Feeder device of dissolving furnace for glass fiber production

A glass fiber and melting furnace technology, applied in glass manufacturing equipment, feeding of melting furnaces, manufacturing tools, etc., can solve problems such as undetectable amount of fed materials, unstable raw material transportation, hidden safety hazards, etc., to achieve use and maintenance Low cost, simple structure, and the effect of ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

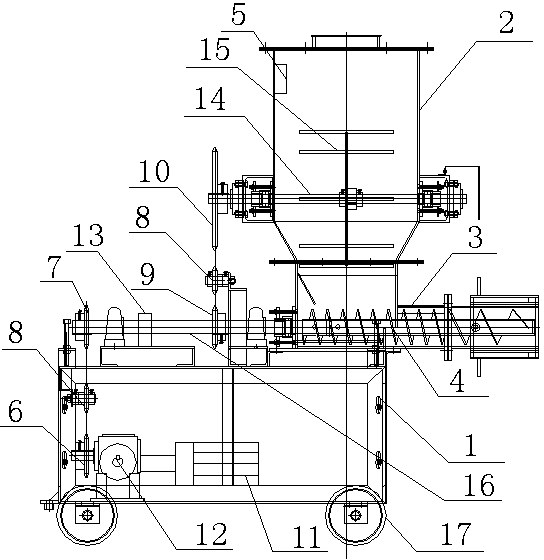

Image

Examples

Embodiment 2

[0034]The rest is the same as that of Embodiment 1, except that the driving mechanism includes a motor and a reducer, and the reducer directly transmits power to the transmission shaft. There is no need to set up the first transition conveying mechanism, which reduces the use cost.

[0035] The dissolving furnace feeding machine equipment for glass fiber production disclosed by the present invention comprises a frame and a silo located on the frame. material transmission device, the transmission device includes a transmission shaft and a drive mechanism to drive the transmission shaft to run, a spiral tube is arranged inside the silo, and the spiral tube extends into the discharge pipe, and the transmission shaft and The spiral tubes are connected; the driving mechanism drives the spiral tubes to rotate, and the material rotates with the spiral tubes under the action of the normal thrust of the spiral tubes to discharge the material, ensuring the stable transportation of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com