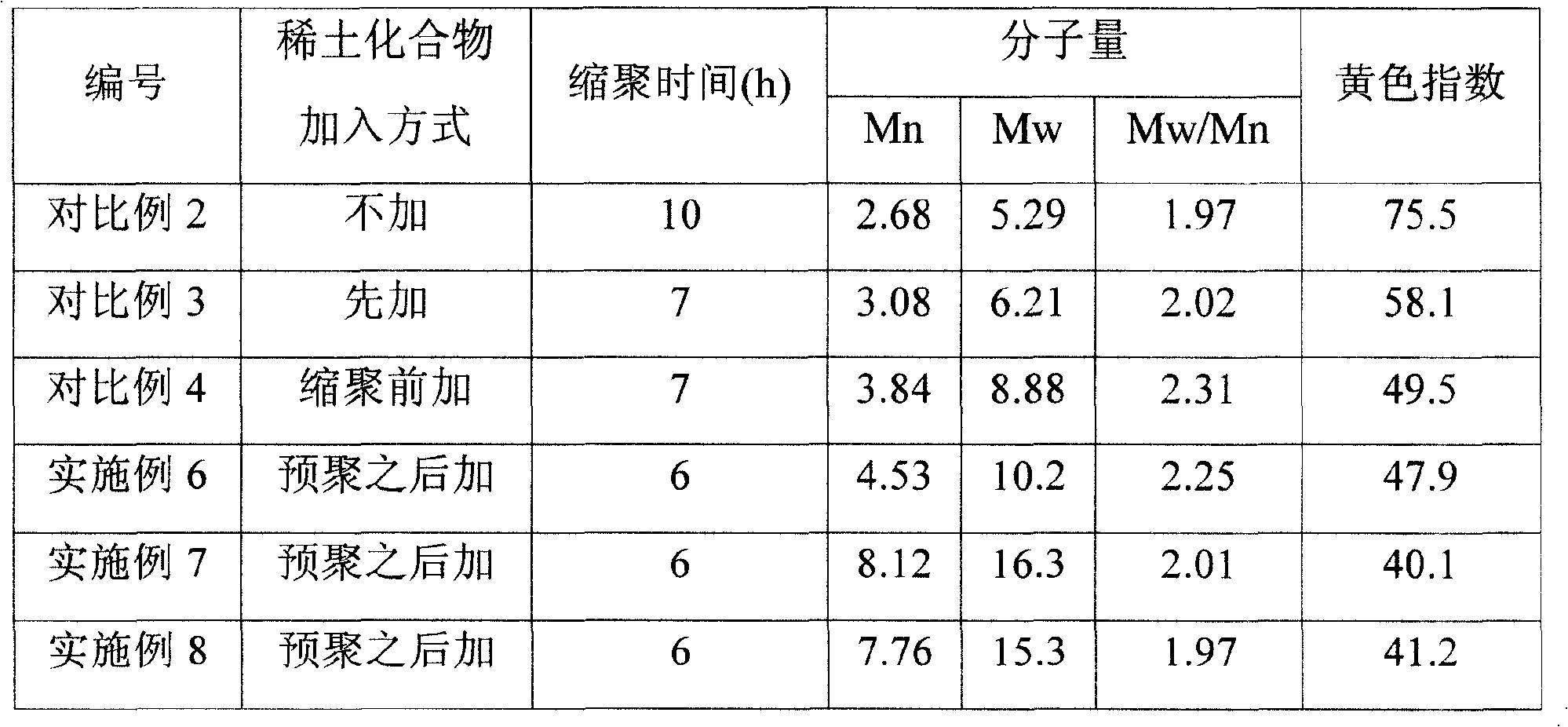

Biodegradable linear random copolyester and its preparation method and uses

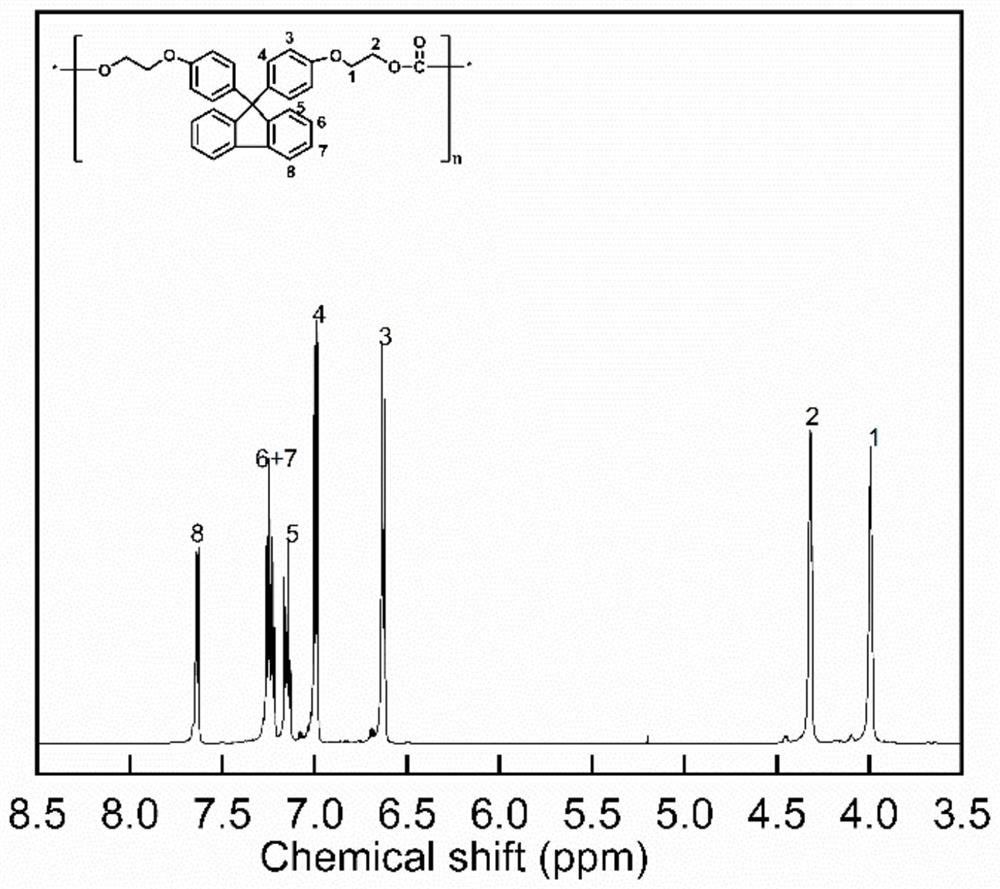

ActiveCN1807485AGood colorSimple operation processMonocomponent polyesters artificial filamentPolyester coatingsCopolyesterStructural unit

