Lithium ion-electron mixed conductor modified ternary anode material and preparation method

A technology of positive electrode materials and mixed conductors, which is applied in the field of lithium ion-electronic mixed conductor modified ternary positive electrode materials and its preparation, can solve the problems of restricting the performance of ternary materials, irreversible capacity loss, poor electronic conductivity, etc., and achieve good lithium Ion and electron conductivity, improvement of lithium ion conductivity and electron conductivity, effect of slowing down corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

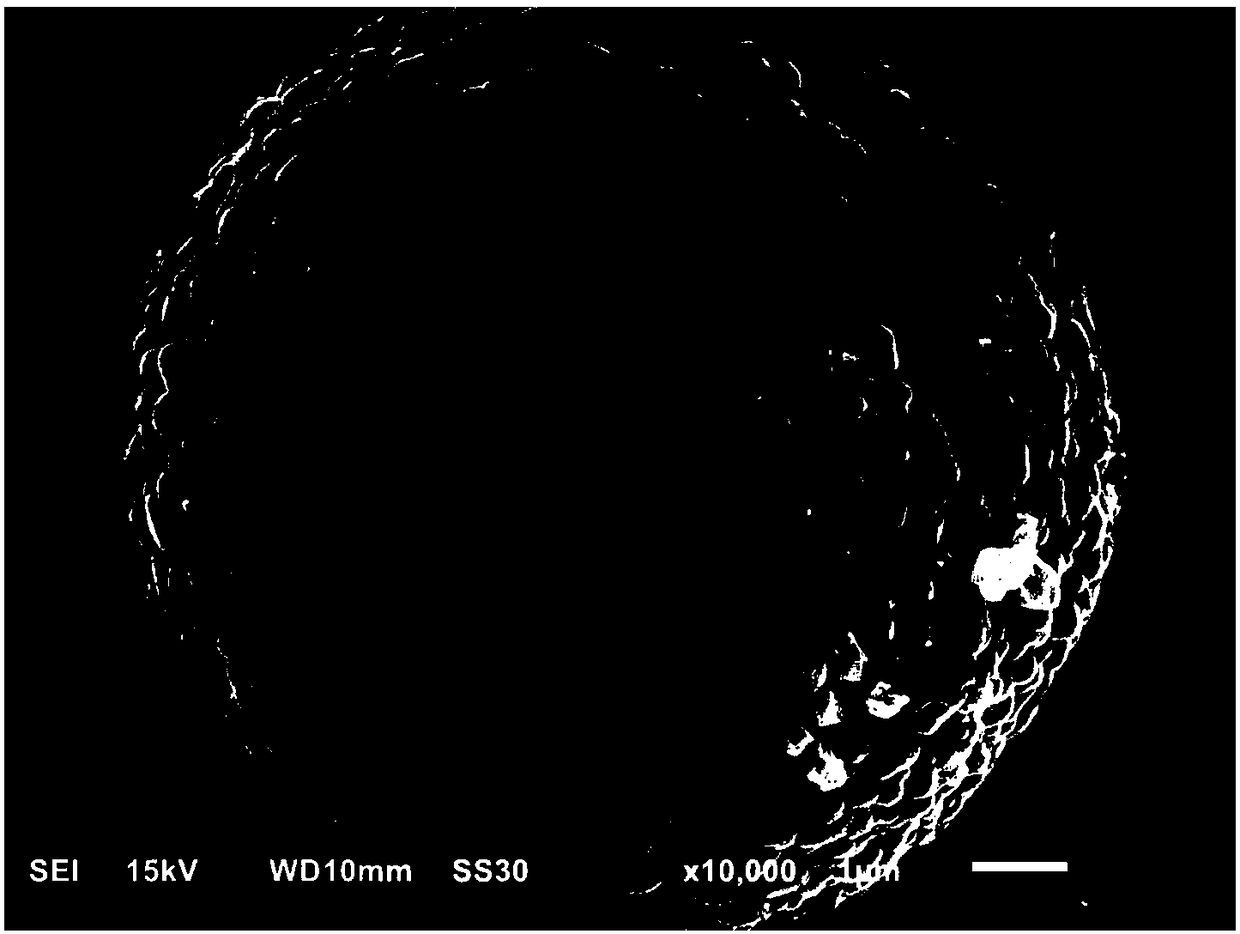

[0041] The preparation method of the lithium ion battery cathode material coated with the lithium ion-electron mixed conductor material of this embodiment is carried out according to the following steps:

[0042] (1) Take an appropriate amount of lithium acetate dihydrate (CH 3 COOLi 2 ·H 2 O), magnesium nitrate (Mg(NO 3 ) 2 ), ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and ammonium fluoride (NH 4 F) be dissolved in water successively, add the citric acid (C 6 h 8 o 7 ) as a dispersant, after fully stirring to obtain a clear and transparent solution, in a volumetric flask, use deionized water to set the volume to 0.1mol / L, which is solution A;

[0043] (2) Weigh a certain quality of 811 type nickel-cobalt-manganese ternary positive electrode powder, according to LiMgPO 4 f 0.05 The coating amount is 2% mass ratio calculation Add solution A, stir and mix thoroughly at room temperature;

[0044] (3) Evaporating the solid-liquid mixture to dryness to obtain a sol...

