Brushless DC motor for energy-saving oil extractor

A technology of brush DC motor and pumping unit, which is applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of low overall efficiency, achieve effective and reliable stroke control, prevent well flushing, and reduce the possibility of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

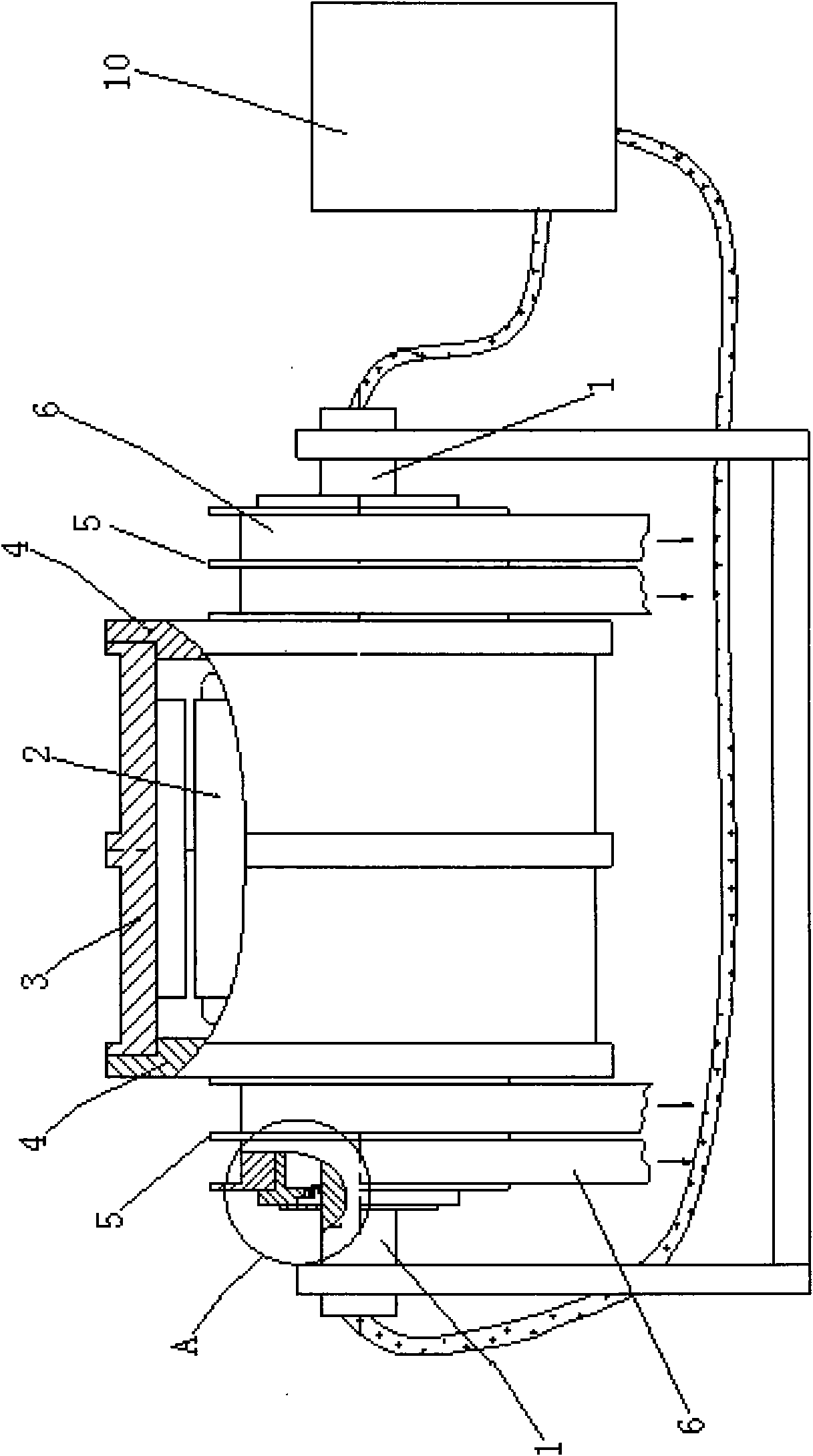

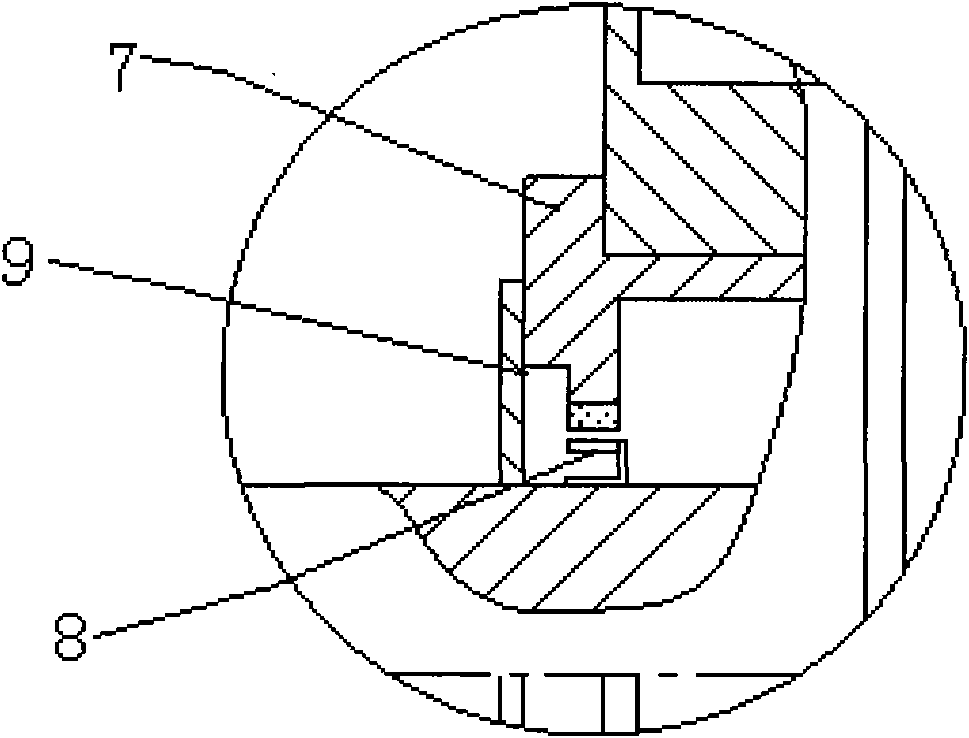

[0016] Embodiment: A brushless DC motor for an energy-saving pumping unit, comprising a fixed shaft 1, a stator 2 and a cylindrical outer rotor 3, the fixed shaft is fixed and passed through the stator, the stator is covered with an outer rotor, and the outer rotor and the stator There is an air gap, the two end covers 4 are