A kind of foamable pet resin and its preparation method and application

A resin and raw material technology, applied in the field of foamable PET resin and its preparation, can solve the problems of low molecular weight of PET polyester, difficulty in normal foaming, unsuitable for foaming, etc., achieve wide molecular weight distribution, shorten operation cycle, The effect of short polycondensation time

Active Publication Date: 2018-04-03

EAST CHINA UNIV OF SCI & TECH

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is to overcome the low molecular weight and poor melt strength of the existing physical recovery PET polyester, which is difficult to normally foam in the reaction extrusion and the simple toughening agent chemically modified PET molecular structure is not suitable for foaming Defects, provide a kind of foamable PET resin and its preparation method and use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

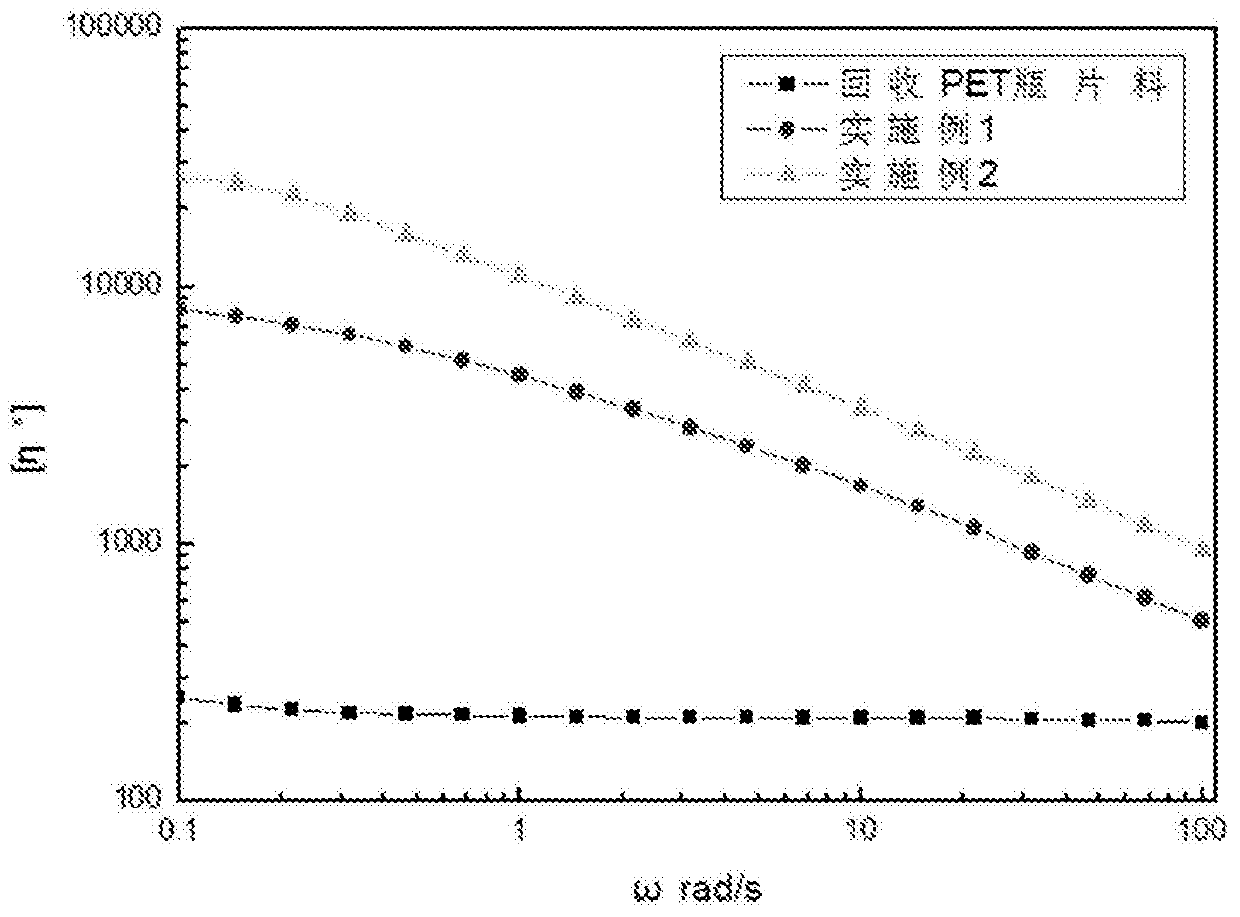

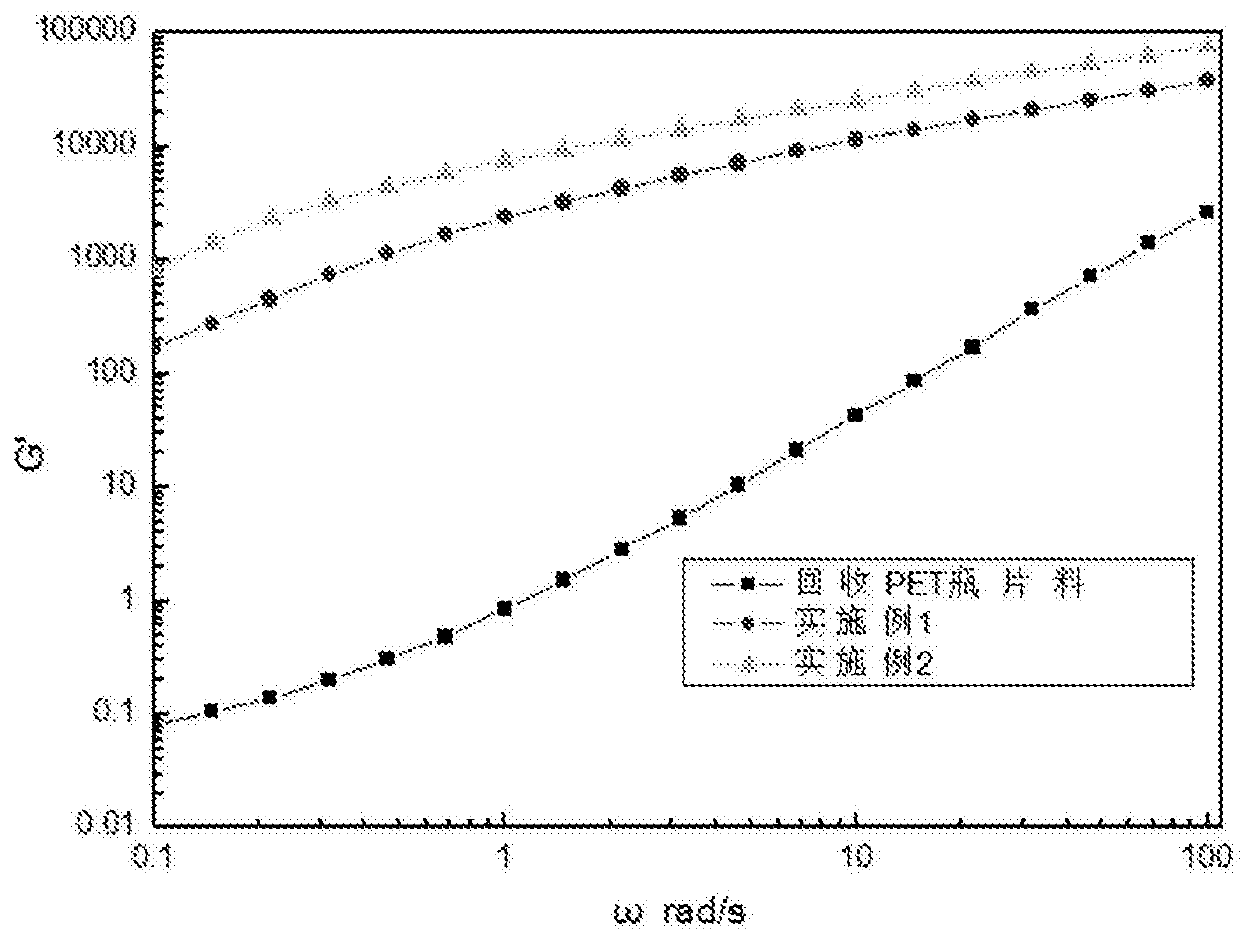

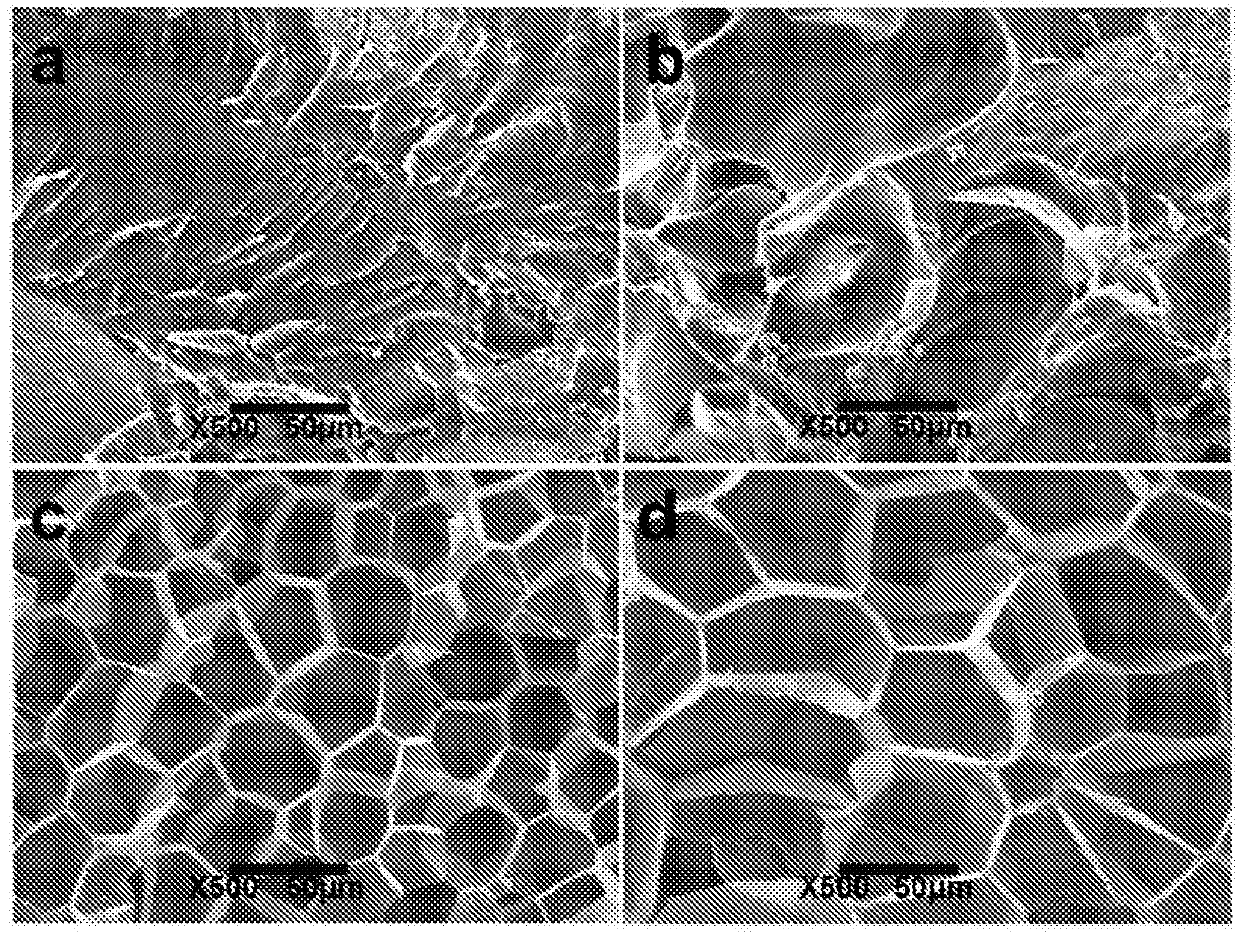