Embodiment 2

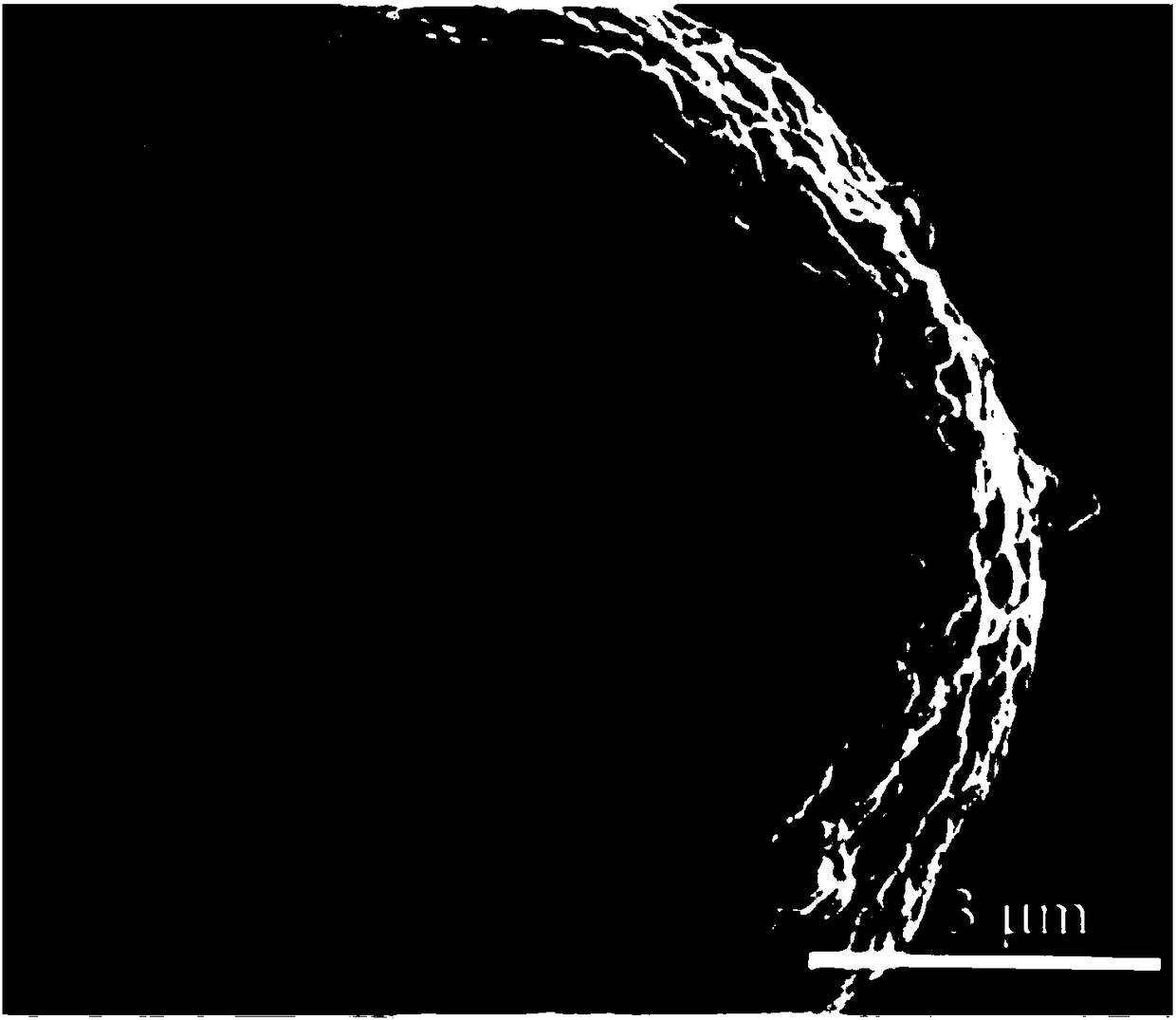

[0047] The preparation method of the lithium ion battery cathode material coated with the lithium ion-electron mixed conductor material of this embodiment is carried out according to the following steps:

[0048] (1) Take an appropriate amount of lithium acetate dihydrate (CH 3 COOLi 2 ·H 2 O), magnesium nitrate (Mg(NO 3 ) 2 ), ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and ammonium fluoride (NH 4 F) be dissolved in water successively, add the citric acid (C 6 h 8 o 7 ) as a dispersant, after fully stirring to obtain a clear and transparent solution, in a volumetric flask, use deionized water to set the volume to 0.1mol / L, which is solution A;

[0049] (2) Weigh a certain quality of 523 type nickel-cobalt-manganese ternary positive electrode powder, according to LiMgPO 4 f 0.05 The coating amount is 2% mass ratio calculation Add solution A, stir and mix thoroughly at room temperature;

[0050] (3) Evaporating the solid-liquid mixture to dryness to obtain a sol...