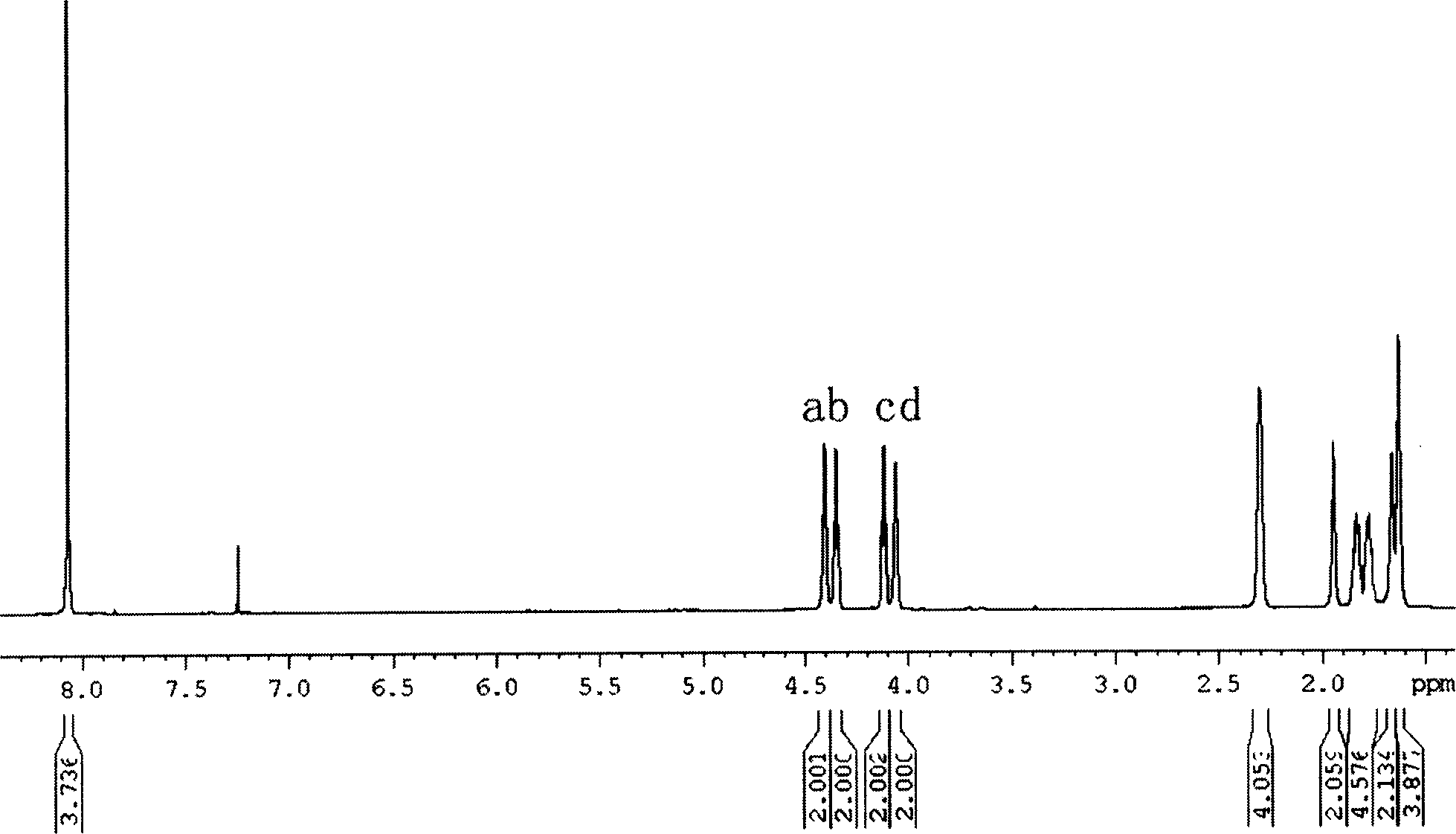

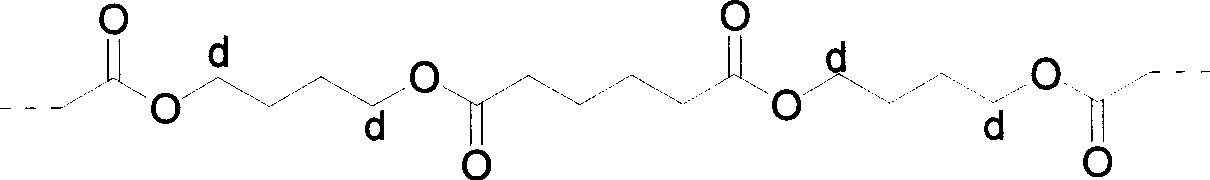

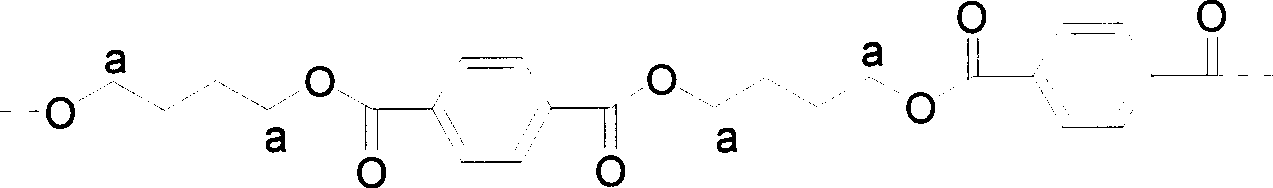

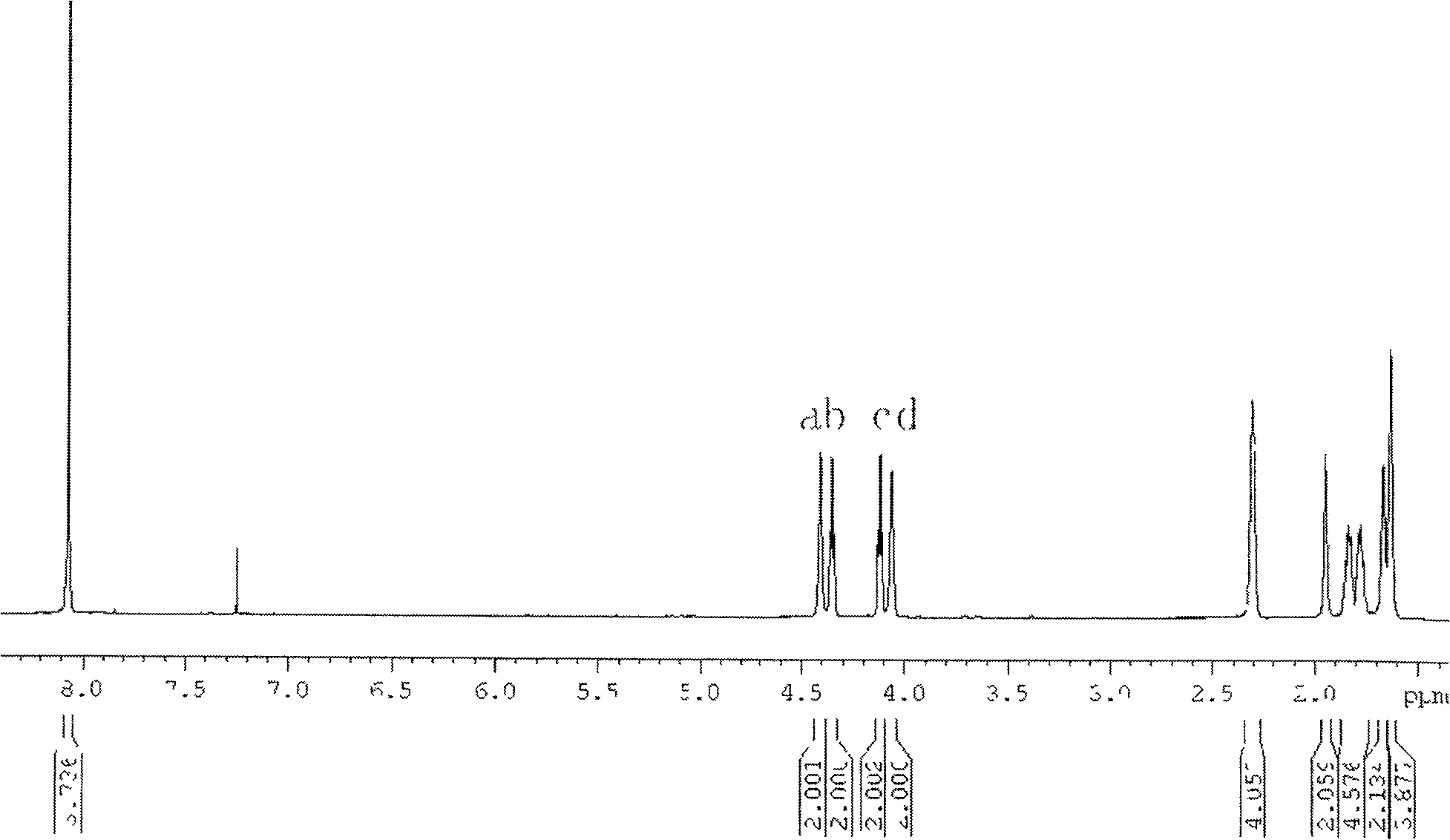

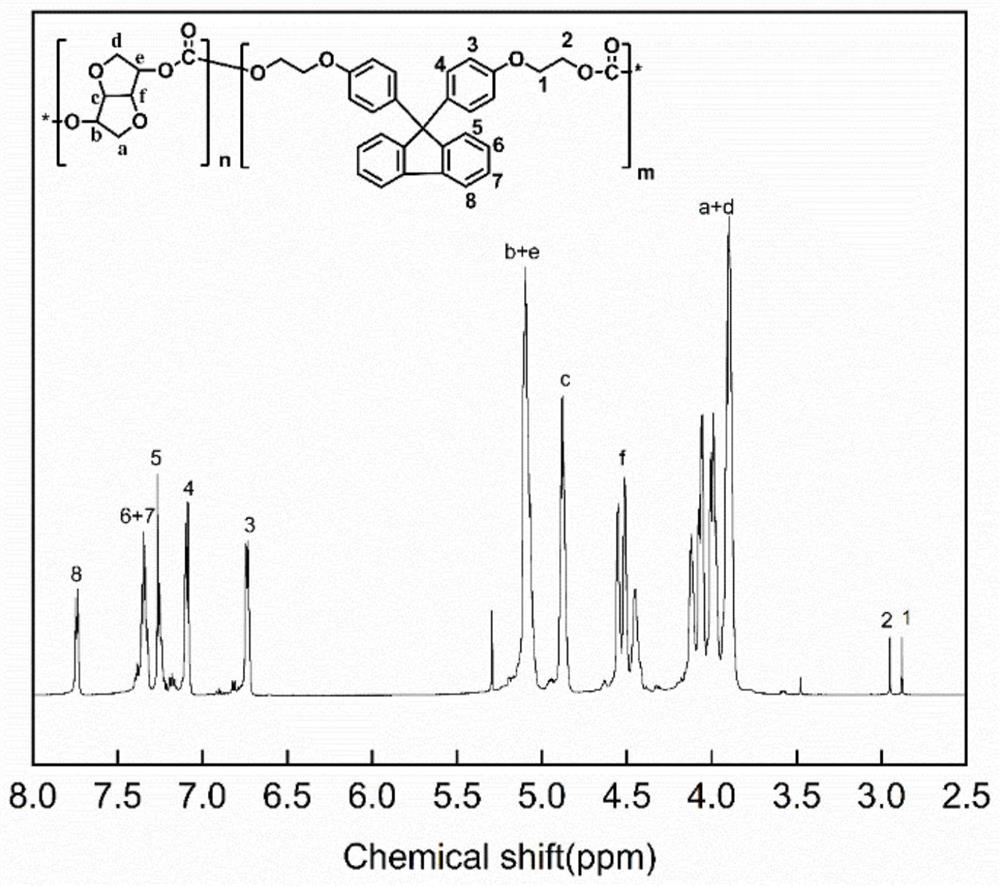

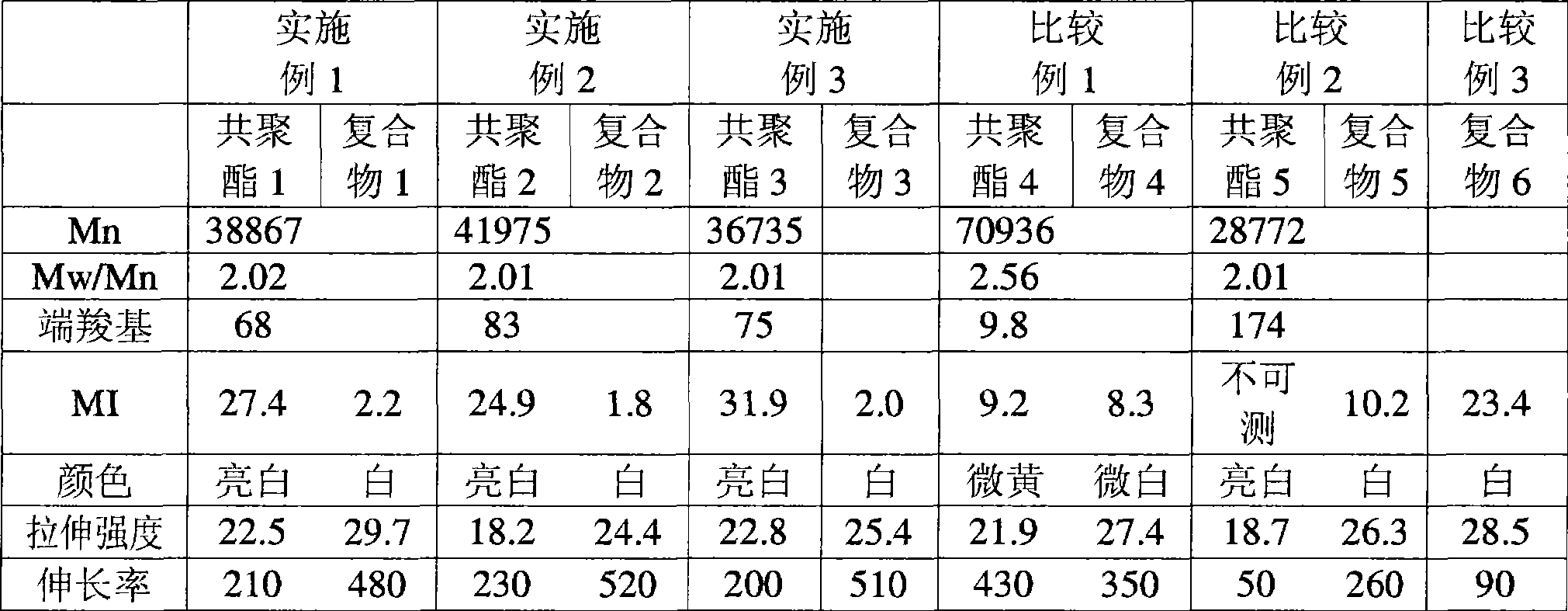

The invention discloses a biodegradable linear random copolyester, its preparation method and uses, wherein the copolyester has a structural unit of (1), wherein m is an integer of 2-10, n is an integer of 0-8, p is an integer of 2-10, m, n, p are identical or different, x is an integer of 1-10, y is an integer of 1-10, the average molecular weight Mw of the copolyester is 100,000-600,000g / mol, its molecular weight distribution is 1.2-3, which is measured through GPC method. The copolyester can be widely applied into section bar, film, fabric and coating.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biodegradable linear random copolyester and its preparation method and uses

ActiveCN100429256CGood colorSimple operation processMonocomponent polyesters artificial filamentPolyester coatingsFiberPolymer science

The invention discloses a biodegradable linear random copolyester, its preparation method and uses, wherein the copolyester has a structural unit of (1), wherein m is an integer of 2-10, n is an integer of 0-8, p is an integer of 2-10, m, n, p are identical or different, x is an integer of 1-10, y is an integer of 1-10, the average molecular weight Mw of the copolyester is 100,000-600,000g / mol, its molecular weight distribution is 1.2-3, which is measured through GPC method. The copolyester can be widely applied into section bar, film, fabric and coating.

Owner:CHINA PETROLEUM & CHEM CORP +1

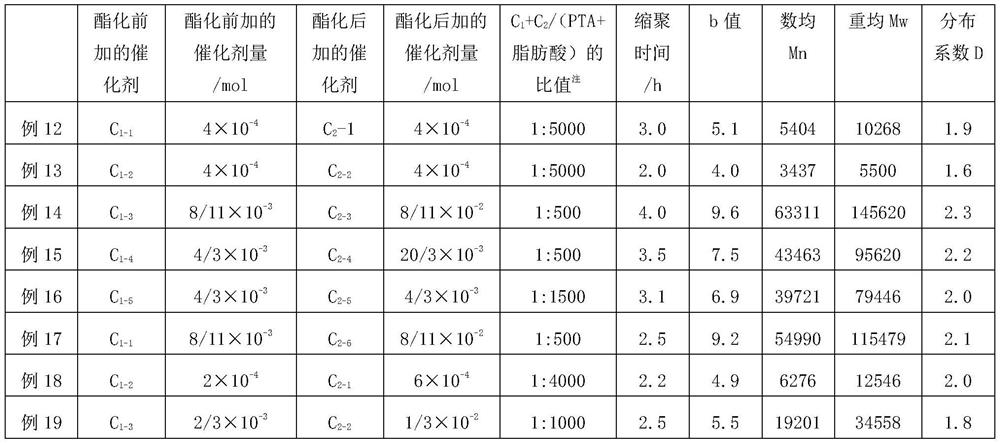

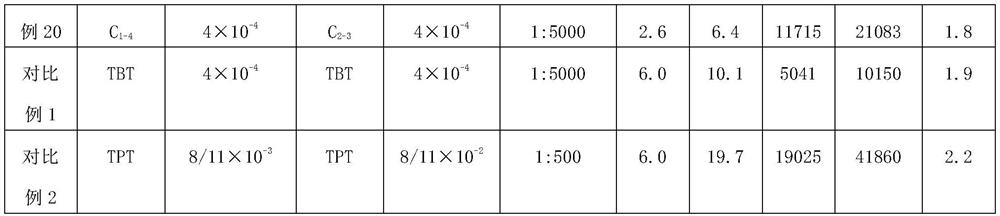

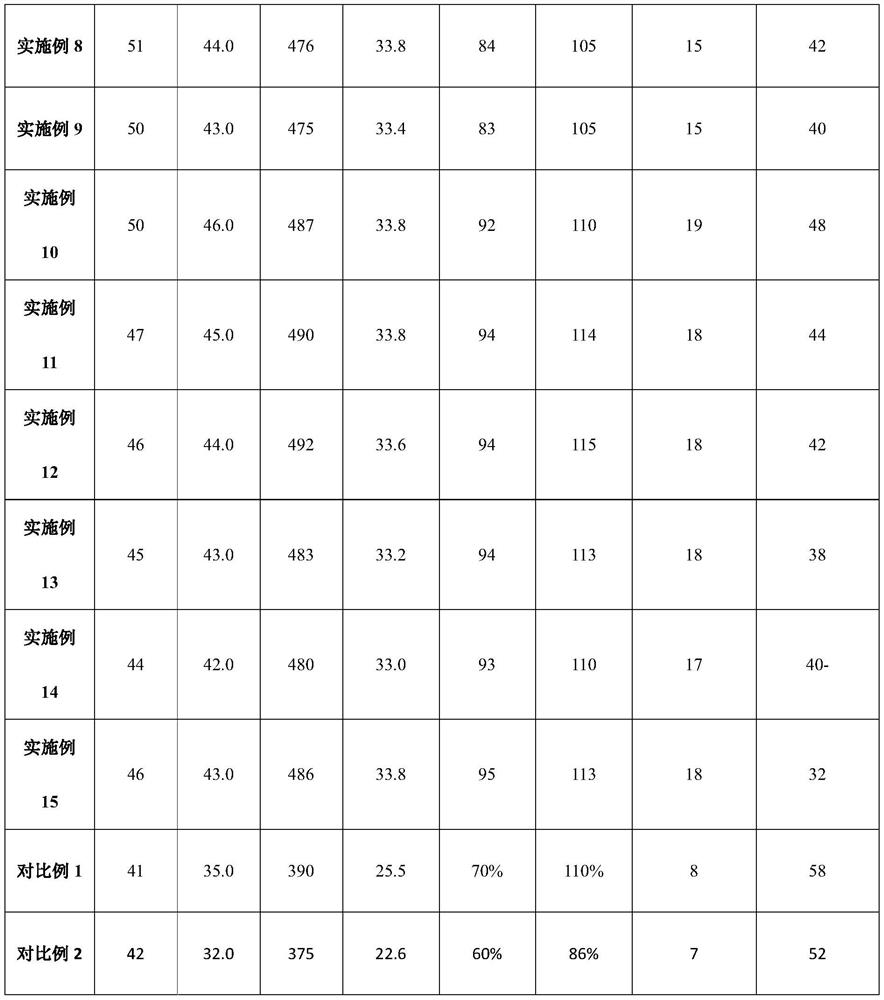

Method for synthesizing polyester by using rare earth catalyst

This invention publishes a synthesis method for polyesters from rare earth catalysts. In this method, single-kettle operation is adopted. One of the compounds of titanium, stibium and zincum is chosen as the catalyst C1 for transesterification and esterification and is added into the reaction kettle with monomer raw materials before reaction. After a certain period of prepolymerization, a rare earth metal compound as catalyst C2 is added for vacuum condensation polymerization. It is due to the single-kettle operation that this invention has the advantages of simplified technique, accelerated polymerization reaction, promoted product molecular weight, reduced side reactions and significantly improved color of polyester product.

