A kind of phosphorus-containing flame-retardant polyester and its preparation method and application

A technology of flame-retardant polyester and polyester, applied in the field of phosphorus-containing flame-retardant polyester and its preparation, can solve the problems of the viscosity not meeting the requirements, the yellowing of the product, the increase of the b value of the product, the color difference of the sample, etc. Degradation degree, shortened polymerization time, good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

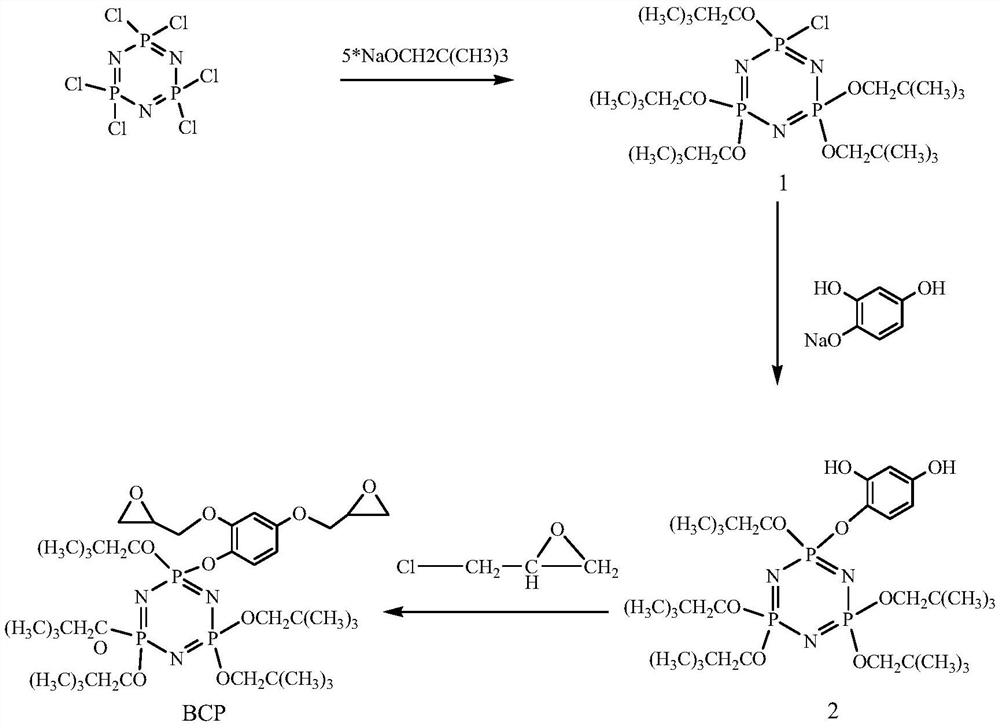

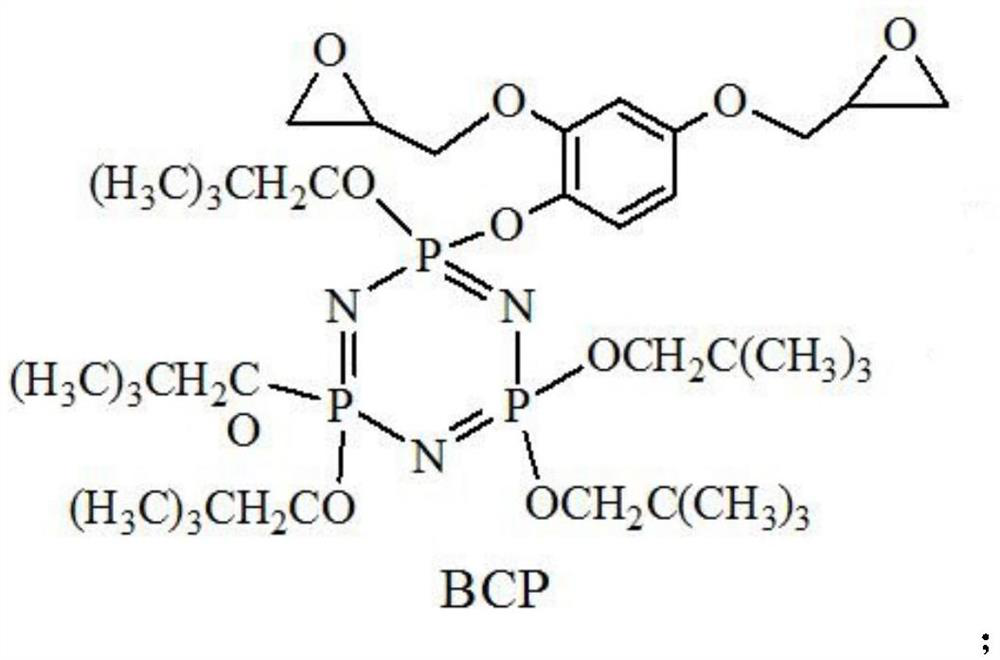

Method used

Image

Examples

Embodiment 1

[0035]Purified terephthalic acid and ethylene glycol are beaten in a molar ratio of 1:1.1, and the anti-ether agent and catalyst are added according to the content of the final polyester, and the content of the anti-ether agent in the polyester is 20mg / kg Add sodium acetate and ethylene glycol antimony with an antimony content of 250mg / kg, add the slurry to a batch reactor for esterification, control the esterification temperature at 230°C-250°C, and the esterification pressure at 0.1MPa-0.3 MPa, when the esterification rate is 85%, the pressure is released, and the flame retardant methyl phosphate di(ethylene glycol) ester and BCP are added in a compound flame retardant with a mass ratio of 10:90, and the flame retardant addition is according to The phosphorus content in the polyester is added at 6500mg / kg, the polycondensation temperature is controlled at 260°C-280°C, the vacuum is ≤80Pa, the discharge time is judged by the change value of the stirring current, and the viscos...

Embodiment 2

[0038] Purified terephthalic acid and ethylene glycol are beaten in a molar ratio of 1:1.8, and the anti-ether agent and catalyst are added according to the content of the final polyester, and the content of the anti-ether agent in the polyester is 10mg / kg Add sodium acetate and ethylene glycol antimony with an antimony content of 200mg / kg, add the slurry to a batch reactor for esterification, control the esterification temperature at 230°C-260°C, and the esterification pressure at 0.1MPa-0.4 MPa, when the esterification rate is 99%, the pressure is released, and the flame retardant phenyl phosphate di(ethylene glycol) ester and BCP are added in a compound flame retardant with a mass ratio of 40:60, and the flame retardant addition is according to The phosphorus content in the polyester is added at 15000mg / kg, the polycondensation temperature is controlled at 260°C-285°C, the vacuum is ≤80Pa, the discharge time is judged by the change value of the stirring current, and the visc...

Embodiment 3

[0041] Purified terephthalic acid and ethylene glycol are beaten in a molar ratio of 1:1.3, and the anti-ether agent and catalyst are added according to the content of the final polyester, and the content of the anti-ether agent in the polyester is 80mg / kg Add sodium acetate and ethylene glycol antimony with an antimony content of 300mg / kg, add the slurry to a batch reactor for esterification, control the esterification temperature at 240°C-260°C, and the esterification pressure at 0.2MPa-0.4 MPa, when the esterification rate reaches 92%, the pressure is released, and the flame retardant ethyl phosphate di(ethylene glycol) ester and BCP are added in a compound flame retardant with a mass ratio of 70:30, and the flame retardant addition is as follows: The phosphorus content in the polyester is added at 9000mg / kg, the polycondensation temperature is controlled at 270°C-280°C, the vacuum is ≤80Pa, the discharge time is judged by the change value of the stirring current, and the vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com