Catalyst system for synthesizing aliphatic-aromatic copolyester and application of catalyst system

A catalyst and aromatic technology, used in the field of catalysts for polyester synthesis, can solve the problems of yellowish hue and high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

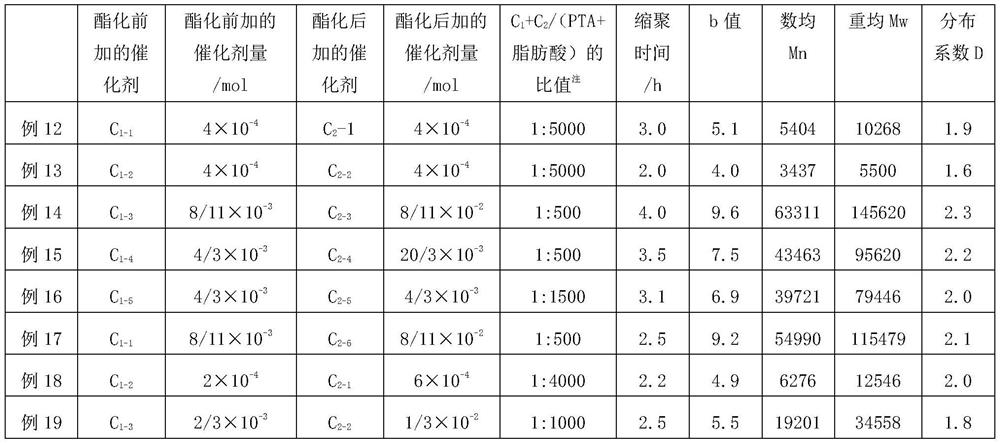

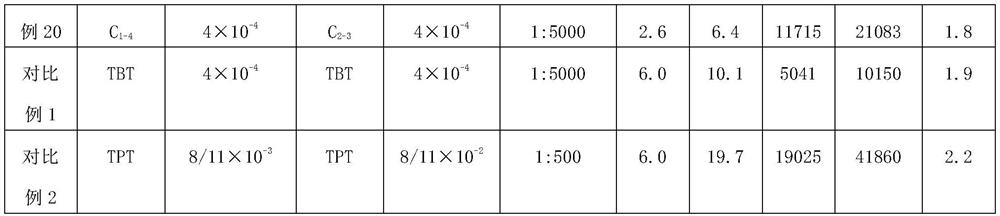

Examples

Embodiment 1- example 5

[0033] The preparation of embodiment 1-example 5 titanium series composition

example 1

[0035] The molar ratio of titanium compound to hydroxycarboxylic acid is 1:5, the molar ratio of titanium compound to phosphoric acid ester is 1:10, and the molar ratio of titanium compound to 1,4-butanediol is 1:40.

[0036] First weigh 34g (0.2mol) of tetramethyl titanate, 211g (1mol) of citric acid, 280g (2mol) of trimethyl phosphate and 720g (8mol) of 1,4-butanediol and place them in a reactor with a reflux device , stirred and reacted at 50°C for 2 hours, distilled off the small molecules to form an intermediate solution, and cooled to room temperature to prepare the catalyst titanium-based composition C 1-1 .

example 2

[0038] The molar ratio of titanium compound to hydroxycarboxylic acid is 1:0.5, the molar ratio of titanium compound to phosphoric acid ester is 1:0.5, and the molar ratio of titanium compound to 1,4-butanediol is 1:2.

[0039] First weigh 46g (0.2mol) of tetraethyl titanate, 21g (0.1mol) of citric acid, 18g (0.1mol) of triethyl phosphate and 36g (0.4mol) of 1,4-butanediol and place them in a In the reactor, stir and react at 160°C for 1 hour, distill off small molecules to form an intermediate solution, and prepare the catalyst titanium-based composition C after cooling to room temperature 1-2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com