Owner:CHINA PETROLEUM & CHEM CORP +1

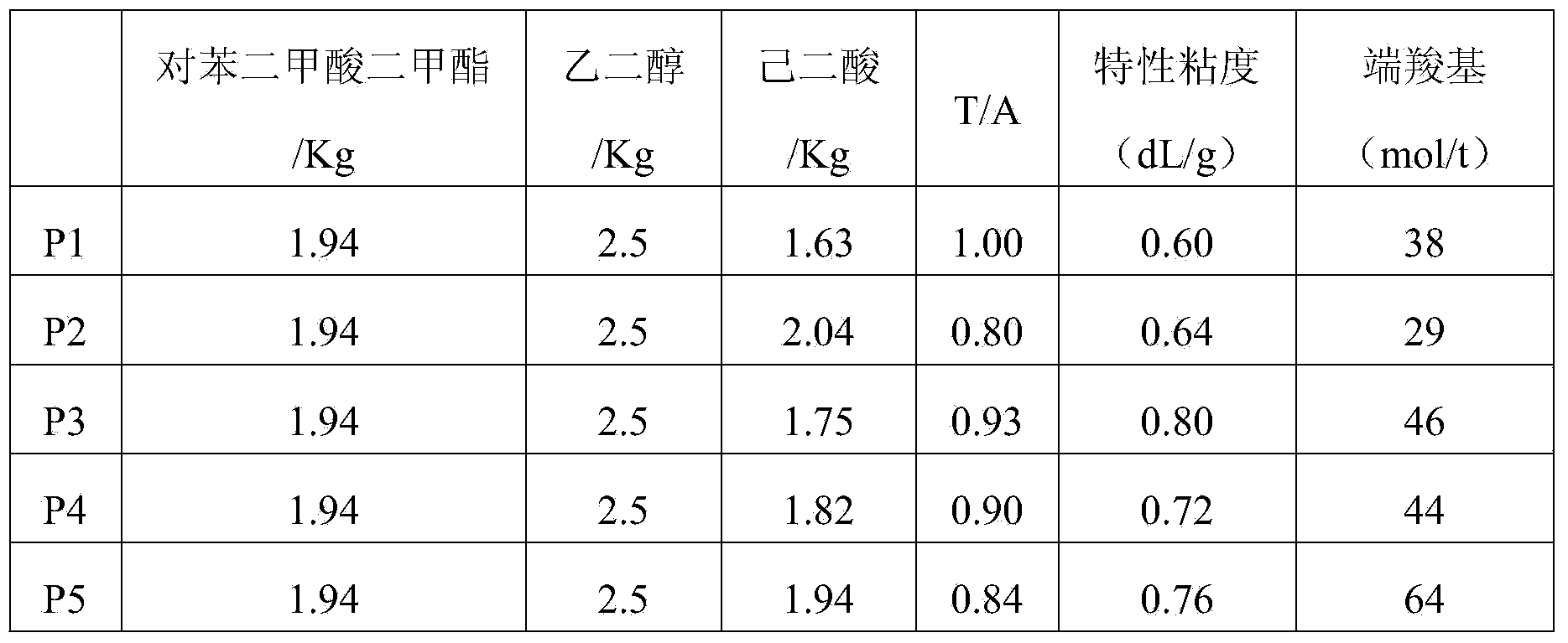

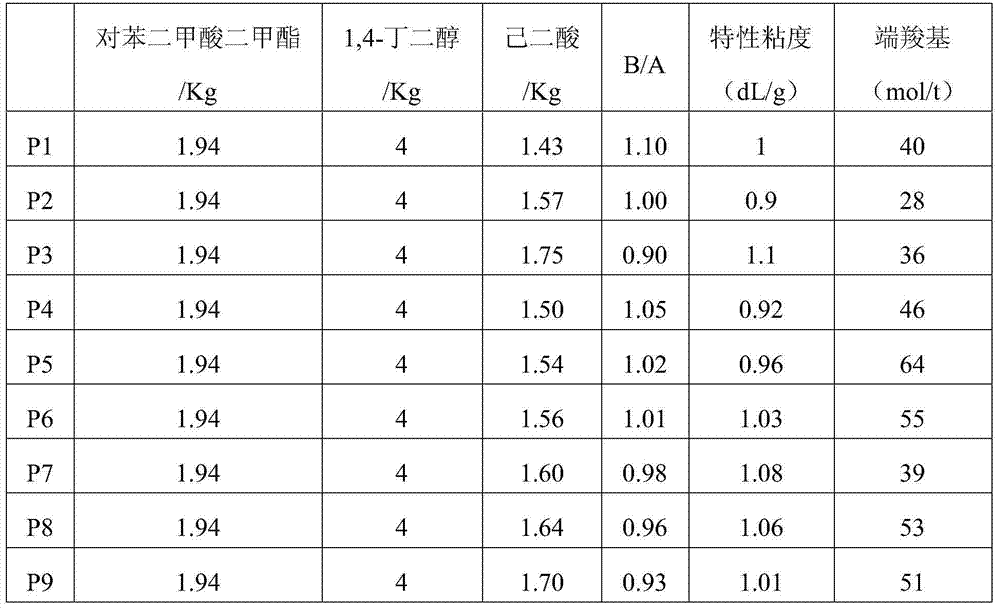

Method for synthesizing biodegradable aliphatic-aromatic copolyester

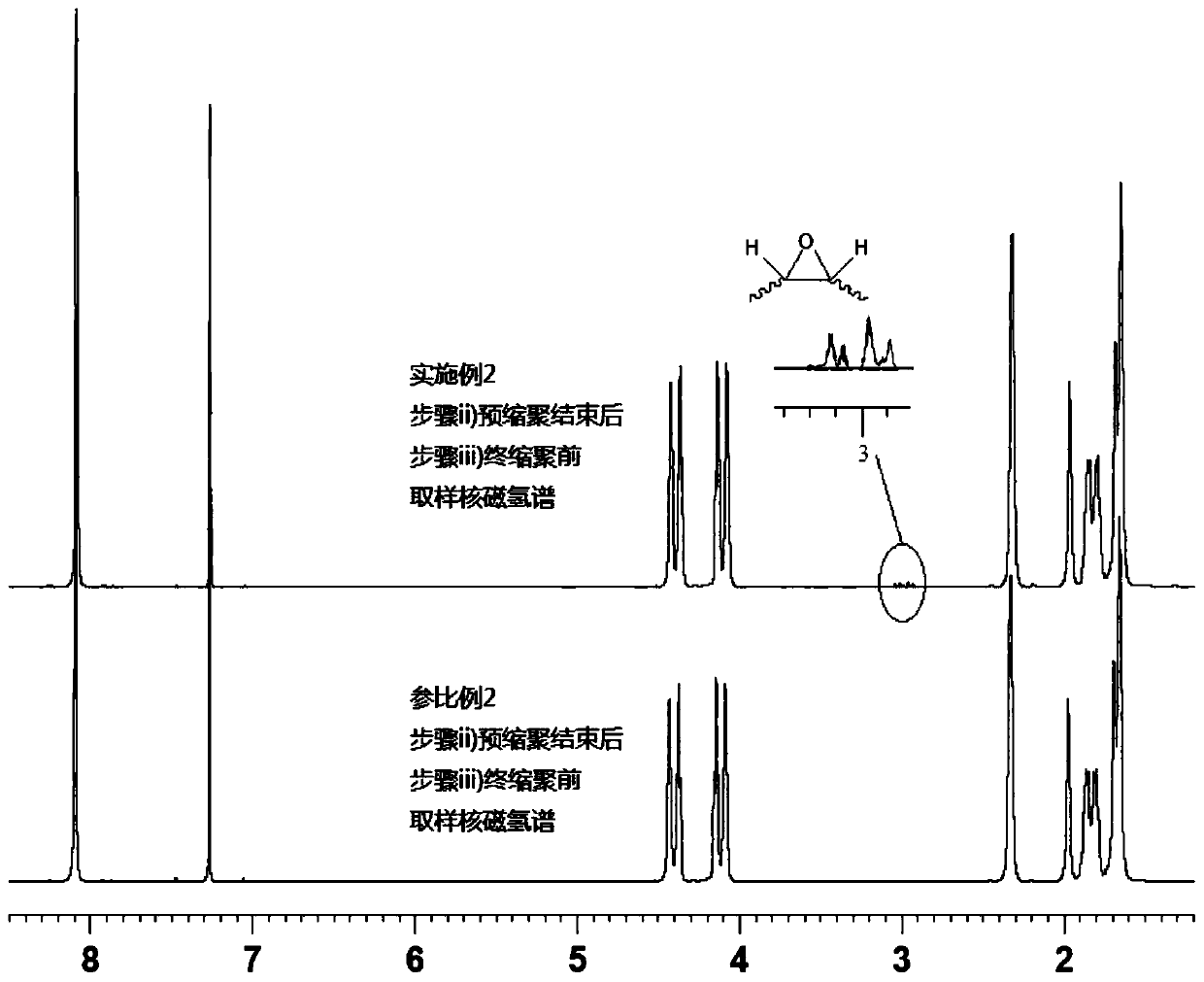

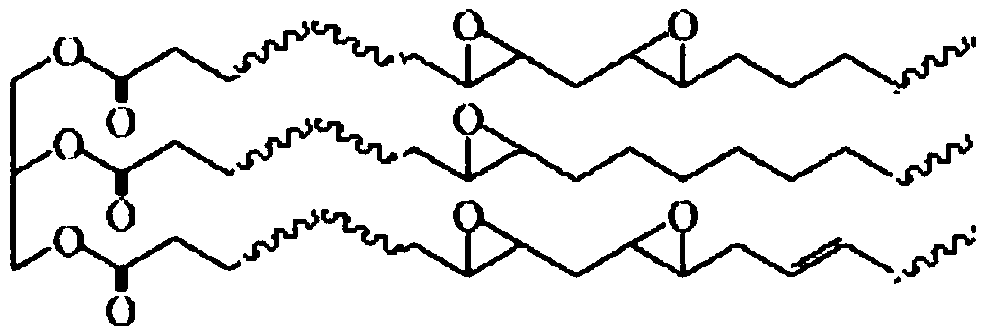

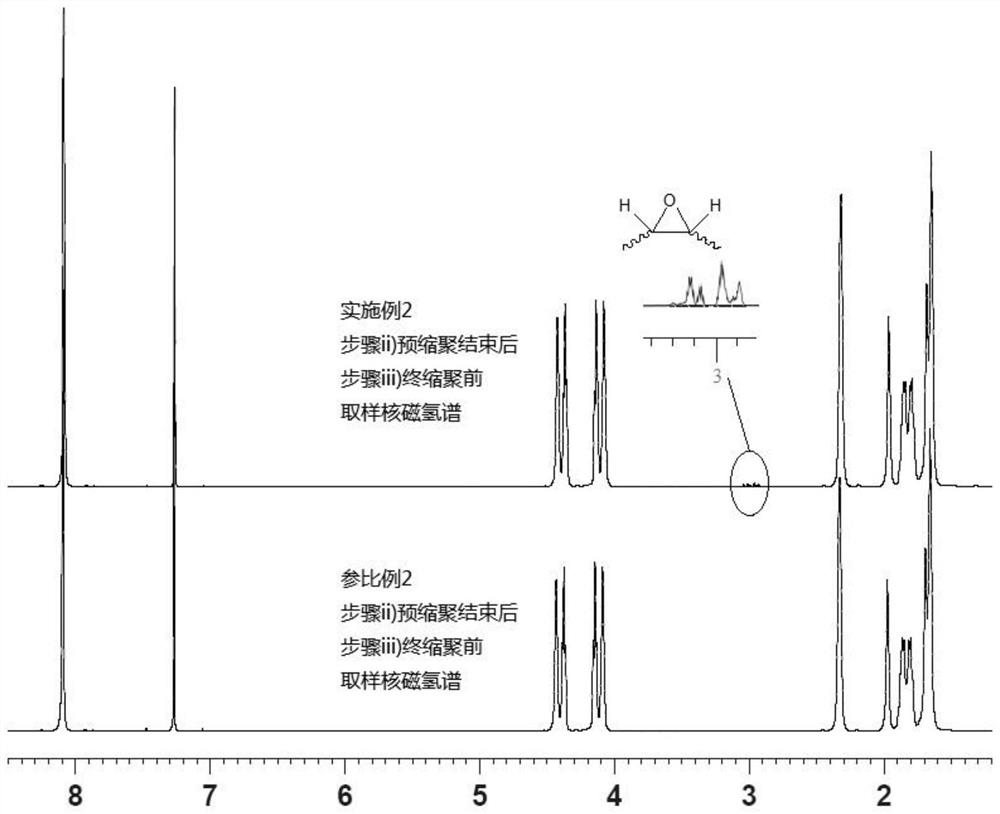

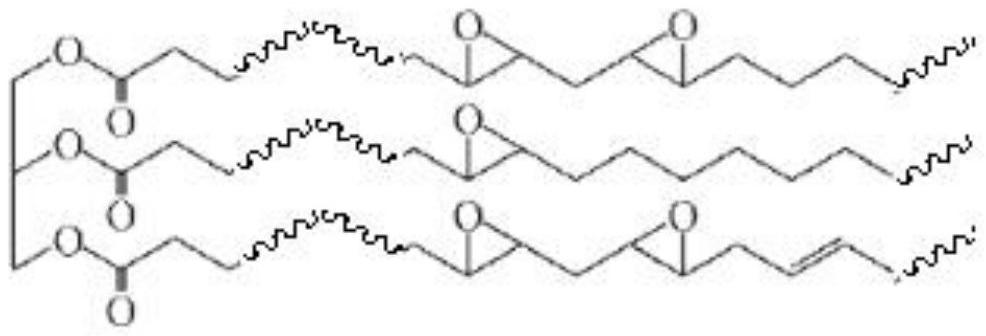

ActiveCN110591057ALess side effectsReduce the carboxyl group value of the productCopolyesterPolyethylene terephtalate

The invention discloses a method for synthesizing a biodegradable aliphatic-aromatic copolyester. The method comprises the following steps: performing continuous esterification on aromatic dicarboxylic acid and aliphatic dicarboxylic acid, adding epoxidized soybean oil, performing continuous prepolycondensation, grafting an epoxy ester into a polyterephthalic acid-adipic acid butanediol PBAT molecular chain in the prepolycondensation process, and performing continuous polycondensation under a condition of a higher temperature, so as to enable the molecular weight and the specific viscosity totarget values. By adopting the method for synthesizing the biodegradable aliphatic-aromatic copolyester, the polyester can easily meet target specific viscosities and molecular weights, the polycondensation time of a high-temperature high-viscosity material can be shortened, side reactions can be reduced, the carboxyl value of a product end can be reduced, and the problem of resin yellowing can besolved. By adopting the method for synthesizing the biodegradable aliphatic-aromatic copolyester, chain extension is implemented without a micromolecule chain extender, so that the problem that a residual chain extender is migrated to a food from a plastic can be solved.

