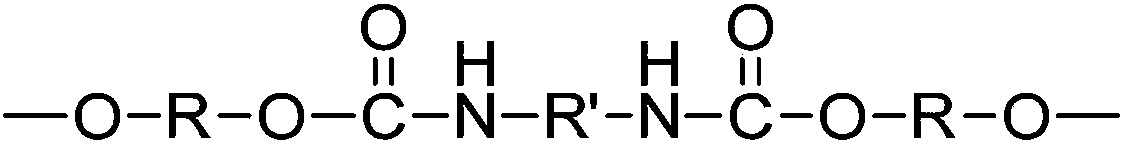

Novel polyether ester elastomer and preparation method thereof

A polyetherester elastomer and trimer technology, which is applied in the field of elastomer materials, can solve the problems that the resilience performance needs to be improved, the mechanical strength of the elastomer is adversely affected, the reaction time of the polyetherester elastomer is long, and the like, and the preparation is improved. The effect of long time, strong hydrolysis stability and better comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

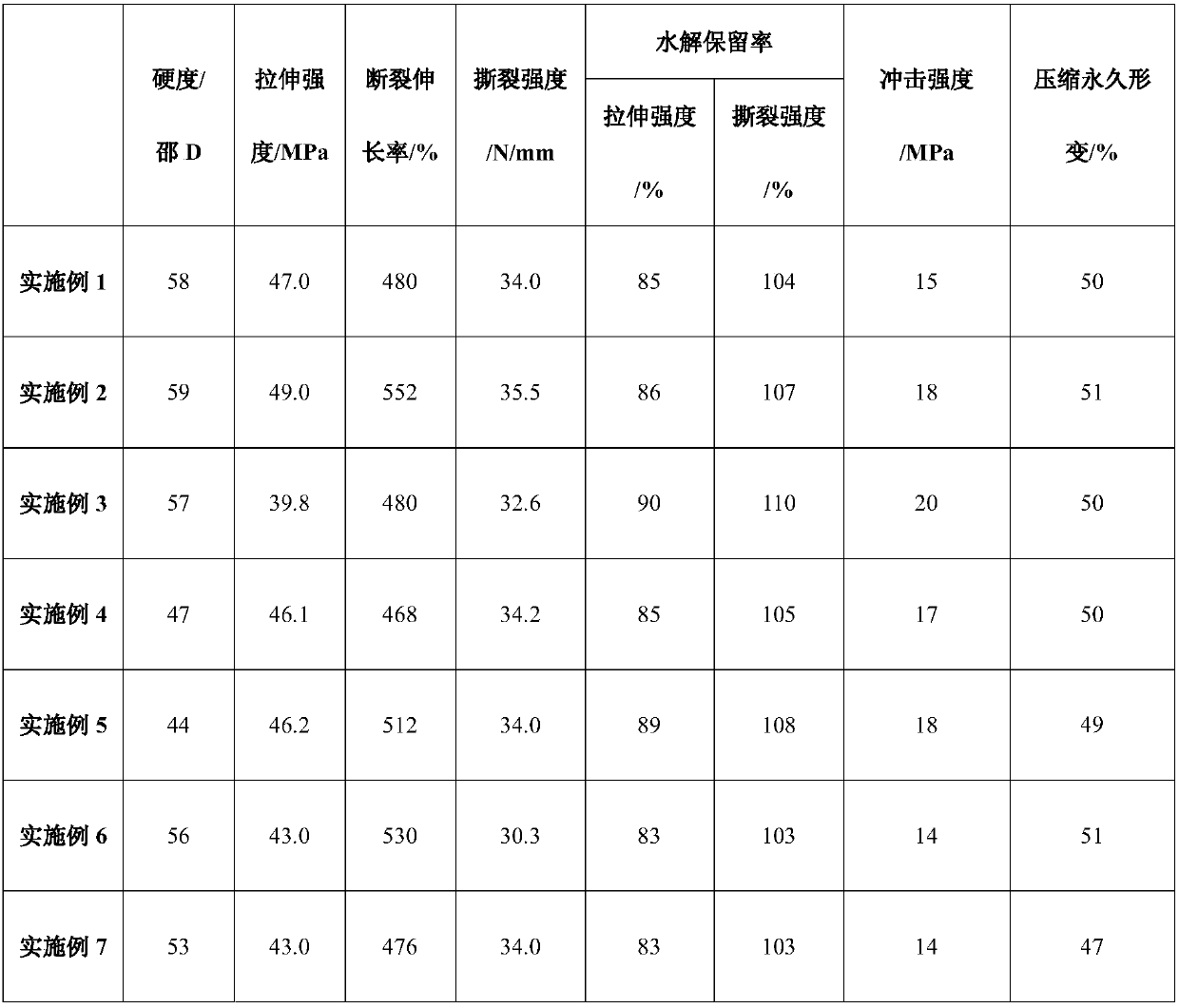

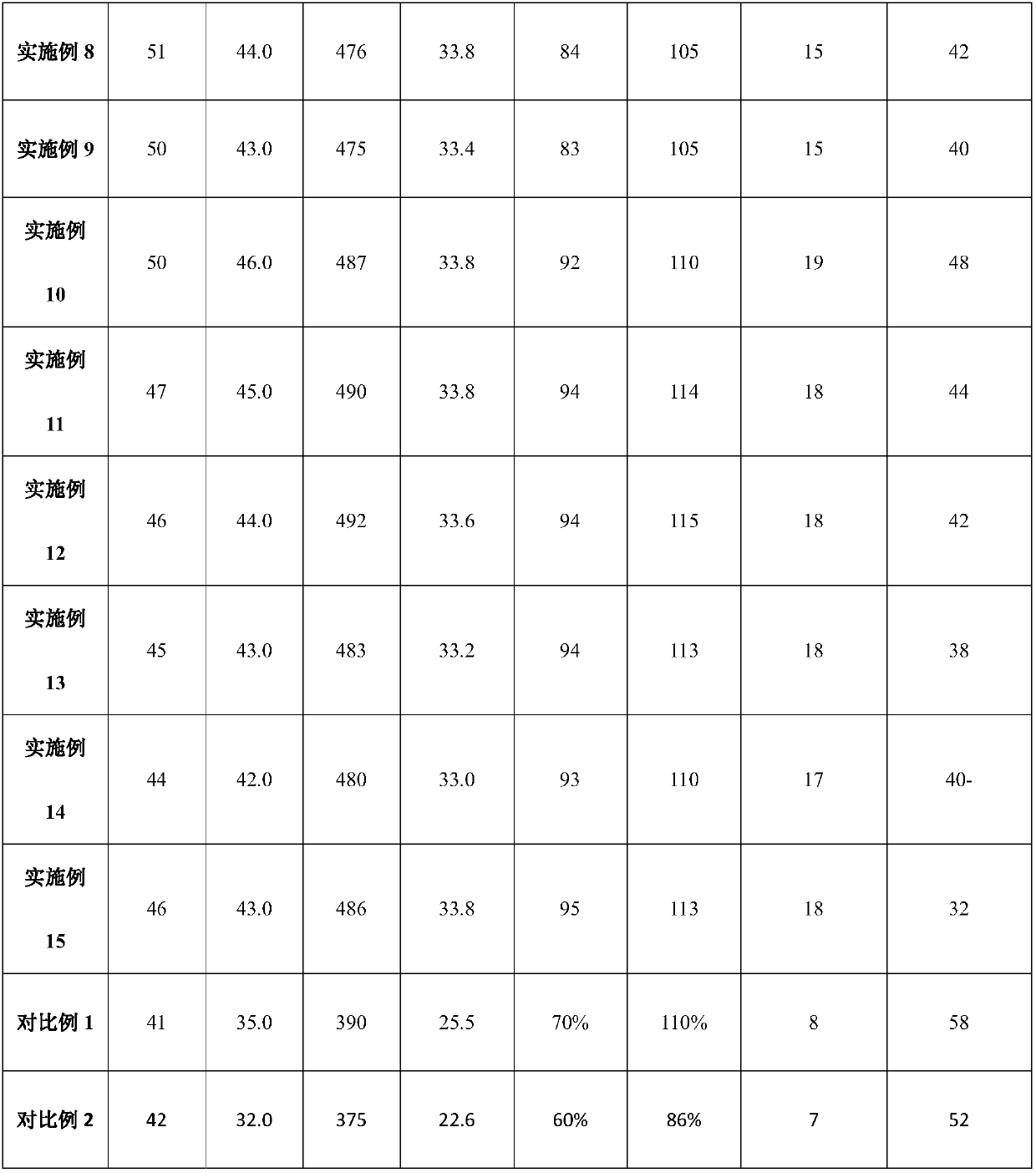

Examples

Embodiment 1

[0040] Preparation of polyester polyol: Mix 830g of terephthalic acid (PTA), 1080g of butanediol (BDO) and 1.0g of tetrabutyl titanate catalyst and vacuum dehydrate, control the system temperature at 180°C for prepolymerization, and react for 3 hours , raise the temperature to 220°C and lower the pressure slowly to 6KPa, keep the temperature for 2 hours to obtain a polyester polyol with a number average molecular weight of 1000 and an acid value of 0.5mgKOH / g, cool down to about 100°C for use.

[0041] Preparation of polyether ester elastomer (the isocyanate index NCO / OH in the formula system is 1): the above-mentioned polyester polyol of 200g, 200g (M n =1000) polytetrahydrofuran (PTMG) and 100 g of diphenylmethane diisocyanate (MDI) were added into a twin-screw extruder to react and pelletize at 180° C. for 30 minutes.

Embodiment 2

