Method for synthesizing polyester by using rare earth catalyst

A catalyst and polyester technology, applied in the field of synthetic polyester, can solve the problems of wide molecular weight distribution of polymer products, further research on process catalysts, complicated operation process, etc., and achieve the advantages of increased polymerization reaction speed, easy control and simplified operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

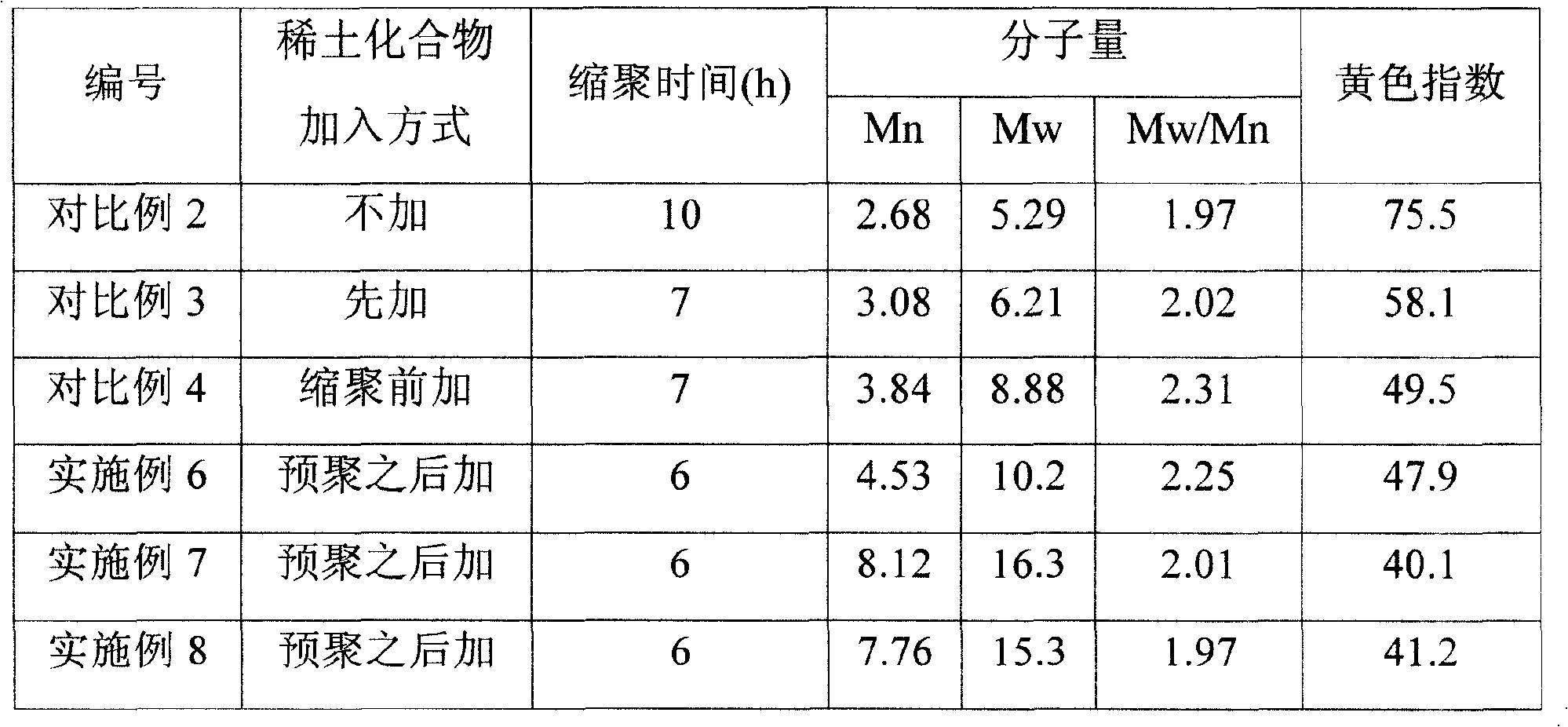

Examples

Embodiment 1-4

[0050] Embodiment 1-4 Preparation of Rare Earth Catalyst C2

Embodiment 1

[0051] Example 1 Anhydrous lanthanum chloride (LaCl 3 ) preparation

[0052] 10g La 2 o 3 Dissolve with excess hydrochloric acid, add metered NH after heating and concentrating 4 Cl(with La 2 o 3 The molar ratio is 3 / 1,), and the excess acid is evaporated by careful heating to obtain LaCl 3 ·nH 2 O+NH 4 For the solid of Cl, grind the solid and add it to the quartz sublimation tube, vacuumize to <5mmHg; slowly heat up to 400°C in the tube furnace, and keep the vacuum for 1hr; cool to room temperature under vacuum, fill with argon, Remove the sublimation tube and transfer it into the tube under the protection of argon for standby.

Embodiment 2

[0053] Example 2 Lanthanum acetylacetonate La(a c a c ) 3 preparation of

[0054] In a 250ml three-necked bottle, LaCl 3 ·7H 2 O (3.47g, 9.37mmol) was dissolved in 50ml of water, added dropwise to 50ml of aqueous solution of acetylacetone (5.63g, 56.2mmol), stirred at room temperature, and adjusted to pH 7 by adding 2NKOH solution. The reaction mixture carries La(a c a c ) 3 The precipitate was stirred, filtered, and vacuum-dried at 60°C to obtain about 4g La(a c a c ) 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com