Owner:RACHEM CHINA CO LTD +1

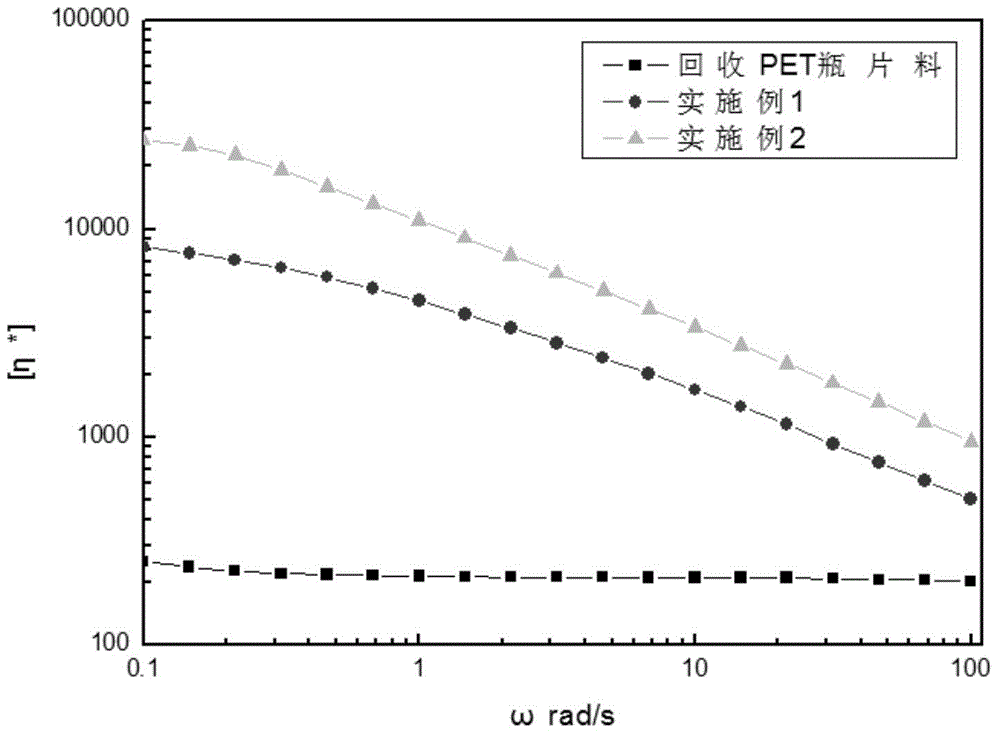

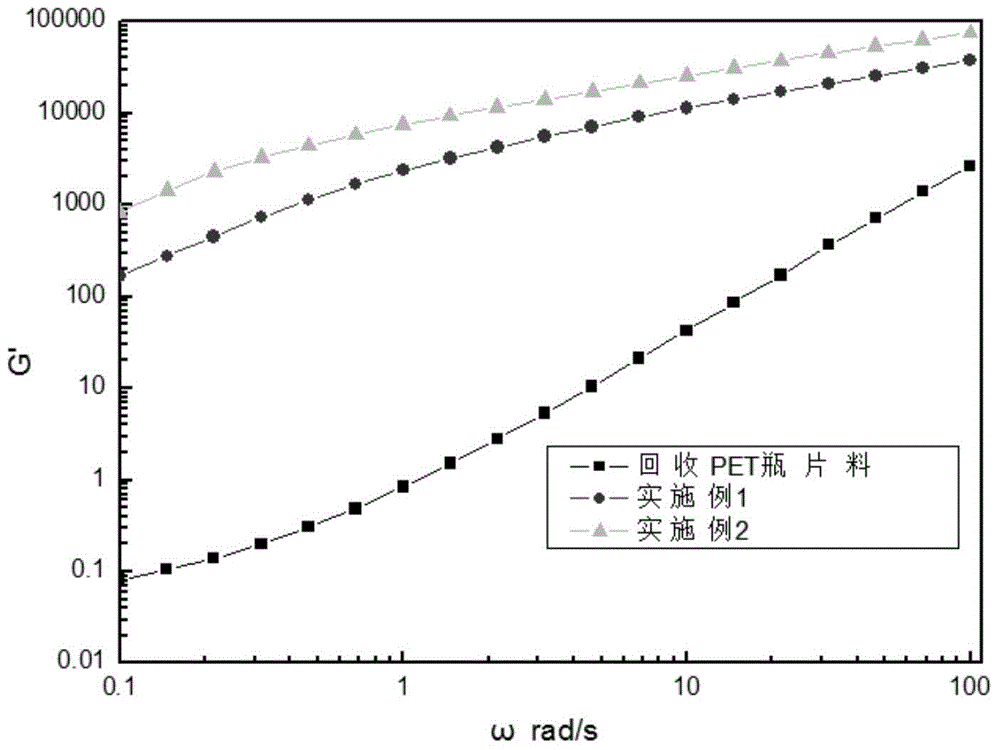

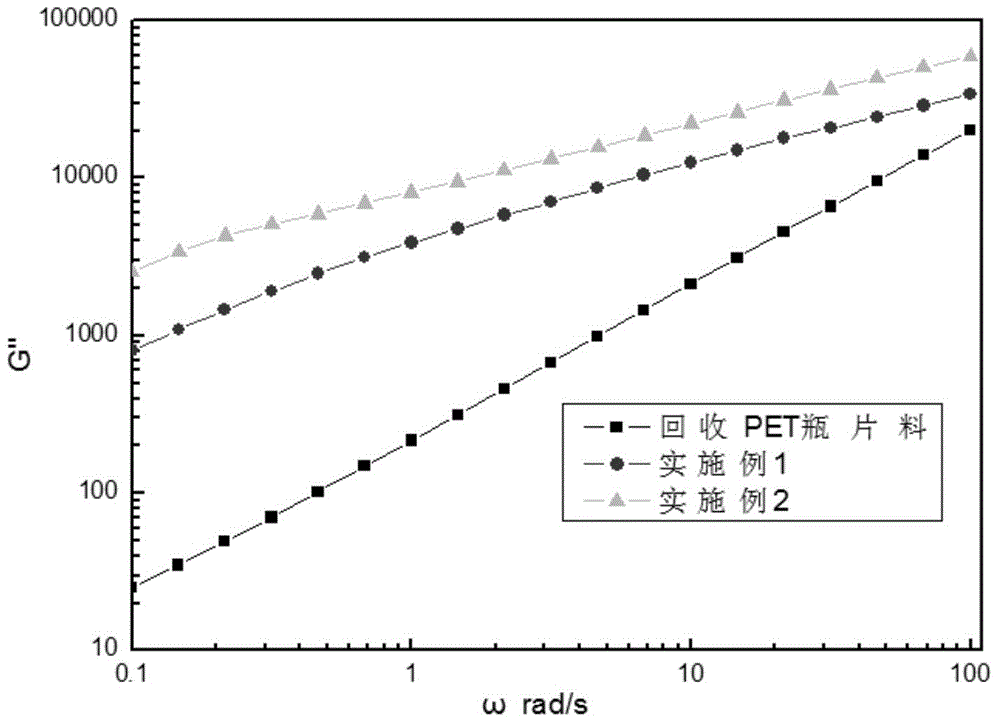

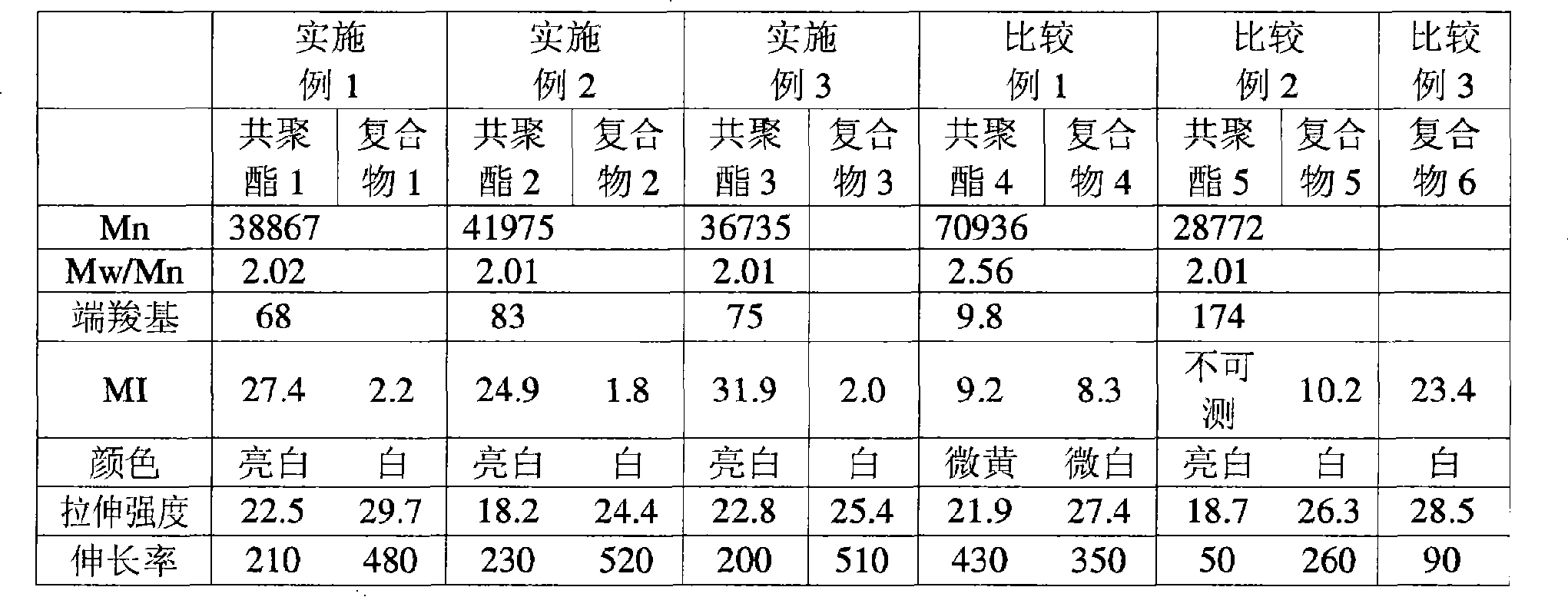

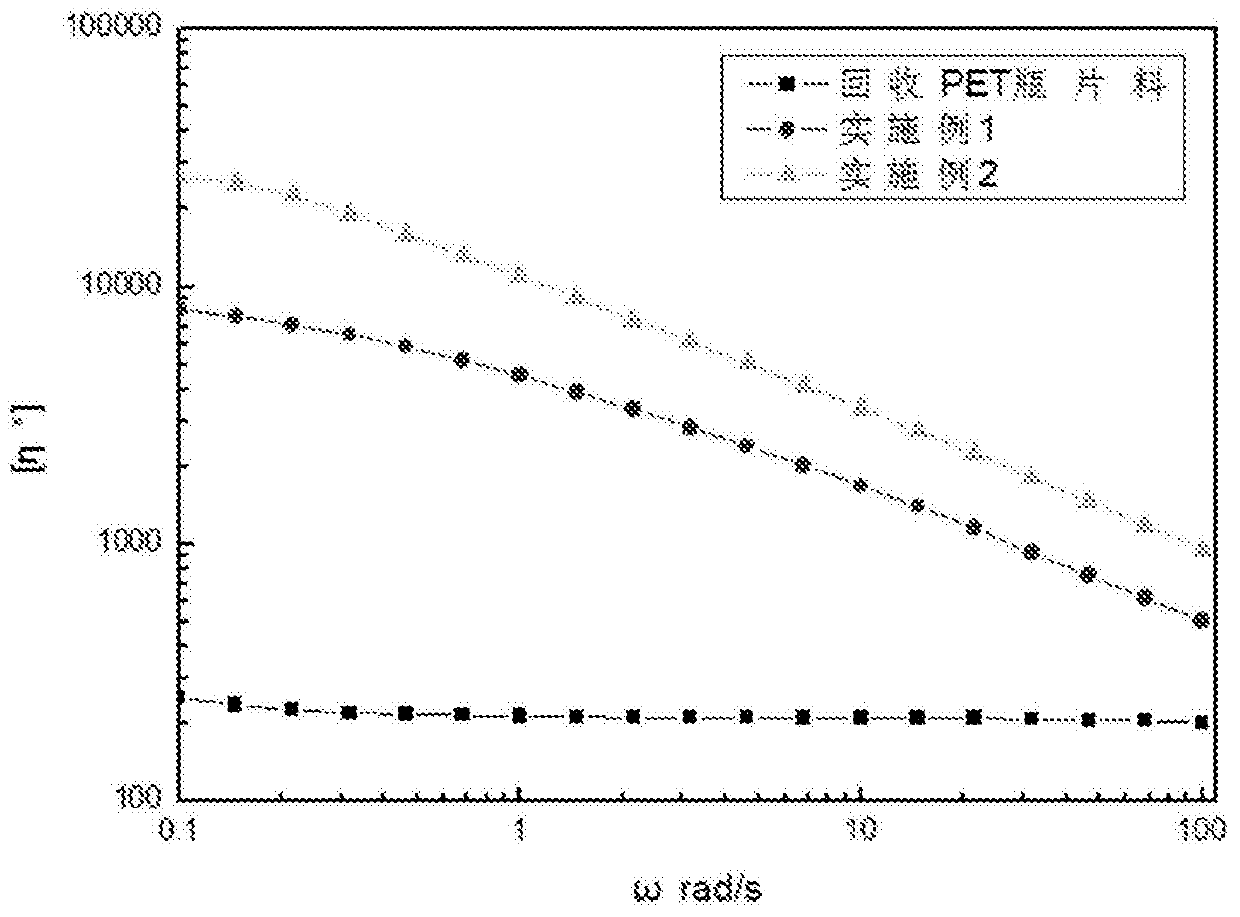

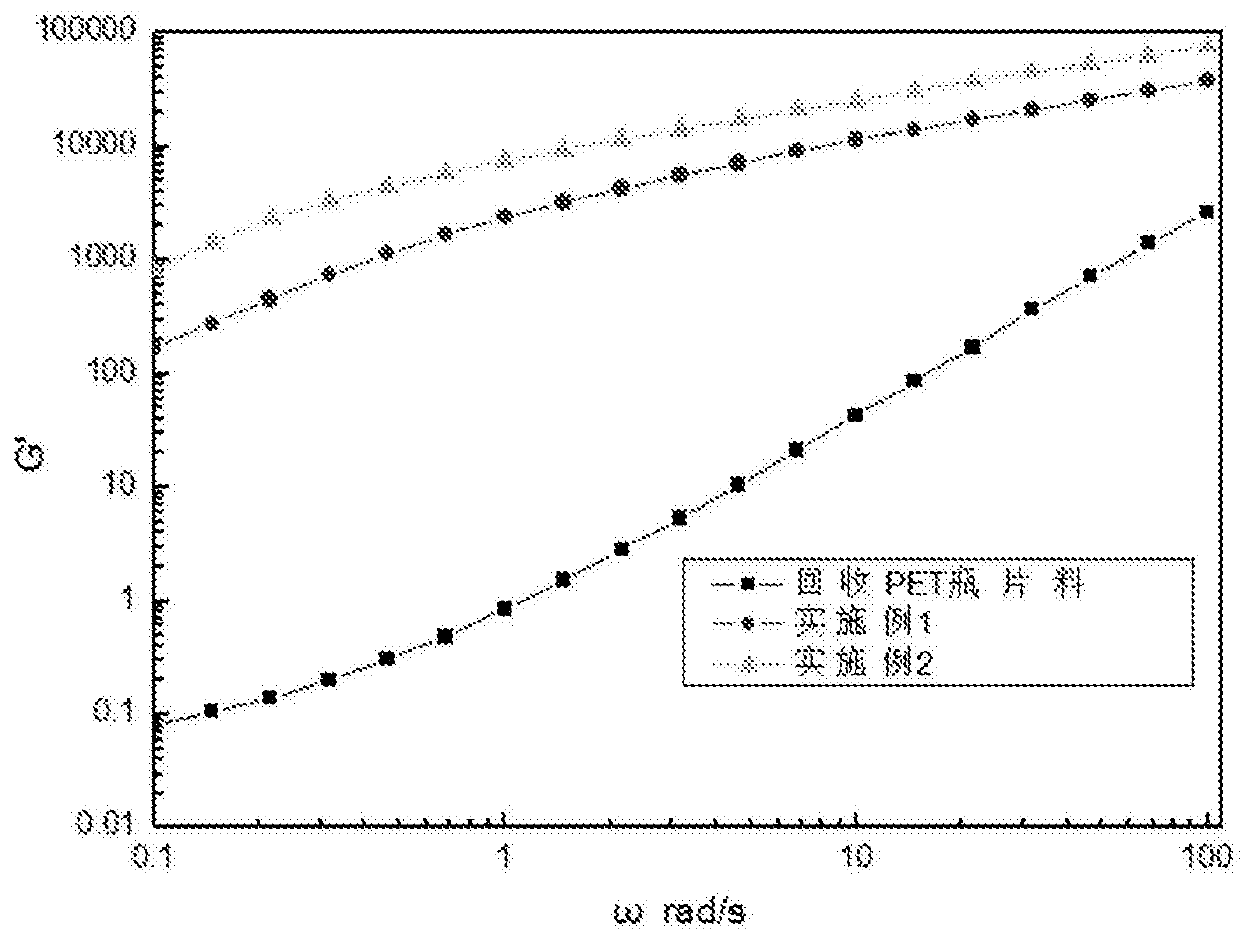

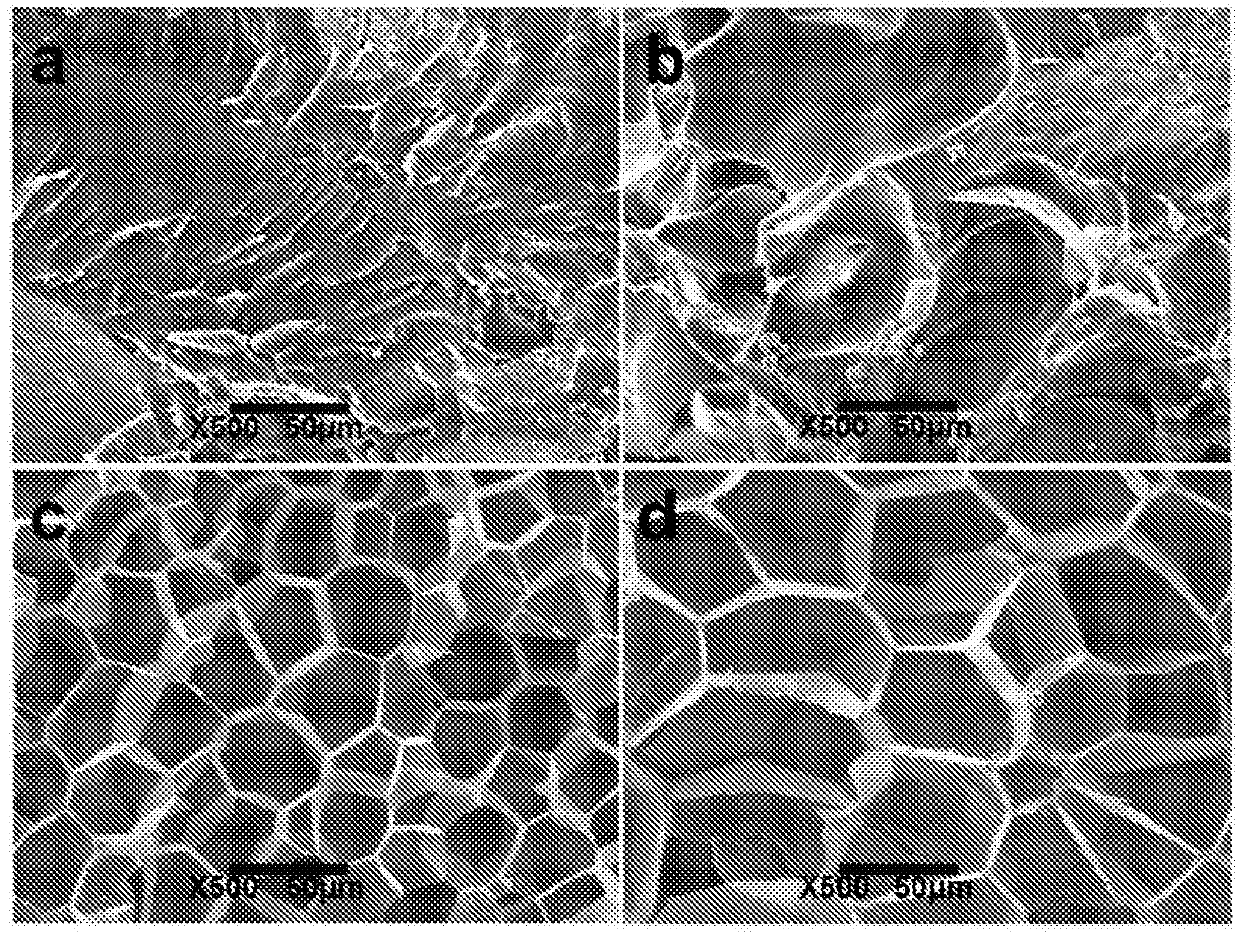

Foamable PET resin, preparation method and uses thereof

The present invention discloses a foamable PET resin, a preparation method and uses thereof. The preparation method comprises: (1) uniformly mixing raw material components, wherein the raw material components comprise 985-995 parts of physically recycled PET bottle flakes, 1-9 parts of a chain extender, 1-3 parts of an antioxidant, and 1-3 parts of a thermal stabilizer, and a three-functional-group chain extension monomer and a multi-functional-group chain extension monomer having a functional group number of 4-6 are compounded according to a mass ratio of 1:3-5:1 to prepare the chain extender; (2) carrying out melt extrusion granulation; and (3) carrying out solid phase condensation polymerization on the obtained material for 1-5 h at a temperature of 210-230 DEG C under a vacuum degree of 5-100 Pa so as to obtain the foamable PET resin. According to the present invention, the foamed PET resin has characteristics of high molecular weight, wide molecular weight distribution, high melt strength, physically recycled PET degrading use changing, low raw material cost, and simple preparation process; and with the combination of the chain extender, the reaction extrusion and the solid phase condensation polymerization are combined, such that the reaction period is shortened, and the industrial production is easily achieved.

Owner:EAST CHINA UNIV OF SCI & TECH

Aliphatic polyester complexes and method of preparing the same

The invention discloses a fatty polyester compound and a preparation method thereof, including the following steps: (1) synthesis of condensation fatty co-polyester: the react between two, three or four fatty dicarboxylic acids or the esters thereof and fatty dibastic alcohol is conducted to achieve condensation fatty co-polyester; (2) the condensation fatty co-polyester reacts with poly lactic acid under the existence of double functional-group chain-extension agent and the extruded out, the achieved fatty polyester compound is the blend of high molecular weight fatty co-polymer, high molecular weight fatty block copolymer and high molecular weight poly lactic acid. The weight percents of condensation fatty co-polyester and poly lactic acid drop is 5:95-95:5. The preparation method has the advantages that the condensation duration is short, the process control is stable and simple, and the method can be directly applied to various processing techniques such as film inflation, extrusion, vacuum molding, blow molding, foaming, and the like; the achieved products have high purity and nice color; the performance adjustment is flexible and convenient, and the cost is low.

Owner:KINGFA SCI & TECH CO LTD +1

Method for preparing oxidized form polysilicic acid ferro-aluminum coagulant

InactiveCN103466771ALarge flocsDense flocWater/sewage treatment by flocculation/precipitationIron sulfateLiquid product

The invention discloses a method for preparing an oxidized form polysilicic acid ferro-aluminum coagulant. The method includes the following steps that (1) a sodium silicate solution is added to a dilute sulphuric acid solution under the stirring condition, the pH value is adjusted to acidity, and standing and polymerization are conducted on the mixture to obtain low-polymerization-degree activated silicic acid; (2) ferric sulfate and aluminum sulfate are added to concentrated sulfuric acid and water to prepare an acidic sulfate ferro-aluminum solution; (3) low-polymerization-degree activated silicic acid and the acidic sulfate ferro-aluminum solution are mixed and stirred, an oxidizing agent and additive are added, stirring is stopped, after standing and curing are conducted, a stabilizing agent is added, and then liquid products are obtained; (4) the liquid products are dried and grinded to obtain the powder coagulant. The products prepared from the method combine the advantages of an iron coagulant and an aluminum coagulant, the defects of polyaluminum chloride and polyferric sulfate coagulants in the using process are overcome, and the products have the advantages of capable of integrating the polysilicic acid cementation, aggregation, adsorption and bridging effects, large in aluminum salt coagulant floc, good in decoloration performance, dense in ferric salt coagulant floc, and high in settling speed.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

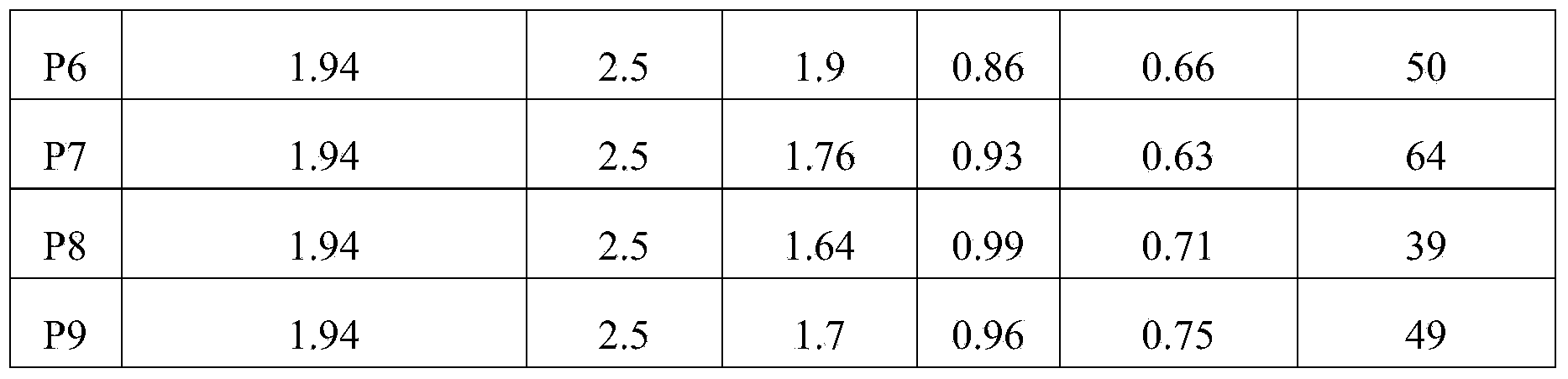

Modified PET copolyester and preparation method and application thereof

The invention belongs to the technical field of polyester preparation, and discloses a modified PET copolyester with high viscosity and a low terminal carboxyl group and a preparation method and application thereof. The copolyester contains the following ingredients in parts by weight: 100 parts of low-viscosity PET copolyester, 0.8-2.0 parts of oxazoline compound and 0.6-2.0 parts of a hydroxyl chain extender. The method prepares the high-viscosity modified PET copolyester by adding the oxazoline compound and the hydroxyl chain extender. The oxazoline compound is added to react with the terminal carboxyl group in resin, the terminal carboxyl group content of resin is reduced, therefore, the hot water resisting performance of resin is increased. The hydroxyl chain extender is added, the molecular weight of resin is increased, and the balance between a physical performance and a processing performance is achieved. The viscosity and the melt strength of the modified PET copolyester are increased, the content of terminal carboxyl group is reduced, and the hot water resisting performance is greatly increased. Moreover, the production method shortens the polycondensation time and the production cycle, effectively reduces the thermal degradation reaction, and also increases the output of equipment.

Owner:KINGFA SCI & TECH CO LTD

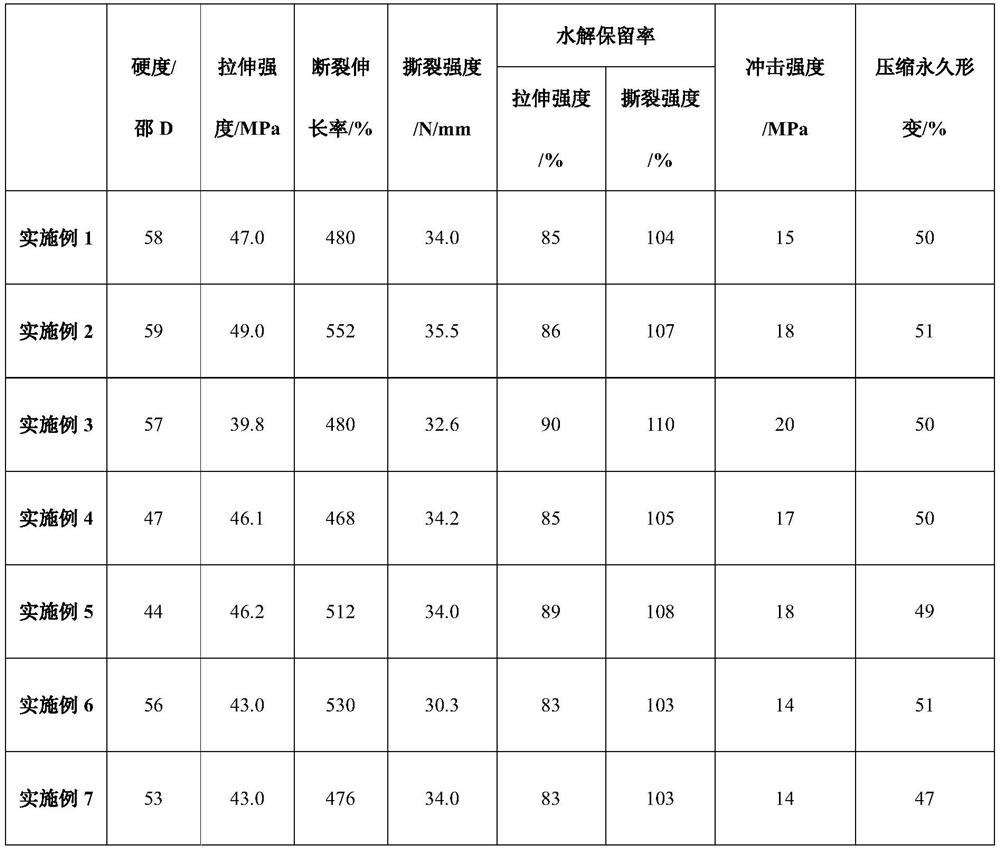

Modified aliphatic-aromatic copolyester and its preparation method and use

The invention belongs to the technical field of polyesters and discloses a modified aliphatic-aromatic copolyester having high viscosity and low carboxyl end group content and its preparation method and use. The modified aliphatic-aromatic copolyester comprises, by weight, 100 parts of a low-viscosity aliphatic-aromatic copolyester, 0.5-3 parts of an oxazoline compound and 0.4-2.5 parts of a hydroxyl chain extender. Through use of the oxazoline compound and the hydroxyl chain extender, the modified aliphatic-aromatic copolyester is prepared. The used oxazoline compound and the carboxyl end group in the resin undergo a reaction so that resin carboxyl end group content is reduced and resin hot-water resistance is improved. Through use of the hydroxyl chain extender, resin molecular weight is improved and the balance of physical properties and processing properties is realized. Viscosity and the melt-strength of the modified aliphatic-aromatic copolyester are improved, carboxyl end group content is reduced and hot-water resistance is improved. The preparation method has a short production period, reduces polycondensation time and effectively reduces thermal degradation reactions.

