Method for preparing polyethylene glycol terephthalate by adopting anchoring agent

A technology of polyethylene terephthalate and tackifier, applied in the field of preparing polyethylene terephthalate with tackifier, can solve the problems of high energy consumption, achieve short polycondensation time, solve High energy consumption problem, good transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

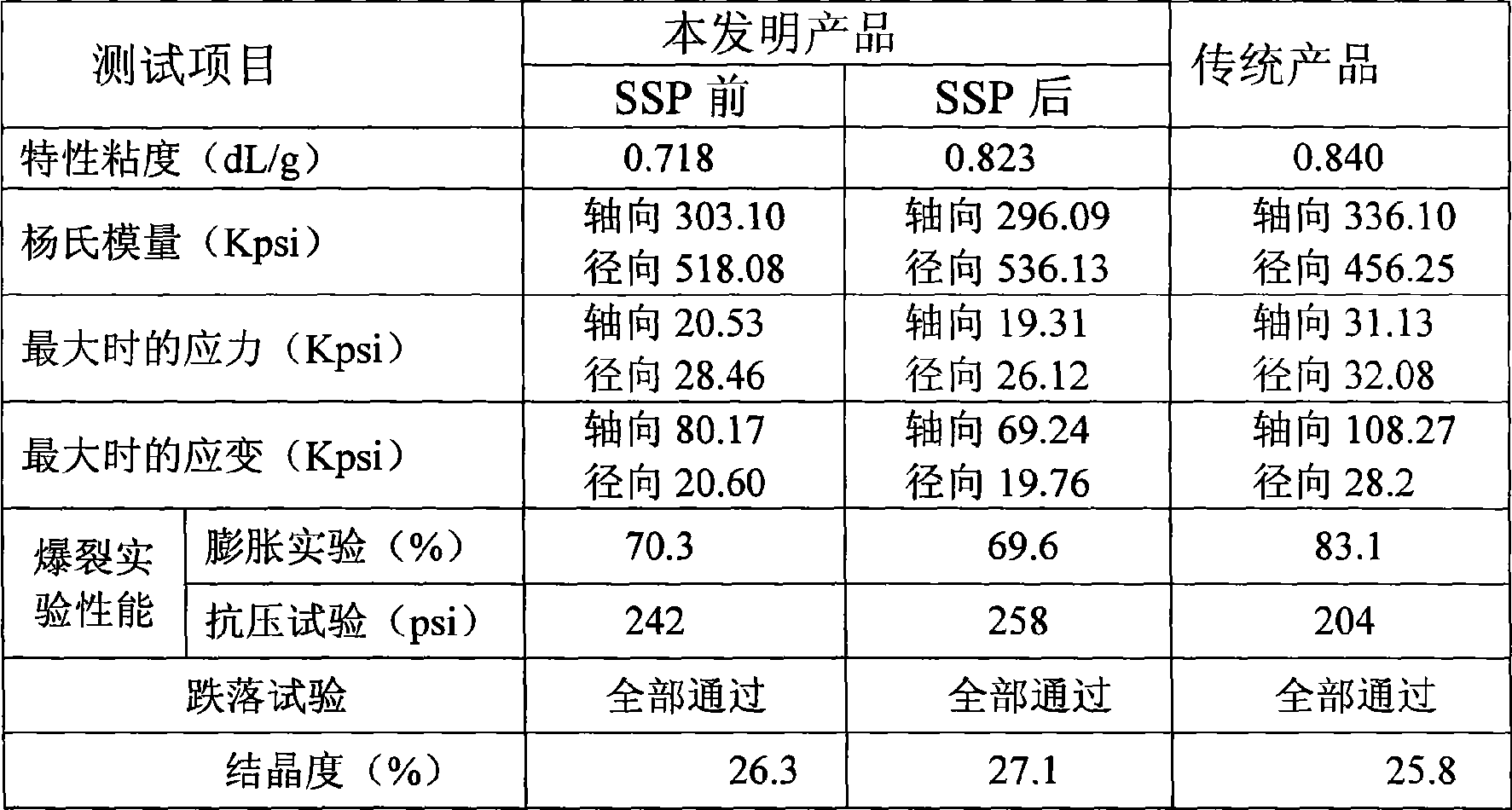

Image

Examples

Embodiment Construction

[0019] Described adopt tackifier to prepare the method for polyethylene terephthalate as follows:

[0020] Using terephthalic acid and ethylene glycol as basic raw materials, prepare a slurry in a molar ratio of 1:1 to 2.5. After stirring evenly, add the slurry into the reaction kettle through a slurry pump for esterification reaction. The time is 0.5-6 hours, the temperature is 250-280°C, and the oligomer is generated; the oligomer after the esterification reaction is injected into the pre-condensation reactor through the oligomer pipeline through the pump, and the oligomer on the oligomer pipeline Additives should be added at the same time with a metering pump; the reaction temperature of the pre-condensation reactor is 270-296°C, the vacuum degree is 0.5-20mmHg, and the reaction time is 0.5-6 hours; the generated product enters the final polycondensation reactor, and the final polycondensation reactor The reaction temperature is 285-295° C., the vacuum degree is ≤1 mmHg, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com