Preparing method for producing flame-retardant polyester fibers through recycled polyester bottle flakes

A technology of flame-retardant polyester and polyester bottle flakes, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, and conjugated synthetic polymer rayon, etc. It can solve the problems that the flame-retardant polyester fiber cannot be manufactured and achieve good flame retardancy The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

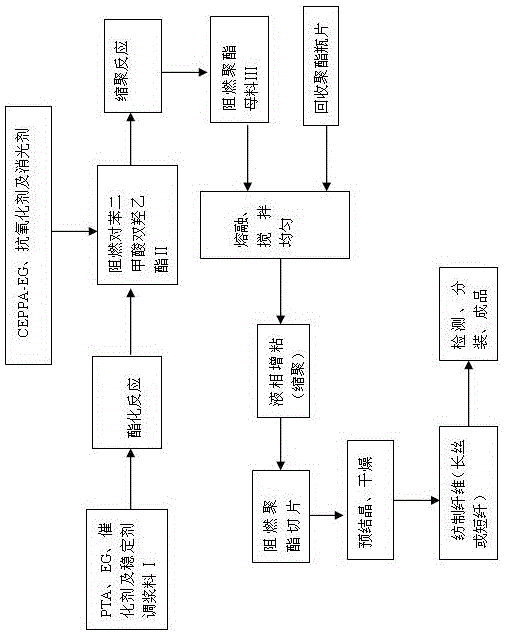

[0007] Embodiment 1: with reference to attached figure 1 . A preparation method for producing flame-retardant polyester fibers by using recycled polyester bottle flakes, the parts by mass are: (1) Preparation of flame-retardant polyester masterbatch: 28-32 parts by mass of ethylene glycol, 68-72 parts by mass of refined Add phthalic acid, 80-300ppm antimony-based catalyst and 100-500ppm stabilizer into the beating kettle and stir for 30-60min to prepare slurry I; import slurry I into the esterification kettle, heat up to 245-260°C for 120- 200min, add 15000~30000ppm flame retardant additives, 0~1.2 parts by mass of matting agent and 200~500ppm antioxidant and continue esterification reaction for 30-60min to obtain flame retardant bishydroxyethyl terephthalate II; flame retardant Bishydroxyethyl terephthalate II is introduced into the polycondensation kettle, the temperature is raised to 265-270°C, the vacuum degree is controlled at 1200-1800Pa, and the pre-condensation is car...

Embodiment 2

[0014] Example 2: On the basis of Example 1, during the melt mixing and polycondensation process, directly add recycled bottle flakes and flame-retardant polyester masterbatch, and slowly heat up to 250-265°C under a vacuum degree of 500-1000Pa to make the material Melt, stir and mix evenly, no need to add ethylene glycol for alcoholysis and polycondensation.

Embodiment 3

[0015] Example 3: On the basis of Example 1, the recycled bottle flakes and the flame-retardant polyester masterbatch are melted by heating and fully stirred, and the flame-retardant polyester chip IV contains the flame retardant 2-carboxyethylphenylphosphine Diethylene glycol diethylene glycol ester (CEPPA-EG) has a uniform distribution of polyester segments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com