Owner:KINGFA SCI & TECH CO LTD

Alkaline soluble polyester and preparation method thereof

The present invention discloses alkali-soluble polyester and the preparation method of the alkali-soluble polyester; the product polyester is polyester terephthalate. A component, B component and or C component are added during the polyester synthesis process, plus a composite stabilizer; in which: A is isophthalic acid glycol ester -5-sodium sulfonate, B aliphatic dibasic acid or correspondent derivative, and C aliphatic diol . The preparation method comprises the etherifying and of polymerization p-phenyl dicarboxylic acid and glycol; During the glycol, isophthalic acid glycol ester-5 -sodium sulfonate, aliphatic dibasic acid or the correspondent derivative as well as composite stabilizer are added. Product obtained by the present invention is of sufficient alkaline hydrolysis, good crystallization as well as excellent spinning maneuverability.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

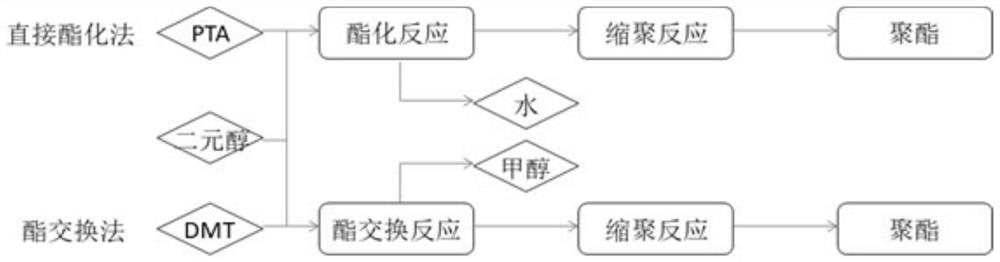

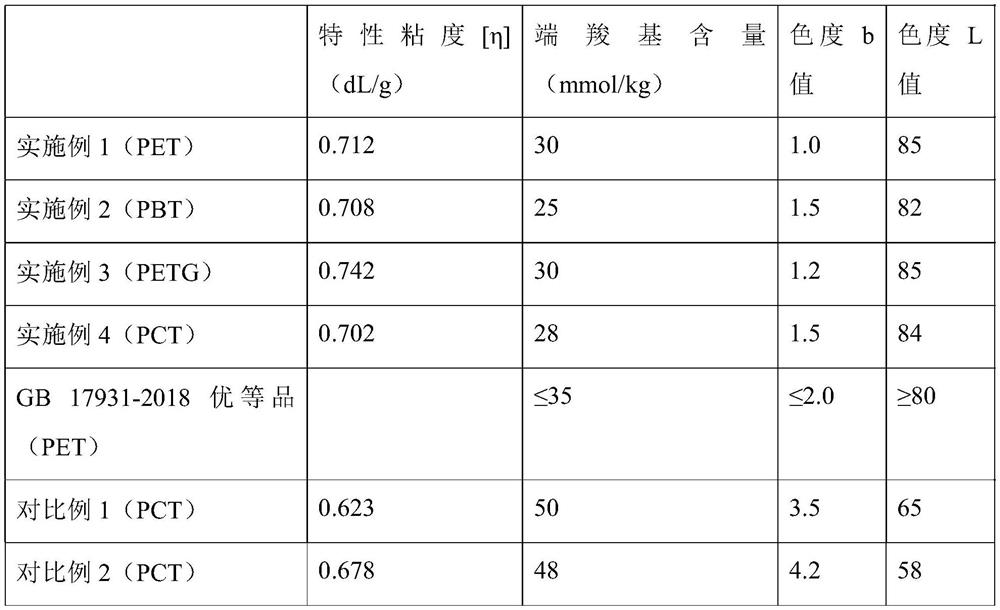

Efficient synthetic method of terephthalic polyester

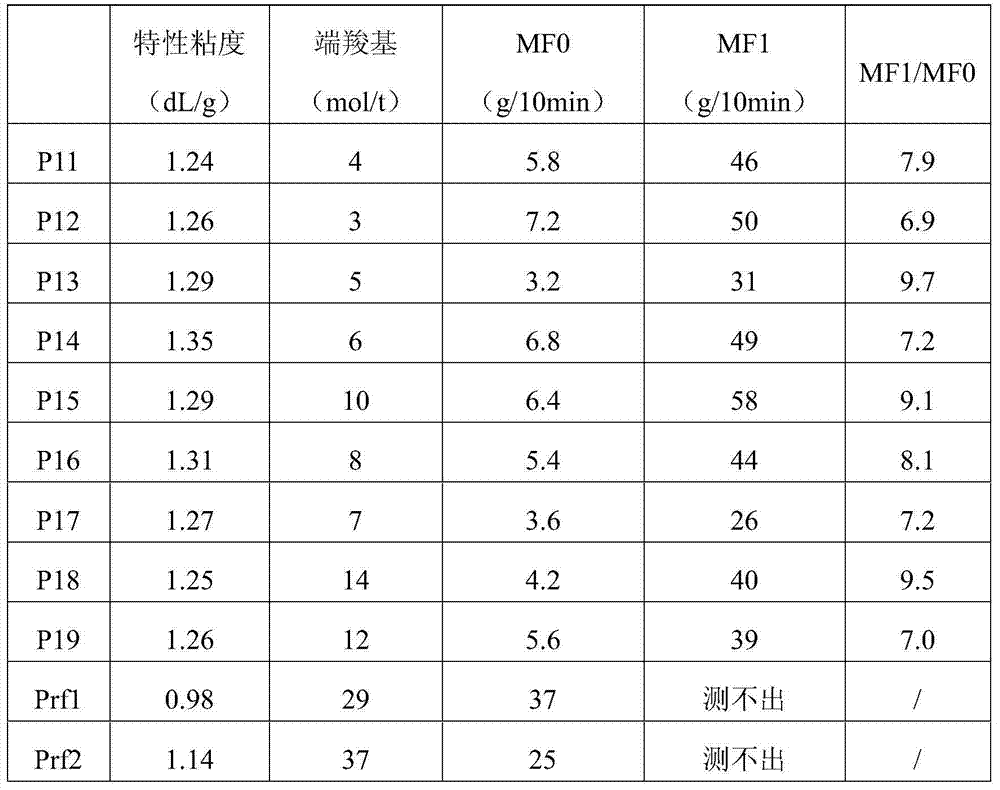

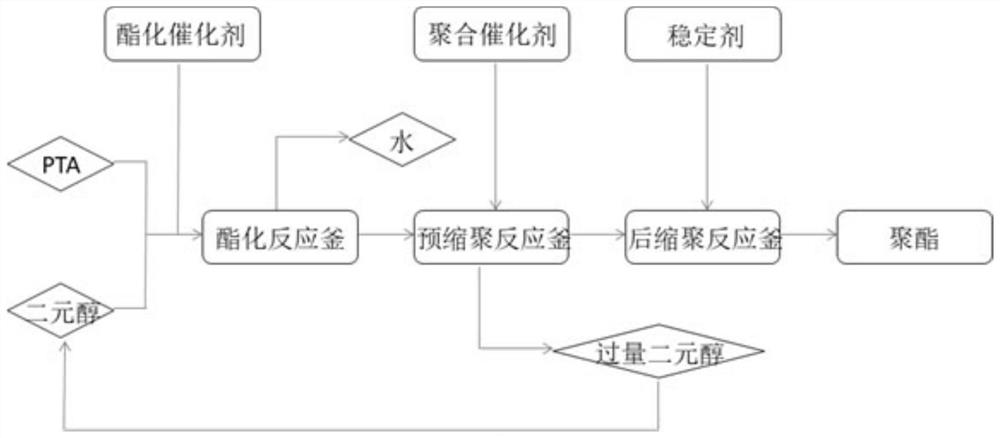

The invention provides an efficient synthetic method of terephthalic polyester, the method comprises the following steps: taking terephthalic acid and various dihydric alcohols as raw materials, sequentially carrying out esterification, pre-polycondensation and post-polycondensation to obtain high-quality polyester, wherein the catalyst is a composite catalyst consisting of an esterification catalyst, a polymerization catalyst and a stabilizer, and is added in sections; and post-polycondensation adopts a continuous production process, so that material back-mixing is avoided, side reactions are effectively reduced, the reaction efficiency and the reaction stability are improved, and indexes such as viscosity, terminal carboxyl group content and chromaticity of the product are also obviously improved.

Owner:CHINA TIANCHEN ENG

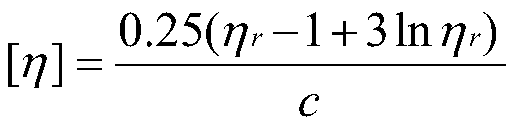

Prepn process of fiber-forming biodegradable fatty copolyester

The present invention is preparation process of fiber-forming biodegradable fatty copolyester. In the single kettle operation, the composite catalyst system comprising the main catalyst of metal compound of Ti, Sb or Zn and the co-catalyst of metal ion salt of Ca, Mg, Na or K, or phosphoric acid derivative, and the monomer material are added into the polymerization kettle simultaneously. After esterification or ester exchange reaction for 1-2 hr, the materials are vacuum polycondensated. The preparation process of the present invention has simple operation, fast polymerization reaction speed, raised polymer molecular weight, less side products and improved polymer color.

Owner:DONGHUA UNIV

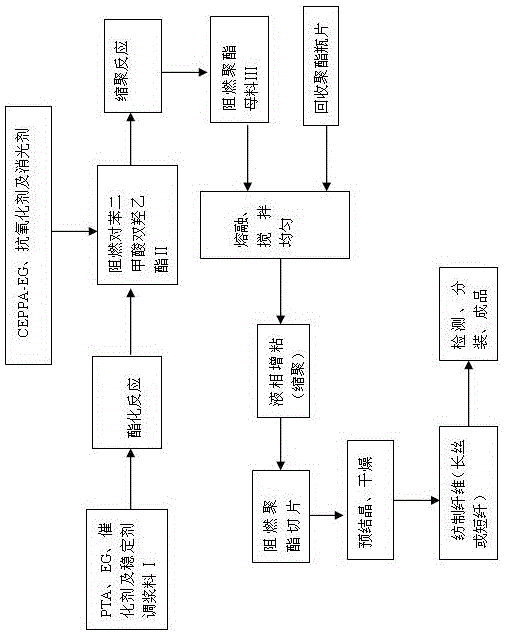

Preparing method for producing flame-retardant polyester fibers through recycled polyester bottle flakes

InactiveCN105088409AAchieve recyclingGood flame retardant functionConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberMasterbatch

The invention relates to a preparing method for producing flame-retardant polyester fibers through recycled polyester bottle flakes. The preparing method includes the step of preparing flame-retardant polyester parent materials, wherein 28 mass parts to 32 mass parts of ethanediol, 68 mass parts to 72 mass parts of purified terephthalic acid, 80 ppm to 300 ppm of antimony-based catalysts and 100 ppm to 500 ppm of stabilizers are added into a pulping kettle to be stirred and prepared into pulp I; the pulp I is guided into an esterification kettle and heated to 245 DEG C to 260 DEG C to be esterified, 15,000 ppm to 30,000 ppm of flame retardant assistants, 0 mass part to 1.2 mass parts of flatting agents and 200 ppm to 500 ppm of antioxidants are added for continuously carrying out the esterification reaction, and flame-retardant bis(2-hydroxyethyl)terephthalate II is prepared; the flame-retardant bis(2-hydroxyethyl)terephthalate II is guided into a condensation polymerization kettle to be heated, the vacuum degree is controlled to be 1,200 Pa to 1,800 Pa, and pre-condensation polymerization is carried out; then the vacuum degree is adjusted to be lower than 80 Pa, and heating is carried out for condensation polymerization till the condensation polymerization reaction is finished; the flame-retardant polyester parent materials III are obtained through band casting, cooling and pellet cutting, and the content A ppm of P of the flame-retardant polyester parent materials III is detected.

Owner:HIGHTEX CO LTD ZHEJIANG

Method for preparing polyethylene glycol terephthalate by adopting anchoring agent

InactiveCN101544750AHigh strengthShort polycondensation timePolyethylene terephthalatePolyethylene glycol

The invention relates to a method for preparing chemical, in particular to a method for preparing polyethylene glycol terephthalate by adopting anchoring agent. The method is as follows by the technical scheme provided by the invention: orthobenzene dicarboxylic acid and glycol which are taken as basic materials are prepared to be sizing agent at the mole ratio of 1:1-2.5 and the sizing agent is put in a reaction kettle for esterification reaction by a sizing agent pump to generate oligopolymer; the oligopolymer after the esterification reaction is injected in a prepolycondensate reaction kettle by a pump through an oligopolymer pipeline and additive is added to the oligopolymer pipeline simultaneously by a metering pump; and the generated product enters a final polycondensation reaction kettle with the temperature of 285-295 DEG C, the vacuum degree smaller than or equal to 1mm Hg for polycondensation reaction of 0.5-5 hour so as to form the polyethylene glycol terephthalate. The invention can shorten the polycondensation reaction time and SSP time.

Owner:JIANGSU CHUNSHENTANG PHARMA

Catalyst system and application in use for synthesizing degradable polyester

ActiveCN100360581CIncrease the weight average molecular weightThe polymerization reaction is fastRare earthTitanium

This invention publishes a biodegradable polyester catalyst system and its application. Such a catalyst system as a binary system consists of rare earth compound C1 and one of the compounds of titanium, stibium and zincum C2, with a C1 / C2 mole ratio of 5:95~100:0. The catalyst is specifically applicable in preparing polyesters with an aliphatic groups / aromatic groups mole ratio of 35 / 65~100 / 0 and a weight-average molecular weight of 3000~200000g / mol (identified by GPC). The catalyst system in this invention significantly promotes the condensation polymerization rate and product molecular weight and improves the problem of yellow-color products from single-component titanium catalyst system.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing linear polyester resin

InactiveCN104479115AReduce manufacturing costShort polycondensation timePolyester coatingsPolymer sciencePtru catalyst

The invention discloses a method for preparing a linear polyester resin. The method is a polymerization process of synthesizing the linear polyester resin from dibasic acid and dihydric alcohol in the presence of a special catalyst. The production process is as follows: adding adipic acid, ethylene glycol and 1,4-butanediol to a reaction still according to the matching ratio to enable the mixed materials to be subjected to an esterification reaction at a temperature of below 140 DEG C; then, increasing the temperate and reacting for several hours at the presence of a new catalyst; removing the water and excess dihydric alcohol generated during the reaction and measuring the acid value and viscosity of the produced material; cooling the material to an indoor temperature when the fact that the reaction is ended is judged and adding a solvent for dilution; packaging the dilute material to obtain the finished product.

