Method for producing seedling breeding container from fibrous solid wastes

A seedling container and solid waste technology, applied in the direction of fiber raw materials, fiber raw material treatment, application, etc., can solve the problems of poor molding effect of seedling container, poor molding effect of seedling pot, poor material treatment effect, etc., to achieve sustainable recycling , Reduce material consumption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

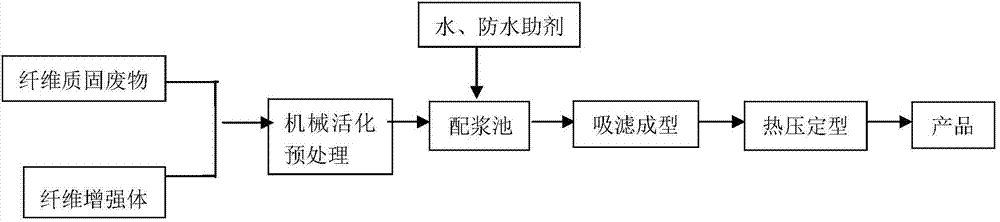

Method used

Image

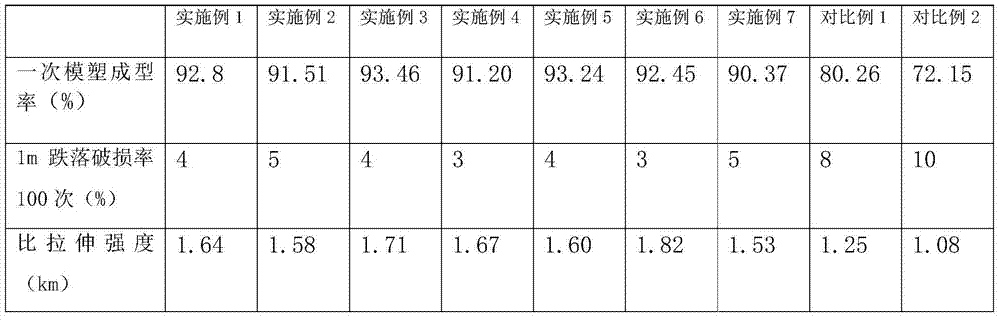

Examples

Embodiment 1

[0046] A method for preparing a seedling raising container by utilizing fibrous solid waste, the following steps are performed in sequence:

[0047] (1) Grinding raw materials:

[0048] Select 10kg cassava wine tank to dry in the sun to make the water content 13%, crush the cassava wine tank to 60 mesh, and then mix it with 0.5kg bagasse bleached pulp to obtain a mixed material.

[0049] (2) Mechanical activation pretreatment:

[0050] Add the above-mentioned mixed material and grinding medium bulk volume into the stirring ball mill according to the ratio of 100g:200mL, adjust the rotating speed to 200rpm and pass in room temperature water to cool down, after reaching the activation time of 15min, stop stirring, take out the raw material and grinding balls, and mix them Separation to obtain modified fibers.

[0051] (3) Mixing slurry:

[0052] Transport the above-mentioned modified fiber to the pulp mixing tank, add the alkyl ketene polymer waterproofing additive with a mas...

Embodiment 2

[0058] A method for preparing a seedling raising container by utilizing fibrous solid waste, the following steps are performed in sequence:

[0059] (1) Grinding raw materials:

[0060] Select 10kg of bagasse to dry in the sun to make the water content 10%, crush the cassava wine tank to 80 mesh, and then mix it with 1.5kg of wood fiber bleached pulp to obtain a mixed material.

[0061] (2) Mechanical activation pretreatment:

[0062] Add the above-mentioned mixed material and grinding medium bulk volume into the stirring ball mill according to the ratio of 100g: 250mL, adjust the rotating speed to 250rpm and pass in room temperature water to cool down. After reaching the activation time of 12min, stop stirring, take out the raw material and grinding balls, and mix them Separation to obtain modified fibers.

[0063] (3) Mixing slurry:

[0064] The above-mentioned modified fiber is transported to the pulp mixing tank, and the acrylic polymer waterproofing agent with a mass r...

Embodiment 3

[0070] A method for preparing a seedling raising container by utilizing fibrous solid waste, the following steps are performed in sequence:

[0071] (1) Grinding raw materials:

[0072] Choose 10kg cassava wine tank and sisal residue mixture to dry in the sun to make the water content 12%, crush the cassava wine tank to 60 mesh, then mix with 1.0kg wood fiber bleached pulp and bagasse bleached pulp mixture to obtain a mixed material.

[0073] (2) Mechanical activation pretreatment:

[0074] Add the above-mentioned mixed material and grinding medium bulk volume into the stirring ball mill according to the ratio of 100g:280mL, adjust the rotating speed to 300rpm and pass in room temperature water to cool down, after reaching the activation time of 12min, stop stirring, take out the raw materials and grinding balls, and mix them Separation to obtain modified fibers.

[0075] (3) Mixing slurry:

[0076] The above-mentioned modified fiber is transported to the pulp mixing tank, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com