Lock sealing structure for yarn dyeing

A sealing structure, yarn dyeing technology, applied in textile and papermaking, textile processing machine accessories, textile material processing and other directions, can solve problems such as insufficient dyeing liquid pressure, yarn roll flushing, dyeing liquid leakage, etc., to avoid The phenomenon of dyeing flowers and avoiding the effect of flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

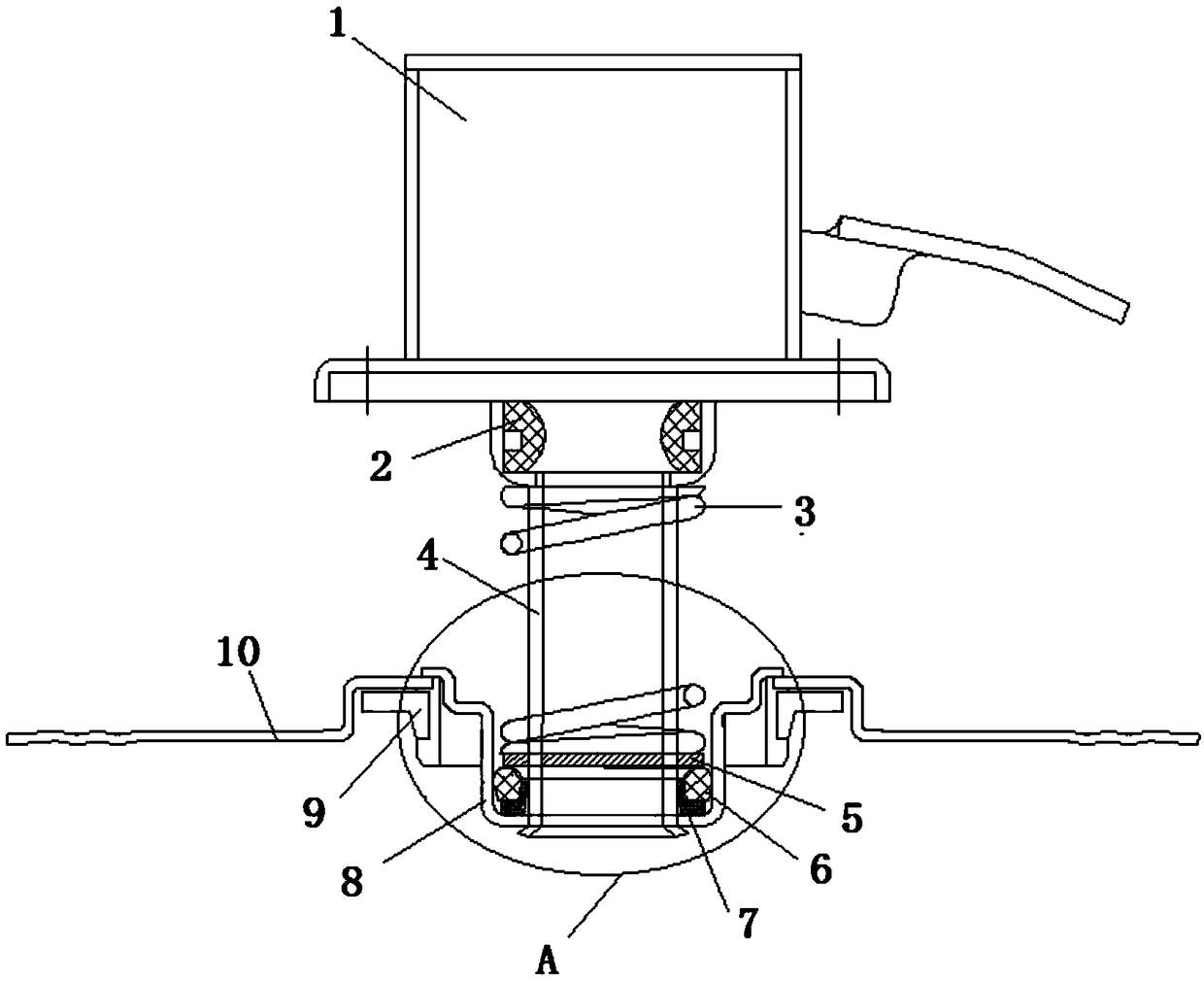

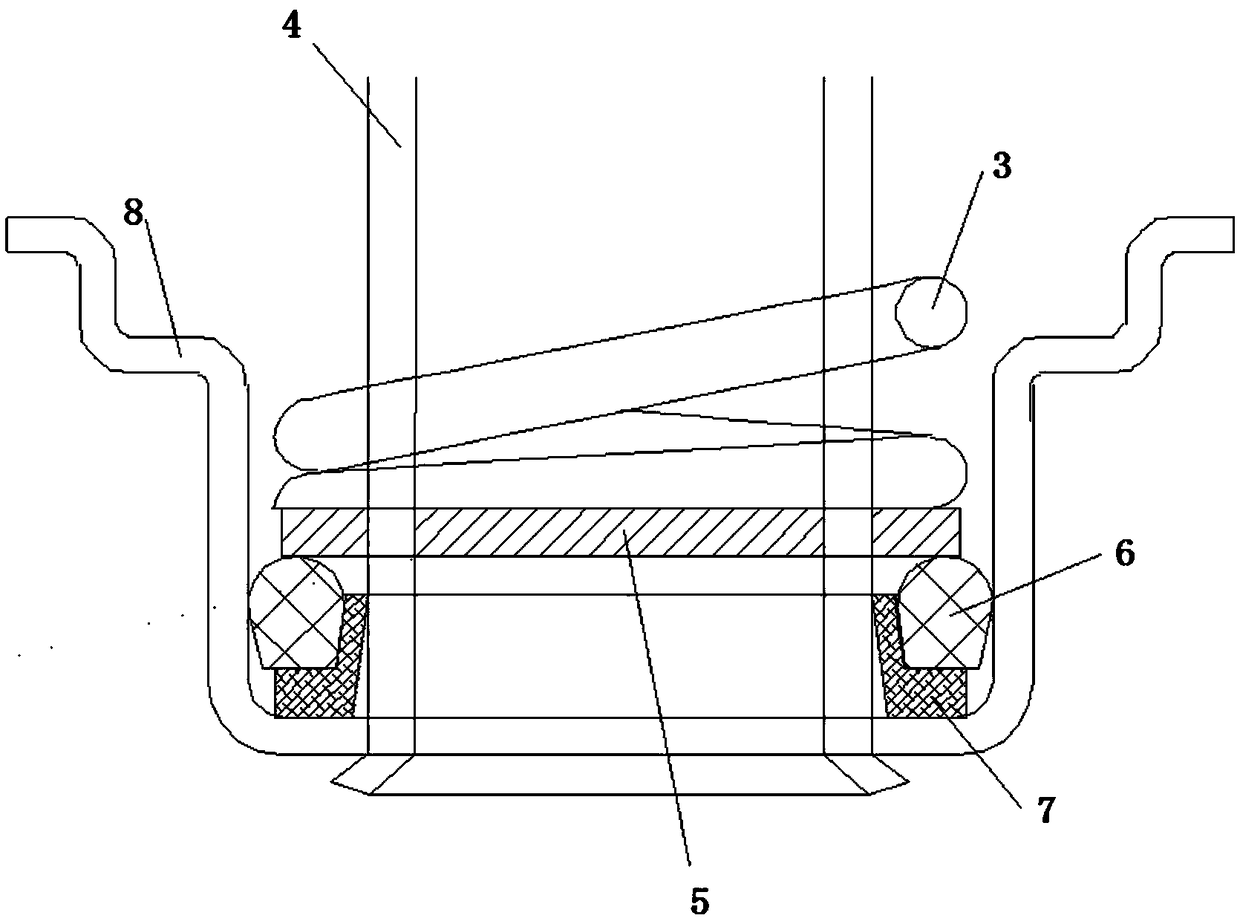