Owner:HENGYANG NORMAL UNIV

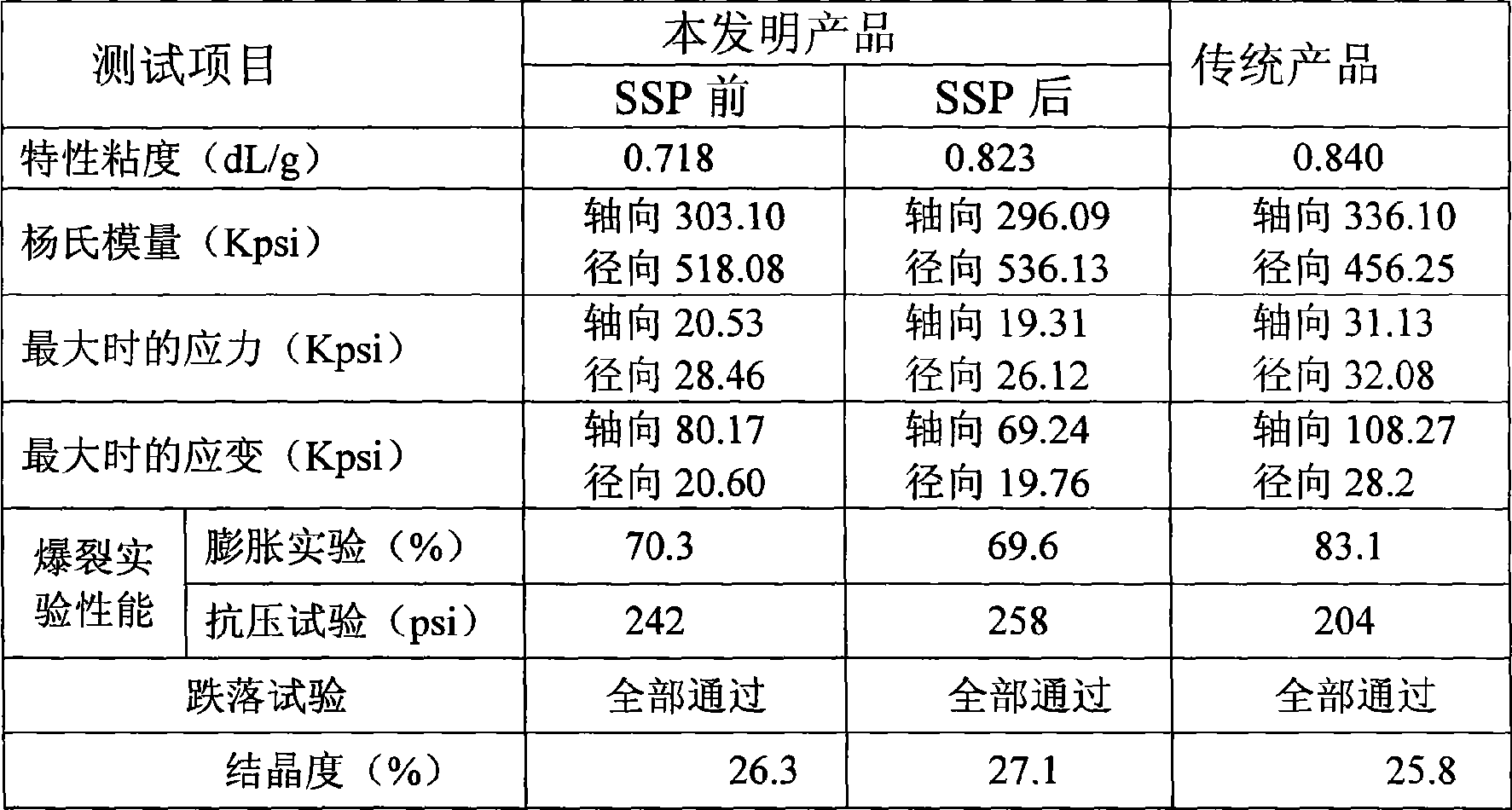

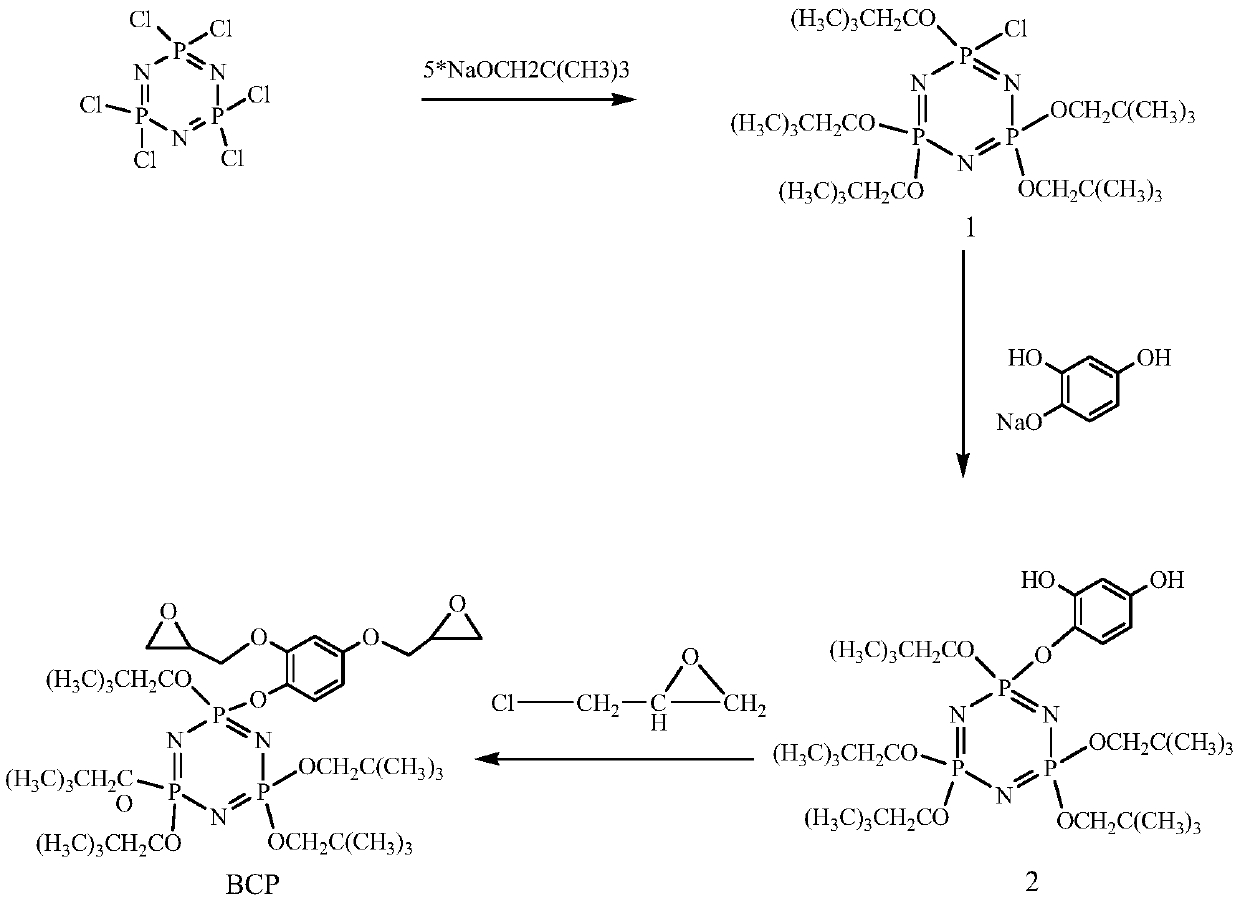

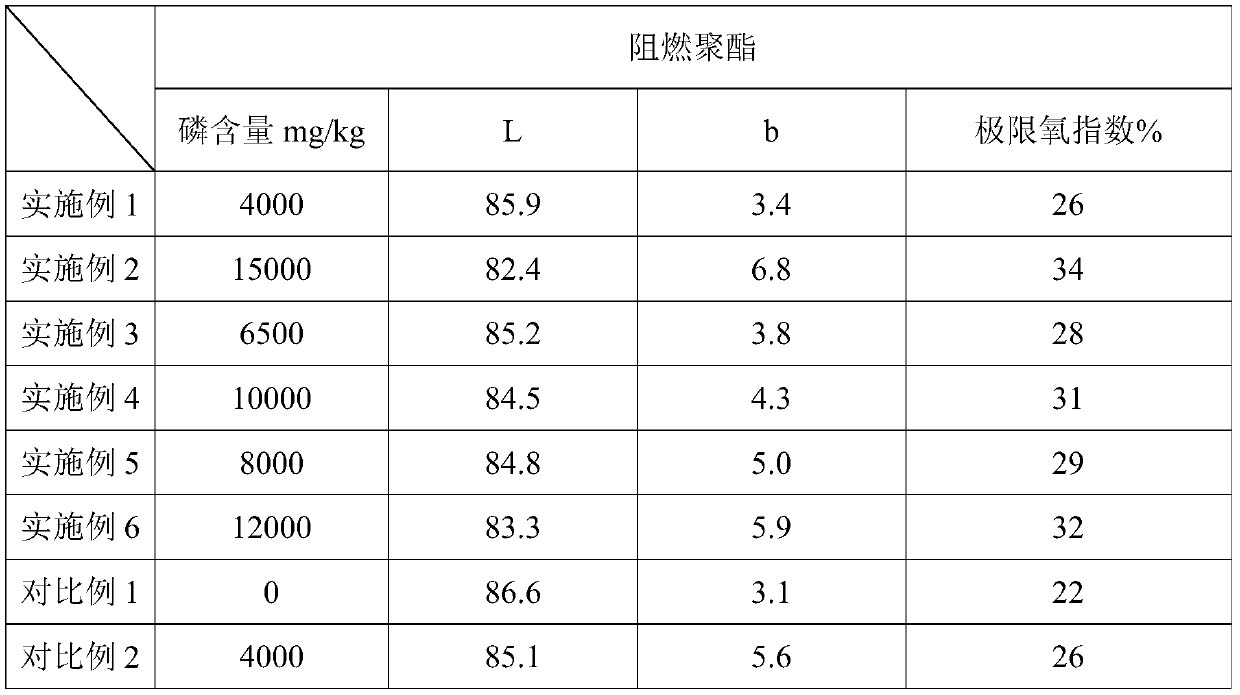

Phosphorus-containing flame-retardant PTT as well as preparation method and application thereof

ActiveCN109776780AShort polycondensation timeGood hueFlame-proof filament manufactureMonocomponent copolyesters artificial filamentFiberPolymer science

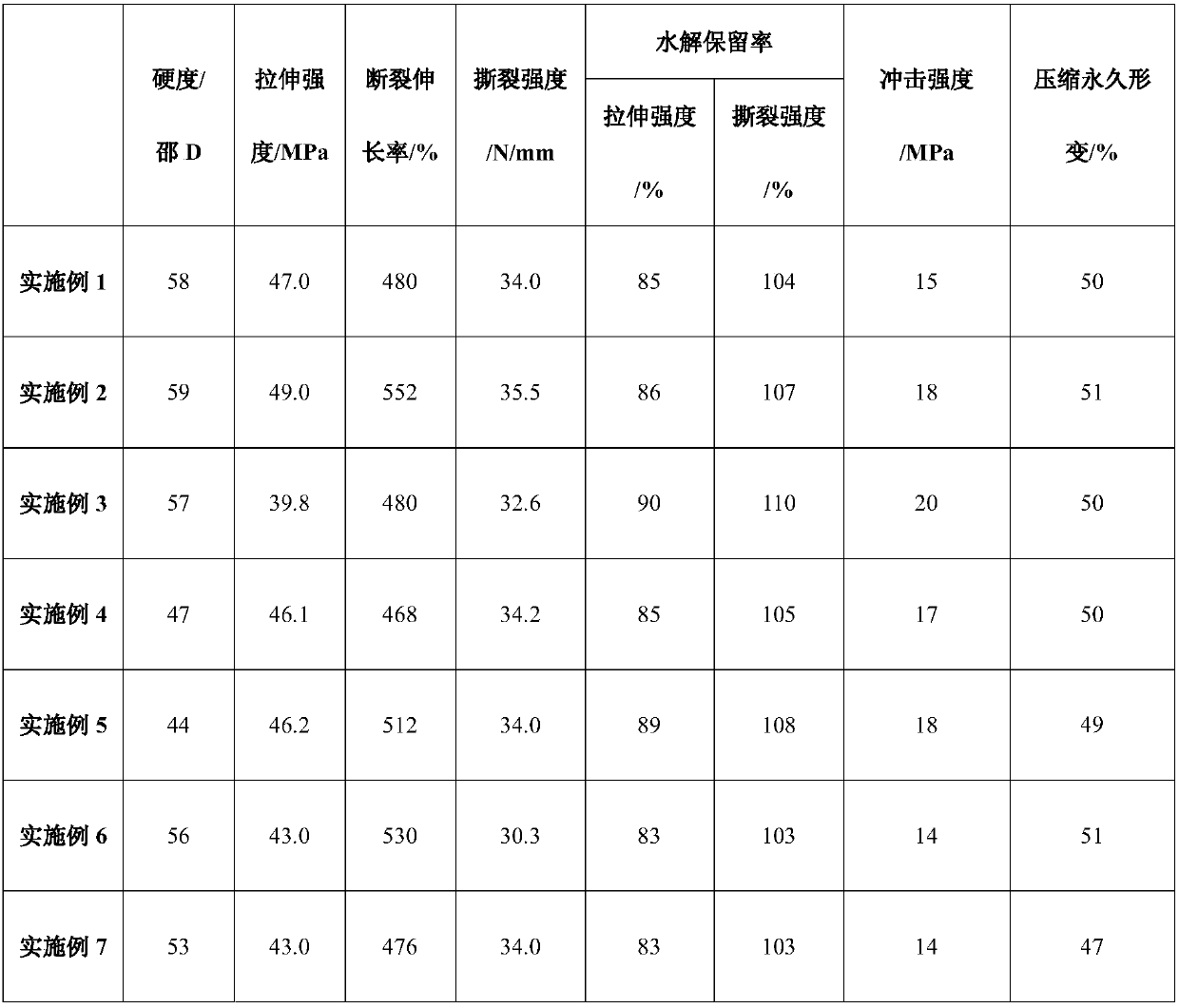

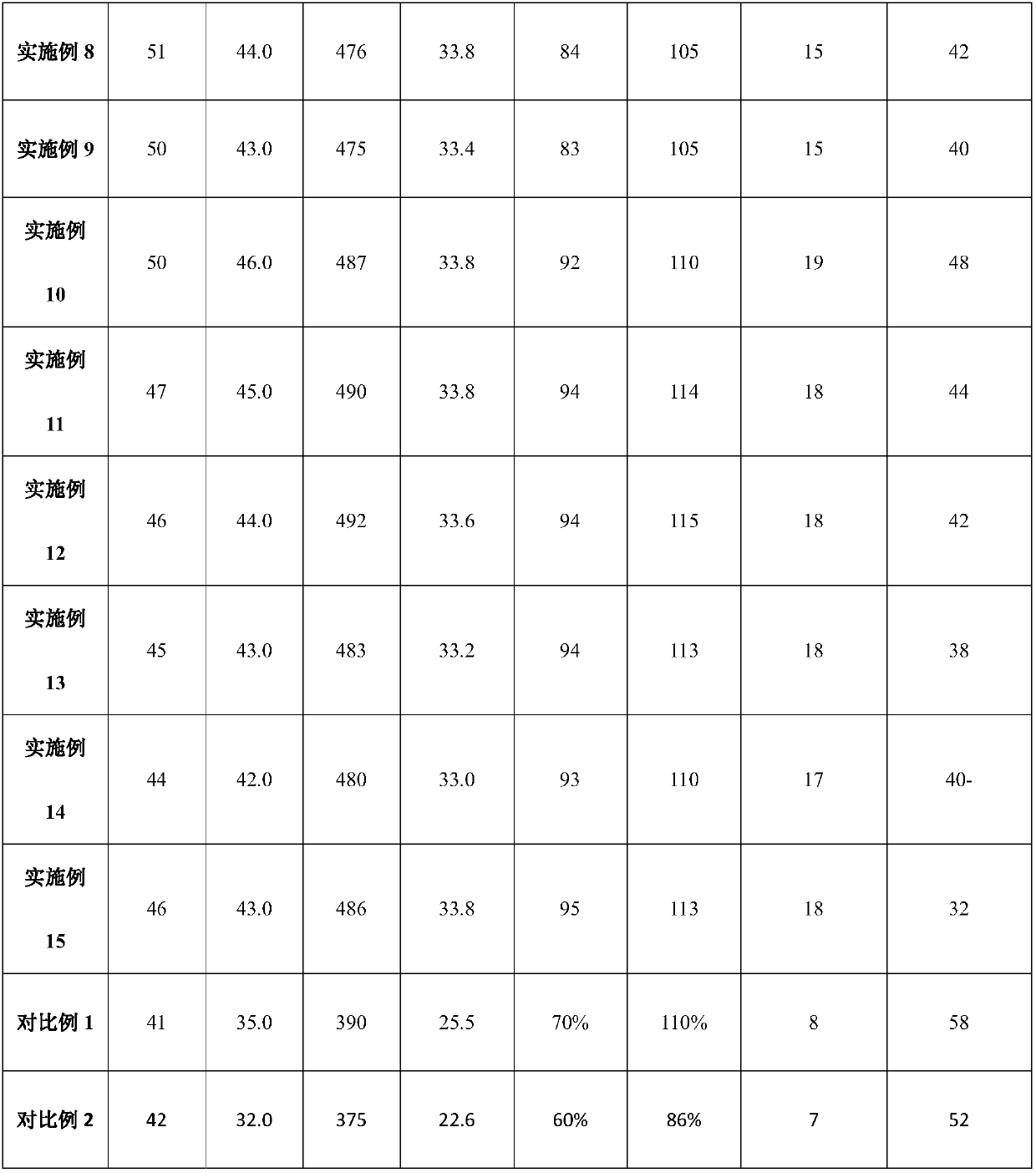

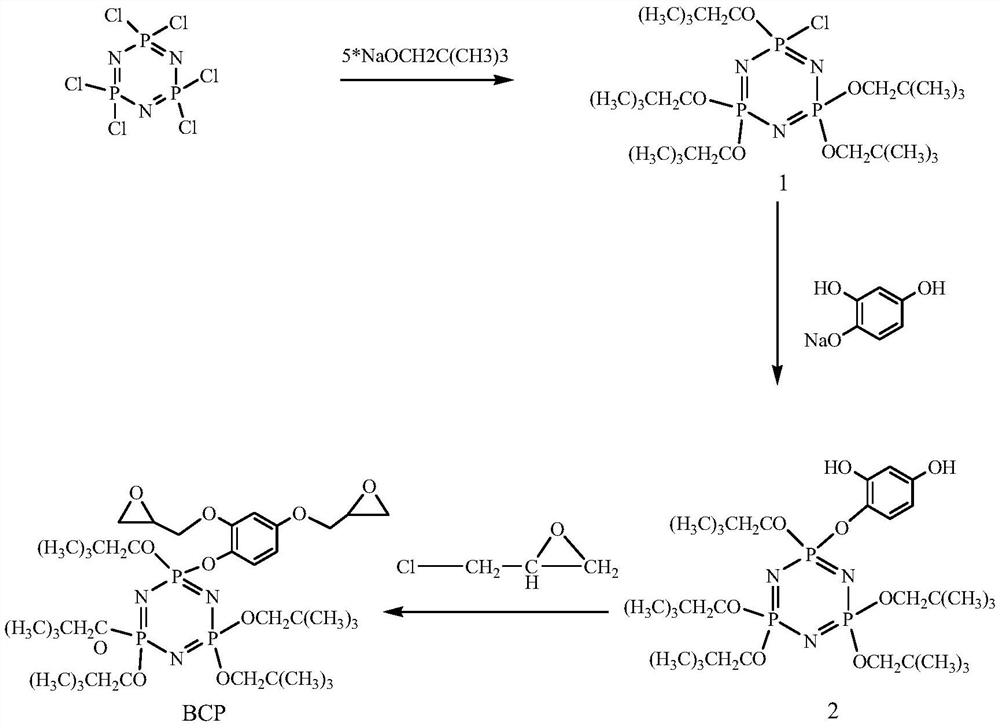

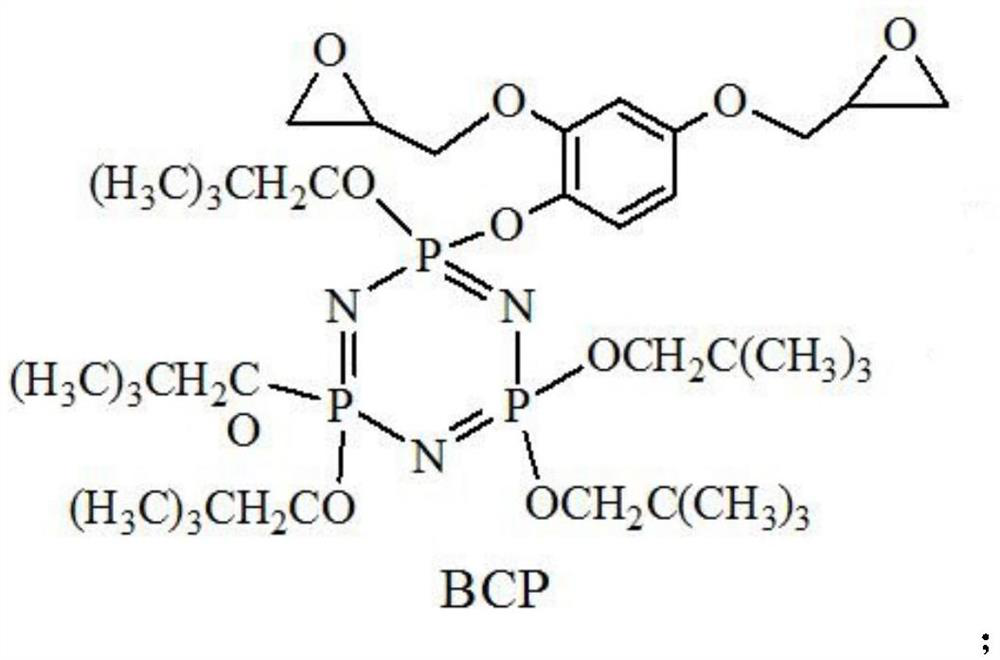

The invention discloses phosphorus-containing flame-retardant PTT as well as a preparation method and application thereof. The phosphorus-containing flame-retardant PTT is mainly prepared by mixing terephthalic acid and propylene glycol, and adding a flame retardant and an auxiliary agent for polymerization, wherein the flame retardant is obtained by compounding alkyl substituted dipropylene phosphate and 2-(tert-butyl alcohol cyclotriphosphazenyl)1,3-benzenediol diglycidyl ether (BCP). The phosphorus-containing flame-retardant PTT prepared by the method provided by the invention has short polycondensation time, good product color and good flame-retardant performance; the L value of the prepared phosphorus-containing flame-retardant PTT reaches 86, the b value is within 6.8, and the polyester flame-retardant property LOI is more than or equal to 26%; and the obtained phosphorus-containing flame-retardant PTT can be widely applied to the fields of fibers and films.

