Polycondensation catalyst for polyester synthesis as well as preparation method and application of polycondensation catalyst

The technology of a polycondensation catalyst and a synthesis method, applied in the field of materials, can solve the problems of insufficient heat and humidity resistance to meet demand, antimony heavy metal pollution, unfavorable recycling of waste polyester, etc., and achieve the effects of imparting antistatic properties, increasing crystallization rate, and shortening polycondensation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Specifically, as an aspect of the technical solution of the present invention, what it relates to is a kind of preparation method for the polycondensation catalyst of polyester synthesis, and it comprises:

[0046] Provide Ti 3 C 2 T x Mxene material;

[0047] the Ti 3 C 2 T x Mxene materials are homogeneously blended with benzoxazine monomers to obtain blends,

[0048] The blend is heated for curing to obtain Ti 3 C 2 T x MXene / benzoxazine resin composites;

[0049] laser on the Ti 3 C 2 T x MXene / benzoxazine resin composites were irradiated to prepare titanium-supported laser-induced graphene composites, which are polycondensation catalysts for polyester synthesis.

[0050] In some embodiments, the preparation method comprises: adopting strong acid to Ti x al y C z MAX phase material is chemically etched to produce Ti 3 C 2 T x Mxene material.

[0051] In some embodiments, the preparation method comprises: the Ti 3 C 2 T x Mxene materials...