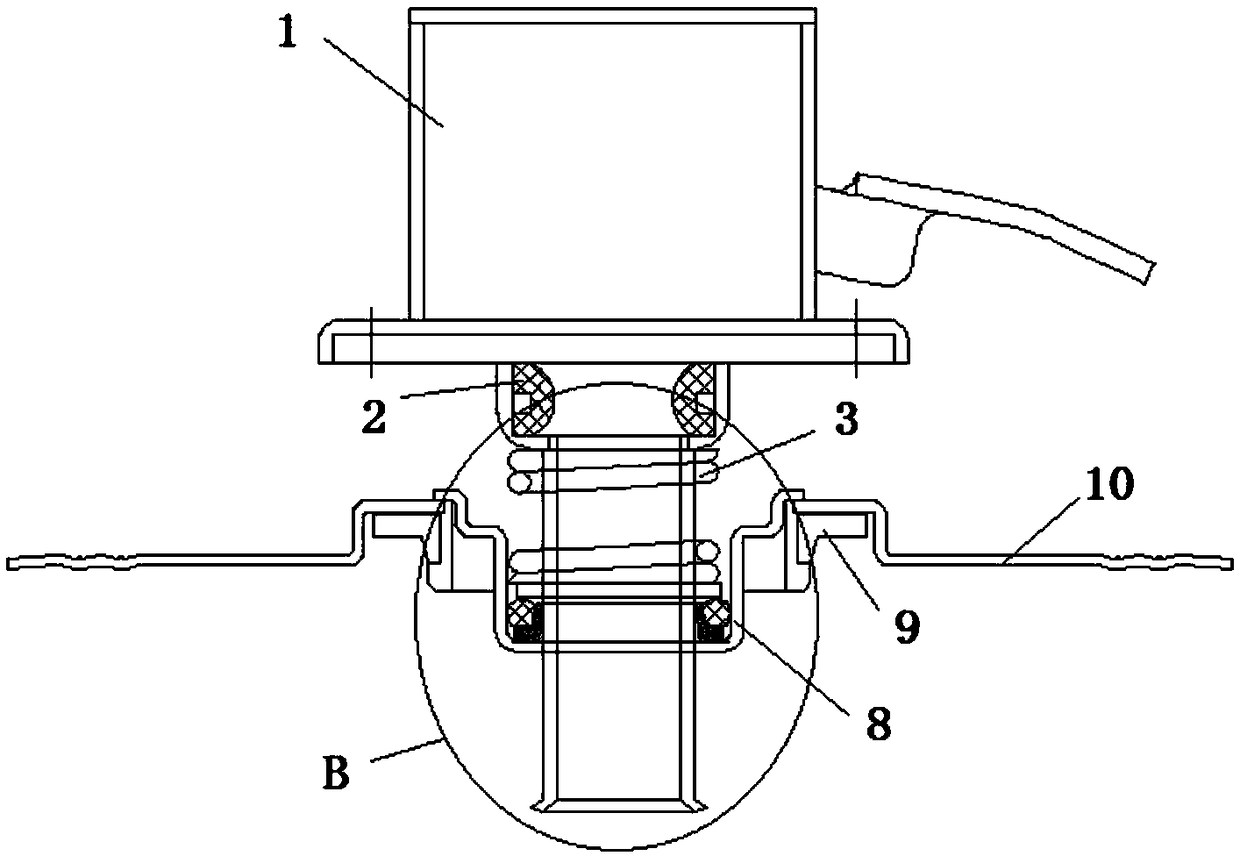

[0027] Such as Figure 1 to Figure 4 As shown, a lock head sealing structure for yarn dyeing includes a locking part 1, an intermediate sealing ring 2 is installed at the lower end of the locking part 1, and a core tube 4 is provided at the lower end of the intermediate sealing ring 2, and the outer sleeve of the core tube 4 is A spring 3 is provided, a sealing seat 8 is provided on the outer side of the core tube 4, and a bobbin sealing part 9 is provided on the periphery of the sealing seat 8, and the bobbin sealing part 9 is connected with a cover sheet 10; the lower end of the spring 3 is provided with a gasket 5;

[0028] An annular elastic pad 2 7 is arranged between the core tube 4 and the sealing seat 8, and an annular groove 701 is formed on the outer upper part of the elastic pad 2 7; an annular elastic pad 1 6 is arranged in the groove 701;

[0029] Such as Figure 5 As shown, the bottom of the groove 701 is a plane, the bottom of the elastic pad 6 is a plane match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com