Owner:CHINA PETROLEUM & CHEM CORP +1

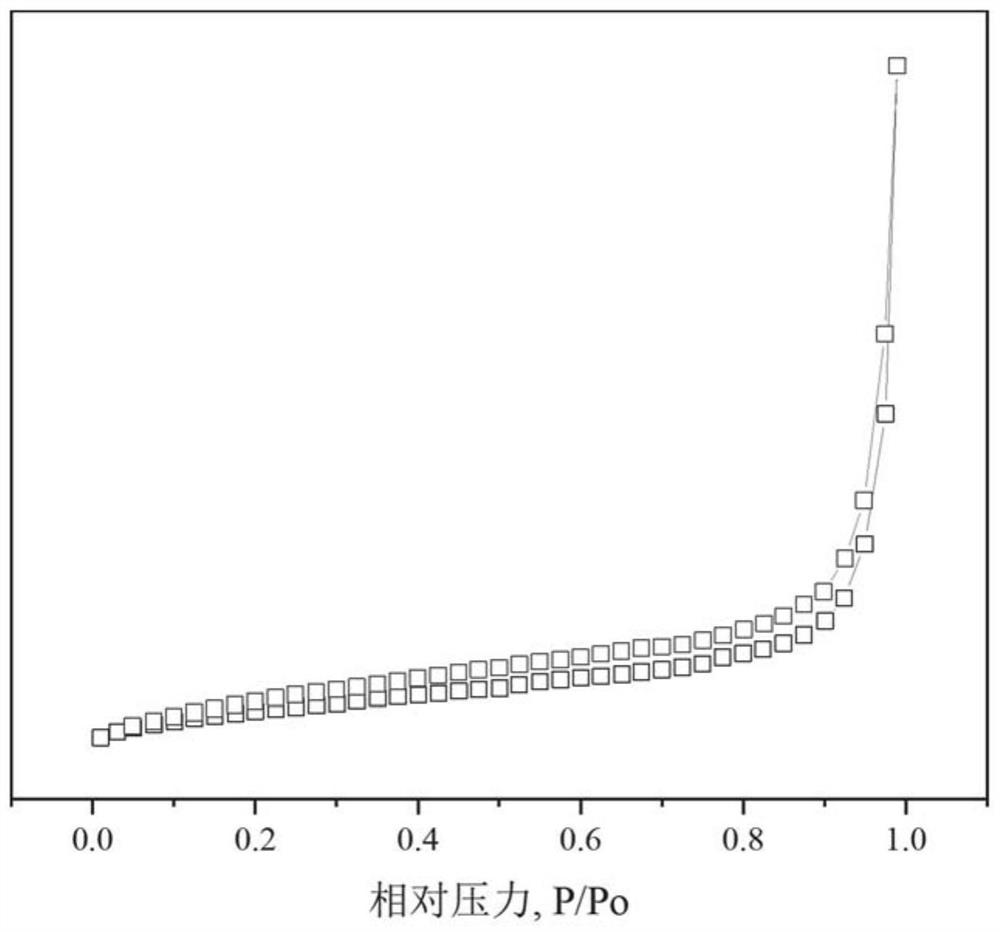

Polycondensation catalyst for polyester synthesis as well as preparation method and application of polycondensation catalyst

The invention discloses a polycondensation catalyst for polyester synthesis and a preparation method and application thereof. The preparation method comprises the following steps: carrying out homogeneous blending on a Ti<3>C<2>T<x>MXene material and a benzoxazine monomer to obtain a blend, then carrying out heating for curing treatment to obtain a Ti<3>C<2>T<x>MXene / benzoxazine resin composite material, and finally, irradiating the Ti<3>C<2>T<x>MXene / benzoxazine resin composite material with laser to prepare the polycondensation catalyst for polyester synthesis. The prepared polycondensation catalyst for polyester synthesis has high catalytic activity, and polyester with higher molecular weight can be obtained through polycondensation polymerization within shorter time, so the tensile modulus, tensile strength and other mechanical properties of polyester are improved. In addition, side reactions such as raw material diacid decarboxylation and thermal degradation of polyester can be inhibited by shorter polymerization time, so the obtained polyester has better hue. Moreover, LIG in the polyester can increase the crystallization rate of the polyester and enhance the conductivity of the polyester, so a polyester product is endowed with antistatic performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

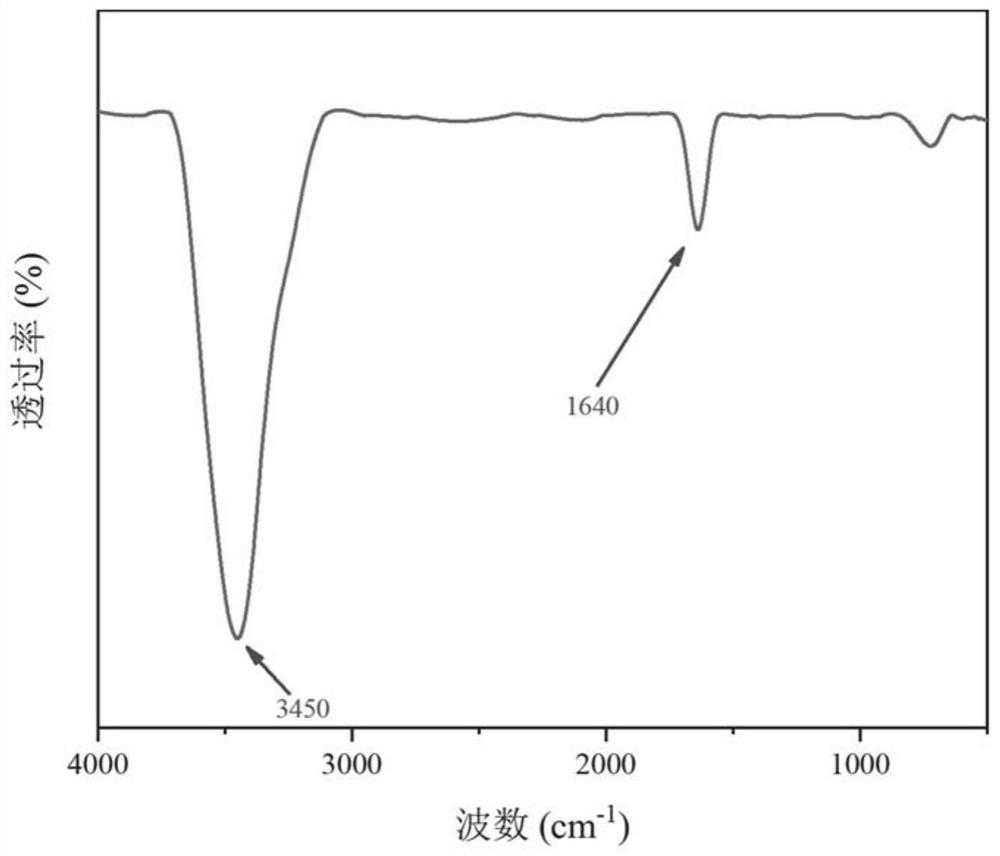

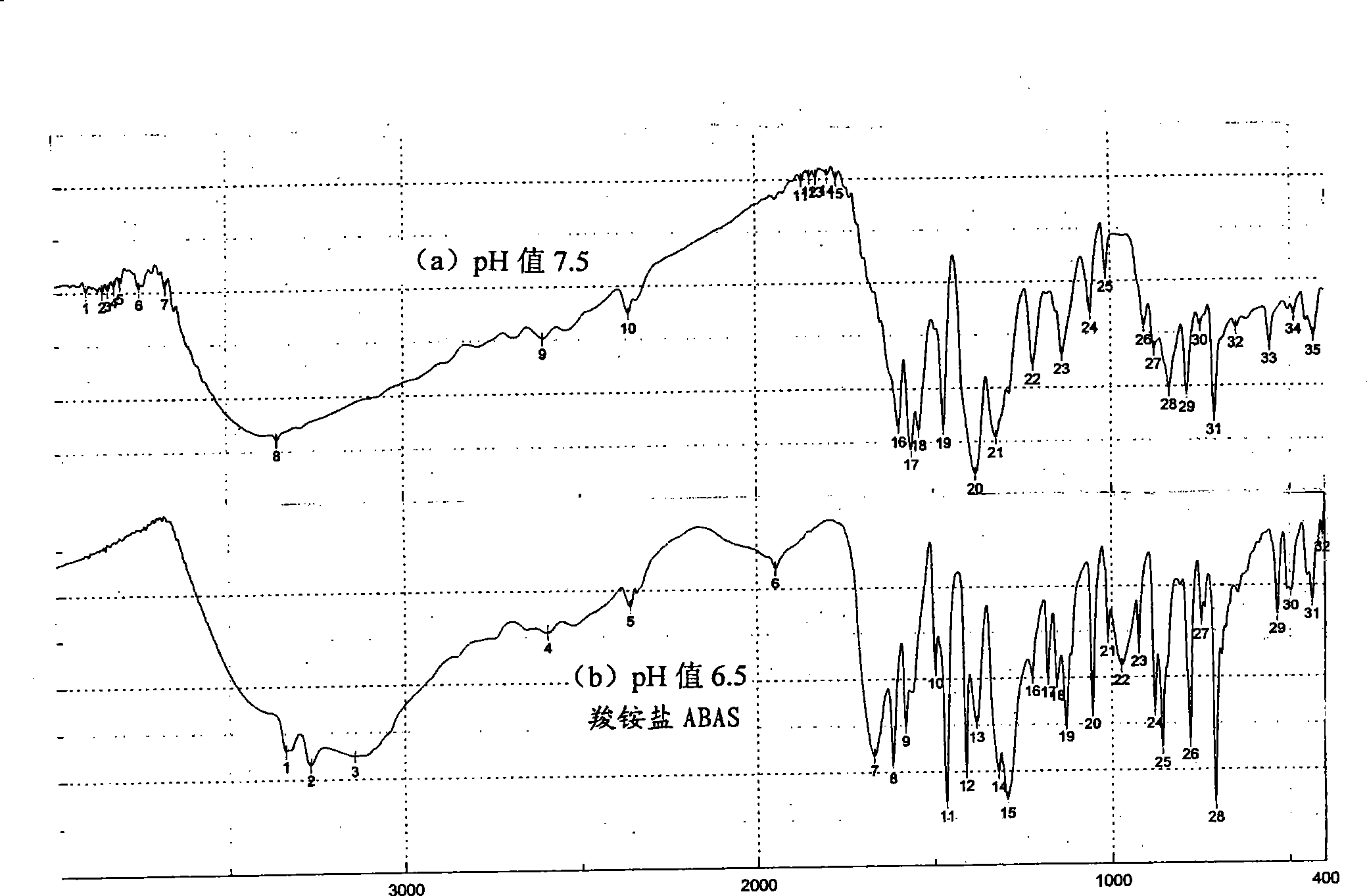

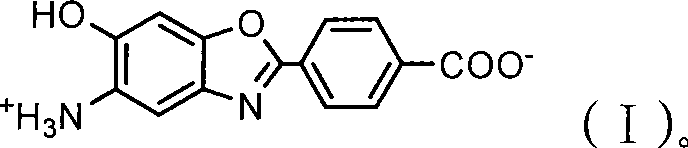

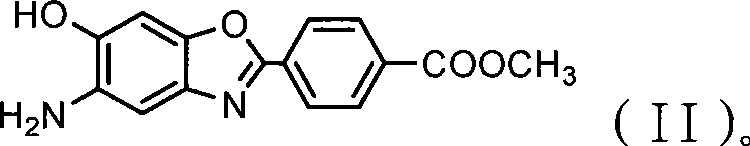

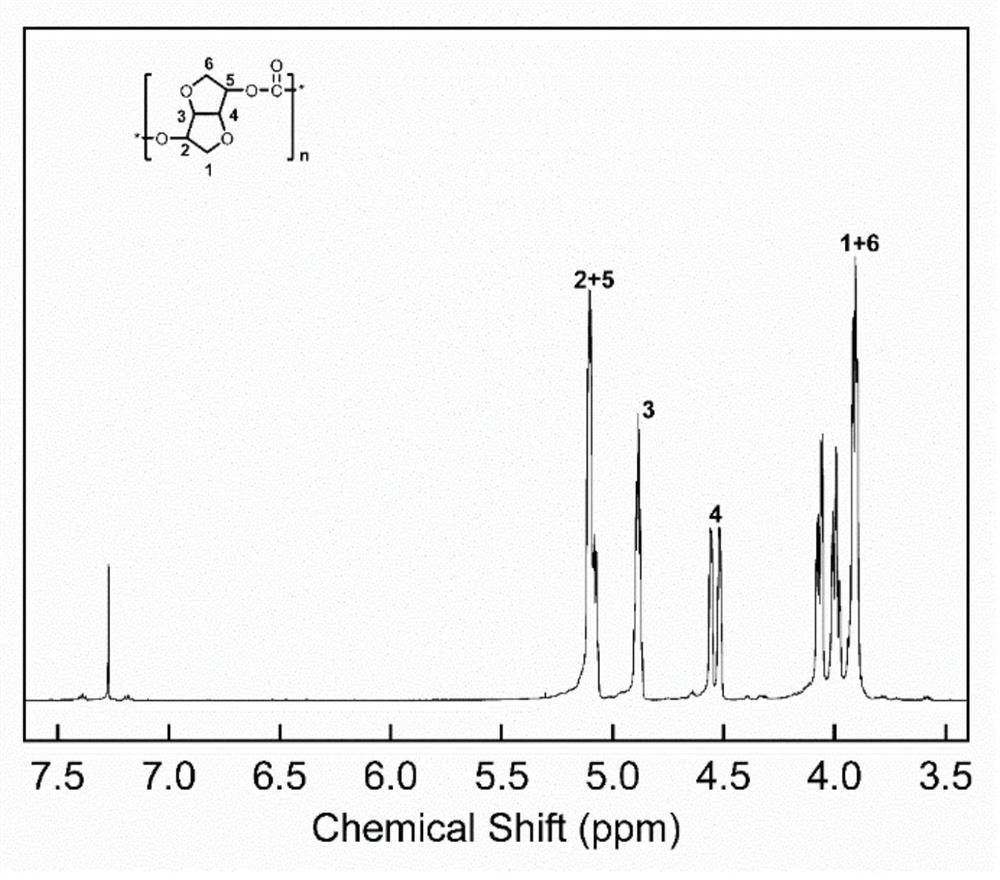

Use of 5-amino-6-hydroxy-2-(p-carboxyphenyl)benzoxazole salt

InactiveCN101372532APlay a role in refining and purifyingGood polycondensation effectFiberBenzoxazole

The invention relates to an application of 5-amido-6-hydroxy-2-(p-carboxyl phenyl) benzoxazole carboxyl ammonium salt (ABAS) in preparing poly(p-phenylene benzobisoxazole) (PBO) resin. The prepared ABAS monomer has the advantages of containing no polymerization inhibitors (such as DMF, DMAc and DMSO and other solvent residues) which affect the condensation polymerization of the ABA for preparing the PBO, good oxidation resistance and thermal stability, and realizing polycondensation with equivalent proportion to further enhance the PBO molecular weight and reduce the polymerization time, and the like, and the application can be developed into a new technology for implementing the PBO resin and the fiber industrialization at low cost.

Owner:ZHEJIANG UNIV OF TECH +1

Method for preparing polycarbonate through catalysis of binuclear ionic liquid

The invention provides a method for preparing polycarbonate through catalysis of a binuclear ionic liquid, which comprises the following steps: by using a dihydroxy compound and a diester carbonate asraw materials, adding the raw materials into a reactor according to the molar ratio of (1: 0.9)-(1: 8), and synthesizing polycarbonate by using binuclear imidazolyl ionic liquid as a catalyst througha melt transesterification method under the protection of inert gas. Compared with literature reports, the weight-average molecular weight of the synthesized polycarbonate reaches 5 * 10 < 4 >-16 * 10 < 4 > g / mol, the transesterification time is shortened by 25%-50%, and the polycondensation time is shortened by 20%-40% by regulating the length of an alkyl chain between double imidazole rings andchanging the structure of anions under the synergistic catalytic action of anions and cations.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

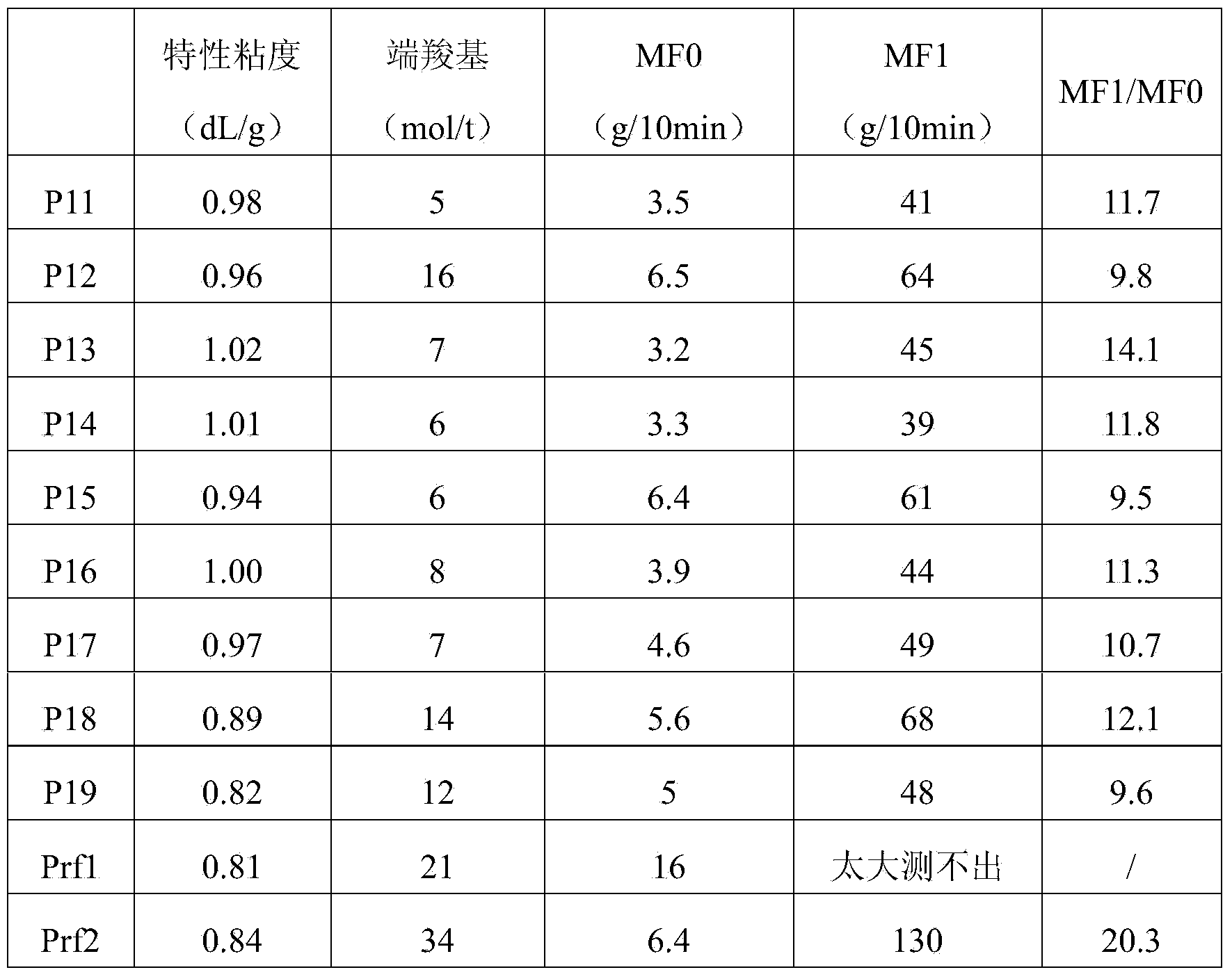

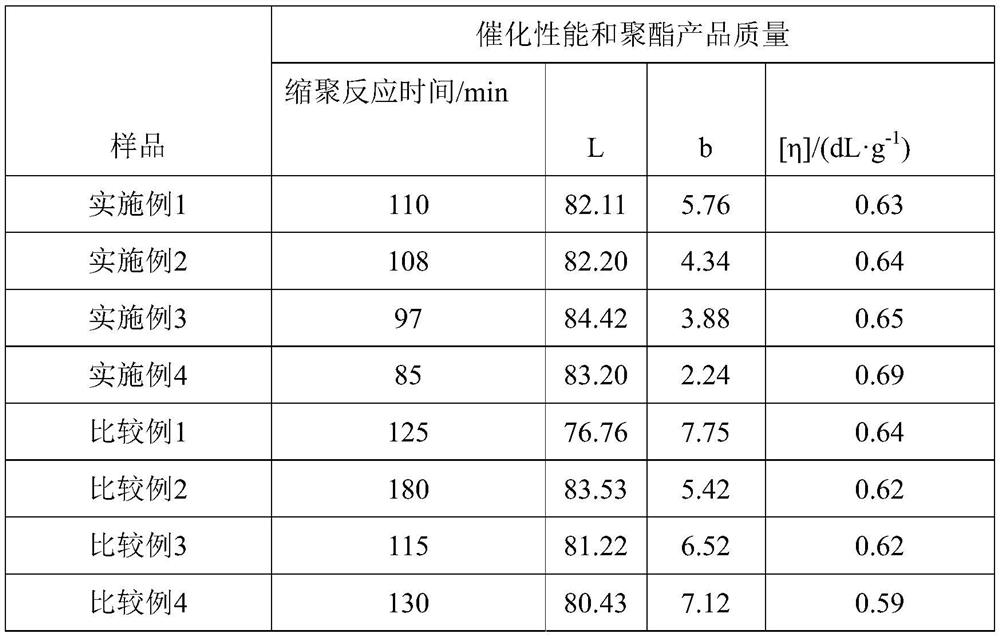

Catalyst system for synthesizing aliphatic-aromatic copolyester and application of catalyst system

The invention discloses a catalyst system for synthesizing aliphatic-aromatic copolyester and application of the catalyst system. The catalyst system is composed of a titanium composition and a metal composition. The titanium composition is prepared by dissolving a titanium compound, hydroxycarboxylic acid and phosphate in 1, 4-butanediol, heating to react, removing small molecules and cooling to room temperature, and the metal composition is prepared by dissolving titanate, tetraethoxysilane and one metal compound selected from aluminum and zinc compounds in absolute ethyl alcohol, and conducting co-hydrolysis reaction, filtration and vacuum drying, wherein the molar ratio of the titanium composition to the metal composition is 1: 1-1: 10. The method is suitable for preparing copolyester with the aliphatic-aromatic group mole number ratio of 70 / 30-30 / 70, and the molecular weight of the copolyester is 5000-150000 g / mol. The catalyst system is environmentally friendly, side reactions are reduced, and the hue of an aliphatic-aromatic copolyester product is improved.