[0043] Preparation of polyester polyol: 830g of terephthalic acid, 900g of butanediol and 1.0g of tetrabutyl titanate catalyst were mixed and vacuum dehydrated, and the temperature of the system was controlled at 180°C for prepolymerization. After 3 hours of reaction, the temperature was raised to 220°C and Slowly lower the pressure to 6KPa, keep it warm for 2 hours to obtain a polyester polyol with a number average molecular weight of 2000, and an acid value of 0.3 mgKOH / g, and lower the temperature to about 100°C for use.

[0044] Preparation of polyether ester elastomer (the isocyanate index NCO / OH in the formula system is 1.03): the above-mentioned polyester polyol of 400g, 400g (M n =2000) polytetrahydrofuran and 103 g of diphenylmethane diisocyanate were added into a twin-screw extruder to react and pelletize at 180° C. for 30 minutes.

Embodiment 3

[0046] Preparation of polyester polyol: 830g of terephthalic acid, 900g of butanediol and 1.0g of tetrabutyl titanate catalyst were mixed and vacuum dehydrated, and the temperature of the system was controlled at 180°C for prepolymerization. After 3 hours of reaction, the temperature was raised to 220°C and Slowly lower the pressure to 6KPa, keep it warm for 2 hours to obtain a polyester polyol with a number average molecular weight of 2000, and an acid value of 0.3 mgKOH / g, and lower the temperature to about 100°C for use.

[0047] Preparation of polyether ester elastomer (the isocyanate index NCO / OH in the formula system is 1.08): the above-mentioned polyester polyol of 400g, 200g (M n =1000) polytetrahydrofuran and 216g of diphenylmethane diisocyanate were added to the reactor and reacted at 180°C. The reaction time was 50 minutes, and granulation was carried out after the reaction was completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com