Method for preparing polyanionic lithium ion battery anode material

A lithium-ion battery, polyanion-type technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of particle-particle agglomeration, large particle size, uneven distribution, etc., and achieve high electronic and ionic conductivity. The effect of uniform particle size distribution and improved coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

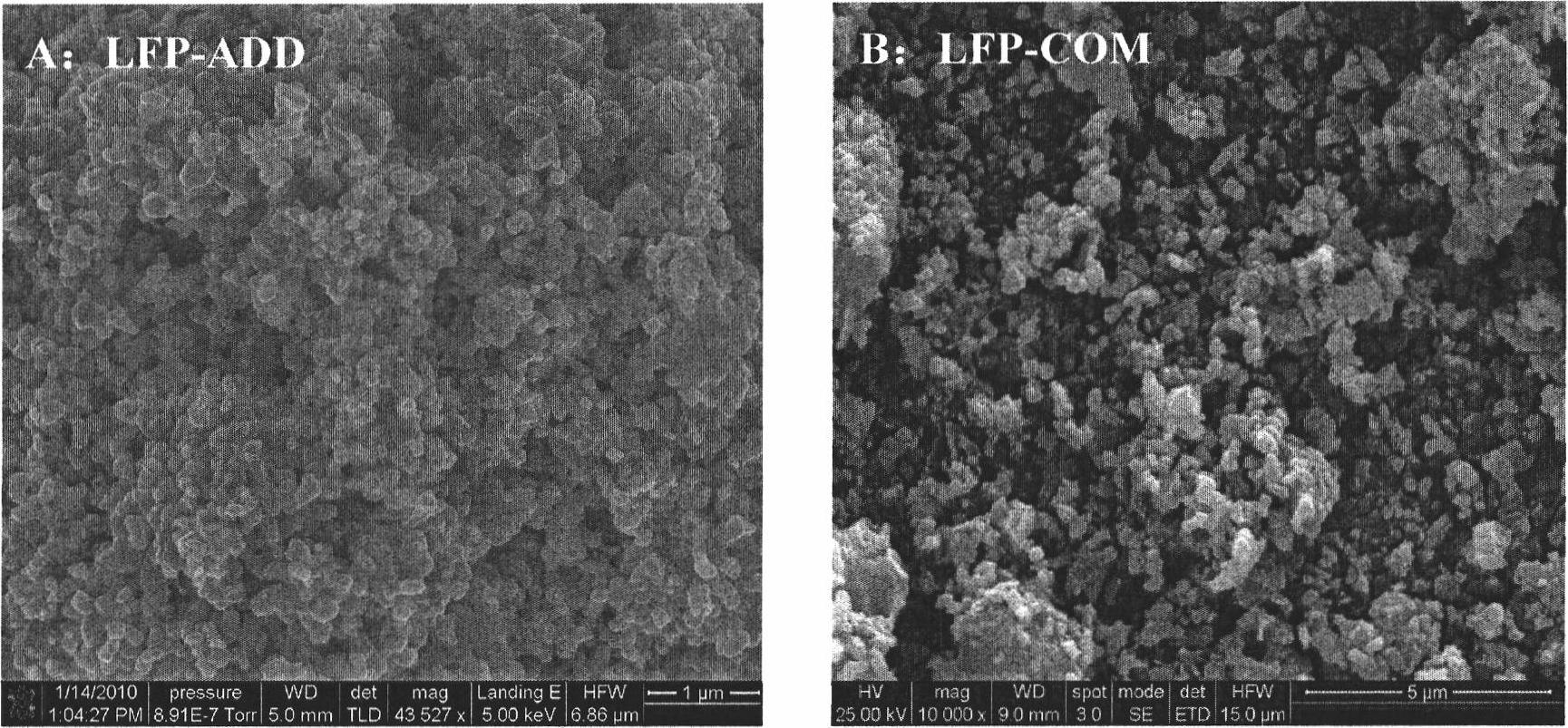

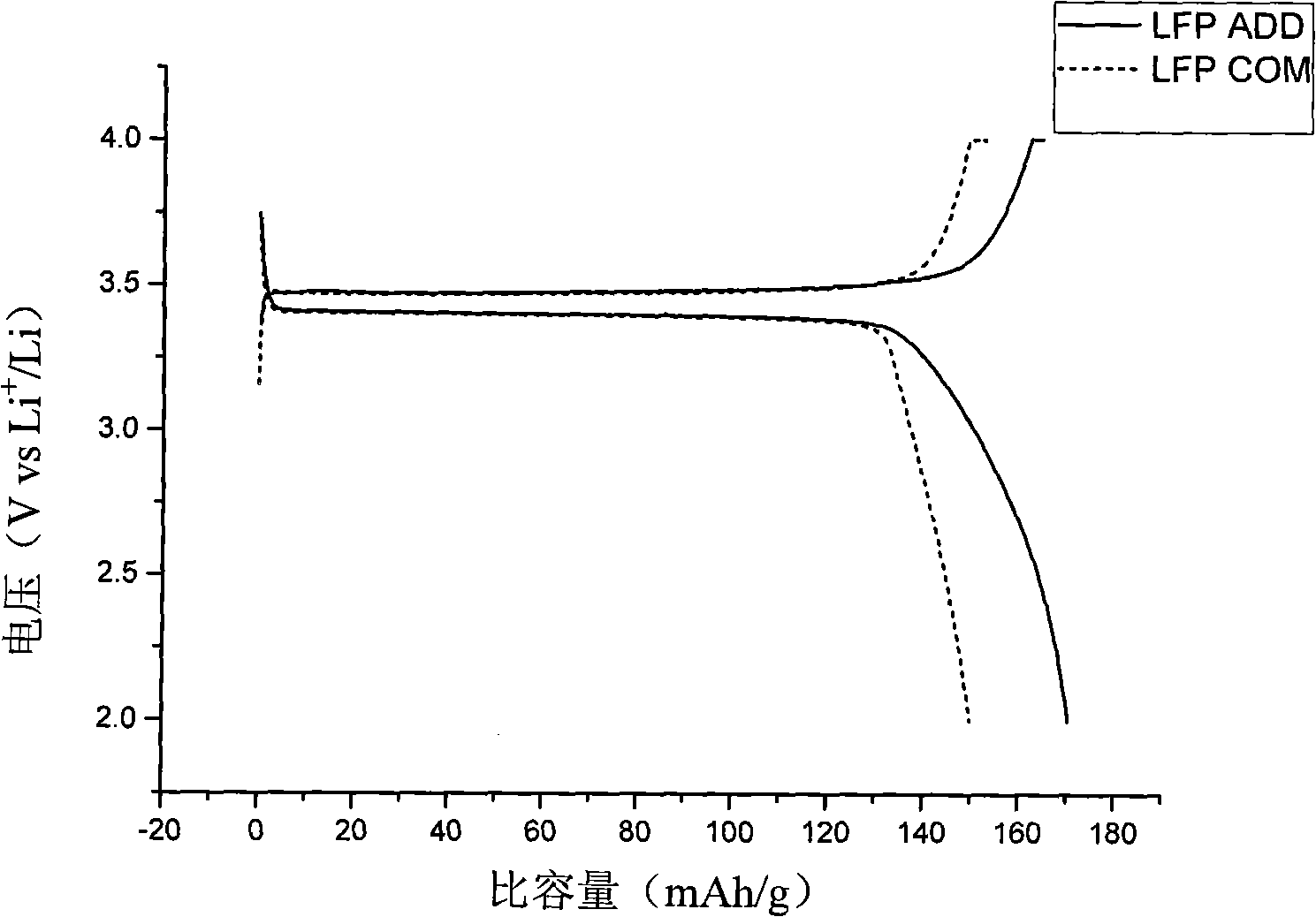

[0036] Dissolve 6.01g of lauric acid in 25ml of acetone, then add 2.23g of lithium carbonate, 6.91g of ammonium dihydrogen phosphate, and 10.86g of ferrous oxalate, grind for 10 hours, and add 1.42g of citric acid during the grinding process. Put the ground material into a drying oven at 40°C for 12 hours, and then place it in a drying oven at 80°C for 12 hours. The dried material is crushed and sieved, then placed in a nitrogen-protected reaction furnace, calcined at 300-900°C for 10-30h, and cooled to room temperature to obtain LiFePO 4 / C powder material, the prepared sample was named LFP-ADD. As a control group, 25ml of acetone was taken without adding lauric acid as a solid-liquid phase mixing dispersant, and the same method as above was used to prepare lithium iron phosphate / carbon, and the prepared sample was named LFP-COM.