Owner:CHINA PETROLEUM & CHEM CORP

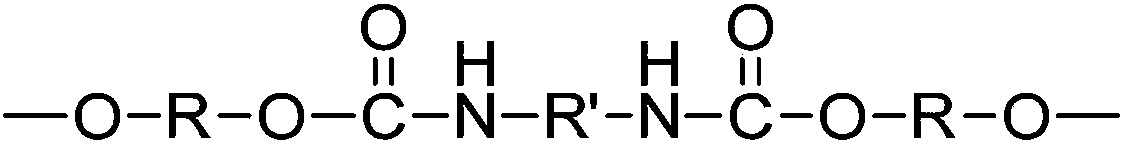

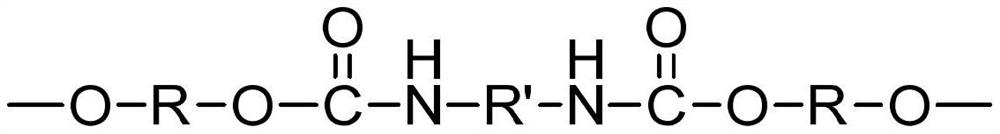

Novel polyether ester elastomer and preparation method thereof

The invention provides a novel polyether ester elastomer and a preparation method thereof, wherein the polyether ester elastomer is prepared by carrying out a mixing reaction on the following components by mass: 100 parts of polyester polyol, 25-100 parts of polyether polyol, and 5-55 parts of isocyanate, preferably, 50-100 parts of polyether polyol, preferably 8-28 parts of isocyanate. Accordingto the present invention, the polyether ester elastomer can be prepared through the reaction within a relatively short time, and has good resilience performance.

Owner:WANHUA CHEM GRP CO LTD

A kind of phosphorus-containing flame-retardant polyester and its preparation method and application

ActiveCN109627430BShort polycondensation timeGood hueFlame-proof filament manufactureMonocomponent copolyesters artificial filamentFiberPolymer science

The invention discloses a phosphorus-containing flame-retardant polyester and its preparation method and application. The flame-retardant polyester is mainly prepared by mixing terephthalic acid and ethylene glycol, and adding auxiliary agents and flame retardants for polymerization; The flame retardant is a flame retardant compounded by alkyl substituted diethylene glycol phosphate and 2-(tert-butanol cyclotriphosphazene) 1,3-benzenediol diglycidyl ether (BCP). The flame retardant polyester prepared by the present invention has short polycondensation time, good product hue, and good flame retardant performance. The L value of the prepared polyester reaches 85, the b value is within 3, and the flame retardant performance of the sample is LOI ≥ 29%; the obtained polyester Widely used in the field of fiber and film, the polyester can be added as a masterbatch or directly used to prepare fibers and films. Fibers prepared from the polyester are used in industrial textiles, architectural interior decoration materials, vehicle interior decoration materials, protective clothing, carpets, etc.; compared with conventional similar polyester films, the films prepared from the polyester have lower Haze and good flame retardant properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aliphatic polyester complexes and method of preparing the same

The invention discloses a fatty polyester compound and a preparation method thereof, including the following steps: (1) synthesis of condensation fatty co-polyester: the react between two, three or four fatty dicarboxylic acids or the esters thereof and fatty dibastic alcohol is conducted to achieve condensation fatty co-polyester; (2) the condensation fatty co-polyester reacts with poly lactic acid under the existence of double functional-group chain-extension agent and the extruded out, the achieved fatty polyester compound is the blend of high molecular weight fatty co-polymer, high molecular weight fatty block copolymer and high molecular weight poly lactic acid. The weight percents of condensation fatty co-polyester and poly lactic acid drop is 5:95-95:5. The preparation method has the advantages that the condensation duration is short, the process control is stable and simple, and the method can be directly applied to various processing techniques such as film inflation, extrusion, vacuum molding, blow molding, foaming, and the like; the achieved products have high purity and nice color; the performance adjustment is flexible and convenient, and the cost is low.

Owner:KINGFA SCI & TECH CO LTD +1

A kind of synthetic method of biodegradable aliphatic-aromatic copolyester

ActiveCN110591057BSolve the problem that the color b value increases (yellow)Address migration into foodEpoxyPolymer science

The invention discloses a method for preparing a biodegradable aliphatic-aromatic copolyester. The steps include: adding epoxy soybean oil after continuous esterification of aromatic dicarboxylic acid and aliphatic dicarboxylic acid, and continuously Pre-condensation, in the pre-condensation process, the epoxy group is inserted into the polybutylene terephthalate-adipate-PBAT molecular chain through transesterification, and then the polycondensation is carried out continuously at a higher temperature, so that the molecular weight , The intrinsic viscosity reaches the target value. The preparation method of the biodegradable aliphatic-aromatic copolyester disclosed by the present invention can make it easier for the polyester to reach the target intrinsic viscosity and molecular weight, reduce the polycondensation time of high-temperature and high-viscosity materials, reduce side reactions, and reduce product ends. Carboxyl value, solve the problem of resin yellowing. The preparation method of the biodegradable aliphatic-aromatic copolyester disclosed by the invention does not use a small molecule chain extender to extend the chain, and solves the problem of the migration of the residual chain extender from plastic to food.

Owner:RACHEM CHINA CO LTD +1

A kind of foamable pet resin and its preparation method and application

The present invention discloses a foamable PET resin, a preparation method and uses thereof. The preparation method comprises: (1) uniformly mixing raw material components, wherein the raw material components comprise 985-995 parts of physically recycled PET bottle flakes, 1-9 parts of a chain extender, 1-3 parts of an antioxidant, and 1-3 parts of a thermal stabilizer, and a three-functional-group chain extension monomer and a multi-functional-group chain extension monomer having a functional group number of 4-6 are compounded according to a mass ratio of 1:3-5:1 to prepare the chain extender; (2) carrying out melt extrusion granulation; and (3) carrying out solid phase condensation polymerization on the obtained material for 1-5 h at a temperature of 210-230 DEG C under a vacuum degree of 5-100 Pa so as to obtain the foamable PET resin. According to the present invention, the foamed PET resin has characteristics of high molecular weight, wide molecular weight distribution, high melt strength, physically recycled PET degrading use changing, low raw material cost, and simple preparation process; and with the combination of the chain extender, the reaction extrusion and the solid phase condensation polymerization are combined, such that the reaction period is shortened, and the industrial production is easily achieved.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of novel polyether ester elastomer and preparation method thereof

The invention provides a novel polyether ester elastomer and a preparation method thereof. The polyether ester elastomer of the invention is prepared by mixing and reacting components comprising the following parts by mass: 100 parts by mass of polyester polyol; 100 parts by mass of polyether polyol; 25-100 parts by mass of alcohol; 5-55 parts by mass of isocyanate; preferably, 50-100 parts by mass of polyether polyol; preferably, 8-28 parts by mass of isocyanate. The polyether ester elastomer provided by the invention can be prepared by reaction in a relatively short time, and has good rebound performance.

Owner:WANHUA CHEM GRP CO LTD

Method for synthesizing polyester by using rare earth catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method that dinuclear ionic liquid catalyzes and prepares polycarbonate

The invention provides a method for preparing polycarbonate by catalyzing a dual-nuclear ionic liquid. Dihydroxy compound and carbonic acid diester are used as raw materials, and are added to a reactor according to a molar ratio of 1:0.9 to 1:8, and are protected by an inert gas. , polycarbonate was synthesized by melt transesterification using binuclear imidazolium-based ionic liquids as catalysts. Compared with the literature reports, by adjusting the length of the alkyl chain between the bis-imidazole rings and changing the structure of the anion, the weight-average molecular weight of the synthesized polycarbonate reached 5×10 4 ~16×10 4 g / mol, the transesterification time is shortened by 25% to 50%, and the polycondensation time is shortened by 20% to 40%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

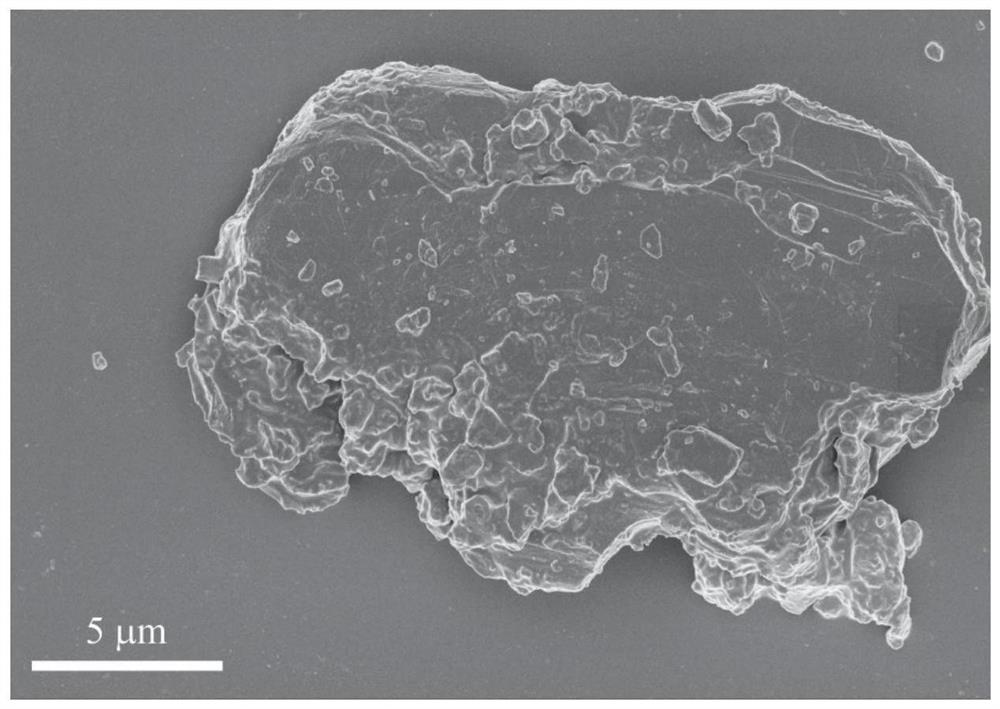

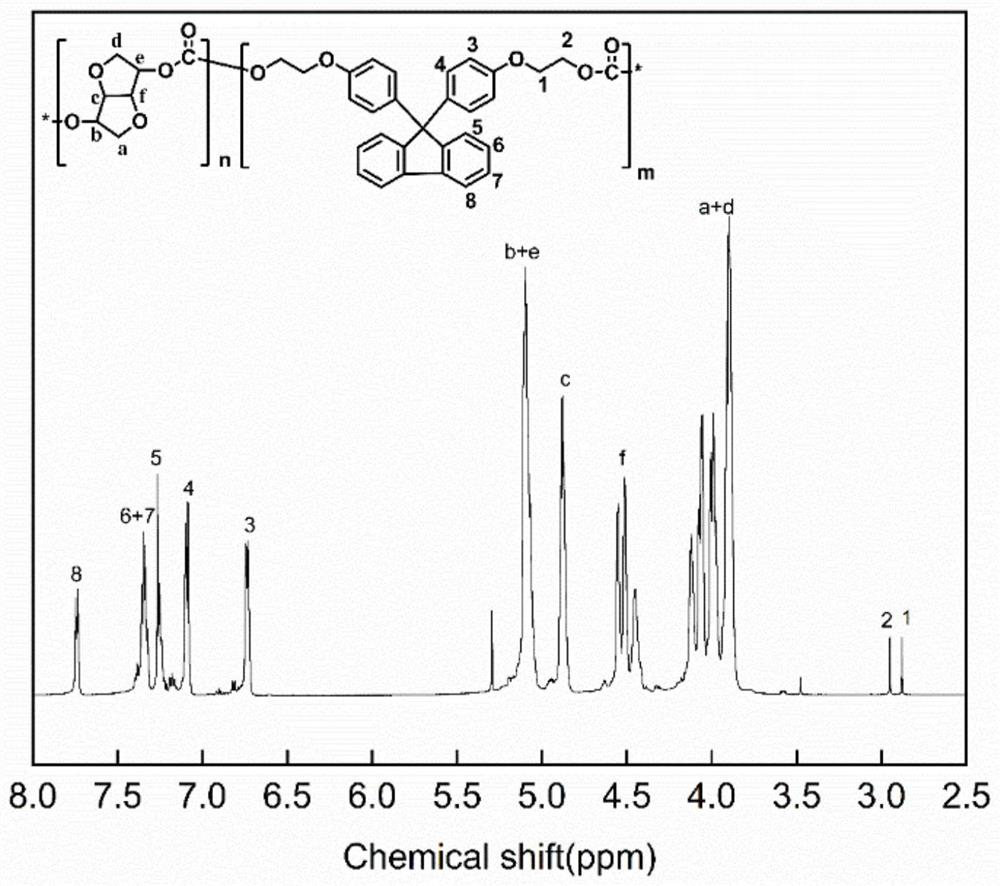

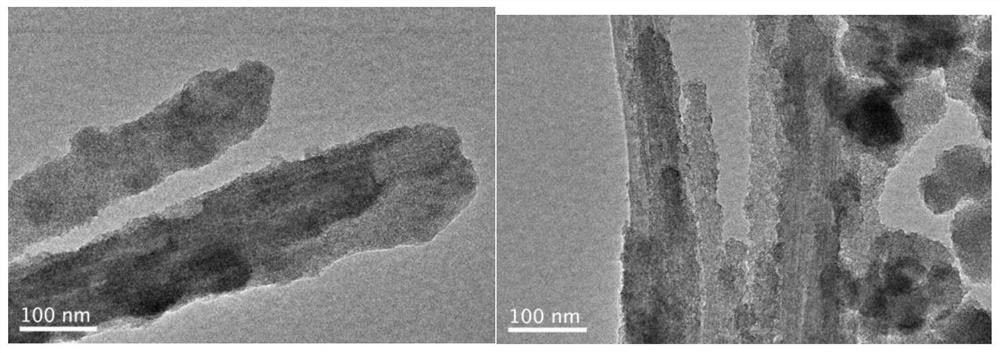

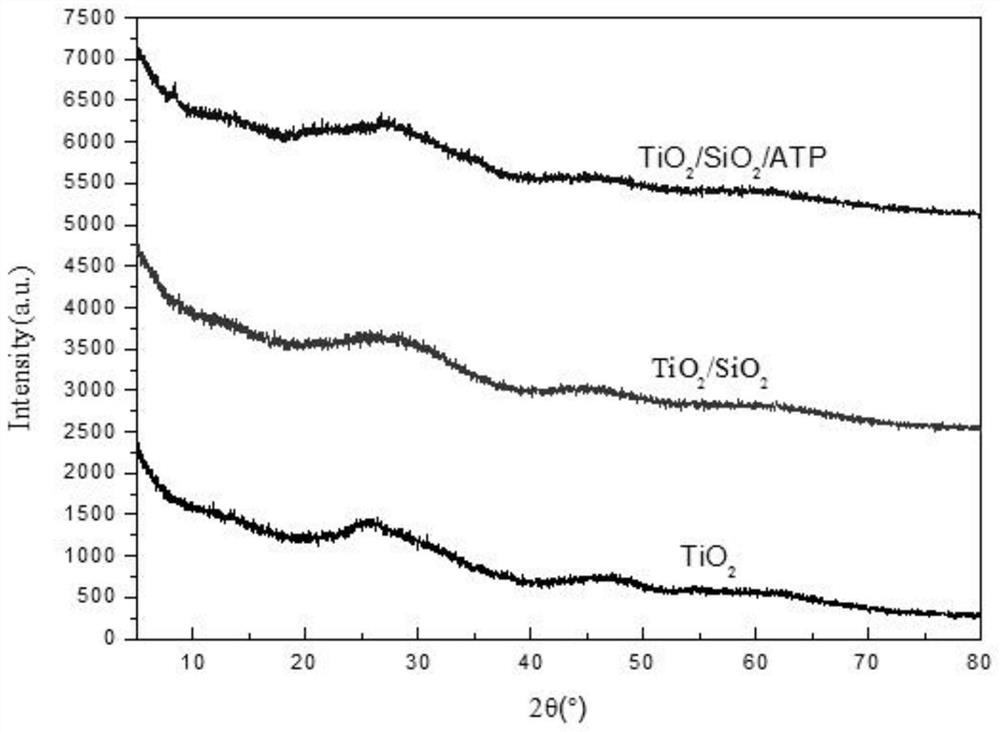

A kind of preparation method and application of green titanium series polyester catalyst

The invention relates to a preparation method and application of a green titanium-based polyester catalyst, which is characterized in that it comprises the following steps: dissolving ethyl orthosilicate in absolute ethanol, adding an appropriate amount of acidified attapulgite, stirring evenly, and continuing to drip Add a mixed solution of titanium tetraisopropoxide and absolute ethanol, add dropwise a mixed solution of deionized water and absolute ethanol, heat in a water bath, hydrolyze for several hours, stop heating and stirring, wash with absolute ethanol, dry and grind to obtain It is a new type of green titanium-based catalyst. The advantage of the present invention is that the titanium oxide / silicon oxide / attapulgite composite titanium-based catalyst is prepared by the mixed hydrolysis method, and silicon oxide is used to suppress the crystallization of titanium oxide, and at the same time, the attapulgite is used as a carrier to improve the dispersion of titanium oxide and silicon oxide properties, making the activity of the catalyst more stable, thereby reducing the side reactions of the polyester and improving the hue of the polyester produced.

Owner:常州大学盱眙凹土研发中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com