Packaging bag forming machine

A packaging bag and forming machine technology, applied in the direction of packaging, transport packaging, multiple packages, etc., can solve the problems of waste of manpower, low packaging efficiency, easy to spill, etc., to avoid waste of items, the amount of filled items is accurate, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

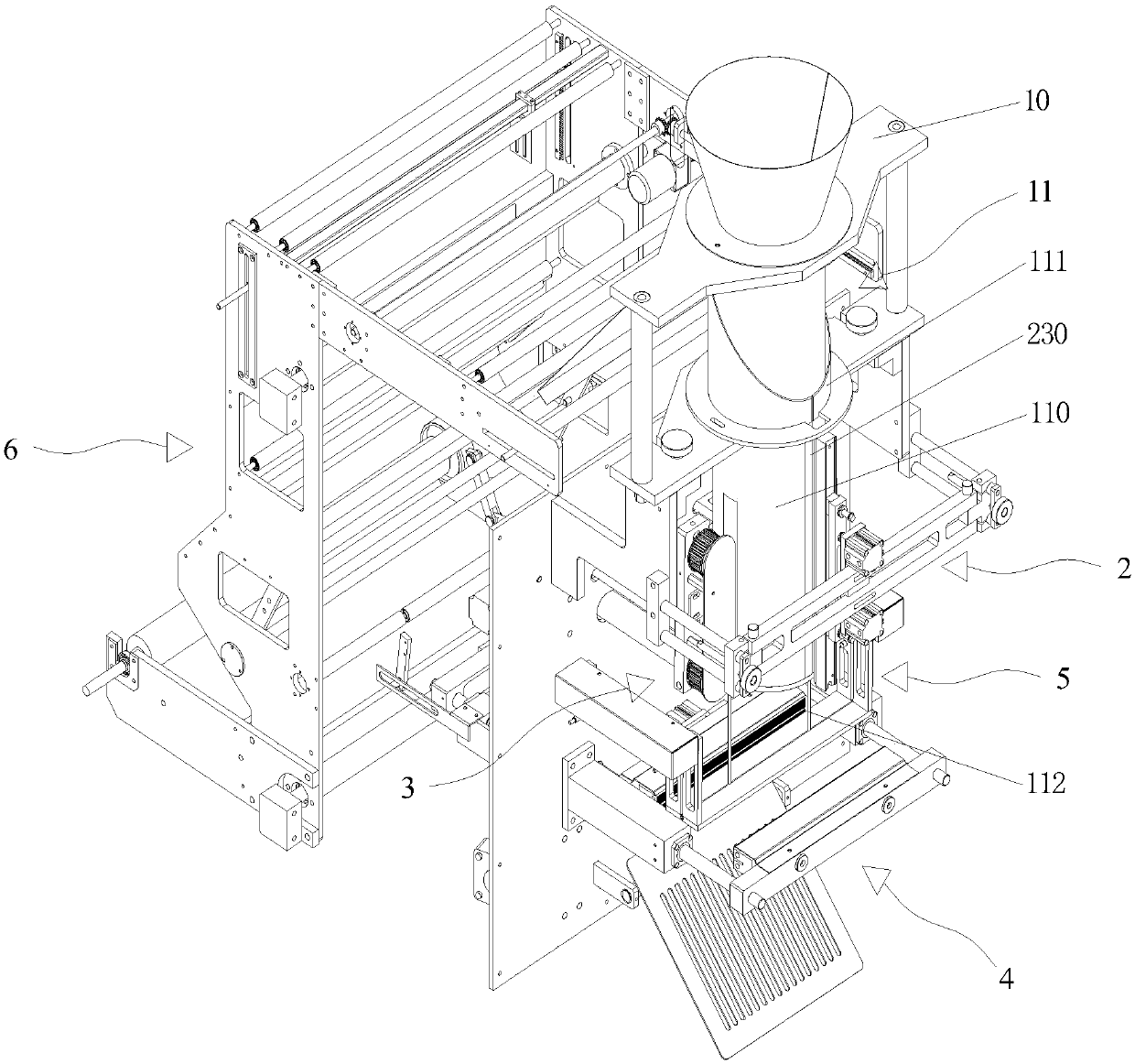

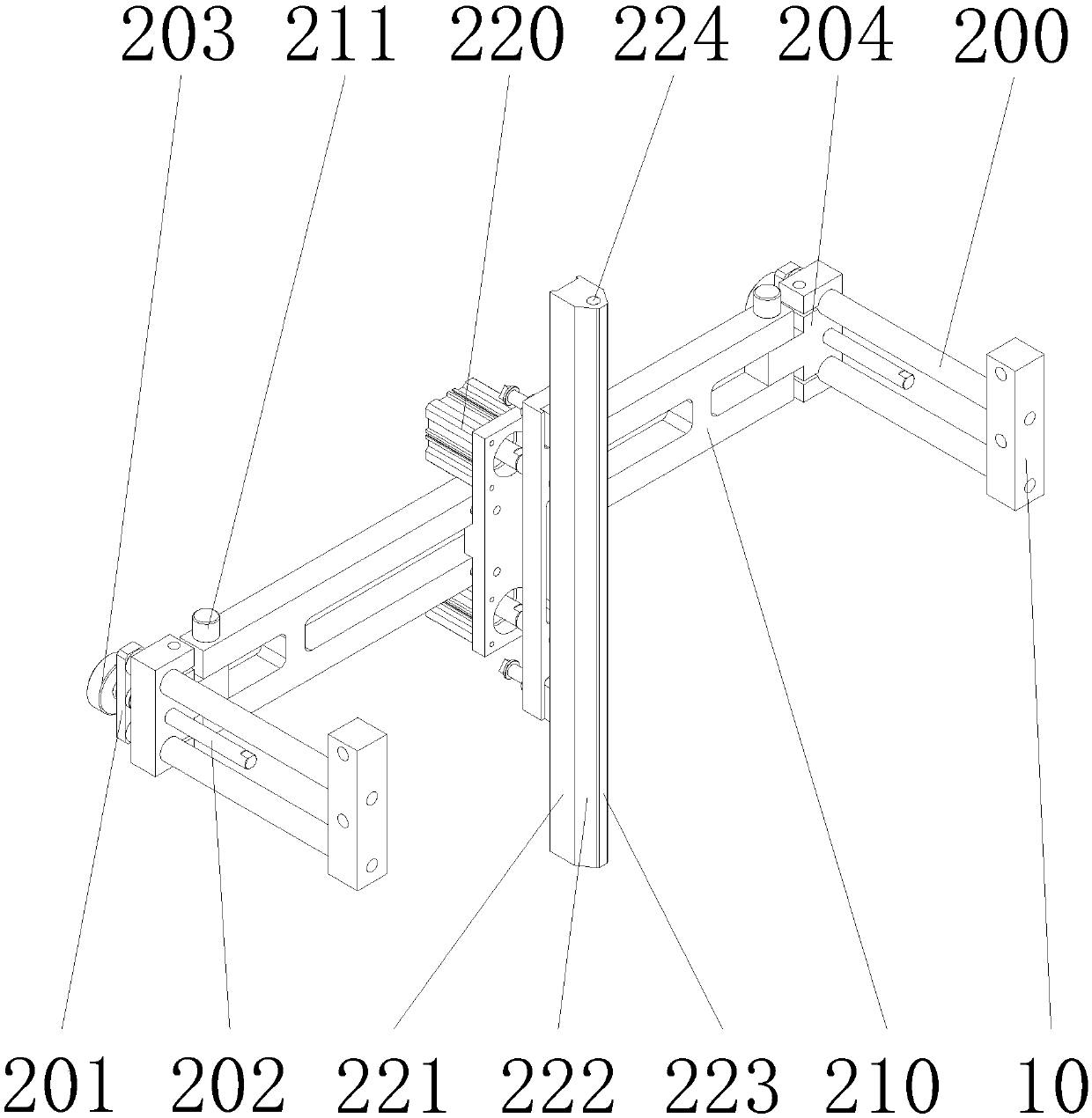

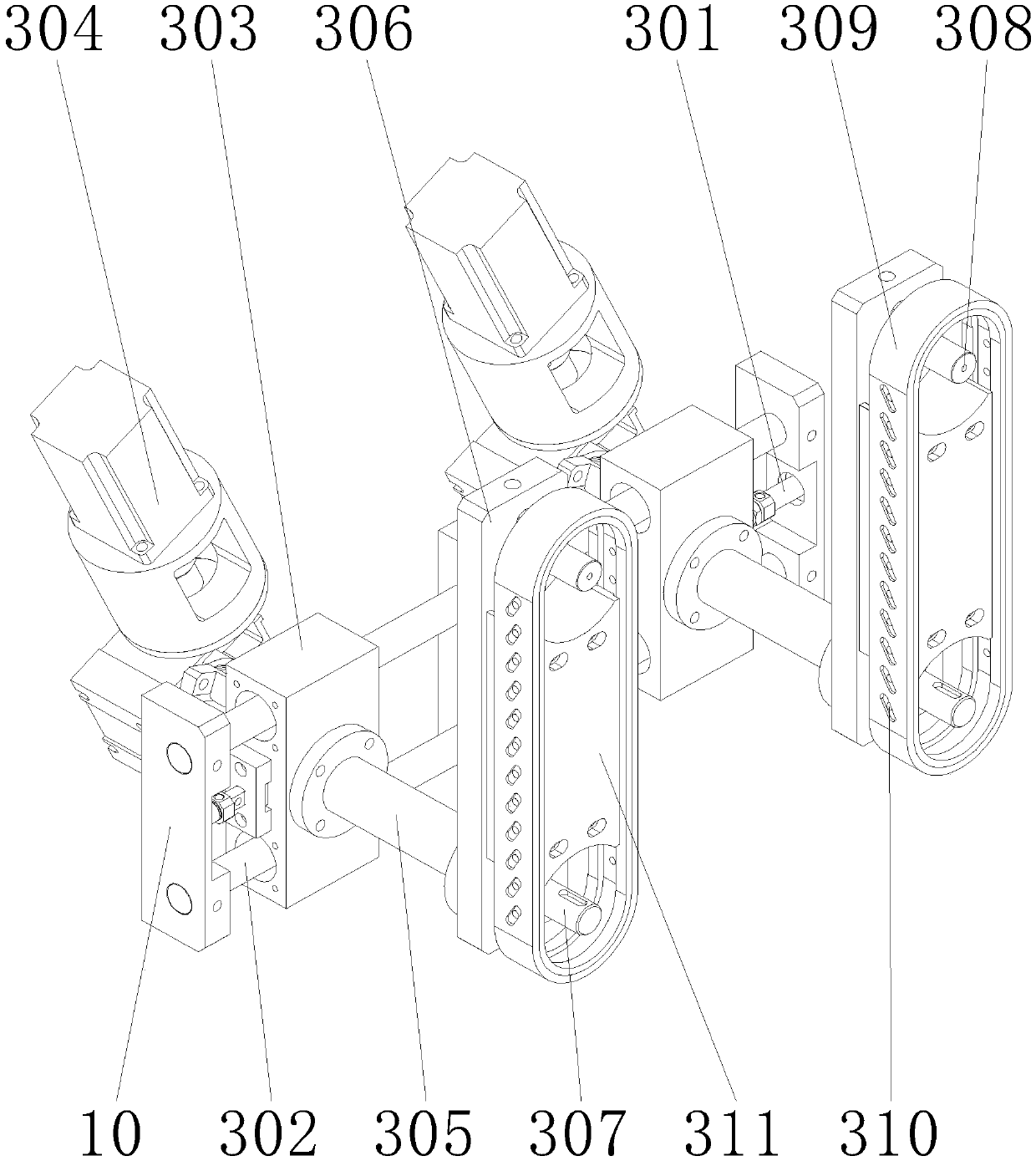

[0039] refer to figure 1 As shown, the present invention discloses a packaging bag forming machine, comprising a frame 10 and a forming device 11 arranged thereon, a back sealing mechanism 2, a film pulling mechanism 3, a horizontal sealing mechanism 4, a buffer mechanism 5 and a feeding mechanism 6.

[0040] Bag forming machine 11:

[0041] The above-mentioned bag forming device includes a filling cylinder 110 arranged on the frame 10 . The filling cylinder 110 is a hollow cylindrical structure. Packaging film can be wrapped around the outside of the filling cylinder 110 for heat sealing. The interior of the filling cylinder 110 is capable of precisely passing the filling item so as to fall into the formed bag.

[0042] The above-mentioned filling cylinder 110 is provided with a bag forming collar 111 and a filling stand 112 . One side opening of the collar 111 of the bag forming device is used for allowing the overlapping part to pass through after the packaging film is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com