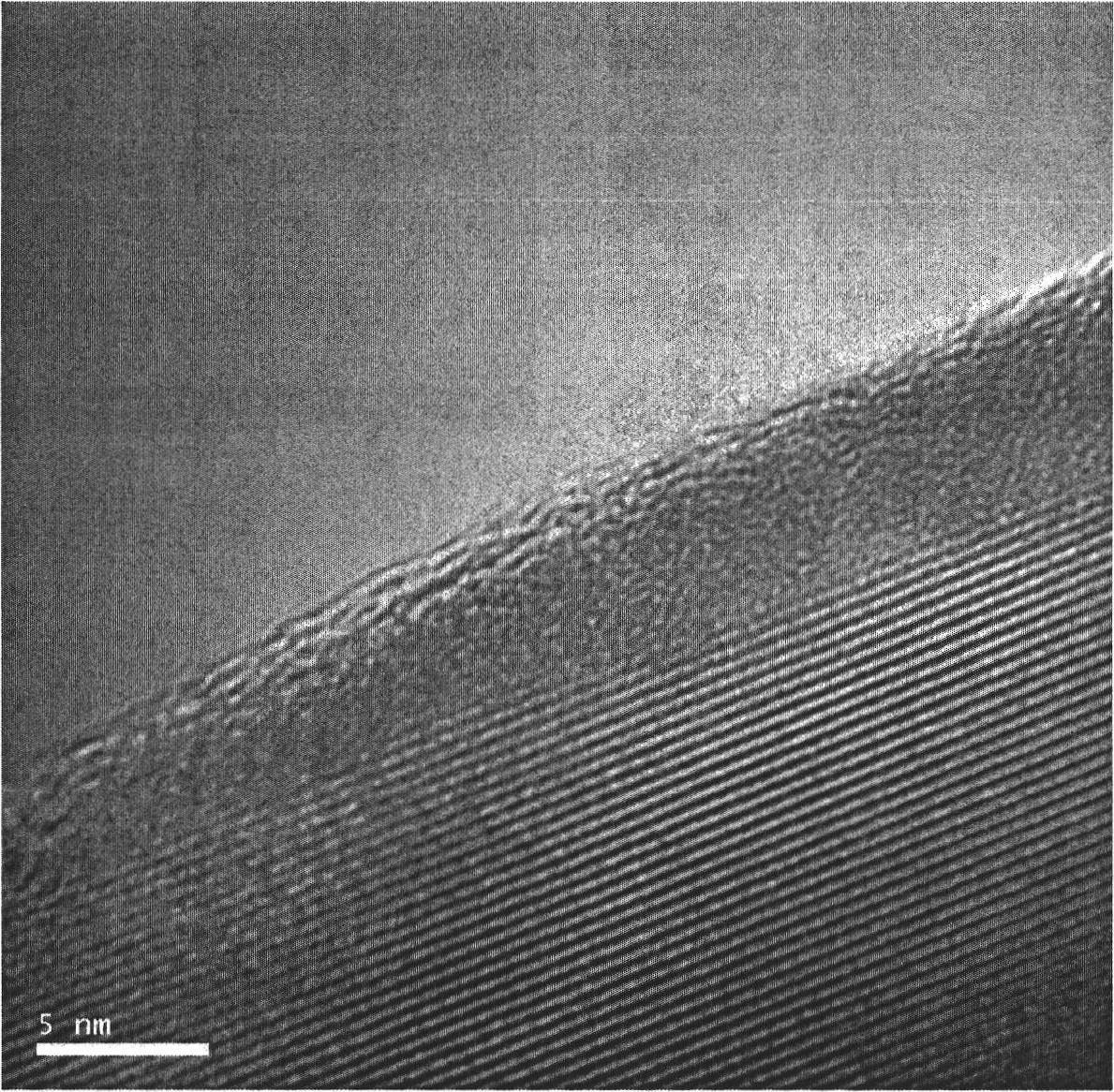

[0037] figure 1 It is the LiFePO prepared in this example 4 / C composite cathode material scanning electron microscope (SEM) image, from figur...

Embodiment 2

[0040] Take 1 mole of ferrous oxalate and 1 mole of lithium dihydrogen phosphate, add them to a high-energy ball mill, and add 300ml of isopropanol as a liquid dispersion medium, mill in a high-energy ball mill for 3 hours, then add 0.1 mole of sucrose and 0.1 mole of oleylamine, Then ball milled for 3 h on a high-energy ball mill. The slurry was taken out from the high-energy ball mill, then placed in a vacuum oven at 40°C for 24 hours, and taken out after the material was completely dried. Put it into a reaction furnace protected by inert gas, and keep it warm at 200-400°C for 5-15 hours to completely decompose the material. Take the material out of the reaction furnace protected by inert gas, re-ball-mill it evenly, then place it in the reaction furnace protected by inert gas, keep it at 600-900°C for 10-20h, and cool to room temperature to obtain LiFePO 4 / C powder material. Calcined LiFePO 4 / C pressed into blocks, X-ray diffraction test. Figure 5 It is an XRD spectr...

Embodiment 3

[0042]Dissolve 0.25mol of methyl laurate in 1000ml of ethanol, then add 2.5mol of lithium dihydrogen phosphate and 2.5mol of manganese dioxide, ball mill evenly, add 0.25mol of cellulose during ball milling, and ball mill for 2-10 hours. The slurry after ball milling is dried by spray drying, the slurry is passed into the inlet of the spray dryer, the spray inlet temperature is set to 200°C, the outlet temperature is 60°C, the flow rate is adjusted, spray drying is carried out, and samples are collected after drying . Place the sample in a reaction furnace protected by nitrogen, calcinate at 300-900°C for 5-30h, and cool to room temperature to obtain LiMnPO 4 / C powder material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com