Embodiment 3

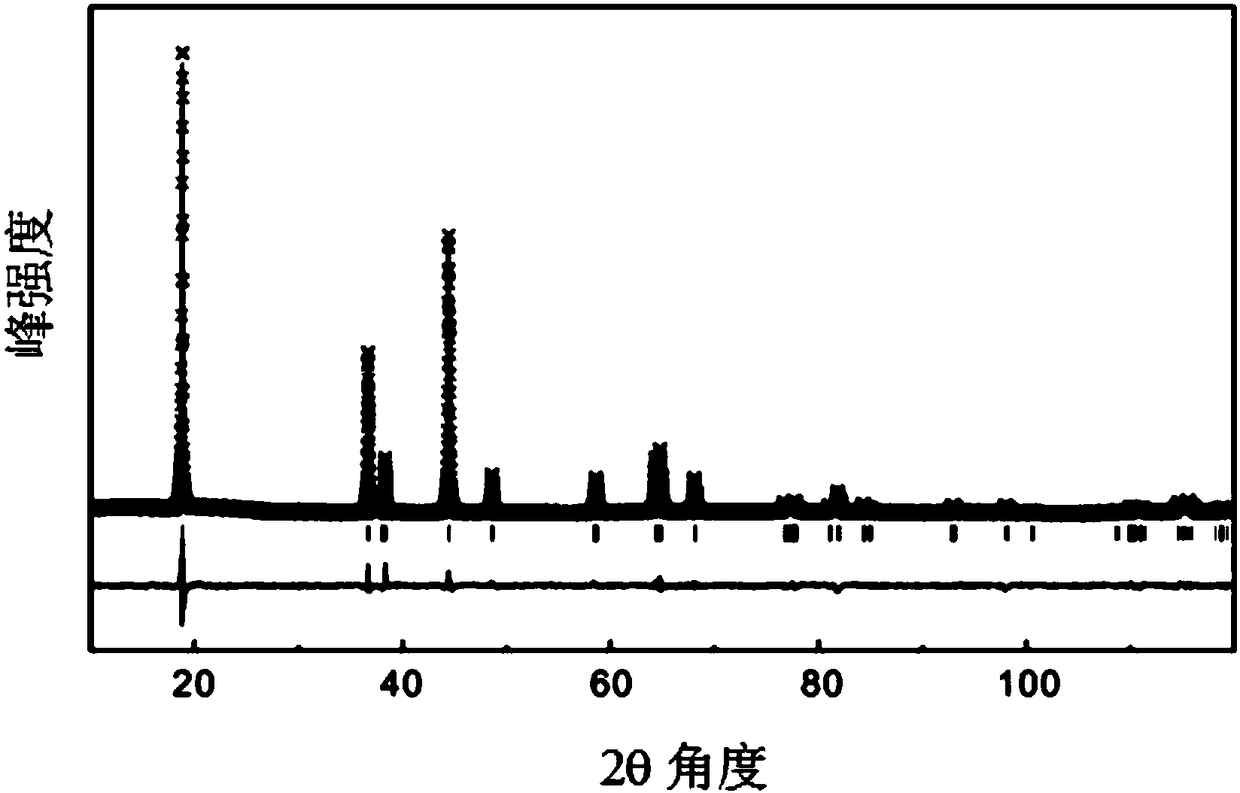

[0053] The preparation method of the lithium ion battery cathode material coated with the lithium ion-electron mixed conductor material of this embodiment is carried out according to the following steps:

[0054] (1) Take an appropriate amount of lithium acetate dihydrate (CH 3 COOLi 2 ·H 2 O), magnesium nitrate (Mg(NO 3 ) 2 ), ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and ammonium fluoride (NH 4 F) be dissolved in water successively, add the citric acid (C 6 h 8 o 7 ) as a dispersant, after fully stirring to obtain a clear and transparent solution, in a volumetric flask, use deionized water to set the volume to 0.1mol / L, which is solution A;

[0055] (2) Weigh a certain quality of 811 type nickel-cobalt-manganese ternary positive electrode powder, according to LiMgPO 4 f 0.05 The coating amount is 2% mass ratio calculation Add solution A, stir and mix thoroughly at room temperature;

[0056] (3) Evaporating the solid-liquid mixture to dryness to obtain a sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com