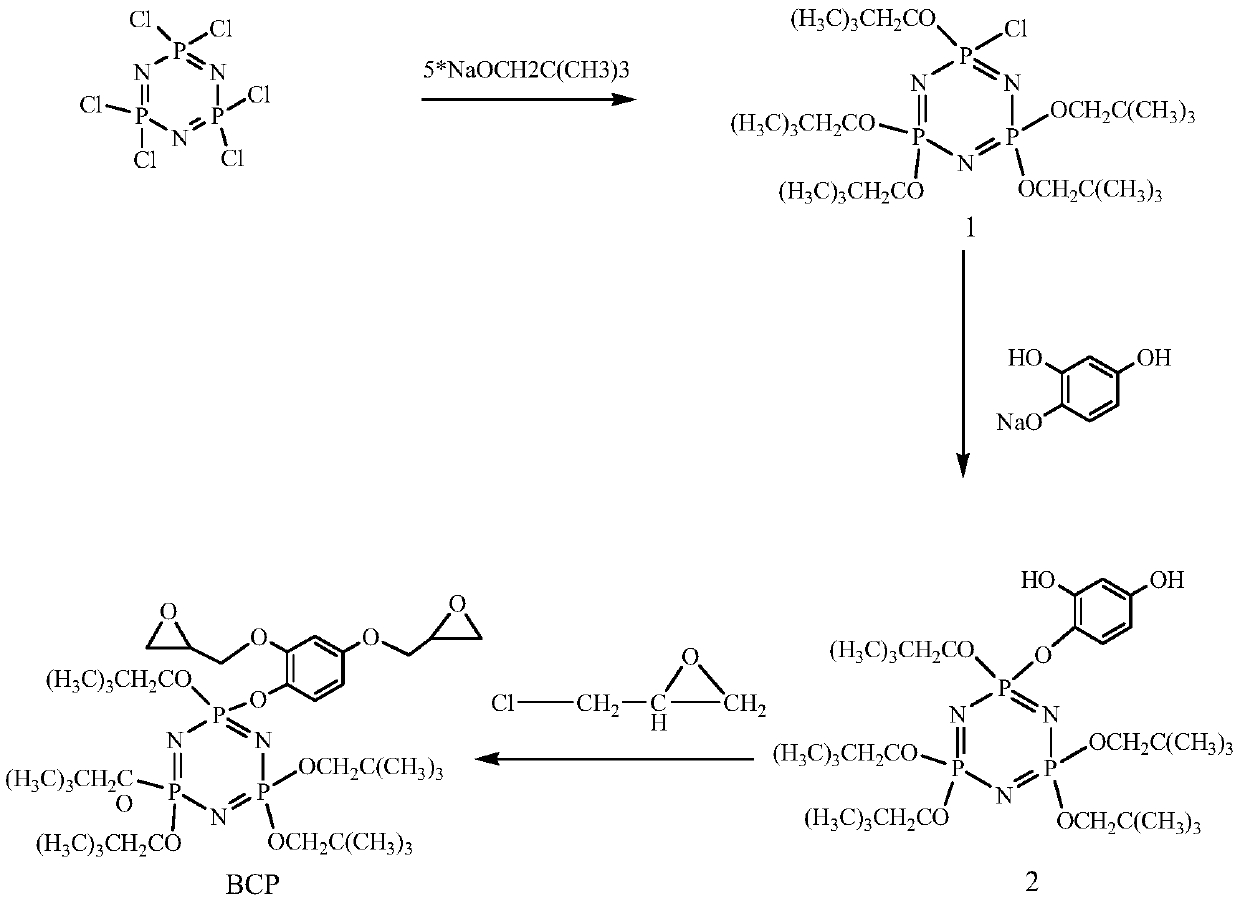

Phosphorus-containing flame-retardant PTT as well as preparation method and application thereof

A flame retardant, alcohol ring triphosphazene technology, which is applied in the field of phosphorus-containing flame retardant PTT and its preparation, can solve the problems such as the viscosity not meeting the requirements, the color of polyester chip fibers being deteriorated, and the color difference of the samples, etc. The effect of reducing the degree of thermal degradation, shortening the polymerization time, and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

