Rare earth element ion extraction method and obtained rare earth enrichment liquid

A rare earth ion and rare earth enrichment technology, which is applied in the field of extraction methods and rare earth enrichment solutions obtained by extraction, can solve the problems of reducing supersaturated emulsification of weakly acidic extractants, strict requirements on pH value, poor separation effect of heavy rare earths, and the like. To achieve the effect of less entrainment of two phases, preventing the reduction of extraction efficiency, not easy to liquid flooding and emulsification back mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

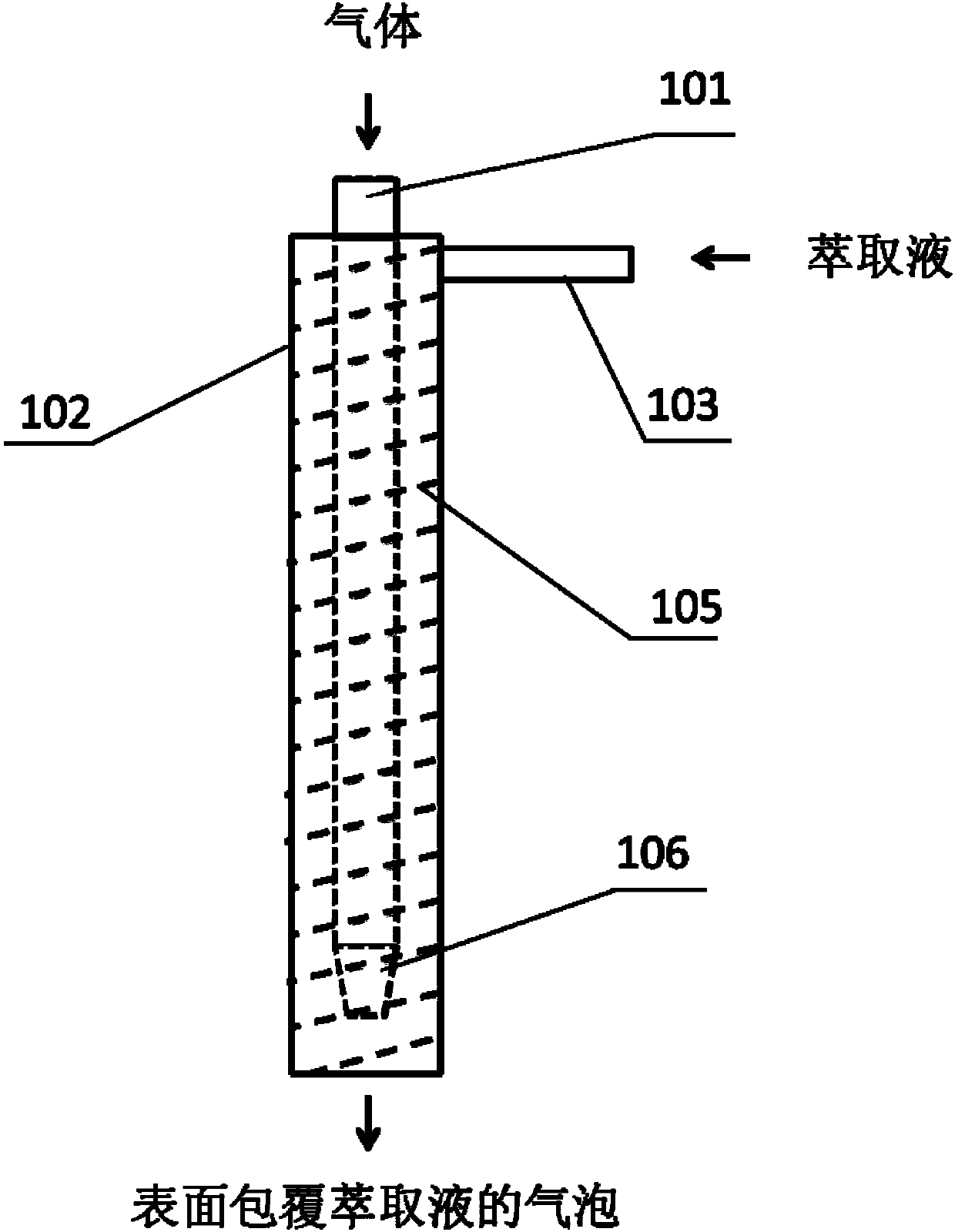

[0057] A kind of sparging device 100, such as figure 1 As shown, it includes an inner hollow straight pipe 101 with an outer diameter of 1 mm for the passage of gas, and an outer hollow straight pipe 102 with an inner diameter of 3 mm that is concentrically nested outside the inner hollow straight pipe 101, and in the axial direction, the outlet At the air port end, the end face of the inner hollow straight pipe 101 is located inside the end face of the outer hollow straight pipe 102 and the distance from the end face of the outer hollow straight pipe 102 is 1mm, and the end face of the inner hollow straight pipe 101 at the air inlet end is located outside the end face of the outer hollow straight pipe. And the distance from the end face of the outer hollow straight pipe is 0.5 mm, the ratio of the outer diameter of the outer hollow straight pipe 102 to the inner diameter of the inner hollow straight pipe 101 is 3:1, and the air outlet 105 of the inner hollow straight pipe 101 ...

Embodiment 2

[0060]The difference with the bubbling device embodiment 1 is that the inner diameter of the inner hollow straight tube 101 is 0.2 mm, the outer diameter of the outer hollow straight tube 102 is 3 mm, and the outer diameter of the outer hollow straight tube 102 is equal to the inner diameter of the inner hollow straight tube 101. The ratio is 15:1, the air outlet 105 of the inner hollow straight pipe 101 is a conical centripetal closing with a lead angle of 60 degrees, and the inner wall of the outer hollow straight pipe 102 is provided with a diversion thread 104 with a height of 0.005 mm and a thread pitch of 1 mm. The distance between the end face of the air outlet of the inner hollow straight pipe 101 and the end face of the outer hollow straight pipe 102 is 1 mm, and the distance between the end face of the air inlet of the inner hollow straight pipe 101 and the end face of the outer hollow straight pipe is 0.5 mm.

Embodiment 3

[0062] The difference with the bubbling device embodiment 1 is that the inner diameter of the inner hollow straight tube 101 is 0.1 mm, the outer diameter of the outer hollow straight tube 102 is 1 mm, and the difference between the outer diameter of the outer hollow straight tube 102 and the inner diameter of the inner hollow straight tube 101 is 0.1 mm. The ratio is 10:1, the distance between the end face of the air outlet of the inner hollow straight pipe 101 and the end face of the outer hollow straight pipe 102 is 2 mm, and the distance between the end face of the air inlet of the inner hollow straight pipe 101 and the end face of the outer hollow straight pipe is 1 mm.

[0063] Example 1

[0064] A method for extracting rare earth ions in the process wastewater containing rare earth chloride and rare earth nitrate produced by a rare earth separation plant (containing rare earth ion aqueous solution), the total concentration of rare earth ions in the industrial wastewater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com