The present invention discloses a foamable PET resin, a preparation method and uses thereof. The preparation method comprises: (1) uniformly mixing raw material components, wherein the raw material components comprise 985-995 parts of physically recycled PET bottle flakes, 1-9 parts of a chain extender, 1-3 parts of an antioxidant, and 1-3 parts of a thermal stabilizer, and a three-functional-group chain extension monomer and a multi-functional-group chain extension monomer having a functional group number of 4-6 are compounded according to a mass ratio of 1:3-5:1 to prepare the chain extender; (2) carrying out melt extrusion granulation; and (3) carrying out solid phase condensation polymerization on the obtained material for 1-5 h at a temperature of 210-230 DEG C under a vacuum degree of 5-100 Pa so as to obtain the foamable PET resin. According to the present invention, the foamed PET resin has characteristics of high molecular weight, wide molecular weight distribution, high melt strength, physically recycled PET degrading use changing, low raw material cost, and simple preparation process; and with the combination of the chain extender, the reaction extrusion and the solid phase condensation polymerization are combined, such that the reaction period is shortened, and the industrial production is easily achieved.

Description

A kind of foamable PET resin and its preparation method and application technical field The invention relates to a polyester foam material, in particular to a foamable PET resin and its preparation method and application. Background technique Polyethylene terephthalate (PET) is the thermoplastic polyester with the largest output and the cheapest price. It has excellent physical, chemical and mechanical properties and is widely used in synthetic fibers, biaxially stretched films and polyesters. In recent years, it has also shown broad application prospects in the field of foam materials. PET polyester foam has the advantages of light weight, high specific strength, high rigidity, good electrical insulation and heat and sound insulation. It can be used in food packaging, building materials, wire insulation, microwave containers, refrigerator inner panels, sports equipment, Automotive, aerospace and other fields. At present, the total output of PET polyester in my country i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L67/02C08K5/1539C08K5/3492C08K5/526C08K5/134C08K5/5399B29C47/92C08G81/00B29C48/92

Inventor 刘涛袁海涛赵玲

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com