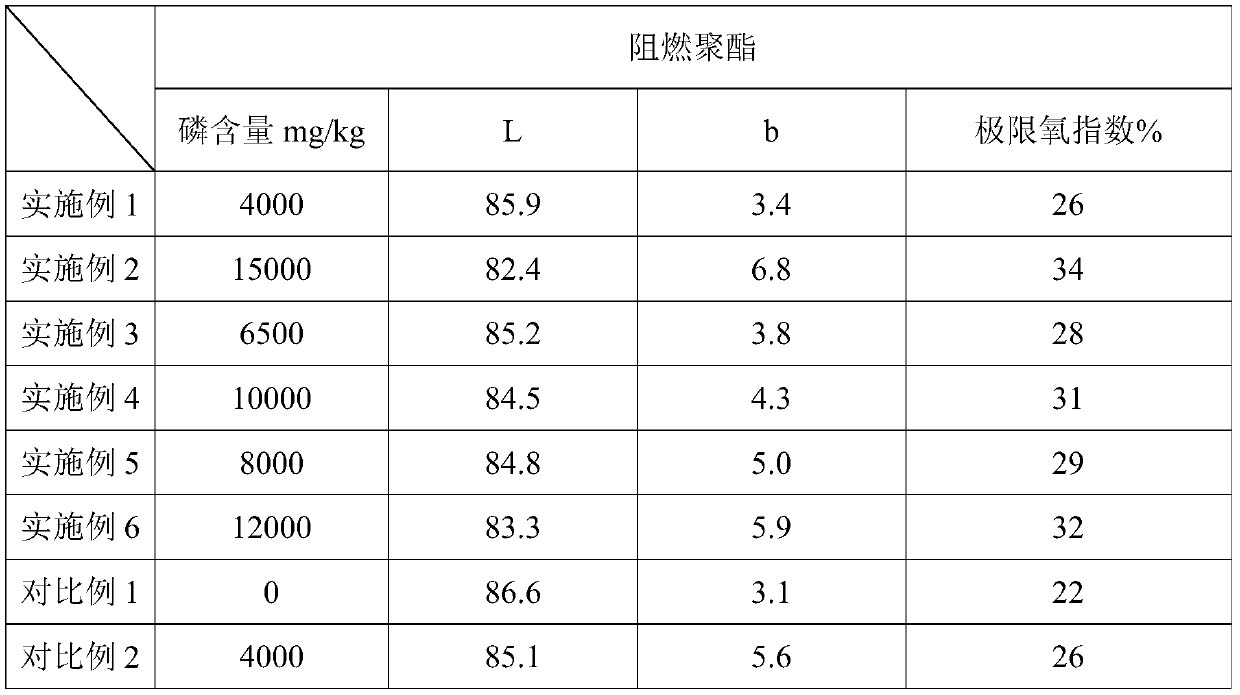

Embodiment 1

[0032] Add purified terephthalic acid and propylene glycol into the batch reactor at a molar ratio of 1:1.6, and add sodium acetate anti-ether agent at the same time. The amount of anti-ether agent added is based on the content of the final polyester. According to the anti-ether agent content in the polyester is 10mg / kg, add sodium acetate to carry out esterification reaction, control the esterification temperature at 230°C-250°C, and the esterification pressure at 0.1MPa-0.4MPa, when the esterification rate reaches 92%. To release the pressure, add the compound flame retardant of the flame retardant di(propylene glycol) methyl phosphate and BCP in a mass ratio of 10:90 and the catalyst tetrabutyl titanate, and the amount of the flame retardant is based on the phosphorus content in the polyester The amount of tetrabutyl titanate added is 50 mg / kg when the titanium content in the final polyester is added, the polycondensation temperature is controlled to be 250°C-270°C, and the ...

Embodiment 2

[0035]Add purified terephthalic acid and propylene glycol into the batch reactor in a molar ratio of 1:1.1, and add lithium acetate anti-ether agent at the same time. The amount of anti-ether agent added is based on the content in the final polyester. According to the anti-ether agent content in the polyester is 10mg / kg, add lithium acetate to carry out esterification reaction, control the esterification temperature at 230°C-250°C, and the esterification pressure at 0.1MPa-0.4MPa, when the esterification rate reaches 85%. Carry out pressure relief, add flame retardant propyl phosphate di(propylene glycol) ester and BCP and be the composite flame retardant of 30:70 by mass ratio and catalyzer potassium fluorotitanate, the addition amount of flame retardant is according to the phosphorus content in polyester 15000mg / kg was added, and the amount of potassium fluorotitanate added was based on the titanium content in the final polyester being 300mg / kg. The polycondensation temperatu...

Embodiment 3

[0038] Add purified terephthalic acid and propylene glycol into the batch reactor with a molar ratio of 1:2.0, and at the same time add magnesium acetate anti-ether agent. The amount of anti-ether agent added is based on the content in the final polyester. According to the anti-ether agent content in the polyester is 50mg / kg, add magnesium acetate to carry out esterification reaction, control the esterification temperature at 230°C-250°C, and the esterification pressure at 0.1MPa-0.4MPa, when the esterification rate reaches 99%. To release the pressure, add flame retardant phenyl phosphate di(propylene glycol) ester and BCP compound flame retardant with a mass ratio of 50:50 and catalyst tetraisopropyl titanate. The content is 6500mg / kg to add, and the amount of tetraisopropyl titanate added is based on the titanium content in the final polyester is 150mg / kg, and the polycondensation temperature is controlled to be 250°C-270°C, and the vacuum is ≤80Pa. The discharge time is ju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com