Method for synthesizing biodegradable aliphatic-aromatic copolyester

A technology for degrading fats and aromatics, applied in the field of polyester, can solve the problems of poor hydrolysis resistance, lower thermal stability, and inability to add and mix chain extenders conveniently, so as to reduce side reactions and reduce product terminal carboxyl groups value, to solve the effect of increasing the b value of resin color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1) 23kg / h of terephthalic acid and 28kg / h of 1,4-butanediol are continuously added to the beating kettle and mixed, and the mixed slurry is continuously sent into the esterification reaction kettle, and In addition, 12kg / h of 1,4-butanediol and 0.015kg / h of tetrabutyl titanate (TBOT) were added, the pressure of the control reactor was -10KPa, the temperature was 220°C, and the residence time was 2 hours. The water generated by the reaction, Tetrahydrofuran and butanediol were distilled off, and the obtained esterified product A was continuously removed from the reactor. The carboxyl-terminal content of the esterified product A was 180 mol / t.

[0059] 2) 22kg / h of adipic acid and 25kg / h of 1,4-butanediol are continuously added to the beating tank and mixed, and the mixed slurry is continuously sent into the esterification reactor, and additionally Add 10kg / h of 1,4-butanediol and 0.001kg / h of tetrabutyl titanate (TBOT), the temperature is 200°C, the residence time is 2 h...

Embodiment 2

[0062] 25kg / h of terephthalic acid, 23kg / h of adipic acid and 36kg / h of 1,4-butanediol are continuously added to the beating kettle for mixing, and then the mixed slurry is continuously sent to the In the esterification reaction kettle. Another way continuously feeds 7kg / h of 1,4-butanediol and 0.02kg / h of tetrabutyl titanate (TBOT) into the esterification reactor, and esterifies at a temperature of 220°C and a pressure of -20KPa. Time 2h, water, tetrahydrofuran and butanediol were distilled off. The carboxyl-terminal content of the obtained esterified product was 120 mol / t.