Embodiment 1

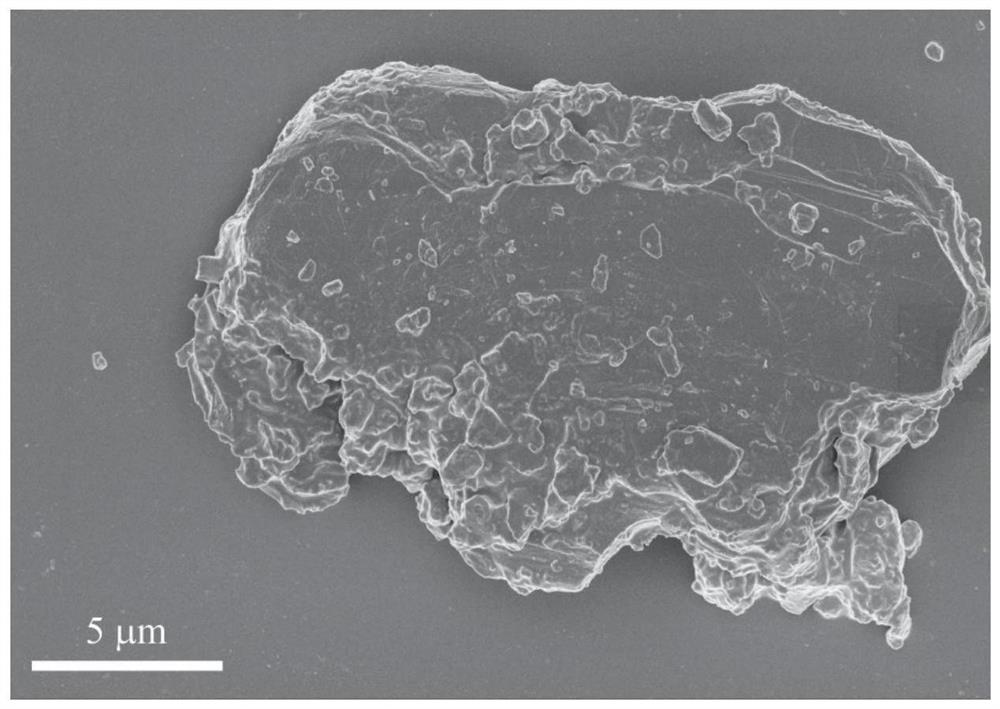

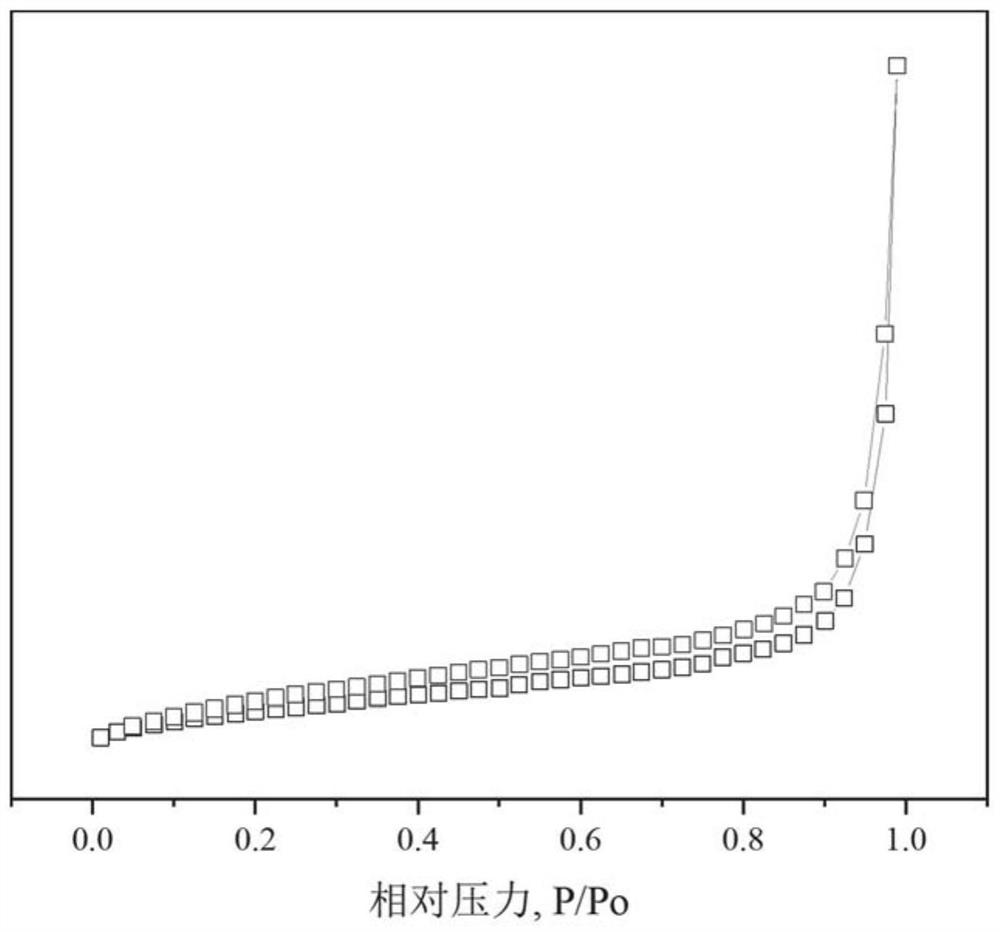

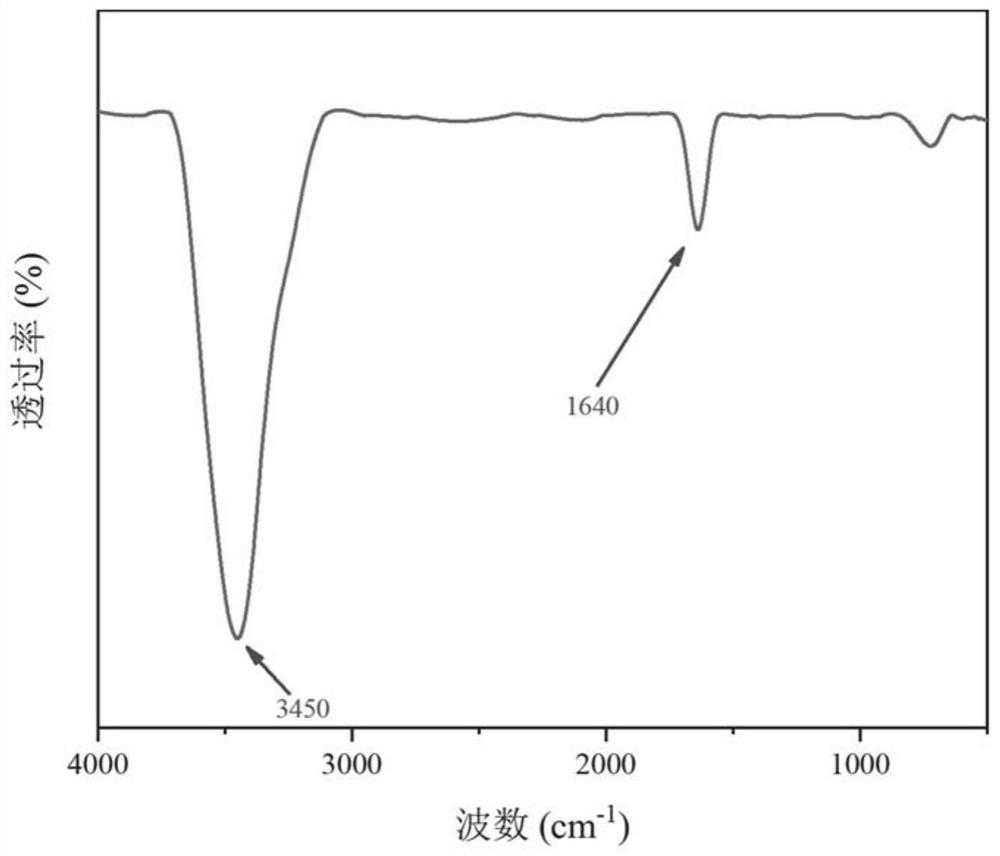

[0095] (1) Put Ti 3 AlC 2 The MAX phase powder was added to the 10% HF solution at a mass ratio of 1:10, stirred for 24 hours, the bottom sediment was collected by centrifugation, and dried in vacuum to obtain Ti 3 C 2 T x Mxene powder. Ti 3 C 2 T x Mxene and benzoxazine monomers (the monomer structure is shown in the figure below) were weighed at a mass ratio of 2:25, blended, heated to 120°C to make the two evenly mixed, and then heated to 150°C, and at this temperature Cured for 6 hours to obtain Ti 3 C 2 T x MXene / poly(PBz) composites;

[0096]

[0097] (2) Use a CW laser with a wavelength of 10.6 microns to Ti 3 C 2 T x The MXene / poly(PBz) composite was irradiated with laser, and the size of the laser irradiated area was set to 20mm×10mm. Under the photothermal action of the laser, Ti 3 C 2 T x The MXene / poly(PBz) composite was directly converted into a titanium-supported LIG polycondensation catalyst with a laser power of 3 W and a laser speed of...

Embodiment 2

[0101] (1) Put Ti 3 AlC 2 The MAX phase powder was added to the 10% HF solution at a mass ratio of 1:10, stirred for 24 hours, the bottom sediment was collected by centrifugation, and dried in vacuum to obtain Ti 3 C 2 T x Mxene powder. Ti 3 C 2 T x Mxene and benzoxazine monomers (monomer structure shown in the figure below) were weighed at a mass ratio of 4:25, blended, heated to 120°C to make the two evenly mixed, and then heated to 150°C, and at this temperature Cured for 6 hours to obtain Ti 3 C 2 T x MXene / poly(PBz) composites;

[0102]

[0103] (2) Using CO with a wavelength of 10.6 microns 2 Laser on Ti 3 C 2 T x MXene / poly(PBz) composites were irradiated with laser, and Ti 3 C 2 T xThe MXene / poly(PBz) composite was directly transformed into a titanium-supported LIG polycondensation catalyst with a laser power of 50 W and a laser speed of 1.27 m / s.

[0104] (3) Add dimethyl furandicarboxylate, glycerol and anhydrous zinc acetate into the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com