Aliphatic polyester complexes and method of preparing the same

A technology of aliphatic polyester and aliphatic copolyester, which is applied in the field of degradable polymer materials, can solve the problems of local overheating and side reaction control, product quality stability control, and interface renewal difficulties, etc., to achieve performance Flexible and convenient adjustment, low cost, good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

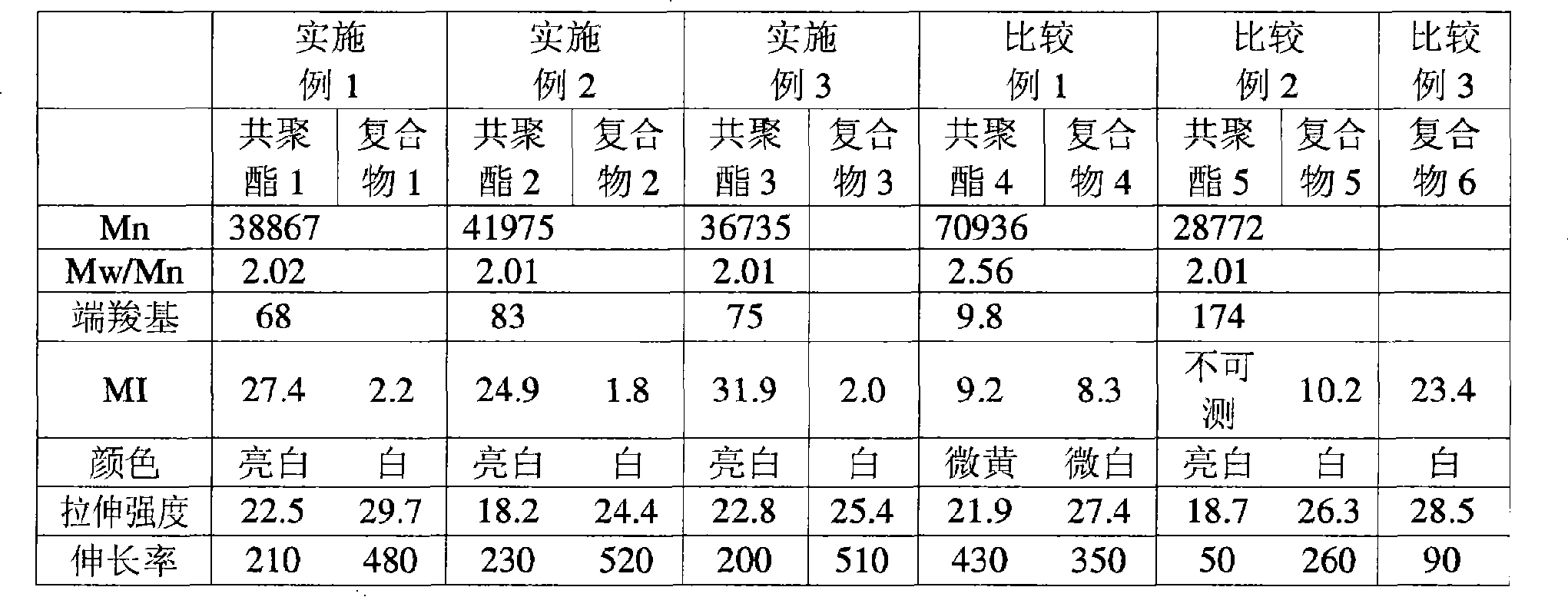

Examples

Embodiment 1

[0032] (1) Preparation of aliphatic copolyester

[0033] Add 20,600g of succinic acid, 25,000g of butanediol, and 7,100g of adipic acid in a reaction kettle with a volume of 100L, and heat up while stirring until the esterification effluent is complete, then add the catalyst Ti(OBu) 4 30g, vacuumize, continue to heat up to 230°C, maintain a vacuum of 20Pa at a constant temperature of 230°C for 2 hours, add nitrogen to supplement pressure, discharge and pelletize to obtain copolyester 1. Test molecular weight and molecular weight distribution, terminal carboxyl group, melt index.

[0034] (2) Preparation of Aliphatic Copolyester Compounds

[0035] Copolyester 1 and polylactic acid (trade name NatureWorks 3001D) obtained above were vacuum-dried at 60° C. for 12 hours for later use. Dried copolyester 1, polylactic acid and 1,4-bis-(2-oxazoline base) benzene are extruded in a double exhaust reaction twin-screw extruder with a length-to-length ratio of 42 in a ratio of 70 / 30 / 0.1...

Embodiment 2

[0037] (1) Preparation of aliphatic copolyester

[0038] Add 18,500g of succinic acid, 25,000g of butanediol, and 8,800g of adipic acid in a reaction kettle with a volume of 100L, and heat up while stirring until the esterification effluent is complete, then add the catalyst Ti(OBu) 4 30g, vacuumize, continue to heat up to 230°C, maintain a vacuum of 20Pa at a constant temperature of 230°C for 2 hours, add nitrogen to supplement pressure, discharge and pelletize to obtain copolyester 2. Test molecular weight and molecular weight distribution, terminal carboxyl group, melt index.

[0039] (2) Preparation of Aliphatic Copolyester Compounds

[0040] Copolyester 2 and polylactic acid (trade name NatureWorks 3001D) obtained above were vacuum-dried at 60° C. for 12 hours for later use. The copolyester 2 after drying, polylactic acid and 2,2'-bis-(2-oxazoline) are extruded by twin-screw extruders with double venting reactions with a length-to-length ratio of 42 in the ratio of 70 / ...

Embodiment 3

[0042] (1) Preparation of aliphatic copolyester

[0043] After nitrogen replacement in a reaction kettle with a volume of 100L, 25100g of dimethyl succinate, 25000g of butanediol, and 8400g of dimethyl adipate were added, and the temperature was raised while stirring until the alcohol was completely transesterified, and the catalyst Ti(OBu ) 4 30g, vacuumize, continue to heat up to 230°C, maintain a vacuum of 20Pa at 230°C for 2 hours, add nitrogen to supplement pressure, discharge and pelletize to obtain copolyester 3. Test molecular weight and molecular weight distribution, terminal carboxyl group, melt index.

[0044] (2) Preparation of Aliphatic Copolyester Compounds

[0045] Copolyester 3 and polylactic acid (trade name NatureWorks 3001D) obtained above were vacuum-dried at 60° C. for 12 hours for later use. Copolyester 3 after drying, polylactic acid and 1,4-bis-(2-oxazoline base) benzene are extruded in a double exhaust reaction twin-screw extruder with a length-to-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com