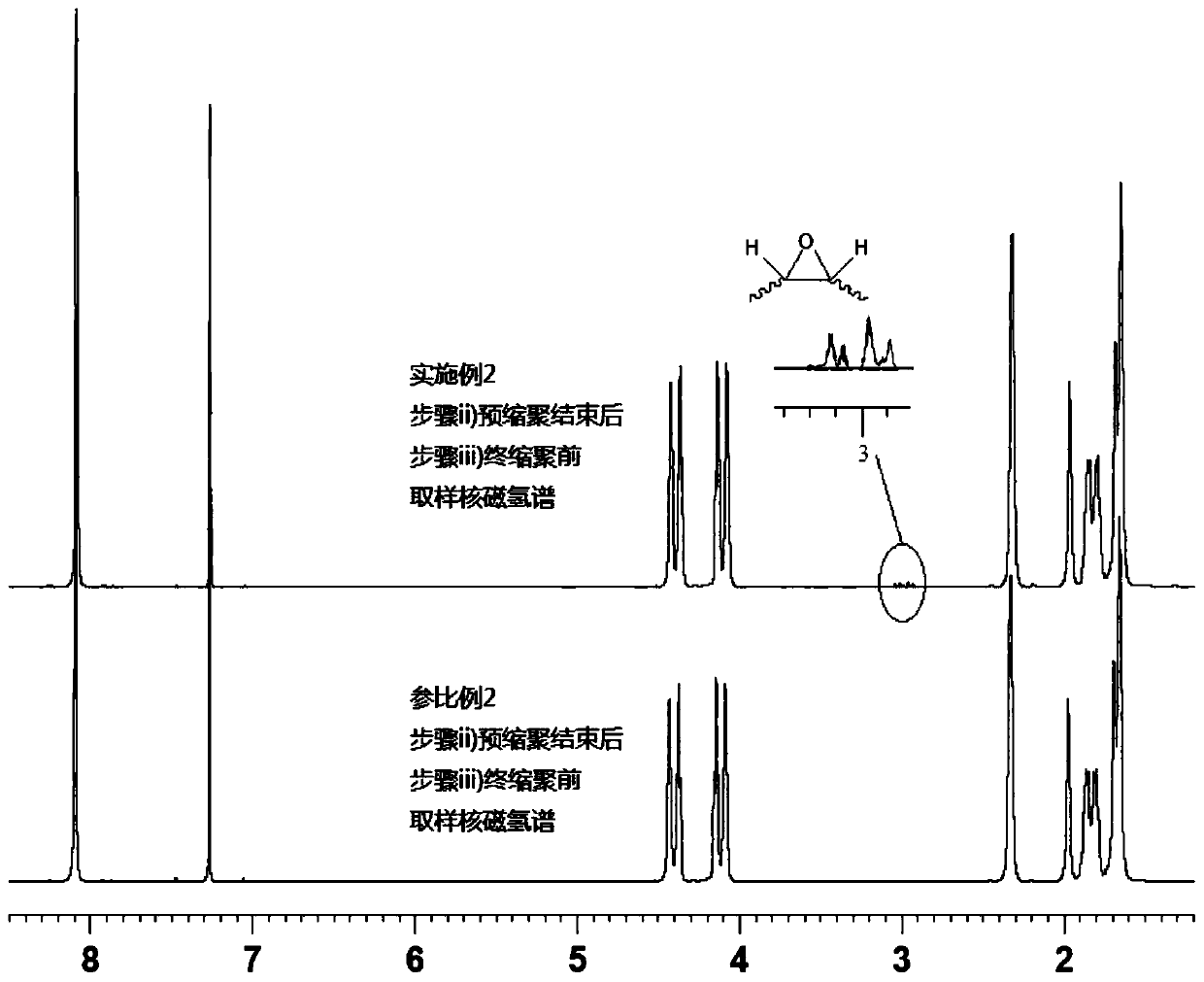

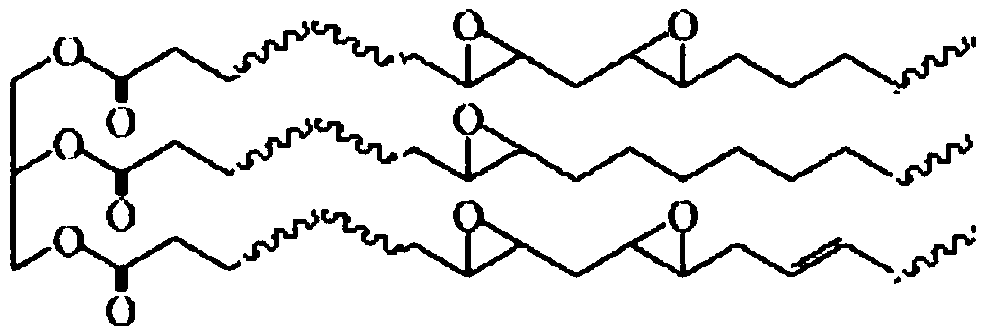

[0063]Then continuously enter into two precondensation reactors connected in series, add tetrabutyl titanate 0.02kg / h simultaneously, add epoxy soybean oil (epoxy value 6.0%) 2.4kg / h simultaneously, material temperature is by 210 ℃, The pressure of the reactor was reduced from 20KPa to 200Pa, the residence time was 2h, the excess butanediol was distilled off, and the intrinsic viscosity of the obtained...

Embodiment 3

[0066] 25kg / h of terephthalic acid, 23kg / h of adipic acid and 36kg / h of 1,4-butanediol are continuously added to the beating kettle for mixing, and then the mixed slurry is continuously sent to the In the esterification reaction kettle. Another way continuously feeds 7kg / h of 1,4-butanediol and 0.02kg / h of tetrabutyl titanate (TBOT) into the esterification reactor, and esterifies at a temperature of 220°C and a pressure of -20KPa. Time 2h, water, tetrahydrofuran and butanediol were distilled off. The carboxyl-terminal content of the obtained esterified product was 120 mol / t.

[0067] Then continuously enter into two precondensation reactors connected in series, add tetrabutyl titanate 0.02kg / h simultaneously, add epoxy soybean oil (epoxy value 6.0%) 0.24kg / h simultaneously, material temperature is by 200 ℃, The pressure of the reactor was reduced from 20KPa to 200Pa, the residence time was 2.5h, the excess butanediol was evaporated, and the intrinsic viscosity of the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

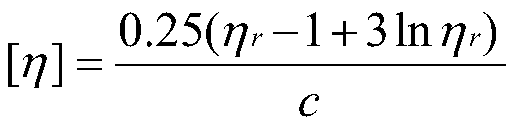

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com