respectively fixed on the two ends of the outer rotor and close the two ends of the outer rotor, the fixed shaft passes through the two end covers, the outer rotor and the two end covers can rotate around the fixed axis, and the magnetic circuit of the stator is greater than two Ten pairs of stages, the cylindrical outer rotor is fixed (adhered) with NdFeB magnets with a magnetic energy product greater than or equal to 35MGOs, so that the energy-saving brushless DC motor for pumping units reaches 1 to 35 rpm Low speed, high torque up to 9500 N m.

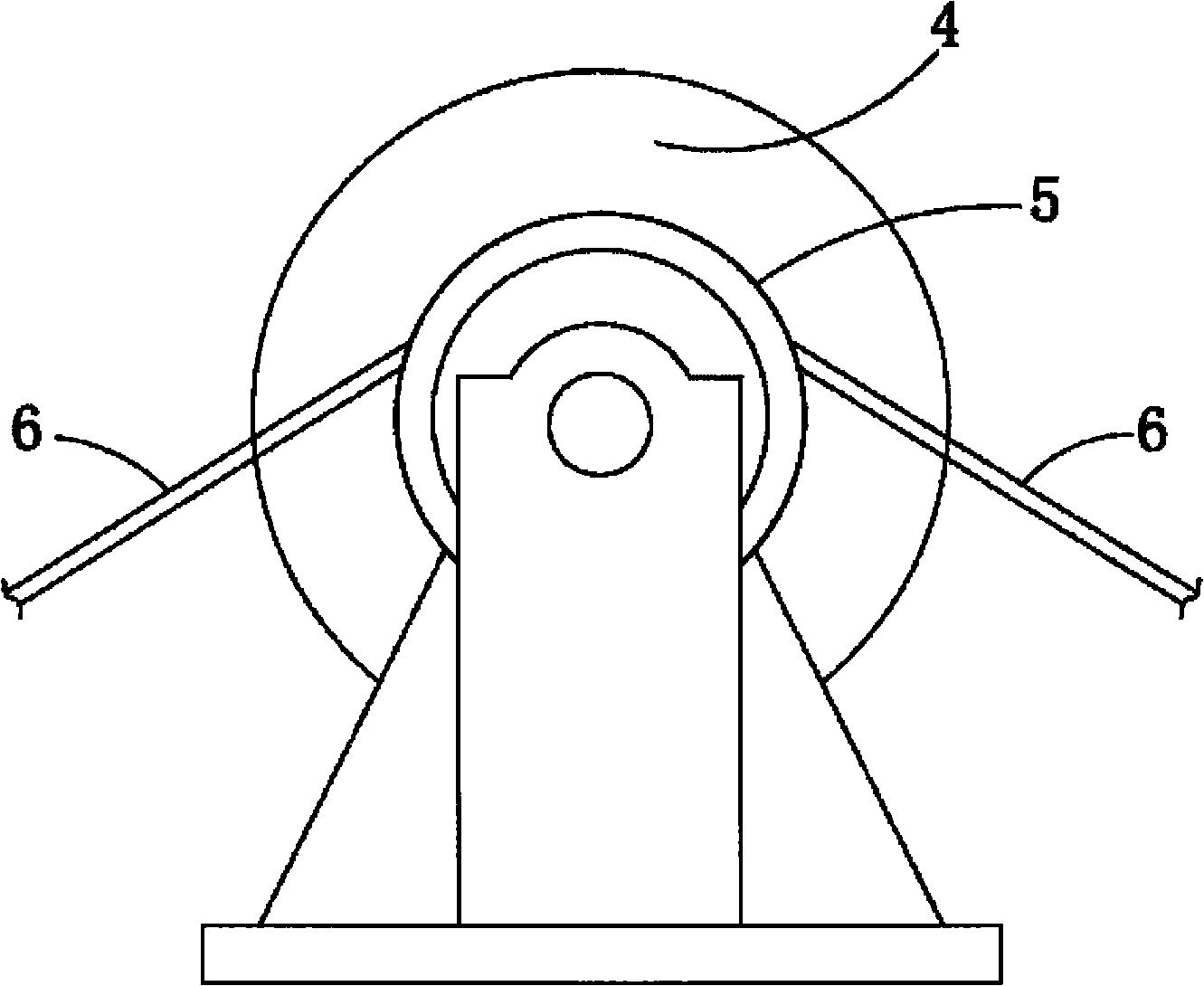

[0017] Two pulleys 5 are respectively fixed on the outer end faces of the two end caps of the outer rotor, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com